Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-44-50-300-010 HPT Stage 1 Cooling (TOBI) Duct - Repair to Adjust The Air Flow, Repair-010 (VRS3177)

Effectivity

FIG/ITEM | PART NO. |

|---|---|

01-010 | 2A0008-01 |

01-010 | 2A1997-01 |

01-010 | 2A1997-001 |

01-010 | 2A1997-002 |

01-010 | 2A1997-003 |

01-010 | 2A2141-01 |

01-010 | 2A3180-01 |

01-010 | 2A3329-01 |

01-010 | 2A3487-01 |

01-010 | 2A3487-001 |

01-010 | 2A3491-01 |

01-010 | 2A3914-01 |

01-010 | 2A3914-001 |

01-010 | 2A4086 |

General

Price and availability - refer to IAE

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-287 WELDING FILLER WIRE | LOCAL | CoMat 03-287 |

Spares

NONESafety Requirements

NONEProcedure

Refer to the SPM TASK 70-31-13-310-501.

It is not necessary to heat treat the weld.

Hardness requirements are waived in the weld zone.

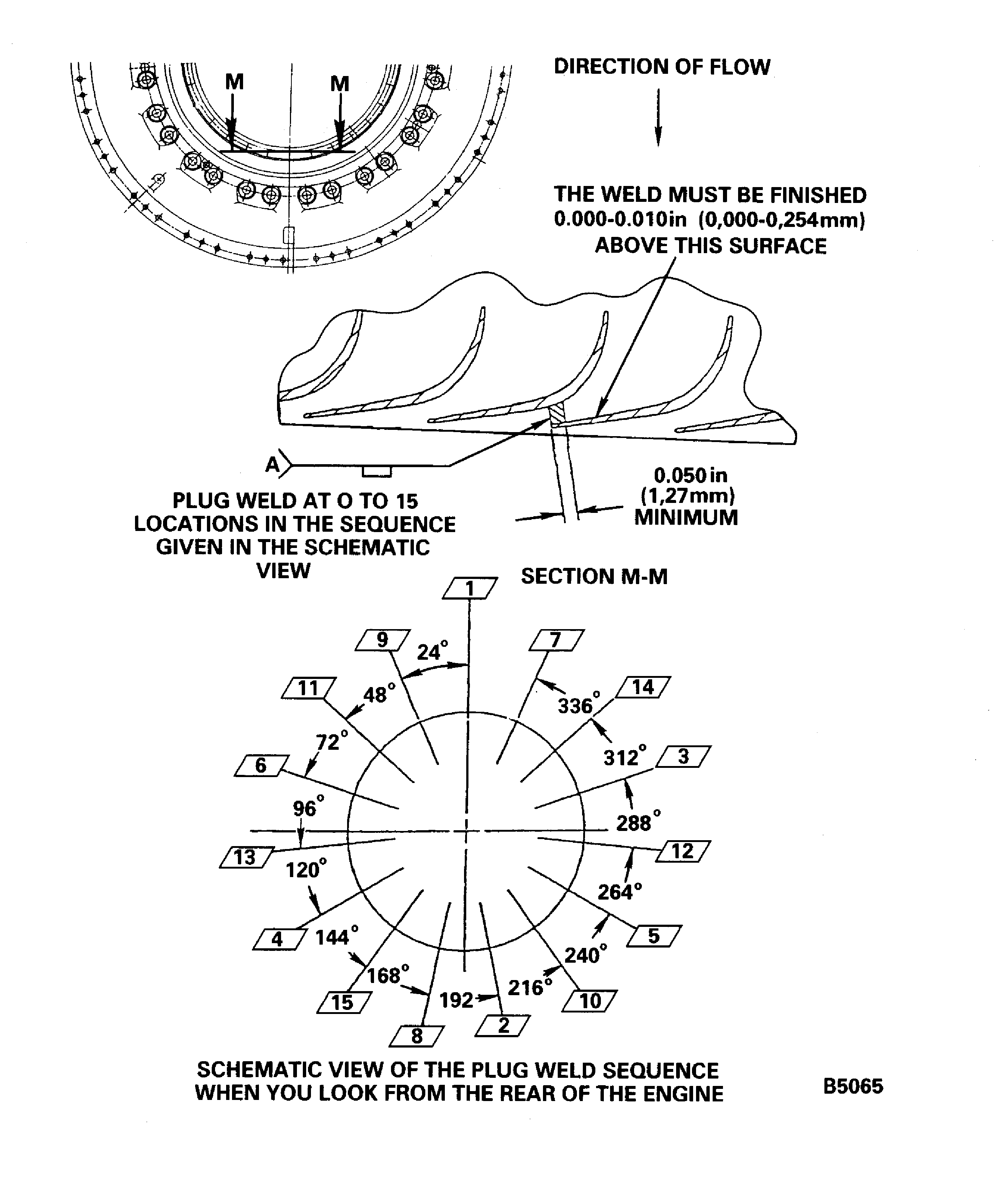

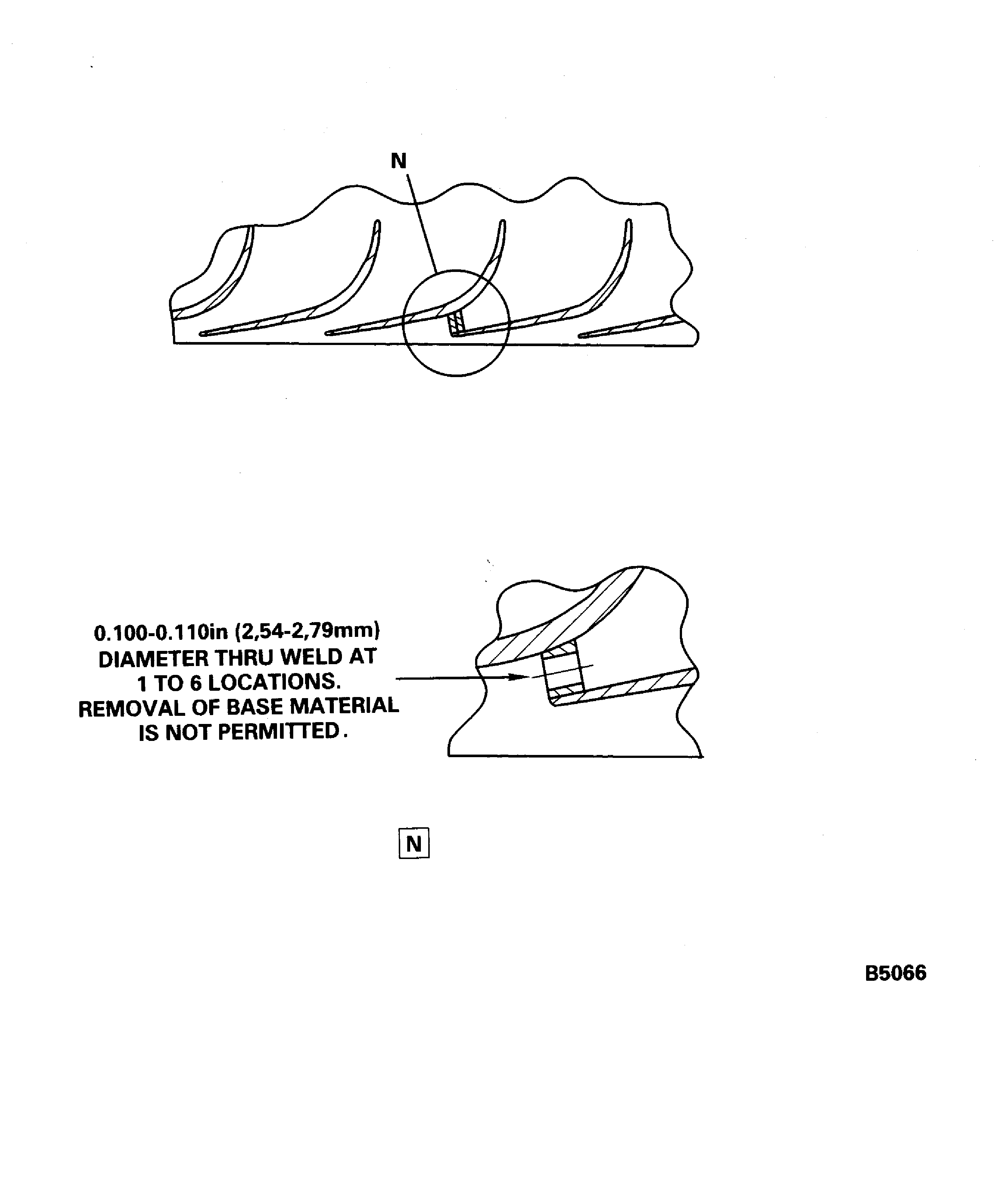

Install new plug welds in the nozzles or weld the trim holes.

