Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-45-14-300-001 HPT Stage 1 Blade - Blend Repair On The Airfoil, Platform, And Root, Repair-001 (VRS3202)

General

This Repair must only be done when the instruction to do so is given in TASK 72-45-14-200-000 (INSPECTION-000).

Do this procedure when you blend the dents, nicks with the base material shown or coating that is damaged on the airfoil, platform and root. All blended areas except the root must be coated.

The practices and processes referred to in the procedure by TASK numbers are in SPM.

Price and availability - none

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Fine File | LOCAL | |||

| Workshop inspection equipment | LOCAL | Workshop inspection equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 05-070 BUFFING POLISHING COMPOUND | 75554 | CoMat 05-070 | ||

| CoMat 05-106 ABRASIVE STONE | K6835 | CoMat 05-106 | ||

| CoMat 05-125 ABRASIVE PAD, SILICON CARBIDE, ULTRA-FINE | LOCAL | CoMat 05-125 | ||

| CoMat 05-126 ABRASIVE PAD, ALUMINUM OXIDE, VERY FINE | LOCAL | CoMat 05-126 | ||

| CoMat 05-137 POLISHING COMPOUND | LOCAL | CoMat 05-137 | ||

| CoMat 05-189 COMPOUND, POLISHING AND BUFFING | IAE65 | CoMat 05-189 | ||

| CoMat 05-190 COMPOUND, SILICON CARBIDE DEBURRING (150 GRIT AND FINER) | IAE65 | CoMat 05-190 | ||

| CoMat 05-191 COMPOUND - POLISHING, GREASELESS, COARSE | 75554 | CoMat 05-191 |

Spares

NONESafety Requirements

CAUTION

Procedure

Refer to SPM TASK 70-35-21-350-501.

All blends must be smooth bottomed and made in the shape of the initial contour.

The minimum blend length to depth is 10 to 1.

