Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-45-27-300-005 HPT Stage 2 Support - Plasma Spray The Front Outer Diameter, Repair-005 (VRS3227)

General

The practices and processes referred to in the procedure by TASK number are in the SPM.

Price and availability - none

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Abrasive Blast Equipment | LOCAL | Abrasive Blast Equipment | ||

| Grinding equipment | LOCAL | Grinding equipment | ||

| Machining equipment | LOCAL | Machining equipment | ||

| Plasma spray equipment | LOCAL | Plasma spray equipment | ||

| Workshop inspection equipment | LOCAL | Workshop inspection equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-080 METAL SPRAYING POWDER,Co BASE ALLOY | IE426 | CoMat 03-080 | ||

| CoMat 03-089 METAL SPRAYING POWDER Ni/Al (95/5) | 33870 | CoMat 03-089 | ||

| CoMat 03-090 METAL SPRAYING POWDER Ni/Al (95/5) | X111X | CoMat 03-090 |

Spares

NONESafety Requirements

CAUTION

Procedure

Refer to Repair, VRS3228 TASK 72-45-27-300-007 (REPAIR-007).

If you must do Repair-005 (VRS3227) and Repair-006 (VRS3229) at the same time, remove the shoulder pins.

SUBTASK 72-45-27-350-058 Remove all the Shoulder Pins

Refer to TASK 70-11-03-300-503.

Clean the part.

If you removed the damage and coating by grind operation, do a fluorescent penetrant inspection of the part.

Refer to Figure. Make sure you removed all the coating.

NOTE

If the measured axial dimensions in a free condition are not satisfactory, a held condition is permitted. All dimensions apply when Surface E is flat by 0.002 in. (0.05 mm) and Diameter N maintain a clearance envelope of 28.542 in. (724.97 mm) in a free or held condition. In a held condition, hold the air seal only on Surfaces E and F and Diameter N. In a free condition Surface E is flat by 0.010 in. (0.254 mm) and Diameter D is 28.550 to 28.626 in. (725.17 to 727.10 mm) in diameter.

Do a dimensional inspection of the repair area.