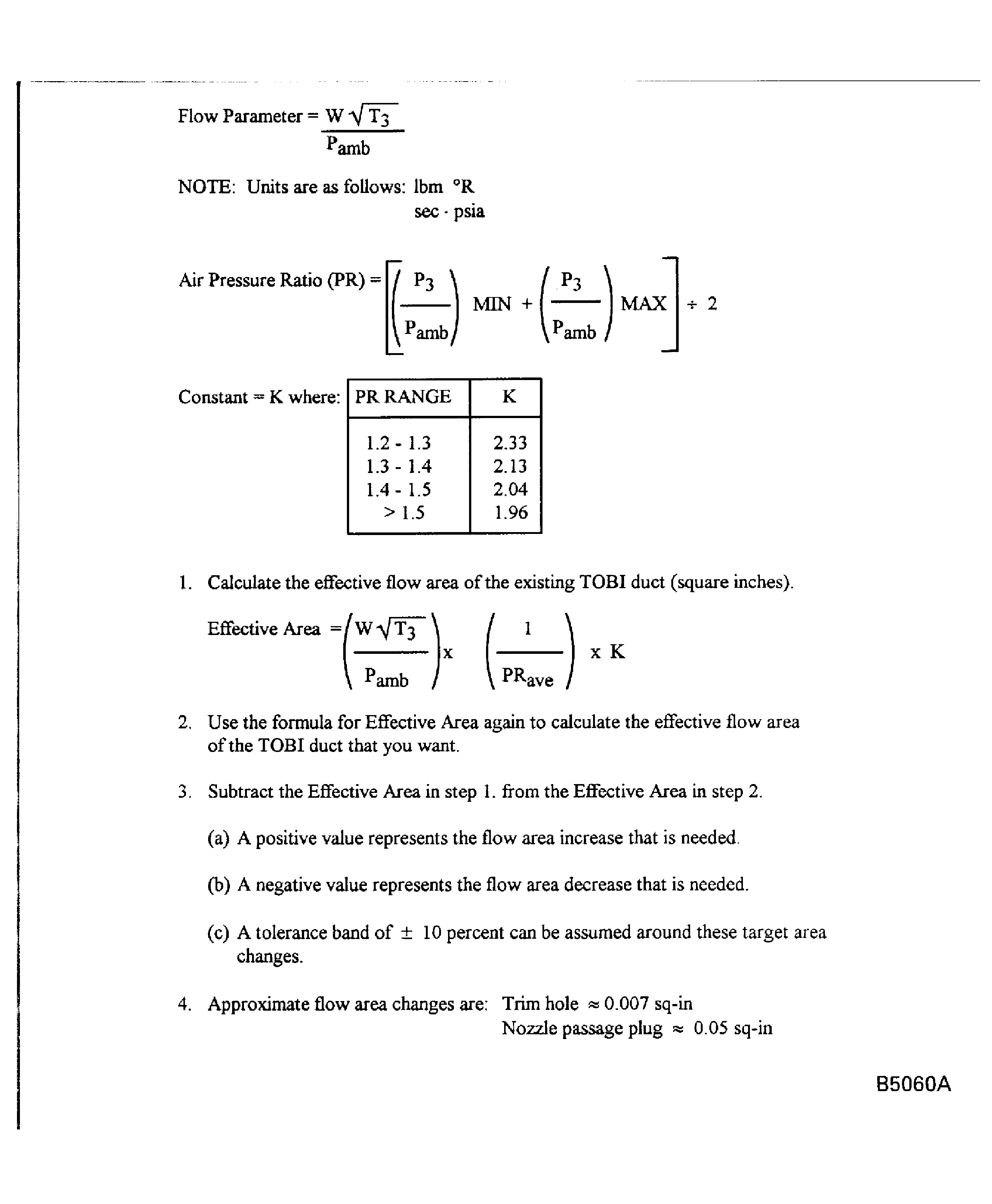

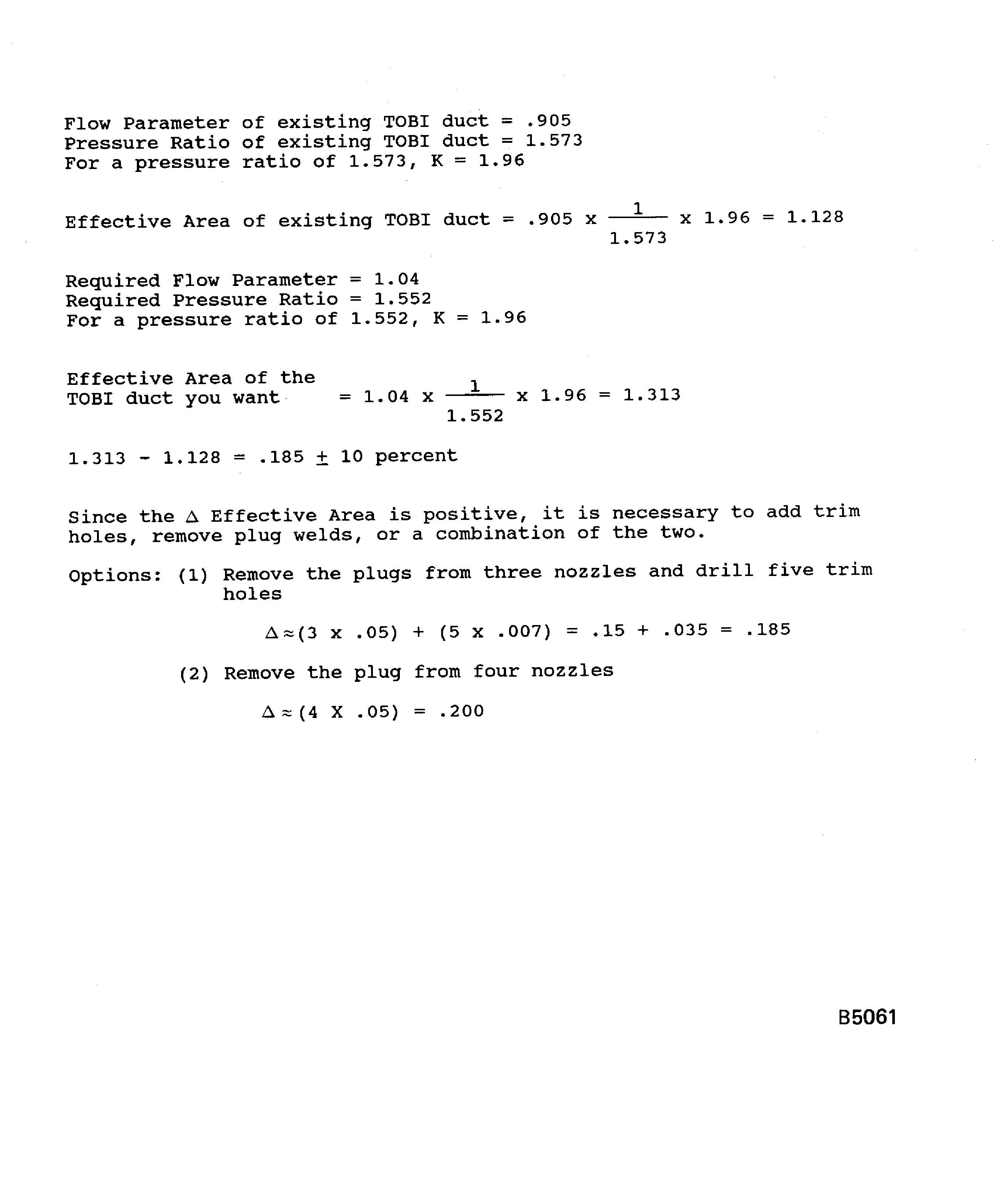

