Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-44-20-300-014 HPT Stage 1 Vane - Replace The Baffle Repair, Repair-014 (VRS3153)

Effectivity

FIG/ITEM | PART NO. |

|---|---|

01-250 | 2A0091CL21 |

01-250 | 2A2591CL21 |

01-251 | 2A0091CL22 |

01-251 | 2A2591CL22 |

01-252 | 2A0091CL23 |

01-252 | 2A2591CL23 |

01-253 | 2A0091CL24 |

01-253 | 2A2591CL24 |

01-254 | 2A0091CL25 |

01-254 | 2A2591CL25 |

01-255 | 2A0091CL26 |

01-255 | 2A2591CL26 |

01-256 | 2A0091CL27 |

01-256 | 2A2591CL27 |

01-257 | 2A0091CL28 |

01-257 | 2A2591CL28 |

01-258 | 2A0091CL29 |

01-258 | 2A2591CL29 |

01-259 | 2A0091CL30 |

01-259 | 2A2591CL30 |

01-260 | 2A0091CL31 |

01-260 | 2A2591CL31 |

01-261 | 2A0091CL32 |

01-261 | 2A2591CL32 |

01-262 | 2A0091CL33 |

01-262 | 2A2591CL33 |

01-263 | 2A0091CL34 |

01-263 | 2A2591CL34 |

01-264 | 2A0091CL35 |

01-264 | 2A2591CL35 |

01-265 | 2A0091CL36 |

01-265 | 2A2591CL36 |

01-266 | 2A0091CL37 |

01-266 | 2A2591CL37 |

01-267 | 2A0091CL38 |

01-267 | 2A2591CL38 |

01-268 | 2A0091CL39 |

01-268 | 2A2591CL39 |

01-269 | 2A0091CL40 |

01-269 | 2A2591CL40 |

01-270 | 2A0091CL41 |

01-270 | 2A2591CL41 |

01-271 | 2A0091CL42 |

01-271 | 2A2591CL42 |

01-272 | 2A0091CL43 |

01-272 | 2A2591CL43 |

01-273 | 2A0091CL44 |

01-273 | 2A2591CL44 |

01-274 | 2A0091CL45 |

01-274 | 2A2591CL45 |

01-275 | 2A0091CL46 |

01-275 | 2A2591CL46 |

01-276 | 2A0091CL47 |

01-276 | 2A2591CL47 |

01-277 | 2A0091CL48 |

01-277 | 2A2591CL48 |

01-278 | 2A0091CL48-5 |

01-279 | 2A0091CL49 |

01-279 | 2A2591CL49 |

01-280 | 2A0091CL49-5 |

01-284 | 2A2591CL50 |

01-286 | 2A2591CL51 |

Material of component

DESCRIPTION | SYMBOL | MATERIAL |

|---|---|---|

Stage 1 HPT vane cluster | - | Cast cobalt alloy |

assembly | ||

Stage 1 HPT vane cover | - | Nickel alloy |

Baffle assembly | - | Nickel alloy |

Cover | - | Nickel alloy |

General

The practices and processes referred to in the procedure by TASK number are in the SPM.

Price and availability - not applicable

Repair Facilities

The Source Demonstration requirements of this repair means that any facility not authorized to accomplish this repair either utilize the Authorized Repair Vendors listed below or contact IAE Repair Development Group to determine if a qualification program can be initiated at their facility.

IAE - INTERNATIONAL AERO ENGINES AG

400 Main Street

East Hartford CT 06108

USA

ATTN: Manager Repair Development

Authorized Repair Vendors for Repair VRS3153 are listed below:

