Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-45-24-300-018 HPT Stage 2 Ring Segment And Vane Cluster - Replace The Vanes, Repair-018 (VRS3391)

Effectivity

FIG/ITEM | PART NO. |

|---|---|

02-050 | 2A2272 |

02-050 | 2A2272-001 |

02-050 | 2A2272-002 |

02-050 | 2A2272-003 |

02-050 | 2A2272-004 |

02-050 | 2A2272-006 |

02-050 | 2A3372 |

02-050 | 2A3372-001 |

02-050 | 2A3812 |

02-050 | 2A4262 |

02-050 | 2A4462 |

02-050 | 2A5102 |

02-050 | 2A5502 |

02-050 | 2A5602 |

02-050 | 2A6102 |

02-060 | 2A2372 |

02-260 | 2A2372-001 |

02-260 | 2A2372-002 |

02-260 | 2A2372-003 |

02-260 | 2A2372-004 |

02-260 | 2A2372-006 |

02-260 | 2A3472 |

02-260 | 2A3472-001 |

02-260 | 2A3822 |

02-260 | 2A4072 |

02-260 | 2A4162 |

02-260 | 2A4562 |

02-260 | 2A5202 |

Material of component

PART IDENT | SYMBOL | MATERIAL |

|---|---|---|

Stage 2 HPT vane | Cast nickel alloy | |

Stage 2 HPT seals | Nickel alloy |

General

The practices and processes referred to in the procedure by TASK number are in the SPM.

Replace one or two detail vanes with non rivet holes and the ring segment assembly with rivet holes.

Price and availability - none

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Deburr tool | LOCAL | Deburr tool | ||