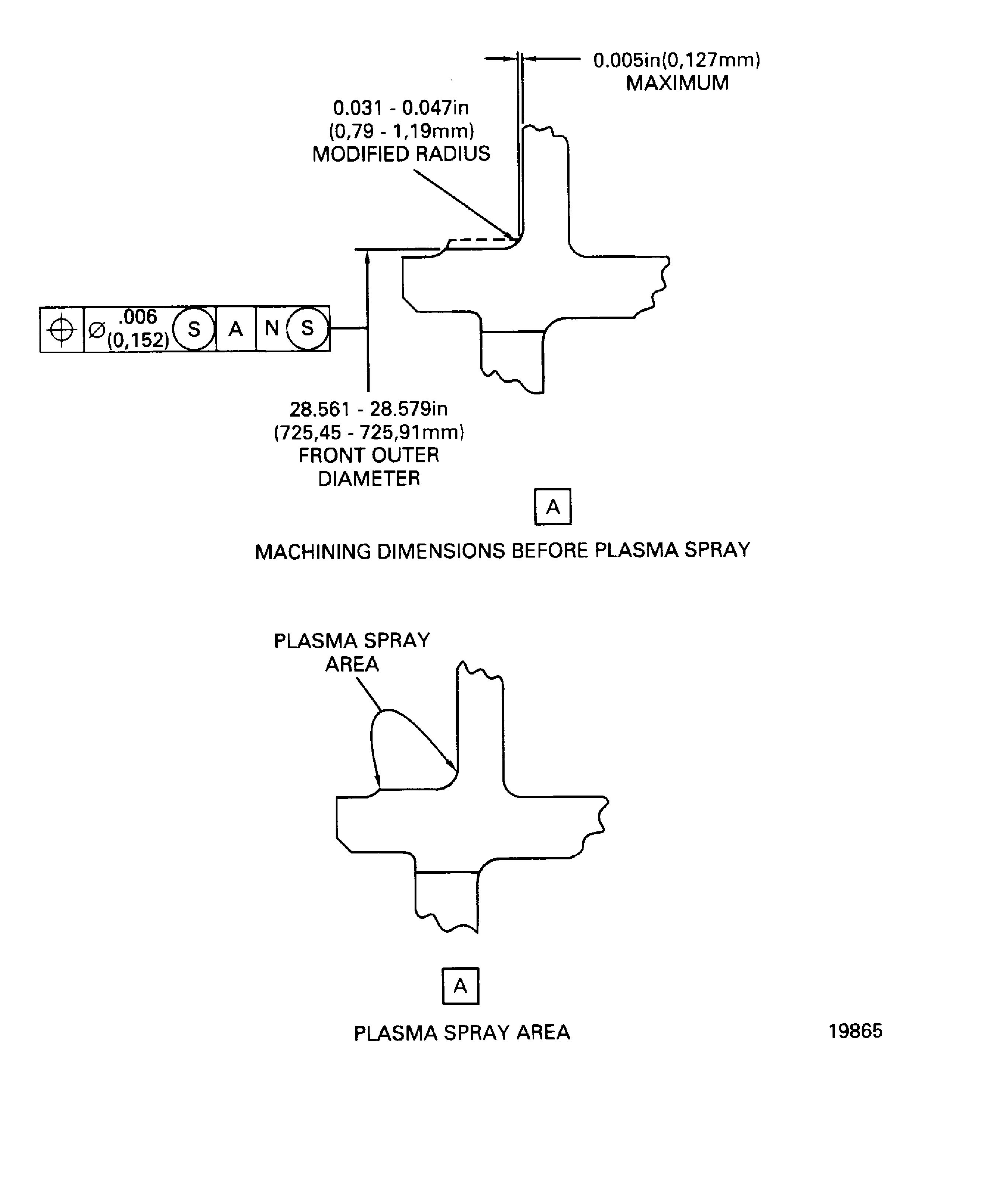

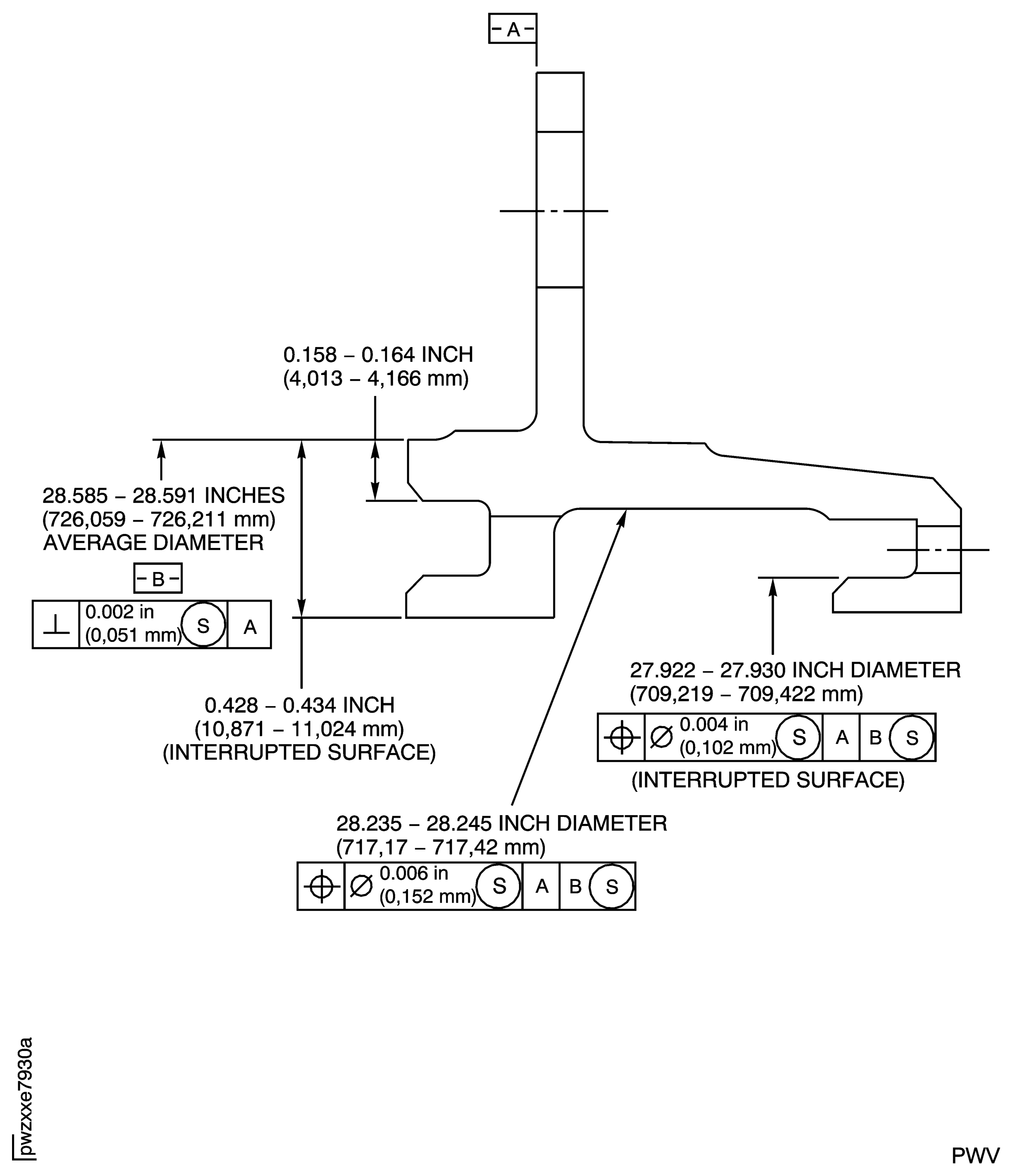

SUBTASK 72-45-27-320-051 Machine the Front Outer Diameter before Plasma Spray

Refer to Figure.

Apply the plasma spray to a sufficient thickness which will permit the final machining of the dimensions given in the figure.

No overpsray is permitted.

Do the procedure given in the SPM TASK 70-34-00-340-501.

Plasma spray the front outer diameter.

SUBTASK 72-45-27-340-051 Plasma Spray the Front Outer Diameter

Refer to Figure.

NOTE

If the measured axial dimensions in a free condition are not satisfactory, a held condition is permitted. All dimensions apply when Surface E is flat by 0.002 in. (0.05 mm) and Diameter N maintain a clearance envelope of 28.542 in. (724.97 mm) in a free or held condition. In a held condition, hold the air seal only on Surfaces E and F and Diameter N. In a free condition Surface E is flat by 0.010 in. (0.25 mm) and Diameter D is 28.550 to 28.626 in. (725.17 to 727.10 mm) in diameter.