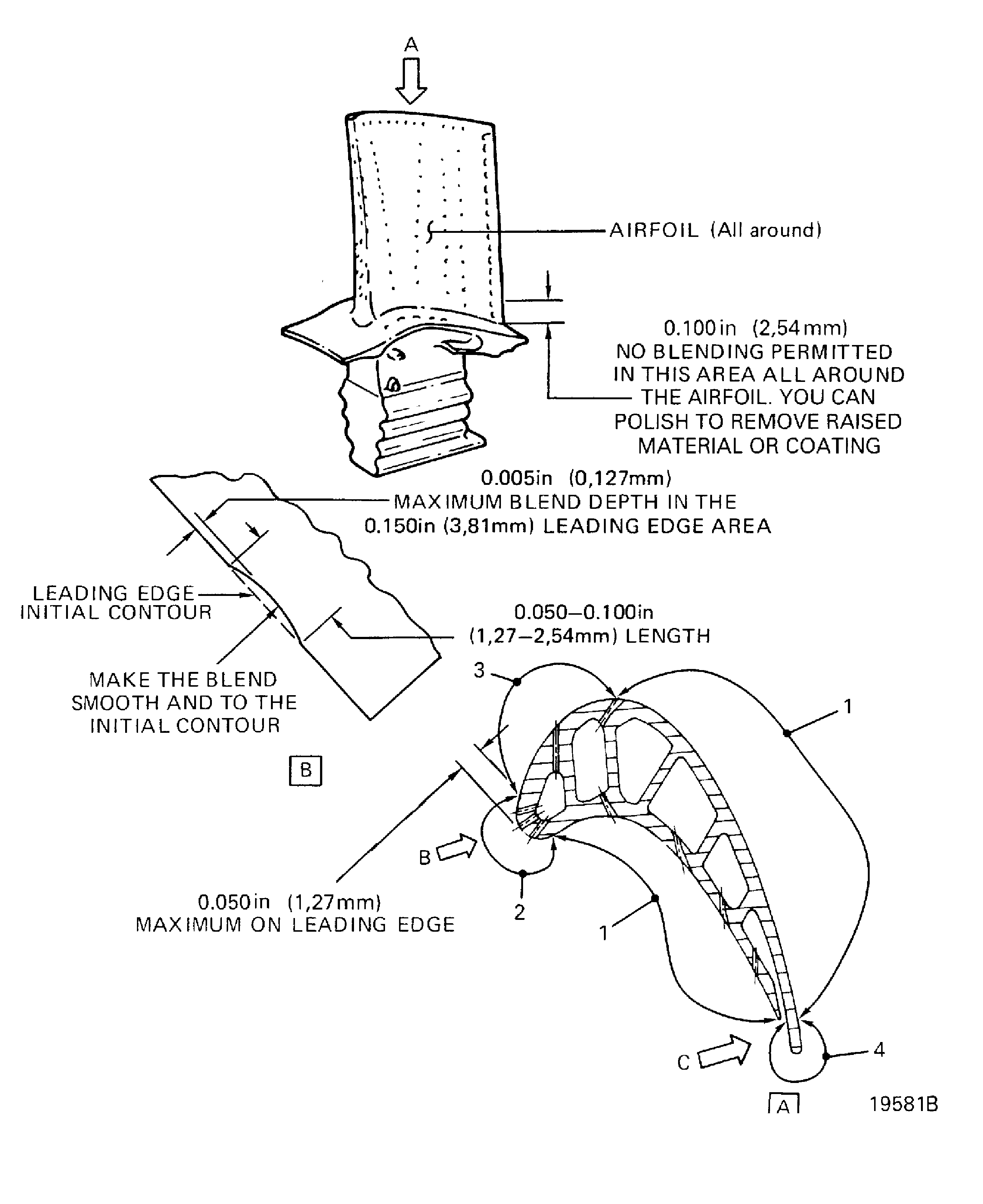

The leading edge maximum blend depth is 0.005 in. (0.13 mm) at Location 2.