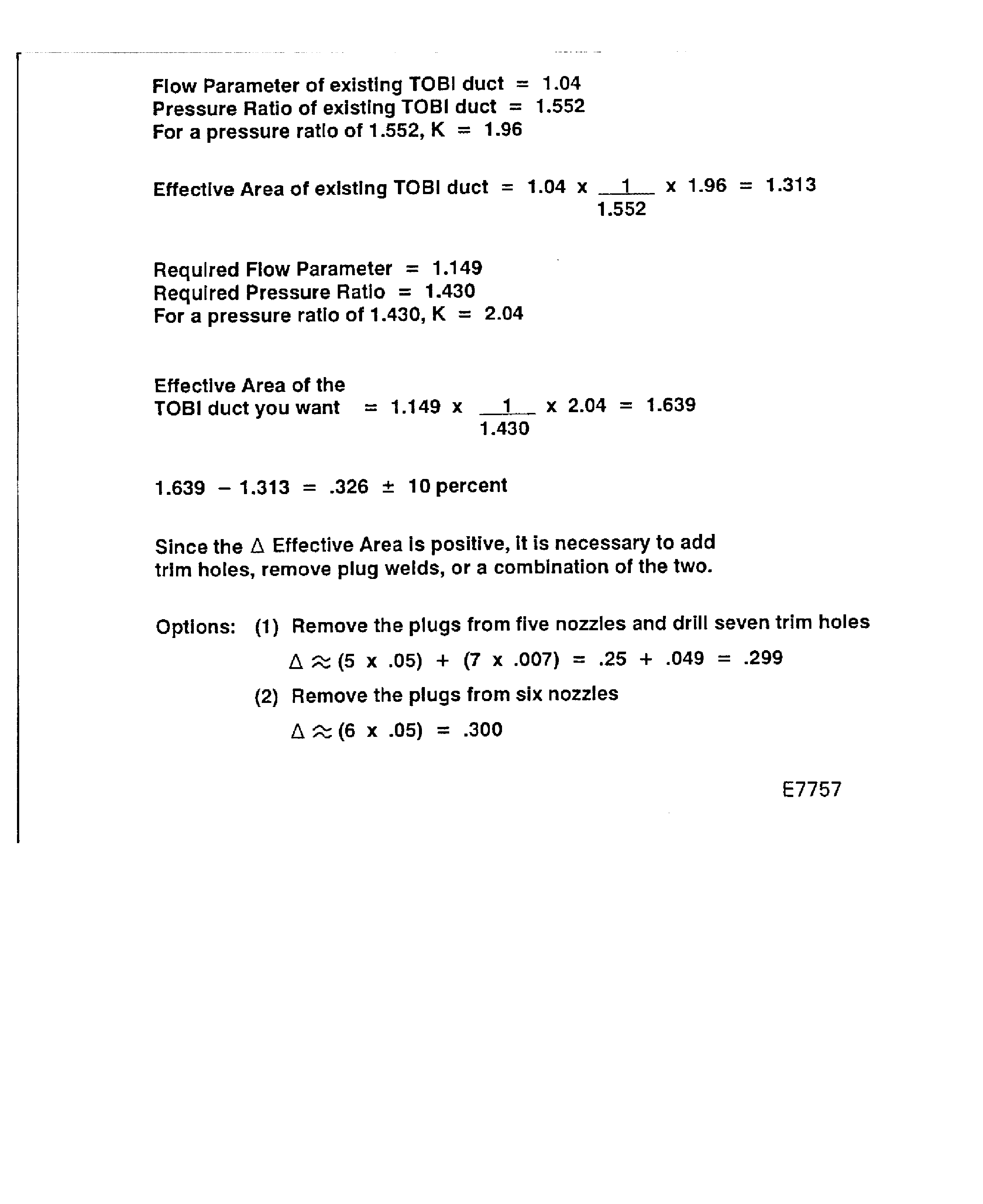

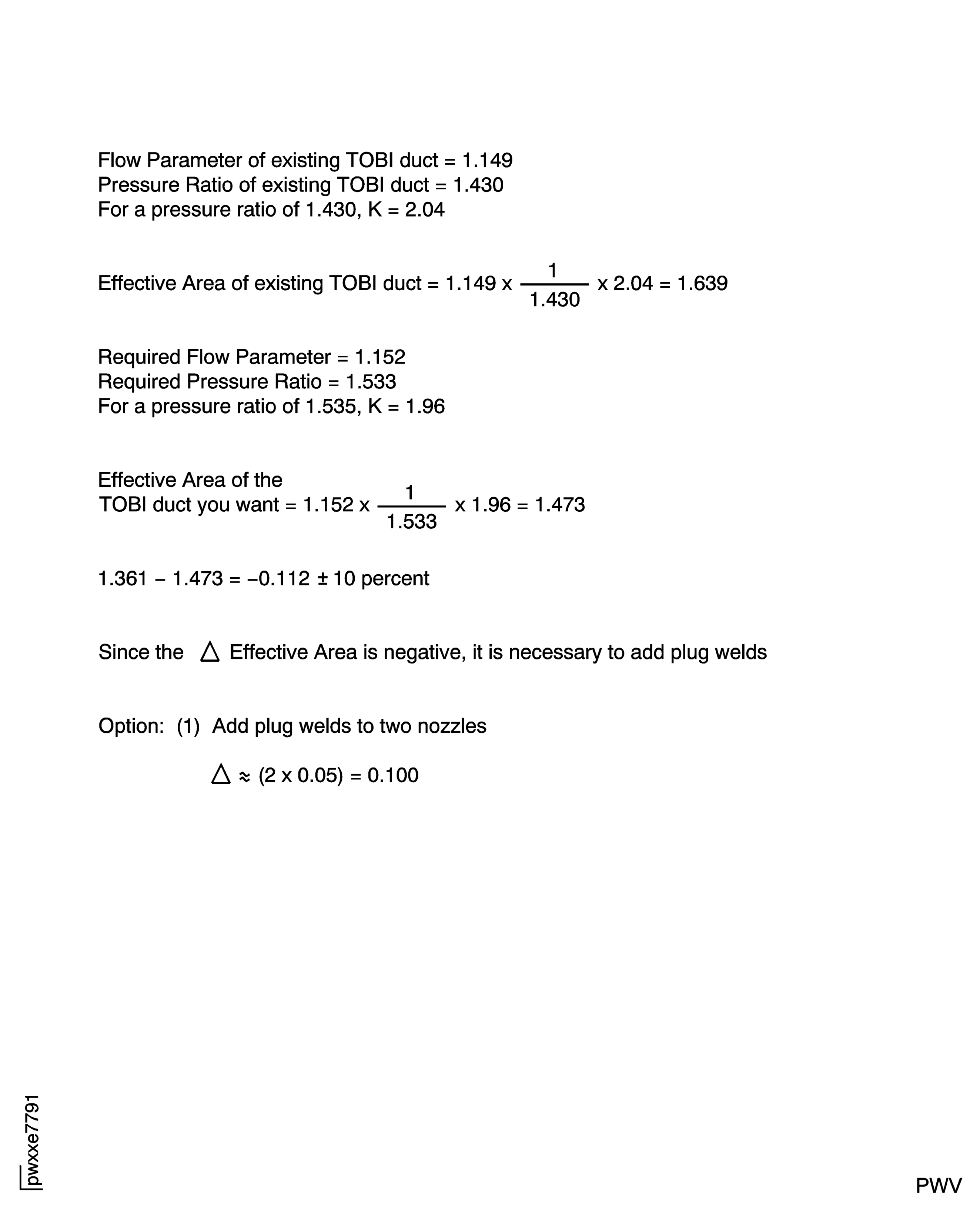

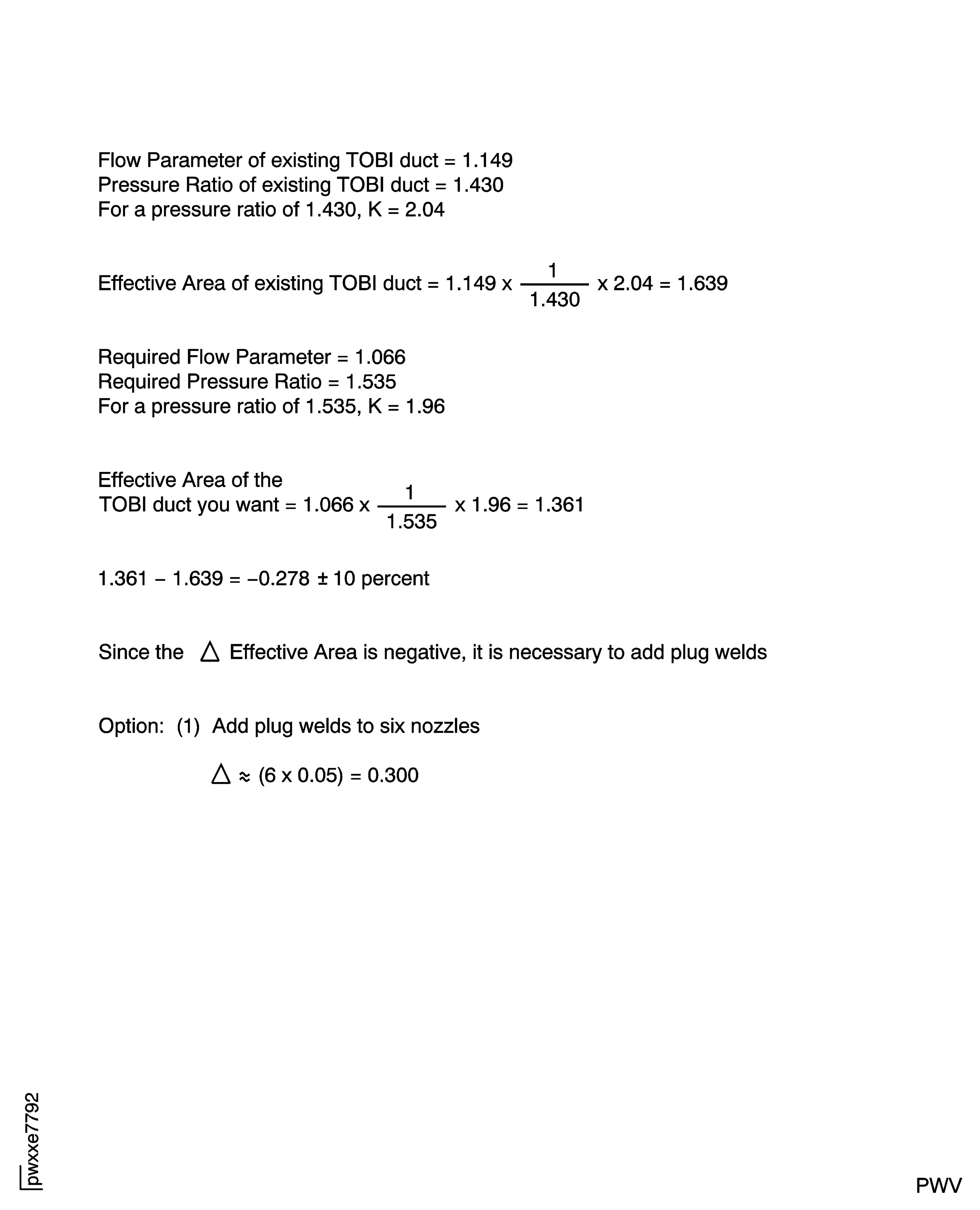