Pratt and Whitney Overhaul Repair Center

Airfoil Repair Technology

415 Washington Avenue,

North Haven CT 06473 USA

CHROMALLOY RESEARCH and TECHNOLOGY

Chromalloy American Corporation

Blaisdell Road

Orangeburg, NY 10962 USA

PWES - TULSA AIRFOIL REPAIR OPERATIONS

2201 E.L. Anderson Boulevard

Claremore, OK 74017

USA

The designation by IAE of an authorized repair vendor indicates that the repair vendor has demonstrated the necessary capability to enable it to carry out the listed repair work. However, IAE makes no warranties or representations concerning the qualifications or quality standards of the repair vendors to carry out the repair work, and accepts no responsibility whatsoever for any work that may be carried out by a repair vendor, other than when IAE is listed as the repair vendor. Authorized repair vendors do not act as agents or representatives of IAE.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Airflow check equipment | LOCAL | Airflow check equipment | ||

| Electro-discharge metal removal (EDMR) equipment | LOCAL | Electro-discharge metal removal (EDMR) equipment | ||

| Portablegrinding equipment | LOCAL | Portable grinding equipment | ||

| Penetrant inspection equipment | LOCAL | Penetrant inspection equipment | ||

| Fusion welding equipment | LOCAL | Fusion welding equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-243 WELDING FILLER WIRE | LOCAL | CoMat 03-243 | ||

| CoMat 03-287 WELDING FILLER WIRE | LOCAL | CoMat 03-287 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Baffle assembly | 2A0024-01 | AR | ||

| Baffle assembly | 2A0027-01 | AR |

Safety Requirements

NONEProcedure

Refer to Figure.

Do the procedure given in the SPM TASK 70-32-03-320-501.

Make sure all the unwanted material is removed.

