Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-44-20-300-007 HPT Stage 1 Vane - Airfoil Touch-Up Coating Repair, Repair-007(VRS3165)

Effectivity

FIG/ITEM | PART NO. |

|---|---|

01-250 | 2A0091CL21 |

01-250 | 2A2591CL21 |

01-251 | 2A0091CL22 |

01-251 | 2A2591CL22 |

01-252 | 2A0091CL23 |

01-253 | 2A0091CL24 |

01-254 | 2A0091CL25 |

01-252 | 2A2591CL23 |

01-253 | 2A2591CL24 |

01-254 | 2A2591CL25 |

01-255 | 2A0091CL26 |

01-256 | 2A0091CL27 |

01-257 | 2A0091CL28 |

01-258 | 2A0091CL29 |

01-259 | 2A0091CL30 |

01-260 | 2A0091CL31 |

01-261 | 2A0091CL32 |

01-262 | 2A0091CL33 |

01-255 | 2A2591CL26 |

01-256 | 2A2591CL27 |

01-257 | 2A2591CL28 |

01-258 | 2A2591CL29 |

01-259 | 2A2591CL30 |

01-260 | 2A2591CL31 |

01-261 | 2A2591CL32 |

01-262 | 2A2591CL33 |

01-263 | 2A0091CL34 |

01-264 | 2A0091CL35 |

01-265 | 2A0091CL36 |

01-266 | 2A0091CL37 |

01-267 | 2A0091CL38 |

01-268 | 2A0091CL39 |

01-269 | 2A0091CL40 |

01-270 | 2A0091CL41 |

01-271 | 2A0091CL42 |

01-272 | 2A0091CL43 |

01-273 | 2A0091CL44 |

01-274 | 2A0091CL45 |

01-275 | 2A0091CL46 |

01-276 | 2A0091CL47 |

01-263 | 2A2591CL34 |

01-264 | 2A2591CL35 |

01-265 | 2A2591CL36 |

01-266 | 2A2591CL37 |

01-267 | 2A2591CL38 |

01-268 | 2A2591CL39 |

01-269 | 2A2591CL40 |

01-270 | 2A2591CL41 |

01-271 | 2A2591CL42 |

01-272 | 2A2591CL43 |

01-273 | 2A2591CL44 |

01-274 | 2A2591CL45 |

01-275 | 2A2591CL46 |

01-276 | 2A2591CL47 |

01-277 | 2A0091CL48 |

01-277 | 2A2591CL48 |

01-278 | 2A0091CL48-5 |

01-279 | 2A0091CL49 |

01-279 | 2A2591CL49 |

01-280 | 2A0091CL49-5 |

01-284 | 2A2591CL50 |

01-286 | 2A2591CL51 |

General

This repair must only be done with the instruction to do so is given in 72-44-20 Inspection/Check.

CoMat 07-057 SLURRY, ALUMINIUM-SILICON or CoMat 02-183 ALUMINIDE COATING - LOCALIZED APPLICATION, LOW ACTIVITY can be used to repair the stage 1 HPT vane cluster assembly that has coating that is chipped, damaged or not there in a local area on the airfoil. Also do this repair to restore the coating on the blended airfoils. The total vane airfoil area to be coated is a maximum of 0.500 sqin. (3.226 sqcm).

This repair must only be done when there is no oxidation or corrosion shown on the base material.

This repair must only be done one time for each vane.

Do not use CoMat 07-057 SLURRY, ALUMINIUM-SILICON and CoMat 02-183 ALUMINIDE COATING - LOCALIZED APPLICATION, LOW ACTIVITY for this repair when you replace all the primary coating on the vane.

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

Price and availability - none

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Workshop inspection equipment | LOCAL | Workshop inspection equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-064 CHEMICAL MILLING MASKANT | 0AM53 | CoMat 02-064 | ||

| CoMat 02-183 ALUMINIDE COATING - LOCALIZED APPLICATION, LOW ACTIVITY | IAE86 | CoMat 02-183 | ||

| CoMat 07-057 SLURRY, ALUMINIUM-SILICON | 0FGH2 | CoMat 07-057 |

Spares

NONESafety Requirements

NONEProcedure

Do the procedure given in the SPM TASK 70-38-14-380-501 except brush coat the vane five times and diffusion heat treat the vane assembly to between 1475 and 1525 deg F (802 and 829 deg C).