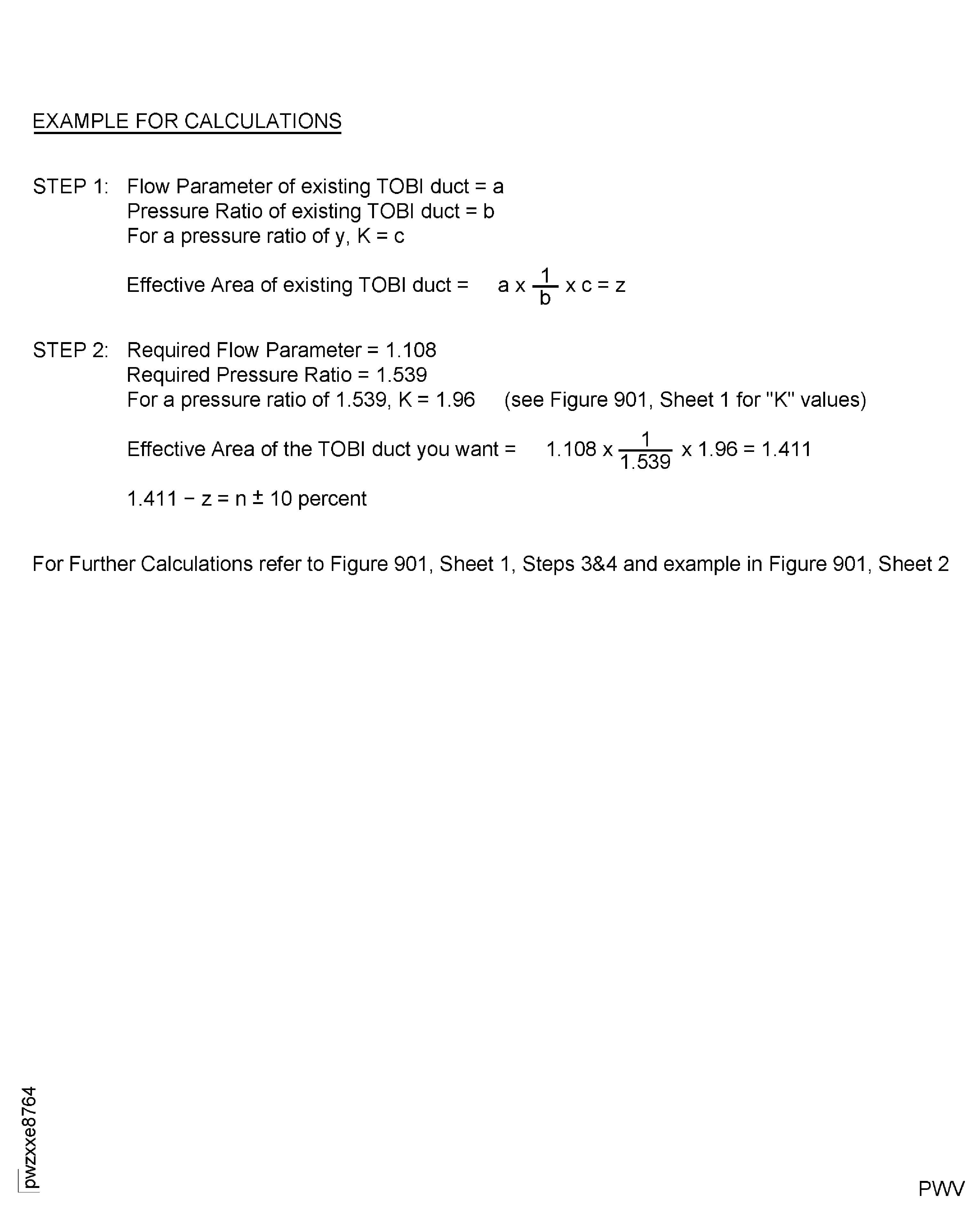

SUBTASK 72-44-50-350-061 Decrease the Air Flow of the Stage 1 HPT Cooling (TOBI) Duct Assembly

Do not add a new plug and then remove it to increase the air flow.