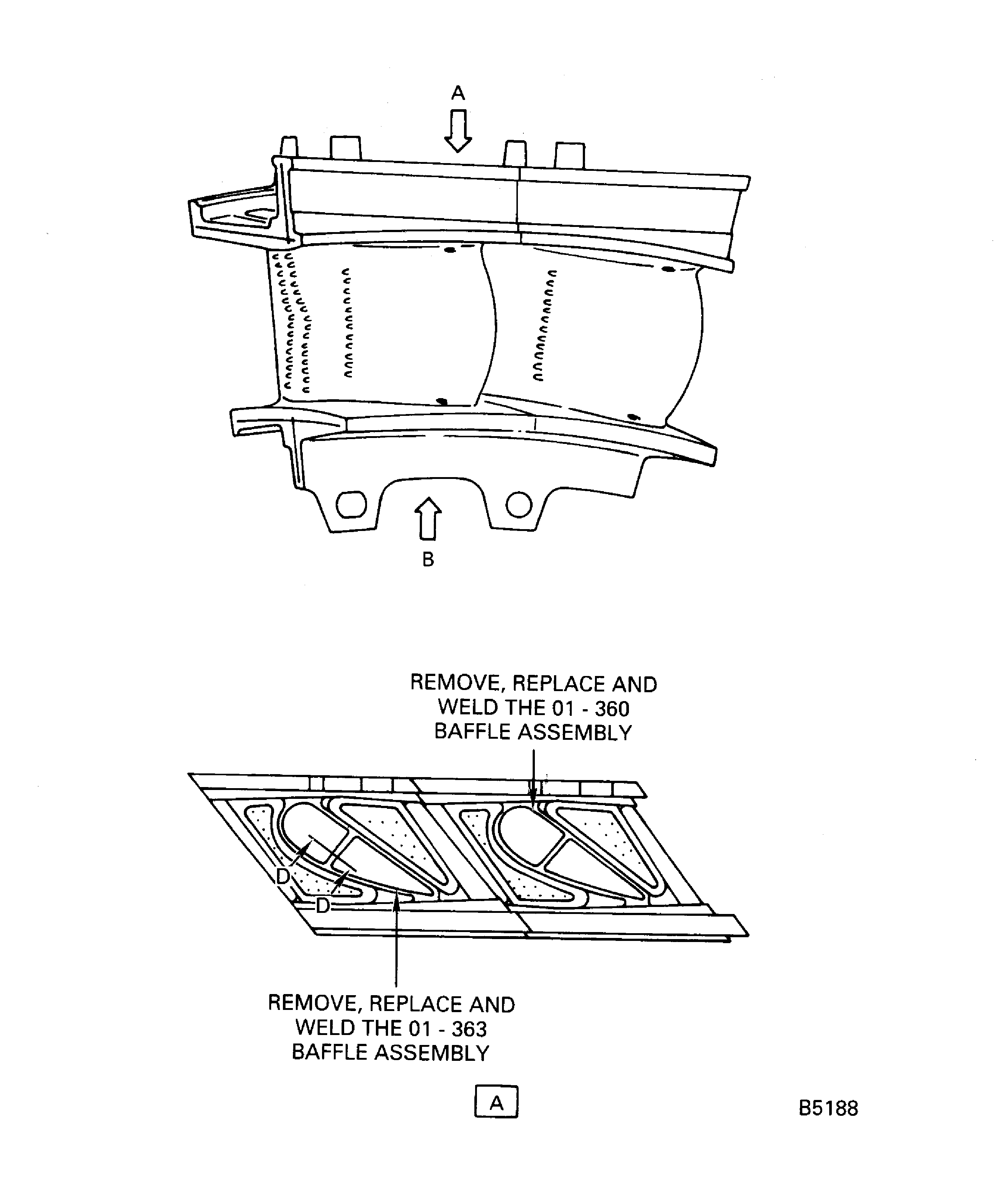

Remove the vane baffle assemblies by the Electro-discharge metal removal (EDMR) method.

SUBTASK 72-44-20-350-057-001 Remove the Baffle Assemblies from the Vane Assembly (EDMR Method)

Refer to Figure.

Use the Portablegrinding equipment.

Make sure all the unwanted material is removed.

Sufficient baffle sealing lips must be maintained.

Refer to Figure.

Remove the vane baffle assemblies by blending the welds.

SUBTASK 72-44-20-350-057-002 Remove the Baffle Assemblies from the Vane Assembly (Blend Method)

Refer to Figure.

Use the Portablegrinding equipment.

Make sure all the unwanted material is removed.

Sufficient baffle sealing lips must be maintained.

Refer to Figure.

Remove the baffles by grinding the welds.

SUBTASK 72-44-20-350-057-003 Remove the Baffle Assemblies from the Vane Assembly (Grind Method)

Refer to the SPM TASK 70-12-01-120-501 or SPM TASK 70-12-02-120-501.

Clean the baffles if they are not damaged.

SUBTASK 72-44-20-120-052 Clean the Baffle Assemblies

Refer to the SPM TASK 70-23-02-230-501.

Fluorescent penetrant inspect the baffles.

SUBTASK 72-44-20-230-056 Examine the Baffle Assemblies

Do the procedure given in TASK 72-44-20-100-000 (CLEANING-000).

Clean the vane assembly.