| Drilling equipment | LOCAL | Drilling equipment | ||

| Nylon strap | LOCAL | Strap, nylon | ||

| Riveting equipment | LOCAL | Riveting equipment | ||

| Shimstock | LOCAL | Shimstock | ||

| Workshop inspection equipment | LOCAL | Workshop inspection equipment | ||

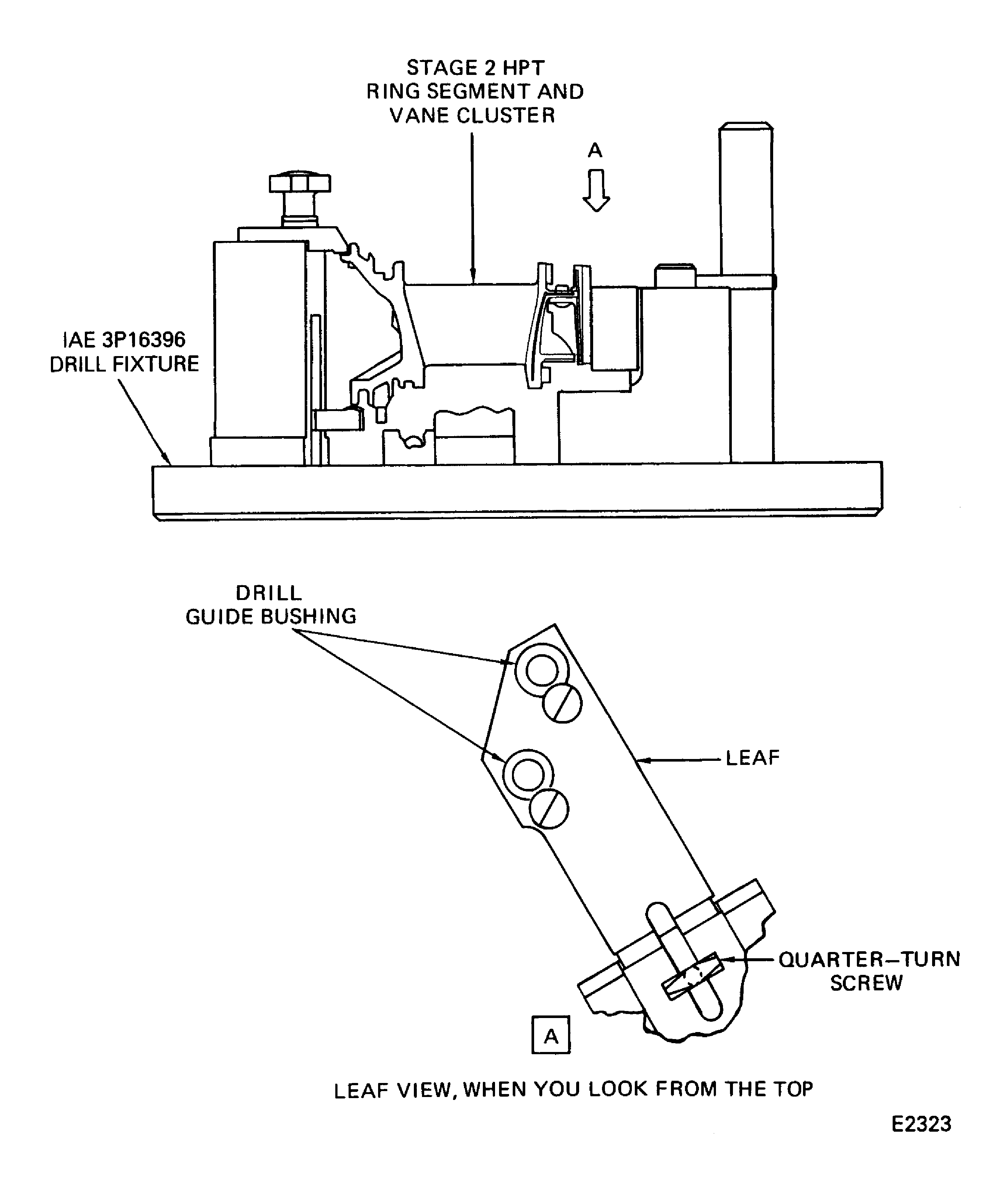

| IAE 3P16396 Drill fixture | 0AM53 | IAE 3P16396 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-009 BEESWAX SUBSTITUTE | 0A341 | CoMat 02-009 | ||

| CoMat 06-110 PENCIL | LOCAL | CoMat 06-110 | ||

| CoMat 06-111 PENCIL | LOCAL | CoMat 06-111 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Rivet, solid universal | ST1219-160 | 2 | ||

| Stage 2 HPT seal | 2A2334 | AR | ||

| Stage 2 HPT seal assembly | 2A2335-01 | AR | ||

| Stage 2 HPT vane | 2A2052 | AR | ||

| Stage 2 HPT vane | 2A2052-001 | AR | ||

| Stage 2 HPT vane | 2A2052-002 | AR | ||

| Stage 2 HPT vane | 2A3352 | AR | ||

| Stage 2 HPT vane | 2A3352-001 | AR | ||

| Stage 2 HPT vane | 2A3402 | AR | ||

| Stage 2 HPT vane | 2A3402-001 | AR | ||

| Stage 2 HPT vane | 2A3572 | AR | ||

| Stage 2 HPT vane | 2A3572-001 | AR | ||

| Stage 2 HPT vane | 2A3832 | AR | ||

| Stage 2 HPT vane | 2A3832-001 | AR | ||

| Stage 2 HPT vane | 2A4182 | AR | ||

| Stage 2 HPT vane | 2A4272 | AR | ||

| Stage 2 HPT vane | 2A2152 | AR | ||

| Stage 2 HPT vane | 2A2152-001 | AR | ||

| Stage 2 HPT vane | 2A2152-002 | AR | ||

| Stage 2 HPT vane | 2A3282 | AR | ||

| Stage 2 HPT vane | 2A3282-001 | AR | ||

| Stage 2 HPT vane | 2A3302 | AR | ||

| Stage 2 HPT vane | 2A3302-001 | AR | ||

| Stage 2 HPT vane | 2A3452 | AR | ||

| Stage 2 HPT vane | 2A3452-001 | AR | ||

| Stage 2 HPT vane | 2A3842 | AR | ||

| Stage 2 HPT vane | 2A3842-001 | AR | ||

| Stage 2 HPT vane | 2A4082 | AR | ||

| Stage 2 HPT vane | 2A4282 | AR |

Safety Requirements

NONEProcedure

Make a mark by the procedure given in SPM TASK 70-09-00-400-501.

Use a CoMat 06-110 PENCIL or CoMat 06-111 PENCIL.

If necessary, mark the detail parts to make sure the same parts are assembled as a set.

Refer to Figure.