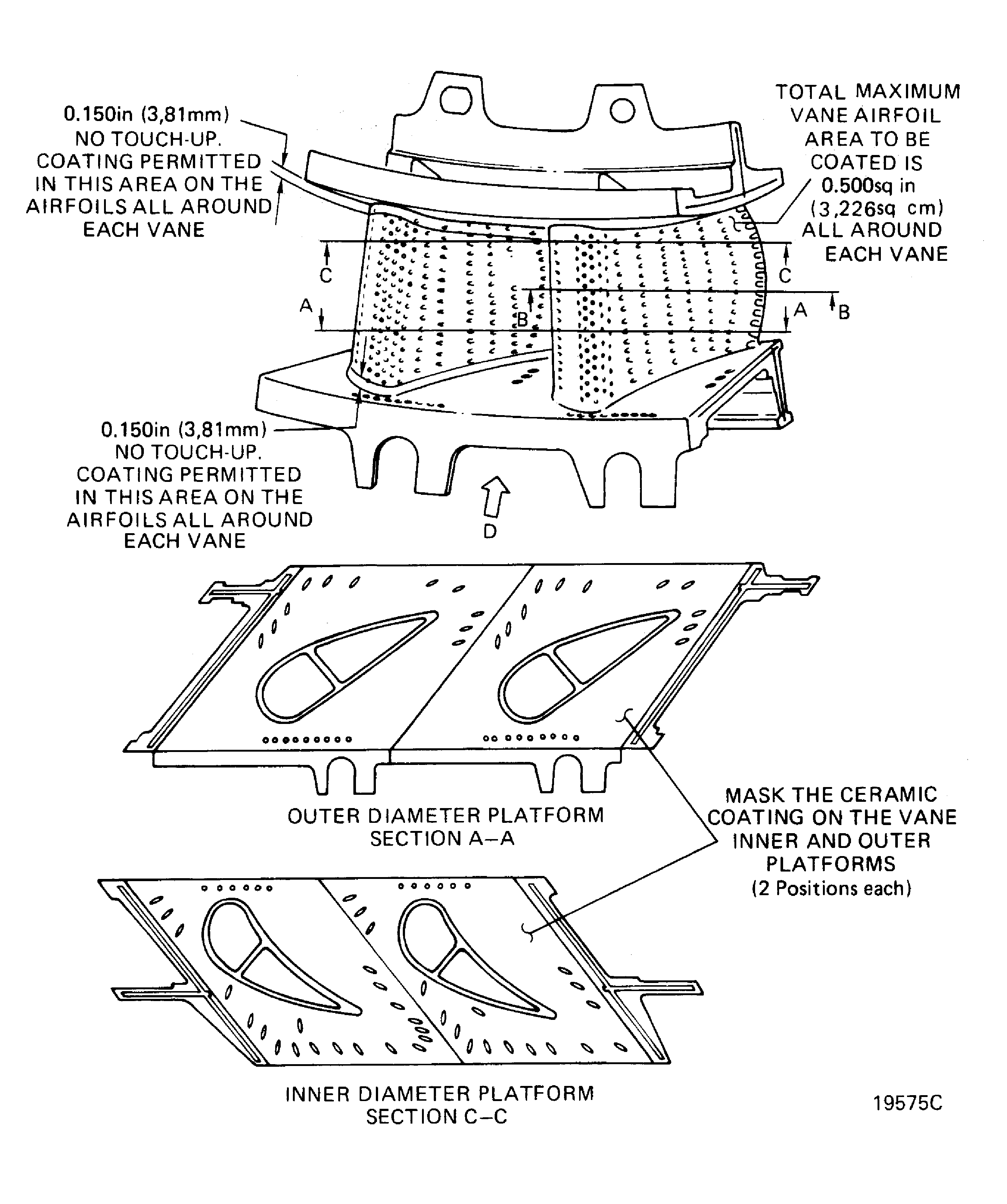

Mask the ceramic coating on the inner and outer diameter platforms.