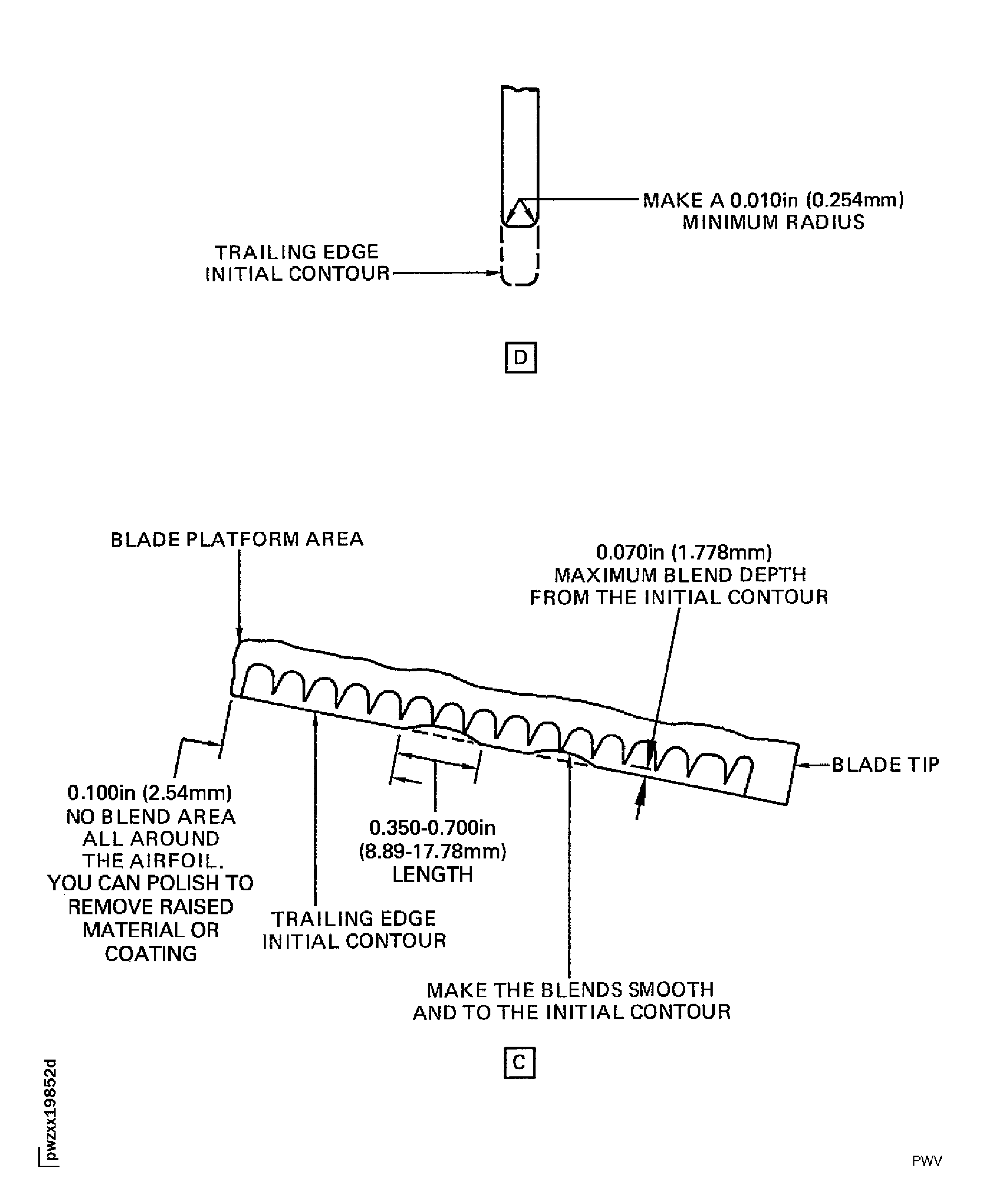

The trailing edge maximum blend depth is 0.070 in. (1.78 mm) at Location 4.

The maximum blend depth of the front airfoil convex surface at Location 3 is 0.010 in. (0.254 mm).

The maximum airfoil blend depth is 0.005 in. (0.13 mm) on the concave and rear convex surfaces at Location 1.

Do not blend the airfoil in less than 0.100 in. (2.54 mm) from the blade platform.

Do not blend in the airfoil radius.

You can remove raised material or coating by polishing in the areas where you are not permitted to blend by SPM TASK 70-35-21-350-501.

Blend the dents, nicks and damaged coating on the airfoil.

SUBTASK 72-45-14-350-051 Blend or Polish the Dents and Nicks on the Airfoil (Not Applicable To PN 2A9321, Or 2A9721)

Refer to Figure.

Refer to SPM TASK 70-35-21-350-501.

All blends must be smooth-bottomed and made in the shape of the initial contour.

The minimum blend length to depth is 10 to 1.

The maximum blend depth is 0.005 in. (0.13 mm) at Location 1.