CAUTION

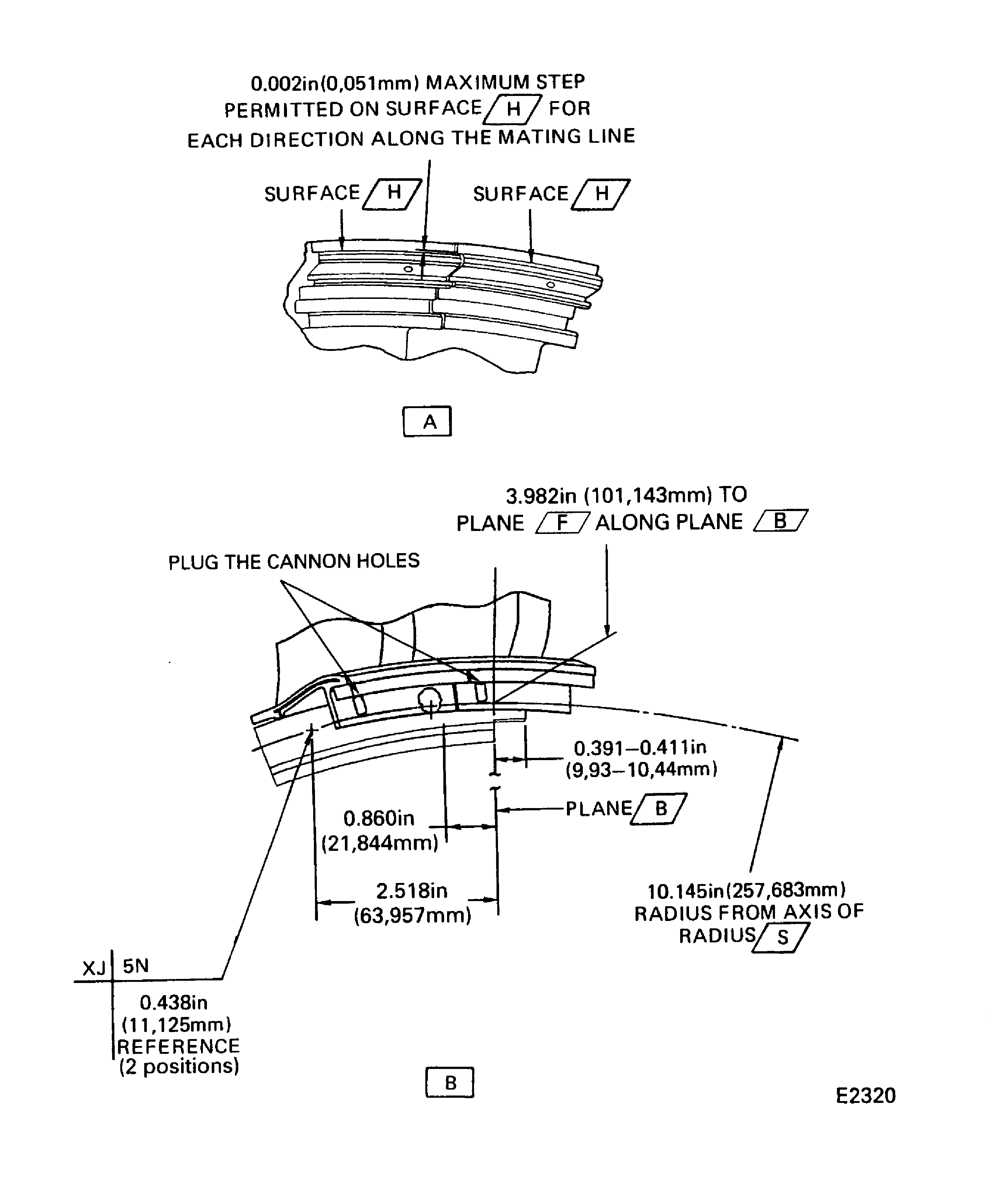

DO NOT USE MASKING TAPE TO COVER THE CANNON HOLES. TAPE RESIDUE CAN CAUSE DAMAGE TO THE PART.Install a locally fabricated plug in the vane inner diameter cannon holes.

Refer to Figure.

Install the vane cluster in the IAE 3P16396 Drill fixture 1 off.