No touch-up coating is permitted in less than 0.150in. (3.81 mm) area of the ceramic coating on the inner and outer platforms.

The maximum total vane airfoil area to be coated is 0.500 sqin. (3.226 sqcm.).

Prepare and touch-up the vane cluster airfoil coating.

Refer to the heat tint inspection in TASK 72-44-20-200-001-A01 (INSPECTION-001, CONFIG-001) .

If the heat tint inspection is unsatisfactory, do the touch-up coating repair again.

Do a heat tint inspection on the required vane.

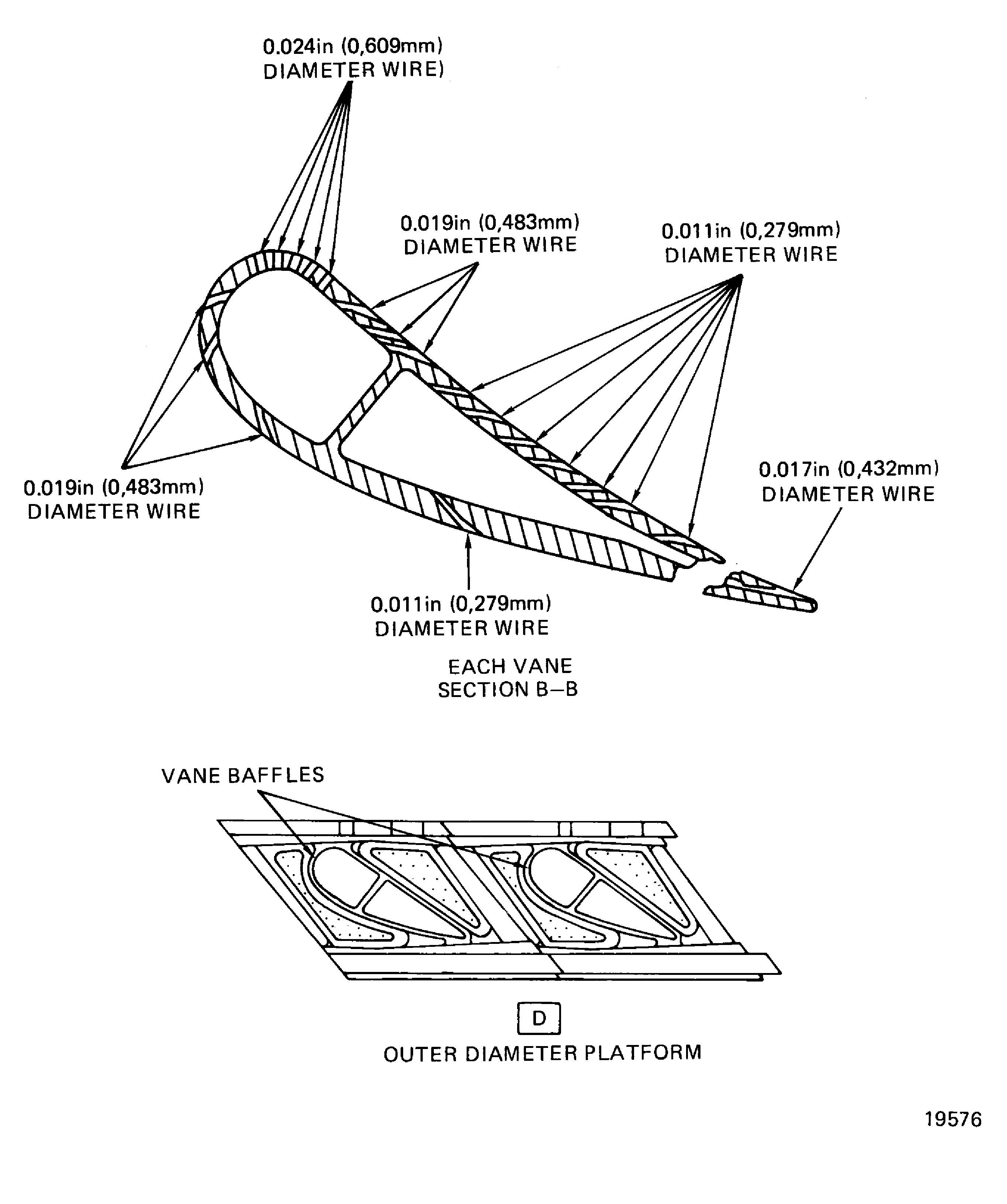

All cooling air holes must be at the minimum diameter.

If applicable open all holes to the minimum diameter.

Refer to Repair VRS3145 TASK 72-44-20-300-013 (REPAIR-013).

Examine the airfoil cooling air holes.

Refer to Repair VRS3152 TASK 72-44-20-300-005 (REPAIR-005).

Water flush the vane cavity to remove all the blockage material.

Install the baffle(s).

If applicable, remove the vane baffle(s) from the airfoil cavity where the cooling holes were opened.

Refer to TASK 72-44-20-200-001-A01 (INSPECTION-001, CONFIG-001).

If applicable do an airflow check on the vane cluster assembly if the baffle(s) were removed.