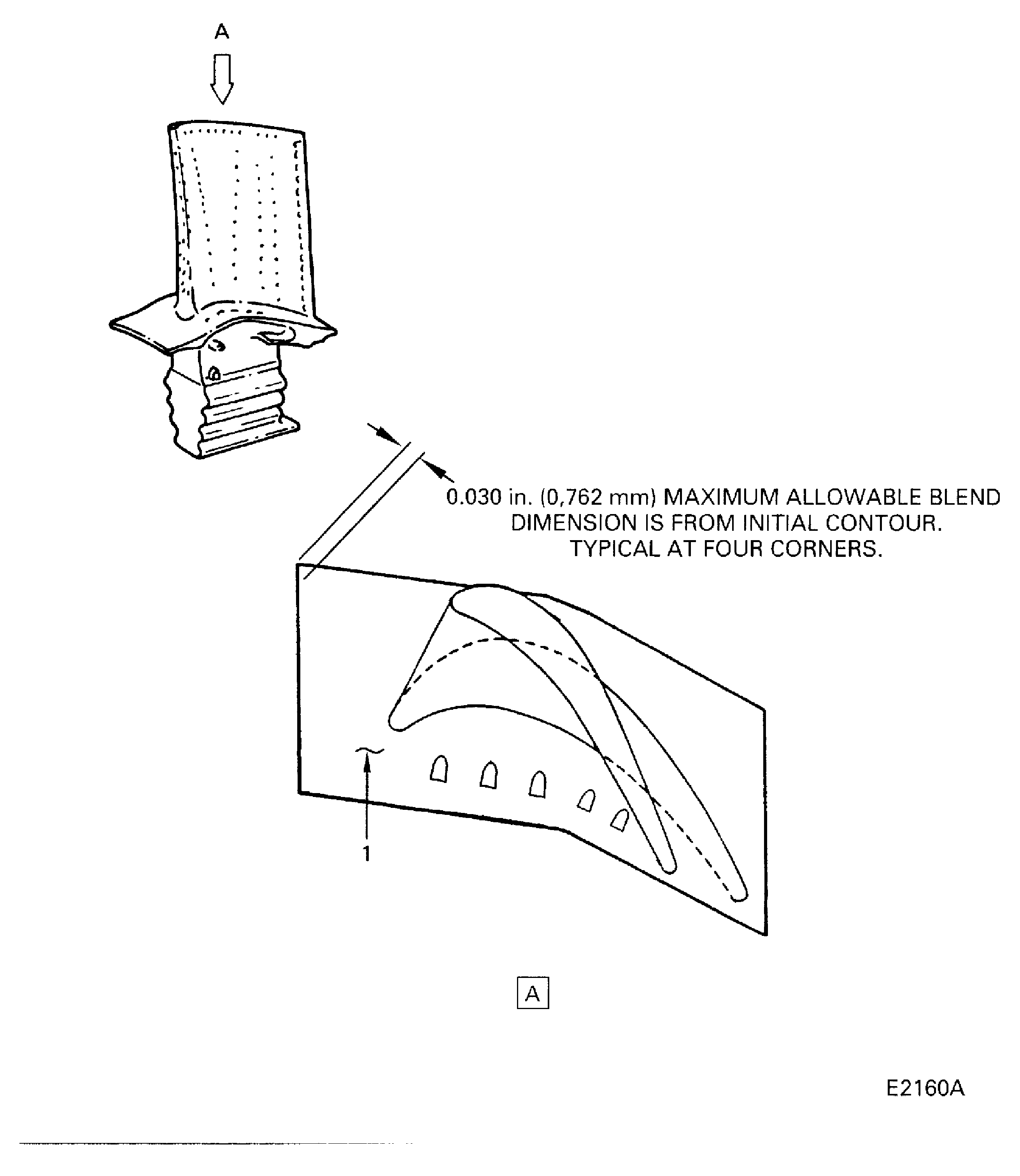

You can blend the platform corners a maximum of 0.030 in. (0.76 mm) from the initial contour.

Do not blend in the airfoil radius.

You can remove raised material or coating by polishing in the areas where you are not permitted to blend by SPM TASK 70-35-21-350-501.

Blend the dents, nicks and damaged coating on the platform.

SUBTASK 72-45-14-350-062 Blend or Polish the Dents and Nicks on the Platform (Not Applicable To PN 2A9321, Or 2A9721)

Refer to Figure.