Be careful not to damage the material on the adjacent parts when you drill.

Refer to Figure.

Drill out the two rivets.

Refer to Figure.

Remove the rivets and disassemble the vane cluster.

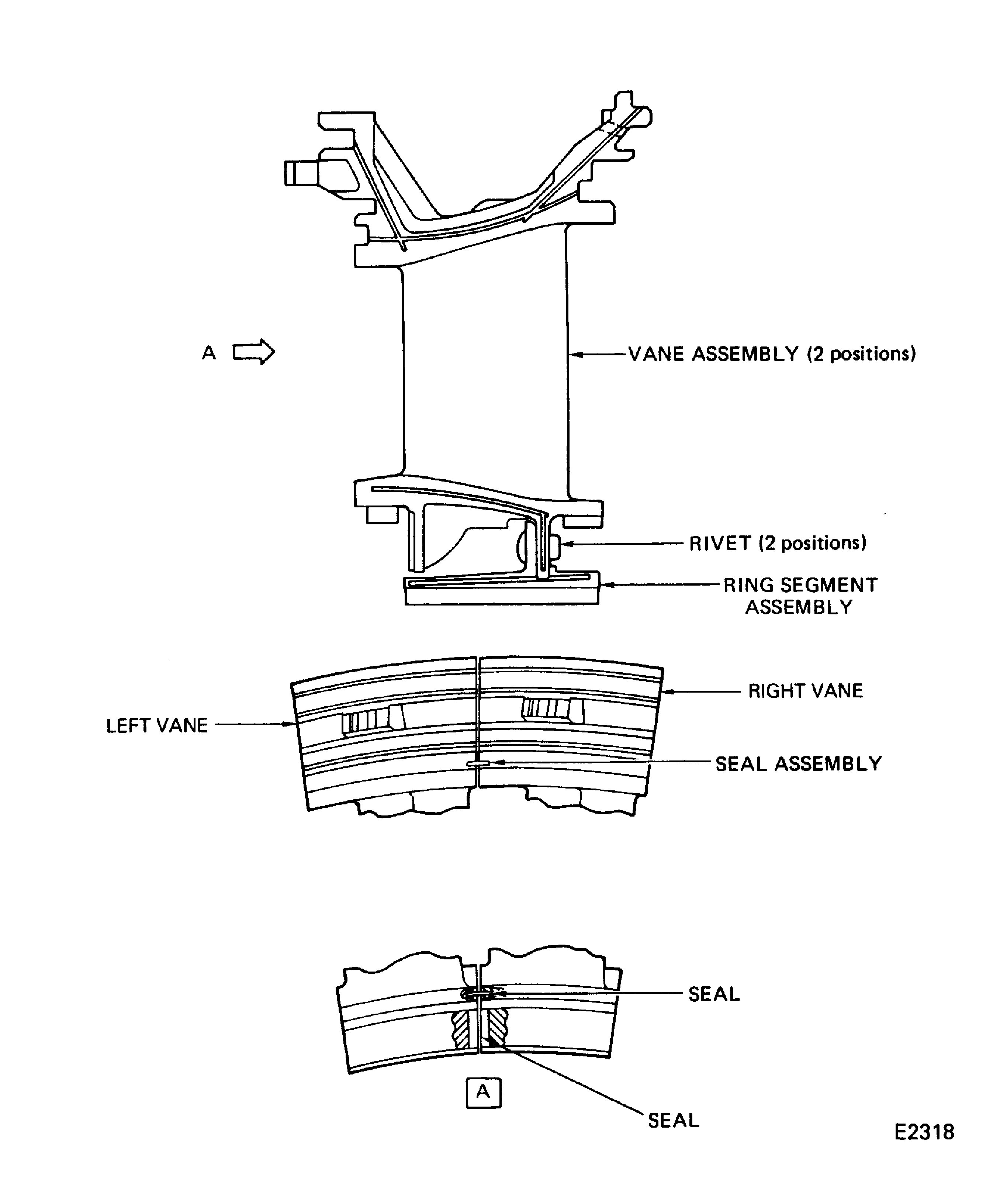

SUBTASK 72-45-24-350-079 Disassemble the Stage 2 HPT Ring Segment and Vane Cluster

Refer to TASK 72-45-24-200-000 (INSPECTION-000).