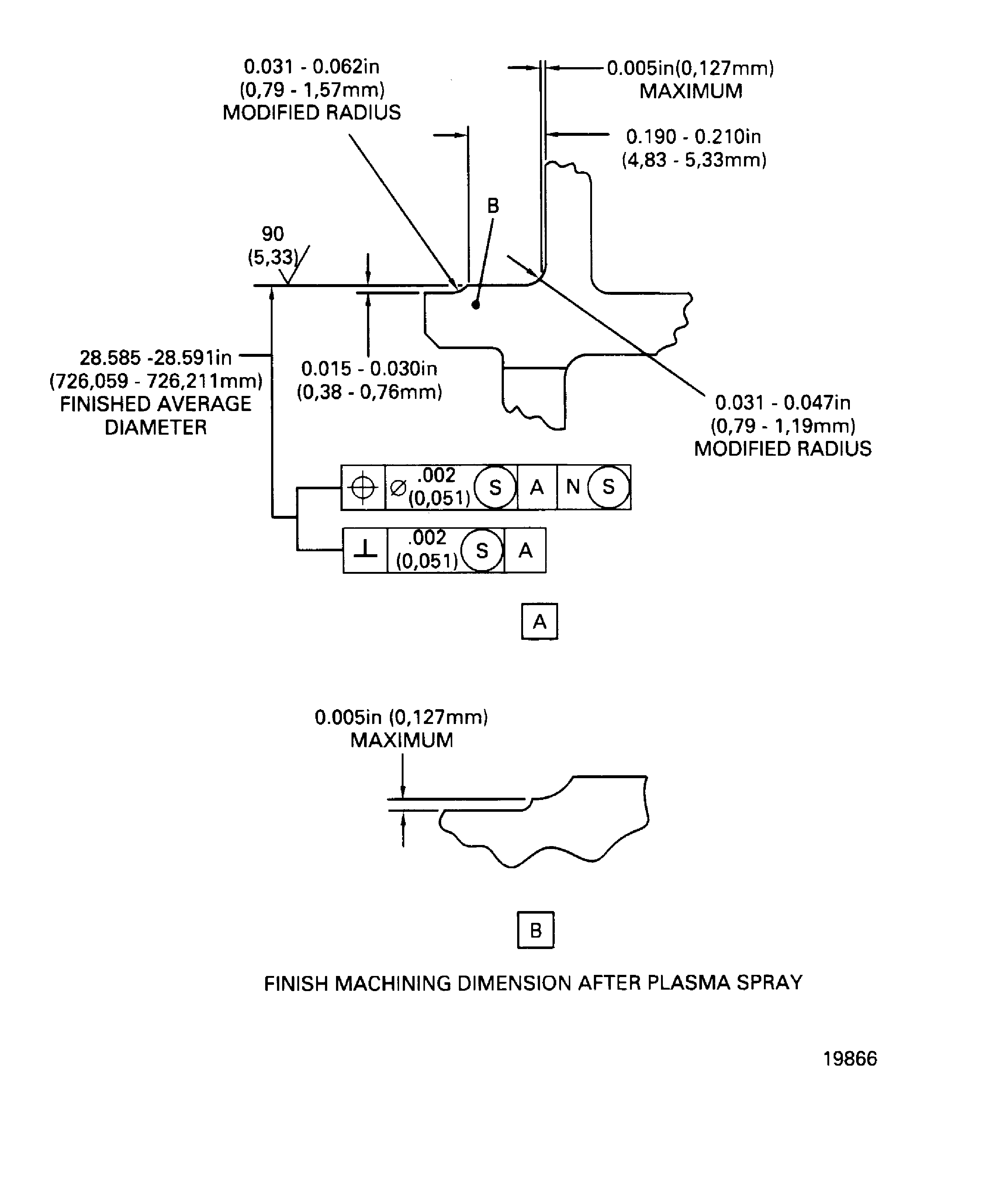

SUBTASK 72-45-27-320-052 Finish Machine the Front Outer Diameter after Plasma Spray

Refer to Figure.

Make a permanent mark by the procedures given in the SPM TASK 70-09-00-400-501. Use the vibration peen method.

Make a mark VRS3227 adjacent to the part number.

SUBTASK 72-45-27-350-052 Identify the Repair

Refer to Repair, VRS3228 TASK 72-45-27-300-007 (REPAIR-007).

Install the shoulder pins.

