Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-45-21-300-014 HPT Case - Replace The Helicoil Inserts In The BSI Bosses, Repair-014 (VRS1987)

Effectivity

FIG/ITEM PART NO. | |

|---|---|

01-010 | 2A0250 |

01-010 | 2A0250SL87VA156 |

01-010 | 2A1591 |

01-010 | 2A1591SL87VA156 |

01-010 | 2A1600 |

01-010 | 2A1600SL114902 |

General

Price and availability - None

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

For the method to clean the parts, refer to CLEANING-000 TASK 72-45-21-100-000.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Installation tool | LOCAL | 7552-4 | Emhart Teknologies Products | |

| Tang removal tool | LOCAL | 3695-4 | Emhart Teknologies Products | |

| Removal tool | LOCAL | 1227-6 | Emhart Teknologies Products | |

| 10X magnifying glass | LOCAL | 10X magnifying glass |

Consumables, Materials and Expendables

NONESpares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Helicoil insert | LOCAL | 1191-4TN250 | AR | FIG/ITEM 01-090 |

Safety Requirements

NONEProcedure

Refer to Figure.

Use Removal tool.

Remove the damaged or loose inserts

SUBTASK 72-45-21-350-087 Remove the Damaged or Loose Inserts

Refer to Figure.

Use Installation tool.

Put the 1191-4TN250 into the tip of the insertion tool.

Put the insert into the threaded hole.

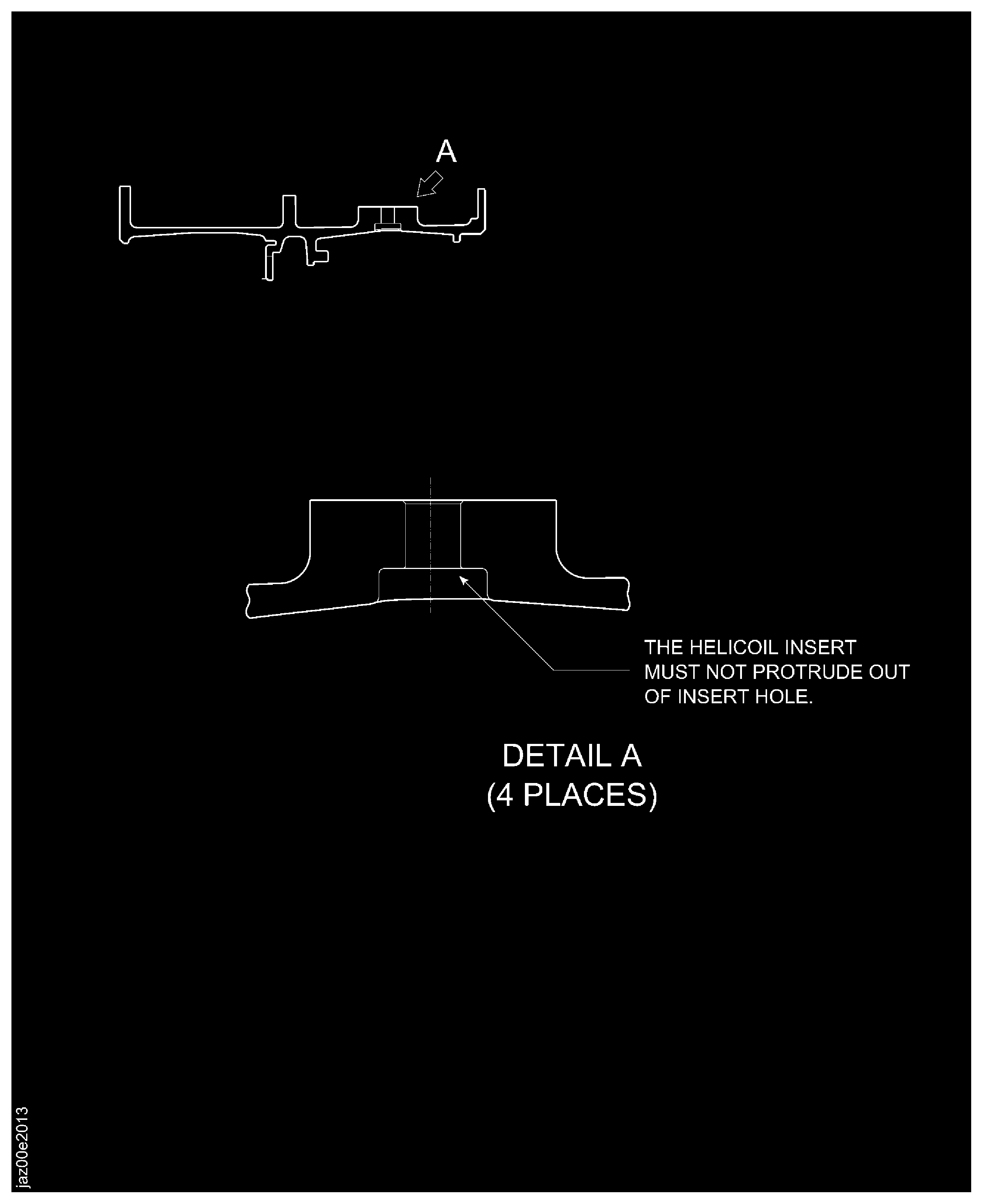

Turn the handle clockwise so the top of the insert is three-quarters to one and a half pitch below the face of the boss.

Use Tang removal tool.

Break the tang of the insert at the notch.

SUBTASK 72-45-21-350-088 Install the New Helicoil Inserts

Torque the bolt to between 65 and 85 lbfin (7.3 and 9.6 Nm).

Refer to SPM TASK 70-35-08-300-501.

Torque check the installed helicoil insert.

The insert must not protrude out of insert hole.

The insert must not move.

Examine the helicoil insert position.

SUBTASK 72-45-21-220-088 Do A Torque Check

Refer to Figure.

Use a 10X magnifying glass.

No damage is permitted.

No cracks are permitted.

Visually examine the repaired area.

SUBTASK 72-45-21-220-089 Examine the Repaired Area

Use vibro-engraving equipment.

Refer to SPM TASK 70-09-00-400-501, (SUBTASK 70-09-00-400-001).

Vibro engrave VRS1987 near to the part number.

SUBTASK 72-45-21-350-089 Vibro Engrave VRS1987

Figure: Repair Details and Dimensions

Repair Details and Dimensions