Examine the ring segment and one detail vane assembly rivet holes.

SUBTASK 72-45-24-220-120 Examine the Ring Segment Assembly and One Detail Vane Assembly Rivet Holes

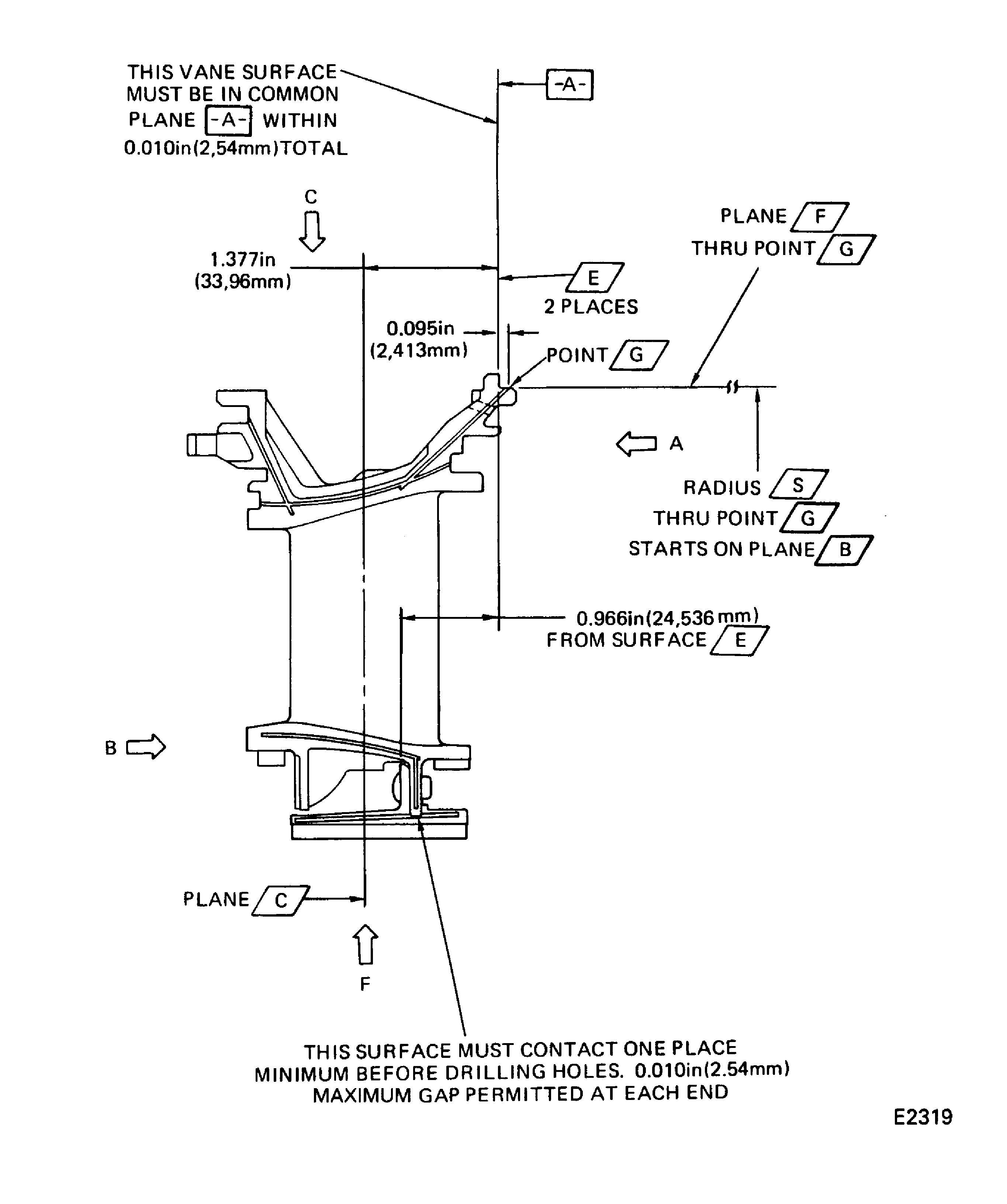

Install the ring segment assembly and two vane assemblies in the IAE 3P16396 Drill fixture 1 off.