SUBTASK 72-44-20-110-052 Clean the Vane Assembly

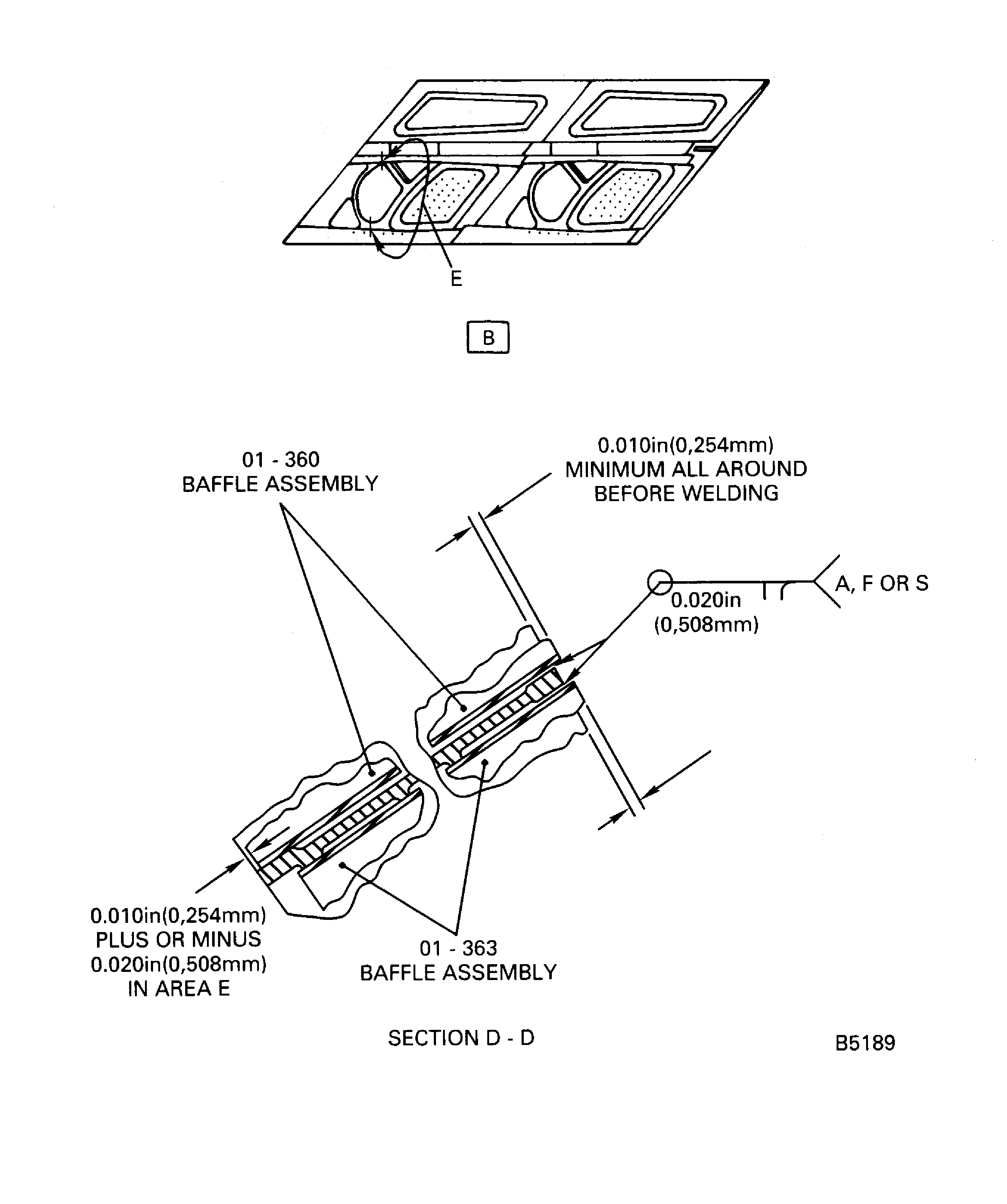

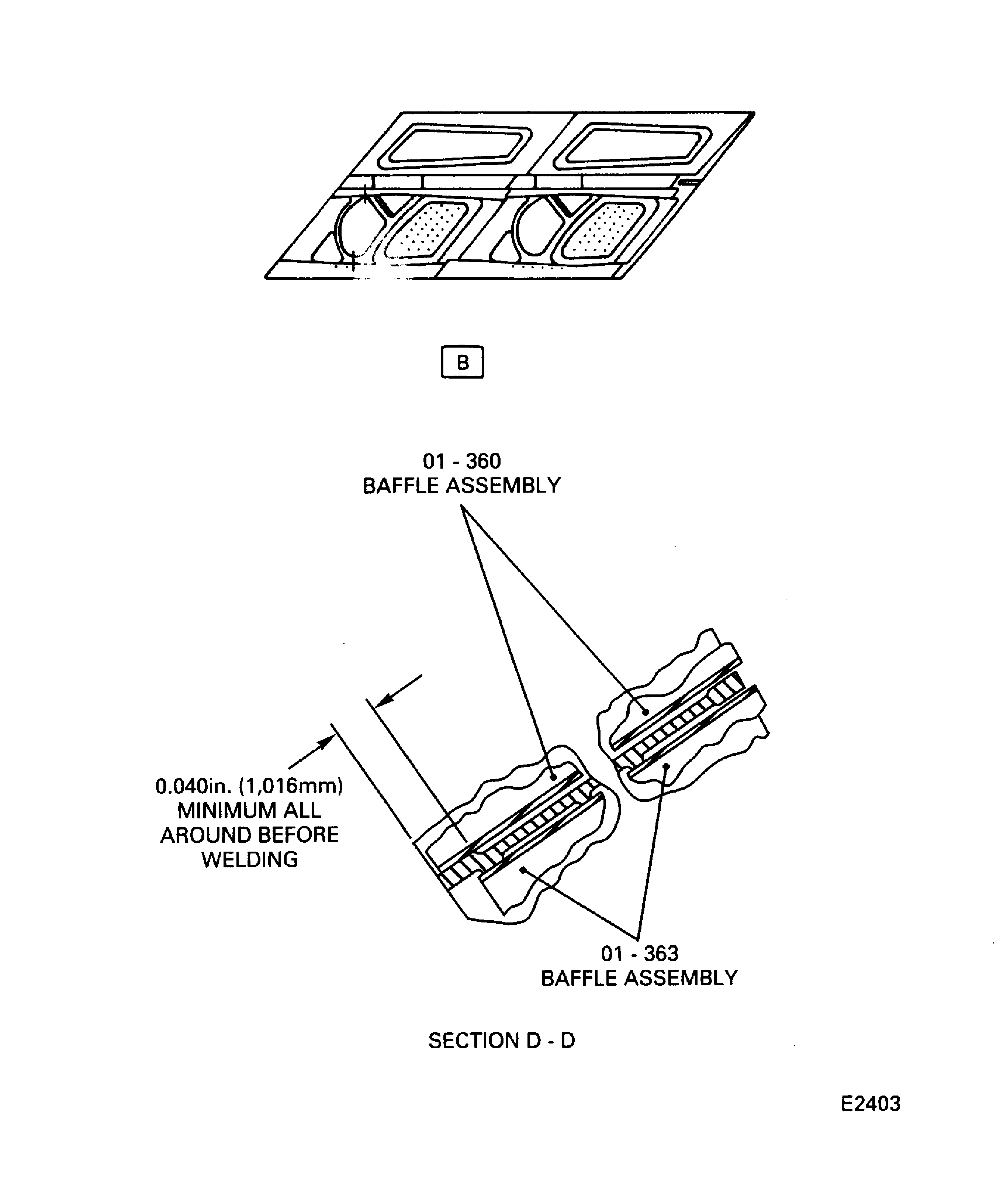

Refer to Figure.

Tack weld to hold the baffles in position for welding by the procedure given in the SPM TASK 70-31-13-310-501.

Install the baffle assemblies as necessary for welding.

Refer to Figure.

Do the procedure given in the SPM TASK 70-31-13-310-501.

Weld all around the baffle assemblies.

SUBTASK 72-44-20-310-052 Weld the Baffle Assemblies on the Vane Assembly

A maximum of six damaged areas that are 0.0313 in. (0.794 mm) are permitted in each joint if they are separated by a minimum of 0.125 in. (3.175 mm).

Cracks in the weld or braze material of each joint that are 0.125 in. (3.175 mm) or less and separated by a minimum of 0.125 in. (3.175 mm) are acceptable.