Refer to the SPM TASK 70-31-13-310-501.

It is not necessary to heat treat the weld.

Hardness requirements are waived in the weld zone.

Install new plug welds then drill trim holes.

SUBTASK 72-44-50-350-062 Increase the Air Flow of the Stage 1 HPT Cooling (TOBI) Duct Assembly

Refer to TASK 72-44-50-200-001-A00 (INSPECTION-001, CONFIG-001), TASK 72-44-50-200-001-B00 (INSPECTION-001, CONFIG-002), TASK 72-44-50-200-001-C00 (INSPECTION-001, CONFIG-003), TASK 72-44-50-200-001-D00 (INSPECTION-001, CONFIG-004), TASK 72-44-50-200-001-E00 (INSPECTION-001, CONFIG-005) or TASK 72-44-50-200-001-F00 (INSPECTION-001, CONFIG-006).

Examine the duct to make sure that the repair and air flow limits are met.

SUBTASK 72-44-50-220-073 Examine the Stage 1 HPT Cooling (TOBI) Duct Assembly after Repair

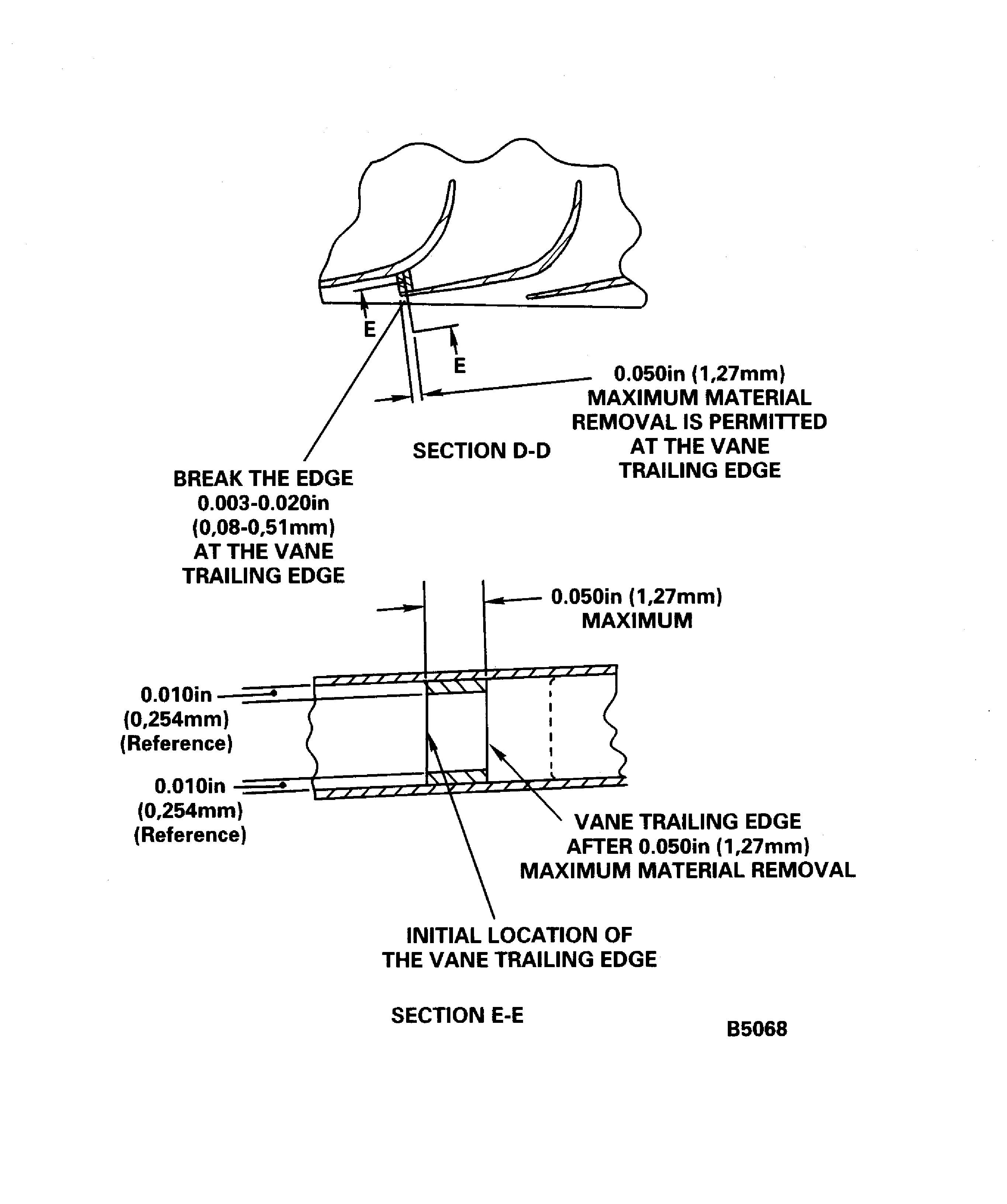

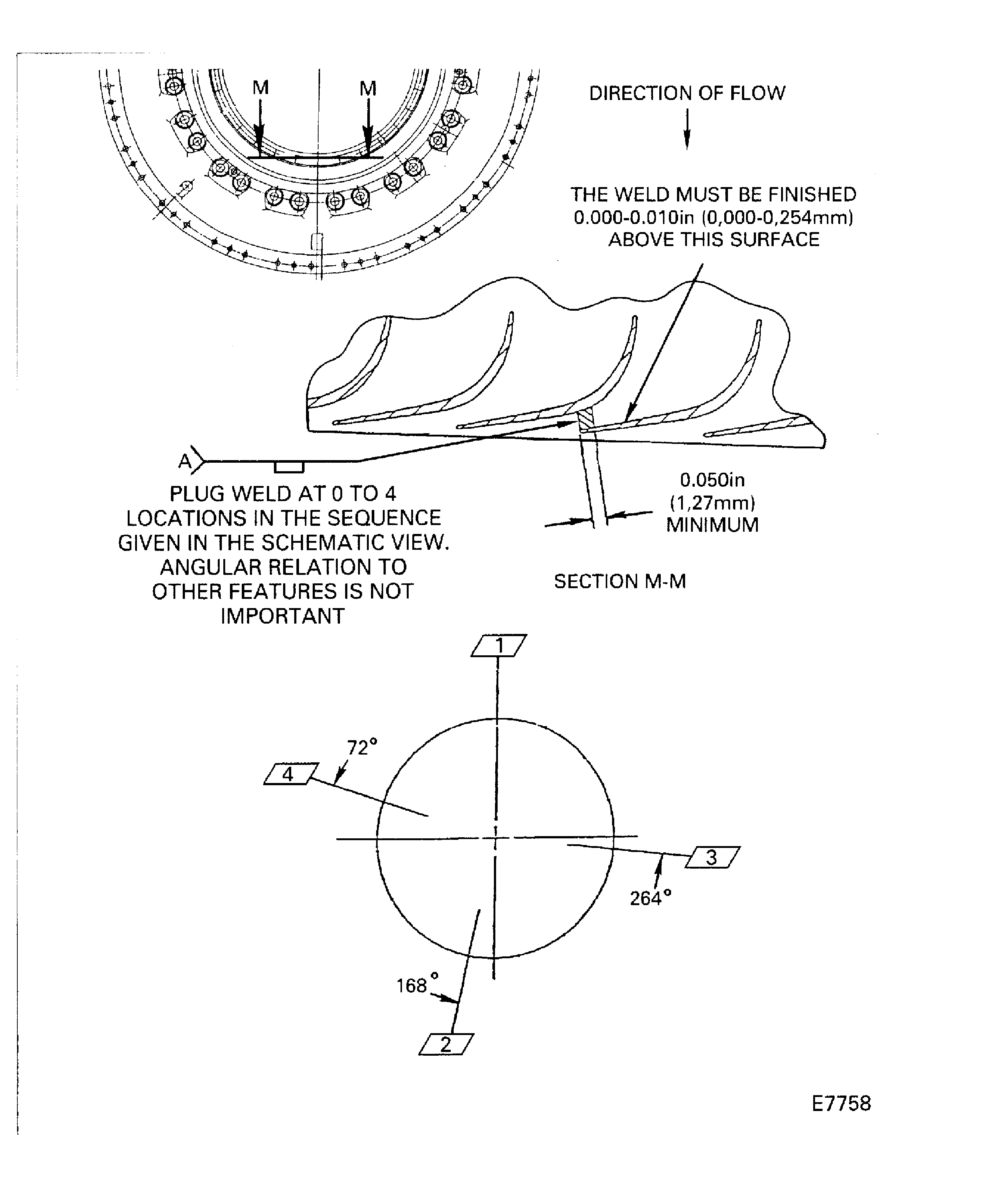

Figure: Repair Details and Dimensions

Sheet 1

Figure: Repair Details and Dimensions (PN 2A0008-01, 2A1997-01, 2A1997-001, 2A1997-002, 2A1997-003, 2A3491-01 and 2A3329-01)

Sheet 2

Figure: Repair Details and Dimensions (PN 2A2141-01)

Sheet 3

Figure: Repair Details and Dimensions (PN 2A3180-01 and 2A3487-01)

Sheet 4

Figure: Repair Details and Dimensions (PN 2A3914-01)

Sheet 5

Figure: Repair Details and Dimensions (PN 2A3487-001, 2A3914-001 and 2A4086)

Sheet 6

Figure: Repair Details and Dimensions (PN 2A0008-01, 2A1997-01, 2A1997-001, 2A1997-002, 2A1997-003, 2A3329-01 and 2A3491-01)

Repair Details and Dimensions (PN 2A0008-01, 2A1997-01, 2A1997-001, 2A1997-002, 2A1997-003, 2A3329-01 and 2A3491-01)