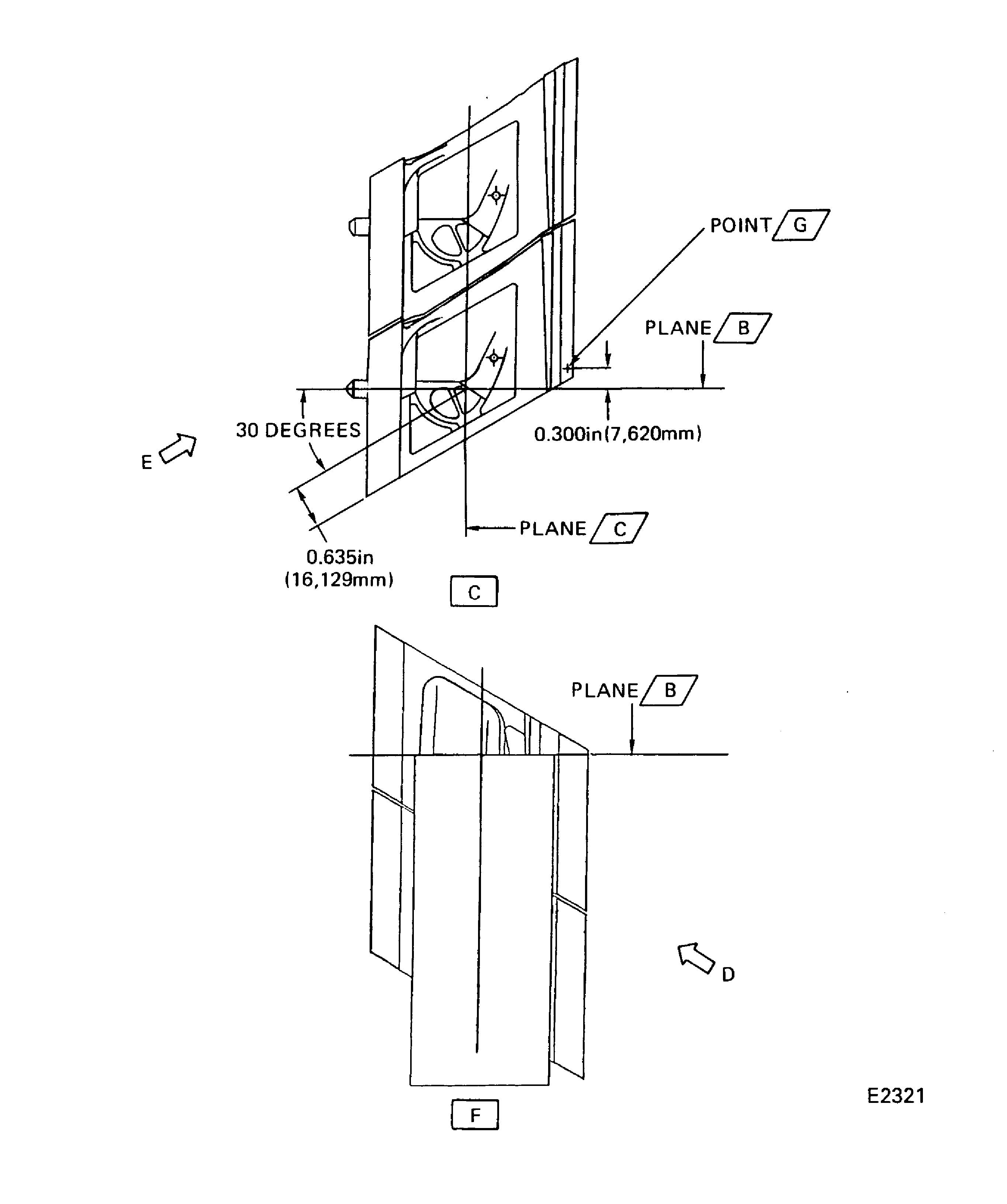

Refer to Figure.