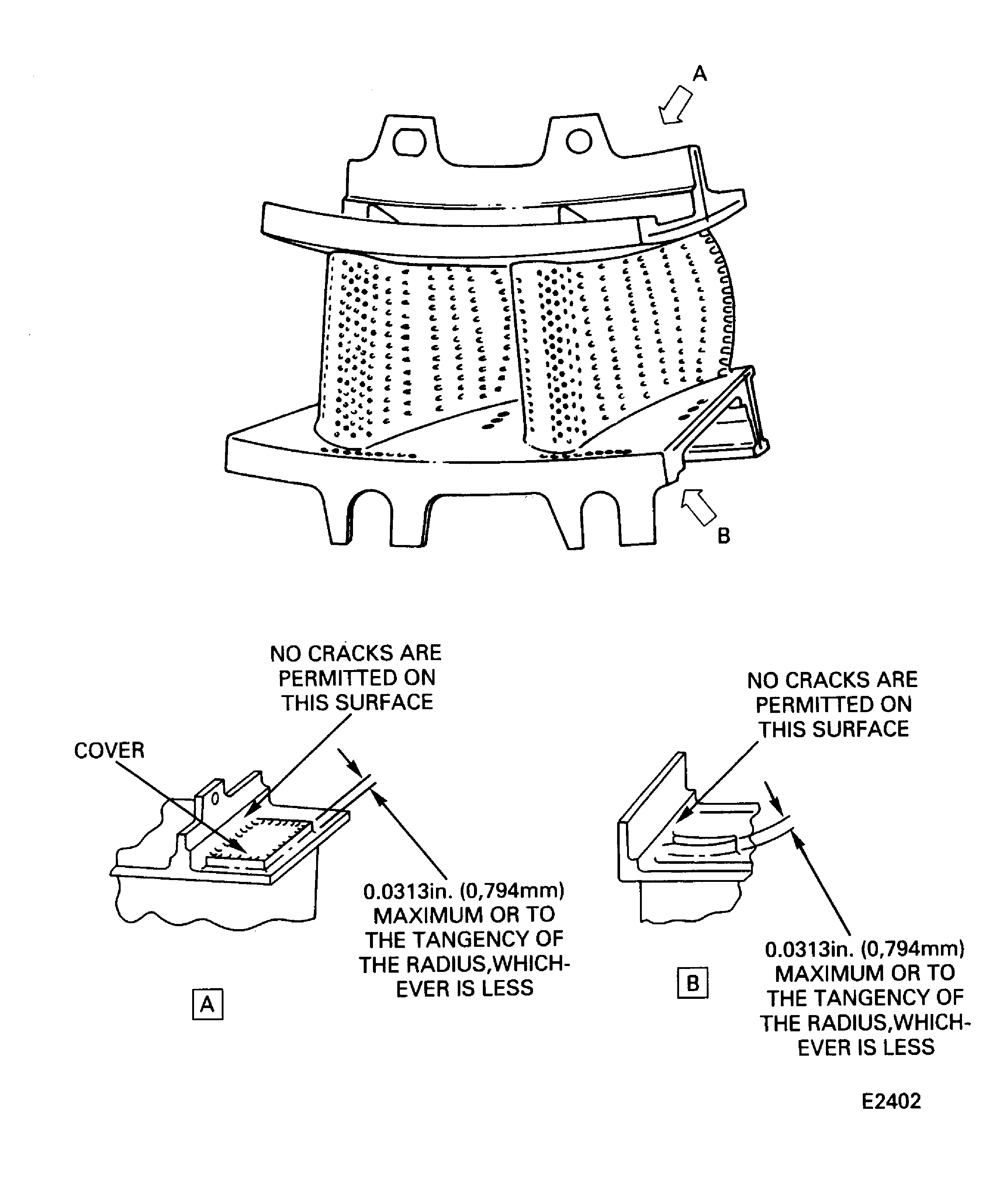

Cracks can go into the cast material as shown in Figure.

On all other joints, cracks can go into the cast material 0.015in. (0.381 mm) maximum.

NOTE

This SUBTASK is an alternative to Step.Visually inspect the repair.

SUBTASK 72-44-20-220-085 Examine the Repair

Refer to Figure.

Do the procedure given in the SPM TASK 70-23-02-230-501.

Use the crack limits given in TASK 72-44-20-200-000 (INSPECTION-000).

NOTE

This SUBTASK is an alternate to Step.Fluorescent penetrant the welded areas.

SUBTASK 72-44-20-230-053 Examine the Repair

Refer to Figure.

Do the procedure given in TASK 72-44-20-200-000 (INSPECTION-000).

Do an airflow check on the airfoil and platform cooling air holes.

