Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-45-22-840-001 HPT Stage 1 Duct Support Segment - Provide A Turbine Case And Vane Assembly That Will Allow Individual Segment Replacement, Rework-001 - SBE 72-0092

General

The practices and procedures referred to in the procedure by the TASK number are in the SPM.

Refer to the indicated Service Bulletin for specific application requirements.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 3P16273 Grind fixture | 0AM53 | IAE 3P16273 | 1 |

Consumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

NUMBER BEFORE: 2A0178.

NEW NUMBER: 2A1313.

Refer to Figure requirements.

Do the procedure given in the SPM TASK 70-09-00-400-501 and use the vibration peen method.

If the duct segment is in the limit, mark the new part number adjacent to the part number that was there before.

SUBTASK 72-45-22-220-064 Examine the Stage 1 Duct Support Assembly

Refer to Figure requirements.

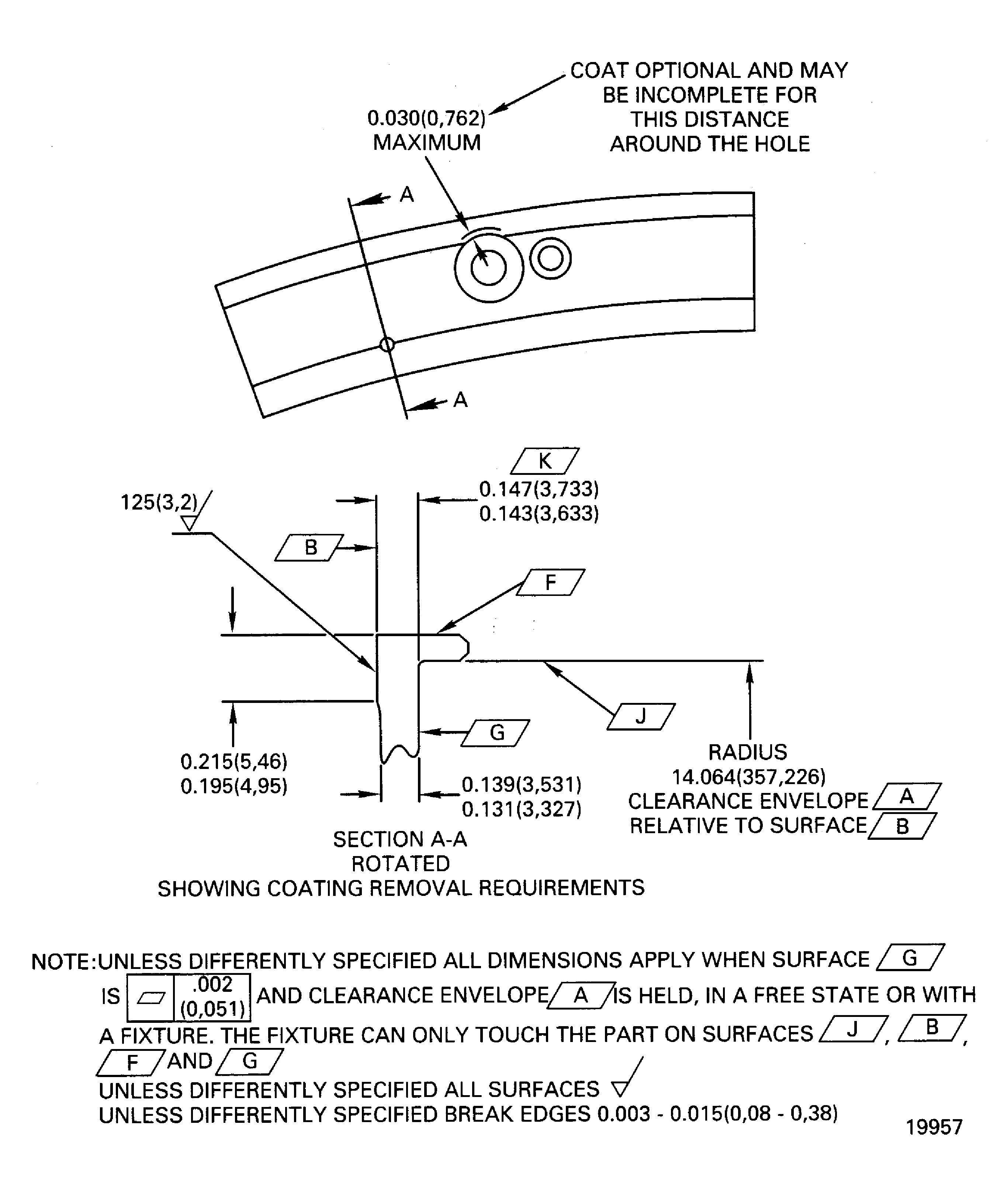

Use the IAE 3P16273 Grind fixture 1 off.