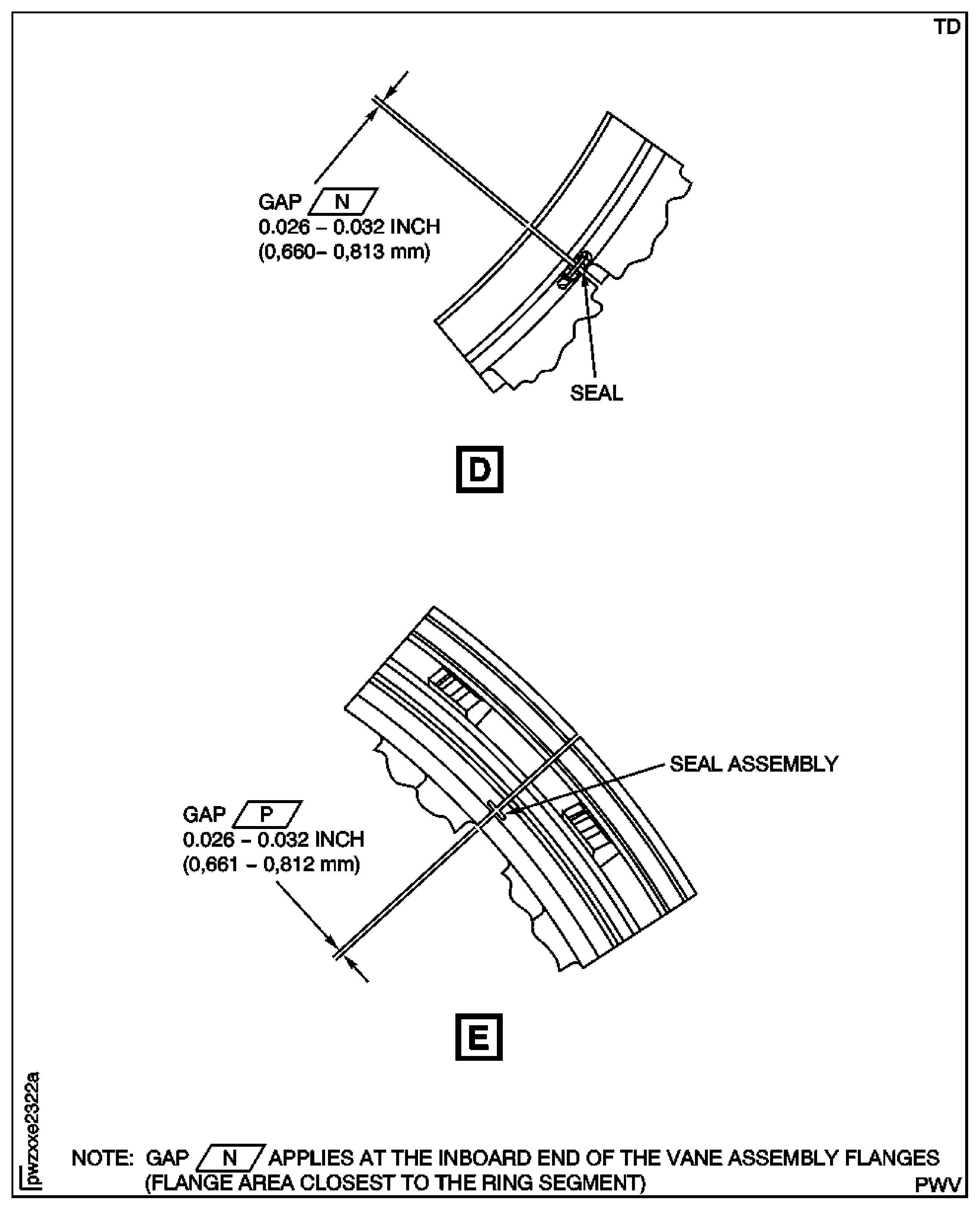

Install shims in Gaps N and P. Use the correct shimstock thickness.

Refer to Figure.

Tighten the vane cluster in the drill fixture.

SUBTASK 72-45-24-350-080-001 Assemble the Vane Cluster Detail Parts for Drilling the Rivets Holes (When You Replace Two Detail Vanes)

NOTE

When two detail vanes are replaced with new or repaired vanes with no rivet holes, the ring segment rivet holes must be welded. Refer to Repair, VRS3221 TASK 72-45-24-300-007 (REPAIR-007).Install the ring segment assembly and two vane assemblies in the IAE 3P16396 Drill fixture 1 off.

Refer to Figure.