SUBTASK 72-44-20-220-066 Examine the Vane Cluster Assembly by the Airflow Check

Figure: Stage 1 HPT vane cluster assembly baffle assembly replacement repair areas

Sheet 1

Figure: Stage 1 HPT vane cluster assembly baffle assembly replacement repair areas

Sheet 2

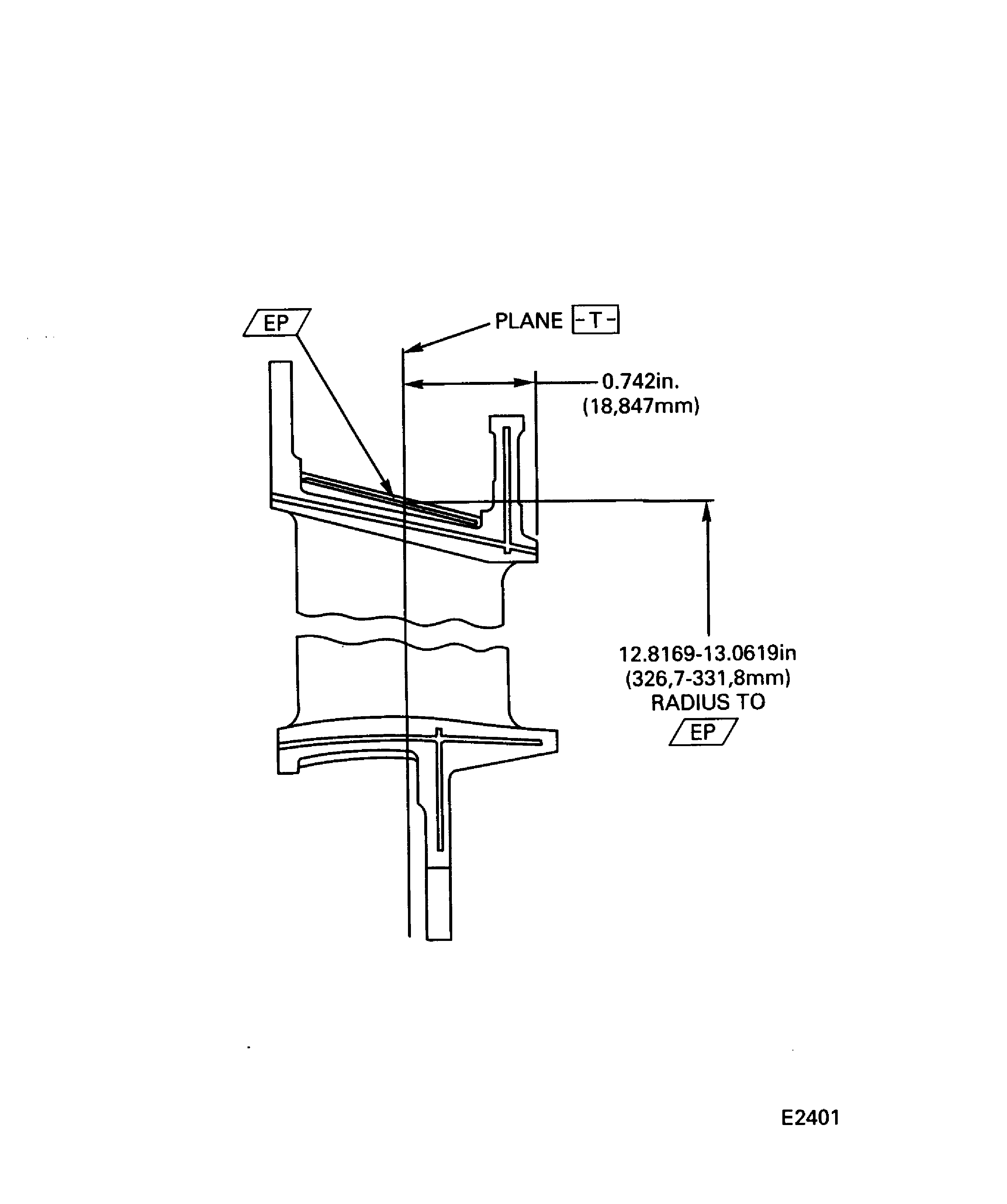

Figure: Stage 1 HPT vane cluster assembly minimum baffle sealing lip

Sheet 3

Figure: Stage 1 HPT vane cluster assembly baffle removal by grinding or blending

Stage 1 HPT vane cluster assembly baffle removal by grinding or blending

Figure: Stage 1 HPT vane cluster assembly visual inspection areas

Stage 1 HPT vane cluster assembly visual inspection areas