Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-45-24-300-028 HPT Stage 2 Ring Segment And Vane Cluster - Weld Repair Cracks Adjacent To The Borescope Hole, Repair-028 (VRS3708)

Effectivity

FIG/ITEM | PART NO. |

|---|---|

02-260 | 2A4562 |

02-420 | 2A2152 |

02-420 | 2A2152-001 |

02-420 | 2A2152-002 |

02-420 | 2A3282 |

02-420 | 2A3282-001 |

02-420 | 2A3302 |

02-420 | 2A3302-001 |

02-420 | 2A3452 |

02-420 | 2A3452-001 |

02-420 | 2A3842 |

02-420 | 2A3842-001 |

02-420 | 2A4082 |

02-420 | 2A4282 |

General

Price and availability - Refer to IAE

The practices and processes referred to in the procedure by the TASK number are in the SPM.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| File | LOCAL | File | ||

| Various stones | LOCAL | Various stones | ||

| Hand grinder | LOCAL | Hand grinder | ||

| Welding equipment | LOCAL | Welding equipment | ||

| Oven | LOCAL | Oven | ||

| Standard induction heater | LOCAL | Standard induction heater |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-197 WELDING FILLER WIRE | LOCAL | CoMat 03-197 | ||

| CoMat 03-287 WELDING FILLER WIRE | LOCAL | CoMat 03-287 |

Spares

NONESafety Requirements

NONEProcedure

Refer to SPM TASK 70-23-05-230-501 (high sensitivity).

Do a local fluorescent penetrant inspection for cracks.

SUBTASK 72-45-24-230-066 Determine Location and Length of Cracks

NOTE

This weld repair is for cracks originating at the borescope boss hole surface. Cracks up to 0.050 in. (1.27 mm) may be repaired by this procedure. Cracks greater than 0.050 in. (1.27 mm) must be rejected.Refer to SPM TASK 70-11-03-300-503.

Clean the part.

SUBTASK 72-45-24-110-065 Clean the HP Turbine Stage 2 Vane

Refer to Figure and Figure and the SPM TASK 70-31-13-310-501.

Refer to Step for weld up of through cracks.

Weld up prepared areas. Use manual tungsten inert gas technique.

SUBTASK 72-45-24-310-056 Weld Up Prepared Surfaces

Refer to SPM TASK 70-37-00-370-501 and SPM TASK 70-37-01-370-501.

Heat treat component.

SUBTASK 72-45-24-370-002 Heat Treat Component in an Oven After Weld

Refer to SPM TASK 70-11-03-300-503.

Clean the part.

SUBTASK 72-45-24-110-066 Clean the HP Turbine Stage 2 Vane

Use high sensitivity.

NOTE

No cracks are permitted.

Refer to SPM TASK 70-23-05-230-501.

Do a local fluorescent penetrant inspection for cracks.

SUBTASK 72-45-24-230-067 Examine the Machined Borescope Hole for Cracks

Refer to SPM TASK 70-11-03-300-503.

Clean the part.