Remove the minimum amount of material and keep the maximum material thickness.

Set-up and machine Surface B to get Dimension K.

SUBTASK 72-45-22-320-054 Machine the Duct Segment

Refer to Figure requirements.

Do the procedure given in the SPM TASK 70-34-03-340-501.

No coating is permitted in the holes.

Coat the duct segment to get a 0.002 to 0.008in. (0.051 to 0.203 mm) thickness after the finish machining.

SUBTASK 72-45-22-340-053 Coat the Duct Segment

NUMBER BEFORE: 2A0178.

NEW NUMBER: 2A1313.

Refer to Figure requirements.

Do the procedure given in the SPM TASK 70-09-00-400-501 and use the vibration peen method.

Mark the new part number adjacent to the part number that was there before.

SUBTASK 72-45-22-350-059 Identify the Duct Segment

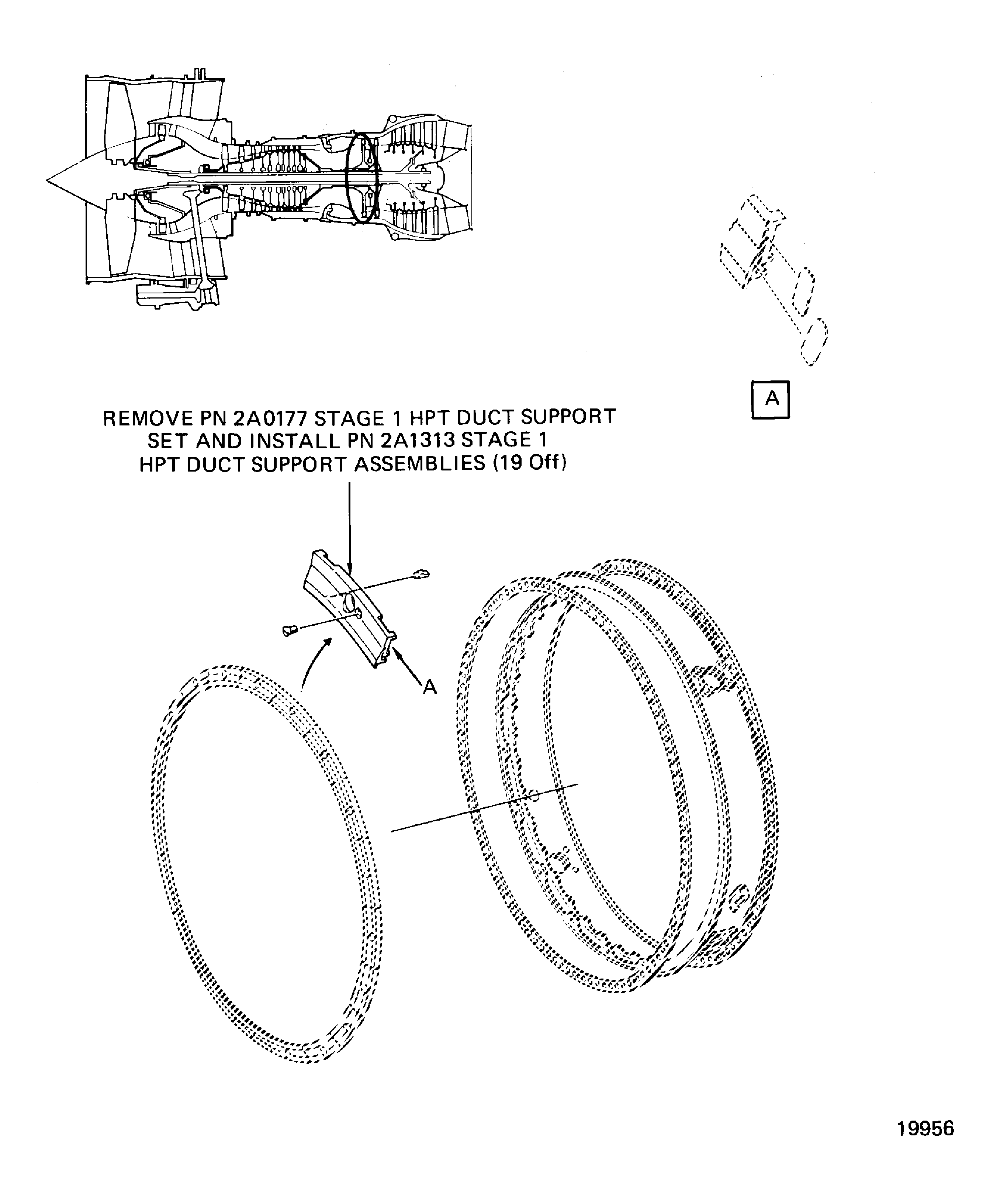

Do the procedure given in TASK 72-45-20-440-001.