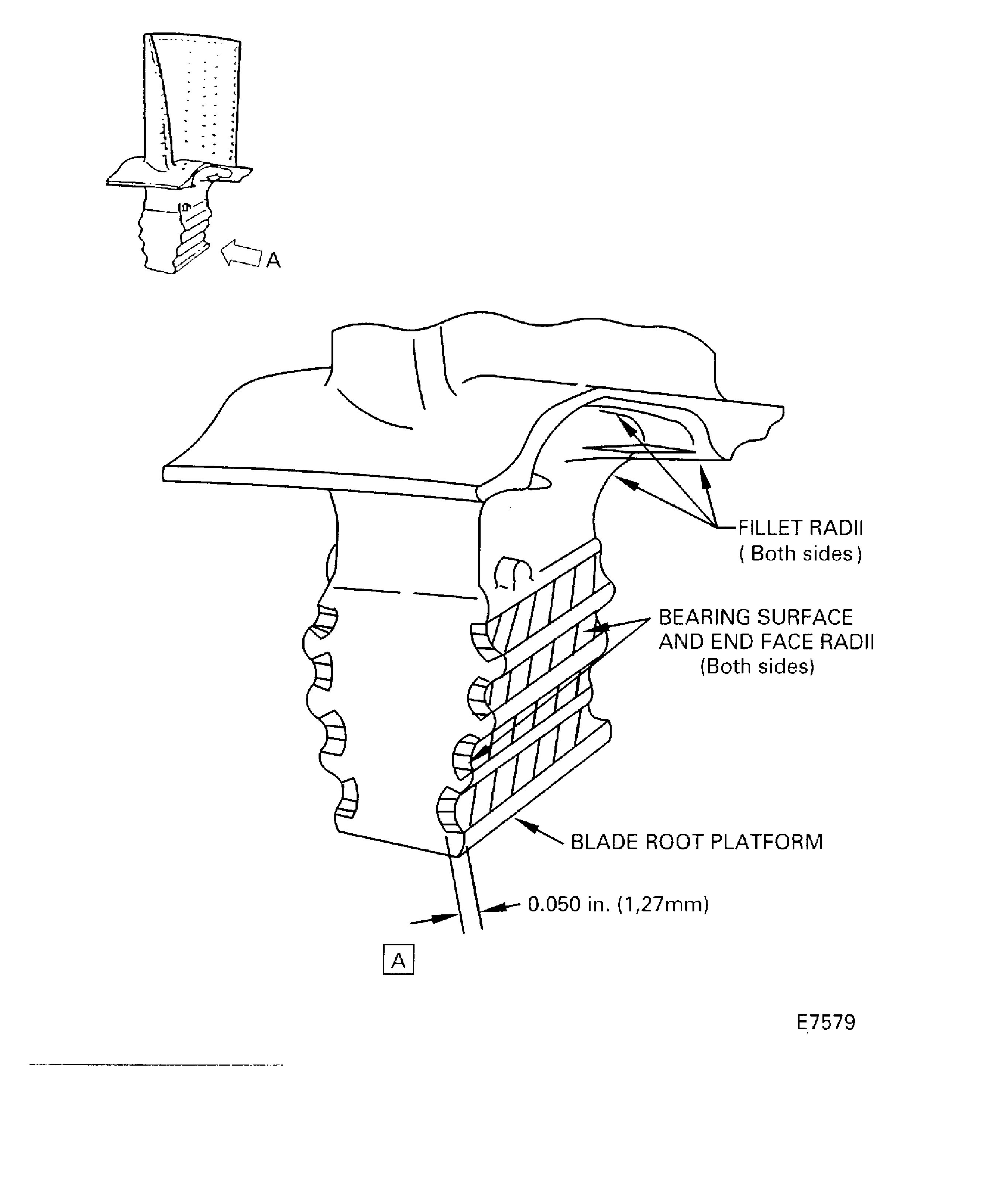

SUBTASK 72-45-14-350-063 Blend the Dents and Nicks on the Root

Refer to Figure.

Examine the airfoil and platform.

SUBTASK 72-45-14-220-061 Examine the Airfoils and Platform

Refer to TASK 72-45-14-200-001-B00 (INSPECTION-001, CONFIG-002).

Examine the blade wall thickness only when the coating is removed and you can see erosion or if you remove all the coating locally when you blend the airfoil. It is necessary to examine the wall thickness only at the locations you blended.

SUBTASK 72-45-14-220-062-B00 Examine the Blade Wall Thickness (PN 2A8901, 2A9001, 2A9101 and 2A9201)

Refer to TASK 72-45-14-200-001-D00 (INSPECTION-001, CONFIG-004).

Examine the blade wall thickness only when the coating is removed and you can see erosion or if you remove all the coating locally when you blend the airfoil. It is necessary to examine the wall thickness only at the locations you blended.

SUBTASK 72-45-14-220-062-D00 Examine the Blade Wall Thickness (PN 2A9721)

Make a permanent mark by SPM TASK 70-09-00-400-501.

Make a mark VRS3202 adjacent to the part number if necessary.

SUBTASK 72-45-14-220-063 Identify the Repair

Do the procedure given in Repair, VRS3042 TASK 72-45-14-300-009 (REPAIR-009).

Coat the airfoil.

SUBTASK 72-45-14-340-051-B00 Coat the Airfoil (PNs 2A8901, 2A9001, 2A9101 and 2A9201)

Figure: Repair Details and Dimensions

Sheet 1

Figure: Repair Details and Dimensions

Sheet 2

Figure: Repair Details and Dimensions

Sheet 3

Figure: Repair Details and Dimensions

Sheet 4