SUBTASK 72-45-24-110-067 Clean the HP Turbine Vane

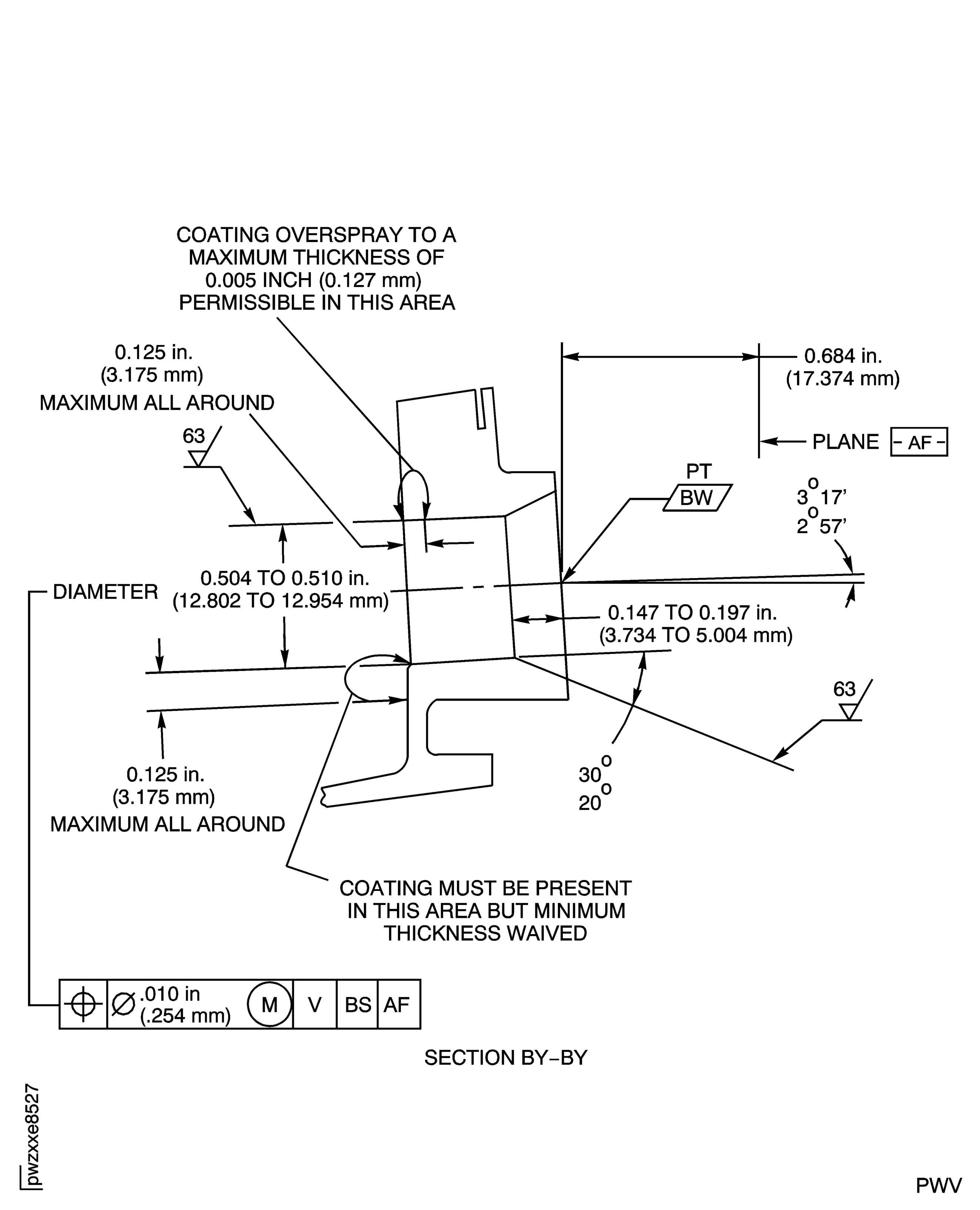

Figure: Repair Details and Dimensions

Sheet 1

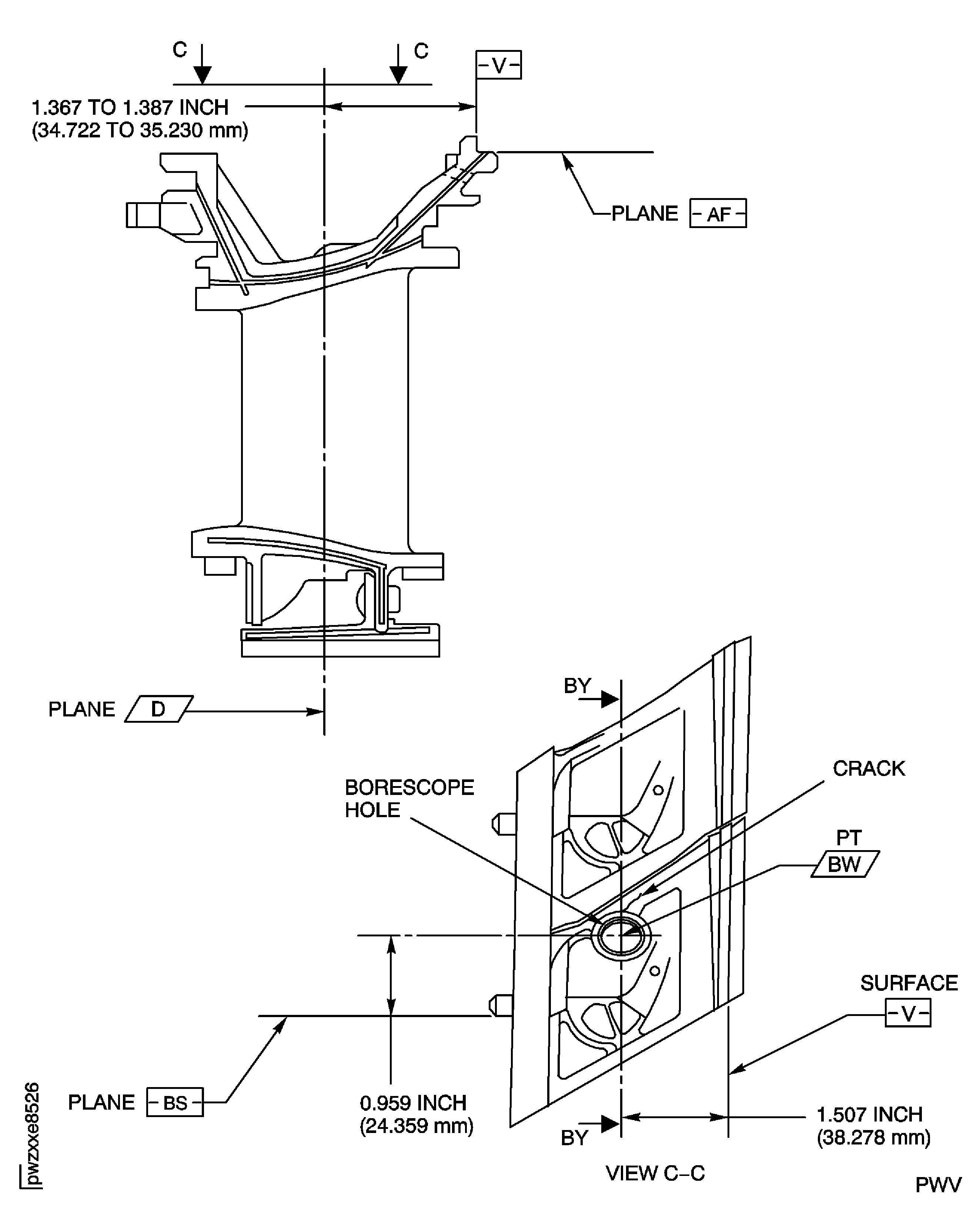

Figure: Repair Details and Dimensions

Sheet 2