Install the 2A1313 stage 1 HPC duct support assemblies (19 off) in the turbine case and vane assembly.

SUBTASK 72-45-22-440-051 Assemble the Turbine Case and Vane Assembly

NUMBER BEFORE: 2A1357.

NEW NUMBER: 2A1764.

Refer to Figure requirements.

Do the procedure given in the SPM TASK 70-09-00-400-501 and use the vibration peen method.

Mark the new part number adjacent to the part number that was there before.

SUBTASK 72-45-22-350-060 Identify the New Turbine Case and Vane Assembly

Figure: Location of the stage 1 HPT duct support assembly

Location of the stage 1 HPT duct support assembly

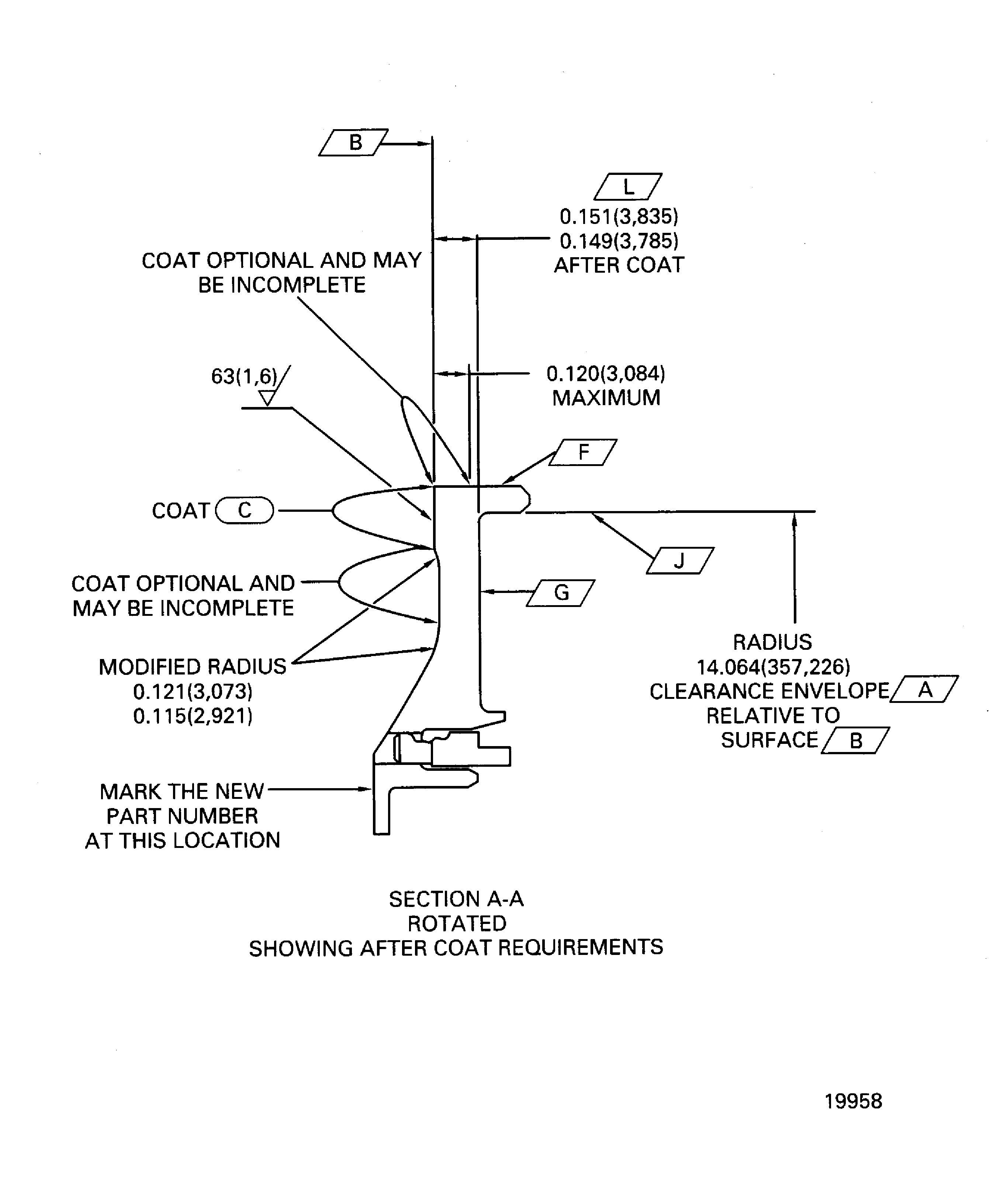

Figure: Modification of the stage 1 duct support assembly

Modification of the stage 1 duct support assembly

Figure: Modification of the stage 1 duct support assembly

Modification of the stage 1 duct support assembly