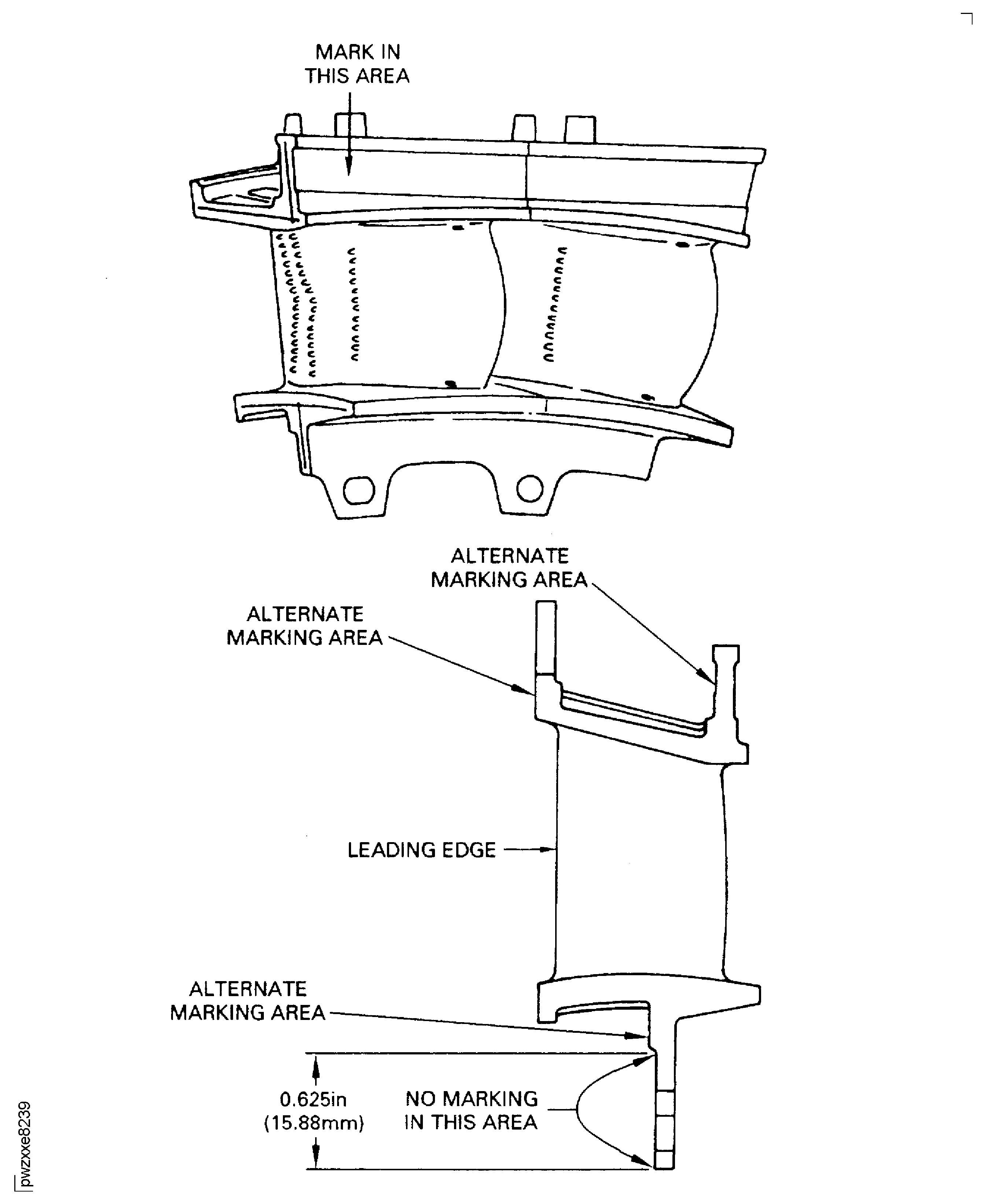

Make a permanent mark by the procedure given in the SPM TASK 70-09-00-400-501.

Use the vibration peen method.

Refer to Figure.

Identify the repair. Make a mark VRS3165 adjacent to the part number or on one of the alternate marking areas.

SUBTASK 72-44-20-350-053-001 Touch-up the Stage 1 HPT Vane Assembly Airfoil Coating with CoMat 07-057 Aluminum-Silicon Slurry

Do the procedure given in the SPM TASK 70-38-26-380-501 except brush coat the vane five times and diffusion heat treat the vane assembly to between 1475 and 1525 deg F (802 to 829 deg C).

Mask the ceramic coating on the inner and outer diameter platforms.

No touch-up coating is permitted in 0.150 in. (3.81 mm) area of the ceramic coating on the inner and outer airfoil platforms.

The maximum total vane airfoil area to be coated is 0.500 sqin. (3.226 sqcm.).

Prepare and touch-up the vane cluster airfoil coating.

Refer to the heat tint inspection in TASK 72-44-20-200-001-A01 (INSPECTION-001, CONFIG-001).

If the heat tint inspection is unsatisfactory, do the touch-up coating repair again.

Do a heat tint inspection on the repaired vane.

All cooling air holes must be at the minimum diameter.