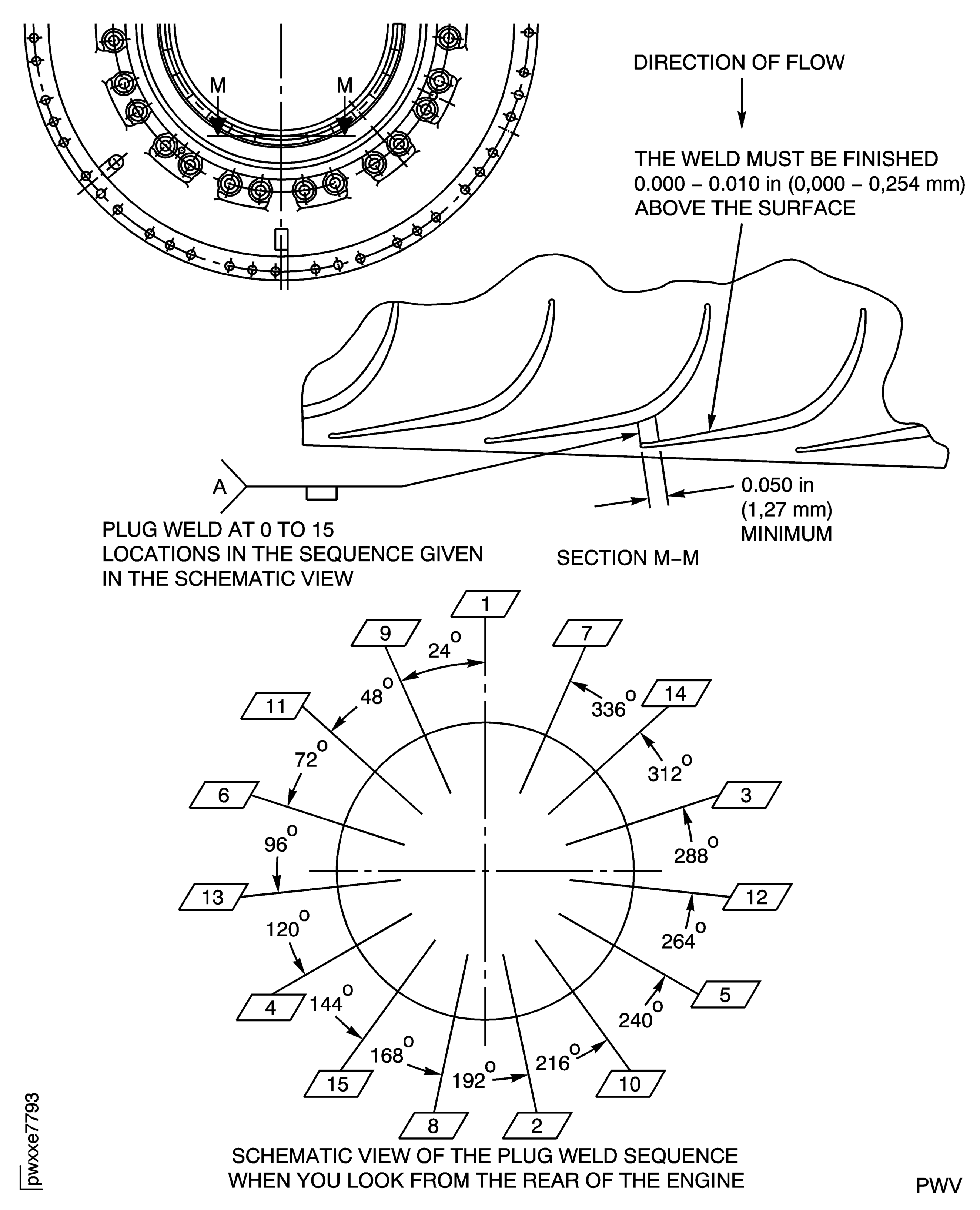

Figure: Repair Details and Dimensions (PN 2A2141-01 and 2A3180-01)

Repair Details and Dimensions (PN 2A2141-01 and 2A3180-01)

Figure: Repair Details and Dimensions (PN 2A3487-01 and 2A3914-01)

Repair Details and Dimensions (PN 2A3487-01 and 2A3914-01)

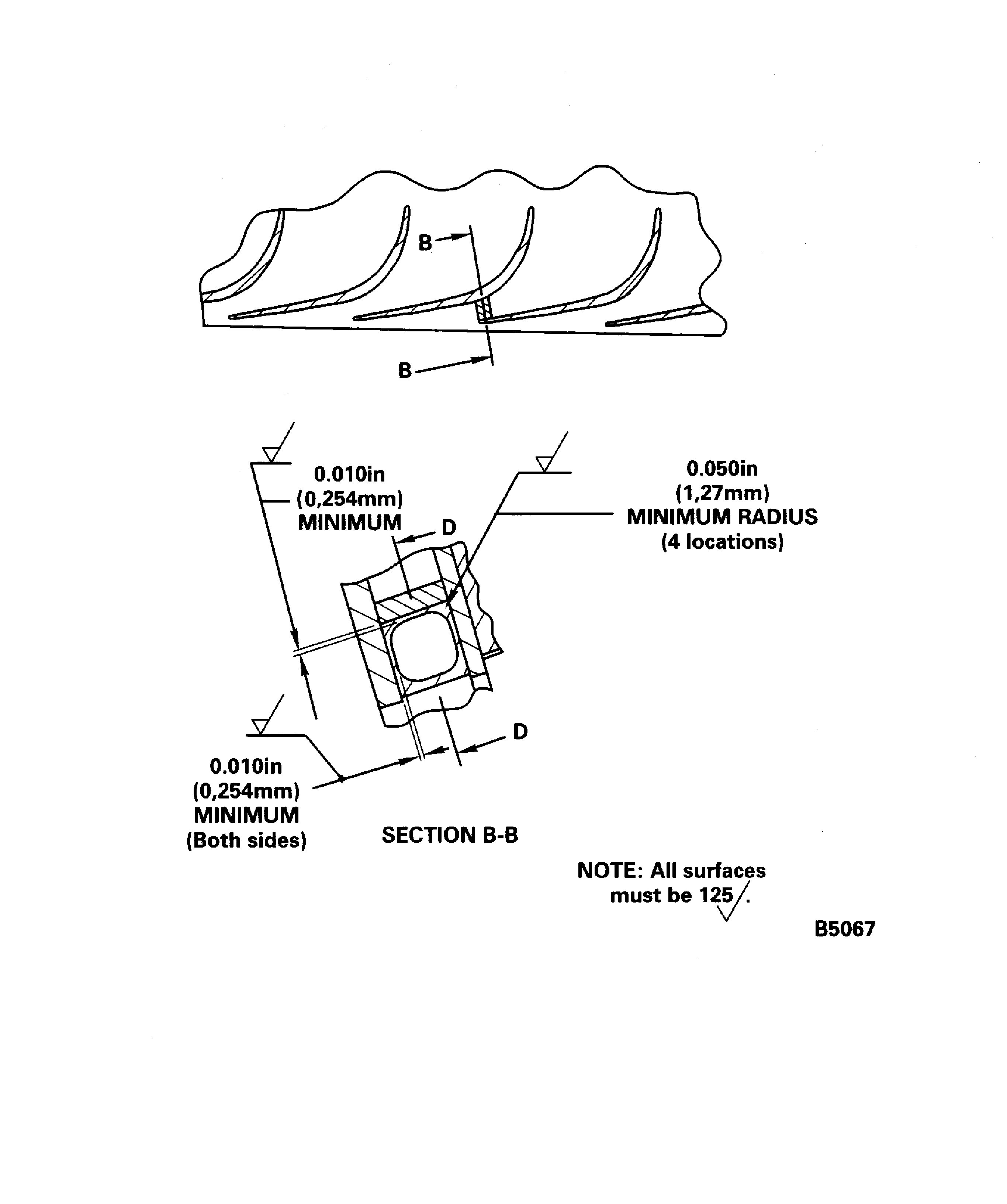

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Sheet 1

Figure: Repair Details and Dimensions

Sheet 2