Put a rivet in the vane rivet hole and ring segment to align the vane assembly that is not to be drilled. Do not set the rivet.

Refer to Figure.

Install shims in Gaps N and P. Use the correct shimstock thickness.

Refer to Figure.

Tighten the vane cluster in the drill fixture.

SUBTASK 72-45-24-350-080-002 Assemble the Vane Cluster Detail Parts for Drilling the Rivet Holes (When You Replace One Detail Vane)

NOTE

When one detail vane assembly is replaced with a new or repaired vane with no rivet holes and ring segment rivet hole corresponding to the vane to be replaced must be welded. Refer to Repair, VRS3221 TASK 72-45-24-300-007 (Repair-007).Install the ring segment assembly and two vane assemblies in the IAE 3P16396 Drill fixture 1 off.

Refer to Figure.

Put a rivet in the vane rivet hole and ring segment to align the vane assembly that is not to be drilled. Do not set the rivet.

Refer to Figure.

Install shims in Gaps N and P. Use the correct shimstock thickness.

Refer to Figure.

Tighten the vane cluster in the drill fixture.

Turn the detail drill fixture quarter-turn screw 90 degrees and position the detail leaf and drill guide bushings up.

Do not use the drill guide bushings to drill the holes.

Use the old vane assembly rivet hole as a transfer guide.

The rivet hole diameter is between 0.159 in. and 0.163 in. (4.039 mm and 4.140 mm).

Transfer drill the ring segment rivet hole.

SUBTASK 72-45-24-350-081 Assemble the Vane Cluster Detail Parts for Drilling the Rivet Holes (When You Replace One Detail Vane With a Vane that has an Existing Hole

NOTE

When on detail vane assembly is replaced with a repaired vane with rivet hole, the ring segment rivet hole of the vane to be replaced must be welded. Use the old rivet hole to locate the new rivet hole. Refer to Repair, VRS3221 TASK 72-45-24-300-007 (REPAIR-007).Refer to SPM TASK 70-39-03-390-501.

Remove the burr and chips.

Deburr the vane assemblies rivet holes.

SUBTASK 72-45-24-350-082 Deburr the Rivet Holes

Refer to Figure.

Assemble the ring segment assembly to the right vane assembly inner diameter.

Refer to Figure.

Install the two rivets.

Use the cold set rivet method.

Refer to SPM TASK 70-39-03-390-501.

Refer to Figure.

Rivet the ring segment assembly to the right vane.

Refer to Figure.

Assemble the left vane to the right vane and seal assembly.

Use CoMat 02-009 BEESWAX SUBSTITUTE to hold the seals in the vane seal grooves.

Use the old seals if they are not bent, burned, cracked or worn.

Install the seals in the seal grooves between the two vane assemblies.

Refer to Figure.

CAUTION

DO NOT USE MASKING TAPE OR WIRE TO HOLD THE VANE CLUSTER ASSEMBLY TOGETHER FOR ASSEMBLY. WIRE OR TAPE RESIDUE CAN CAUSE DAMAGE TO THE AIRFOIL.Hold the vane cluster together with a nylon strap or equivalent.

Refer to Figure.

Install the second rivet.

Refer to Figure.

Examine Gaps N and P and Surface H.

Use the cold set rivet method.

Refer to SPM TASK 70-39-03-390-501.

Refer to Figure.

Rivet the ring assembly to the left vane assembly.

SUBTASK 72-45-24-350-083 Assemble and Rivet the Vane Cluster

NOTE

It is not easy to get access to the rivets because of the ID forward flange of the vane. Thus, rivet the right vane first, then assembly and rivet the left vane. Refer to Figure.Use the procedure given in the SPM TASK 70-39-03-390-501.

Refer to Figure.

Inspect the installed rivets.

SUBTASK 72-45-24-220-121 Install the Rivets

Refer to Figure.

Remove the two plugs from the vane cannon holes.

SUBTASK 72-45-24-350-084 Remove the Plugs

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Sheet 1

Figure: Repair Details and Dimensions

Sheet 2

Figure: Repair Details and Dimensions

Sheet 3

Figure: Repair Details and Dimensions

Sheet 4

Figure: Repair Details and Dimensions IAE 3P16396

Repair Details and Dimensions IAE 3P16396