If applicable open all the holes to the minimum diameter.

Refer to Repair, VRS3145 TASK 72-44-20-300-013 (REPAIR-013).

Examine the airfoil cooling air holes.

Water flush the vane cavity to remove all the blockage material.

Install the baffle(s).

Refer to Repair, VRS3152 TASK 72-44-20-300-005 (REPAIR-005).

If applicable, remove the vane baffle(s) from the airfoil cavity where the cooling holes were opened.

Refer to TASK 72-44-20-200-001-A01 (INSPECTION-001, CONFIG-001).

If applicable do an airflow check on the vane cluster assembly if the baffle(s) were removed.

Make a permanent mark by the procedure given in the SPM TASK 70-09-00-400-501.

Use the vibration peen method.

Refer to Figure.

Identify the repair. Make a mark VRS3165 adjacent to the part number or on one of the alternate markin areas.

SUBTASK 72-44-20-350-053-002 Touch-up the Stage 1 HPT Vane Assembly Airfoil Coating with CoMat 02-183 Cobalt Aluminum Slurry

Figure: Stage 1 HPT vane cluster assembly airfoil touch-up coating areas

Sheet 1

Figure: Stage 1 HPT vane cluster assembly airfoil touch-up coating areas

Sheet 2

Figure: Stage 1 HPT vane assembly alternate marking areas

Stage 1 HPT vane assembly alternate marking areas