SUBTASK 72-45-27-350-063 If Removed the Shoulder Pins, Replace all the Shoulder Pins

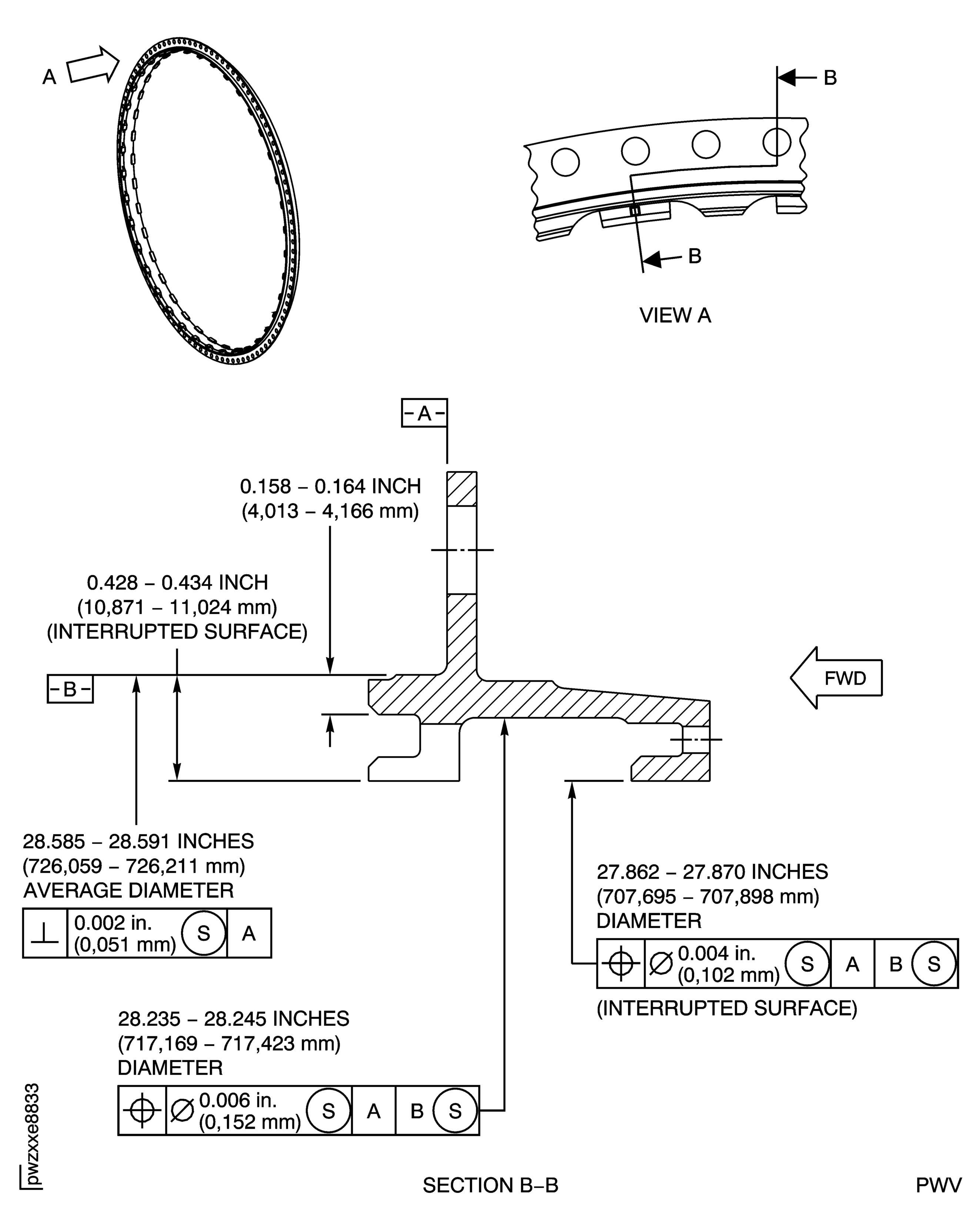

Figure: Repair Details And Dimensions

Repair Details And Dimensions

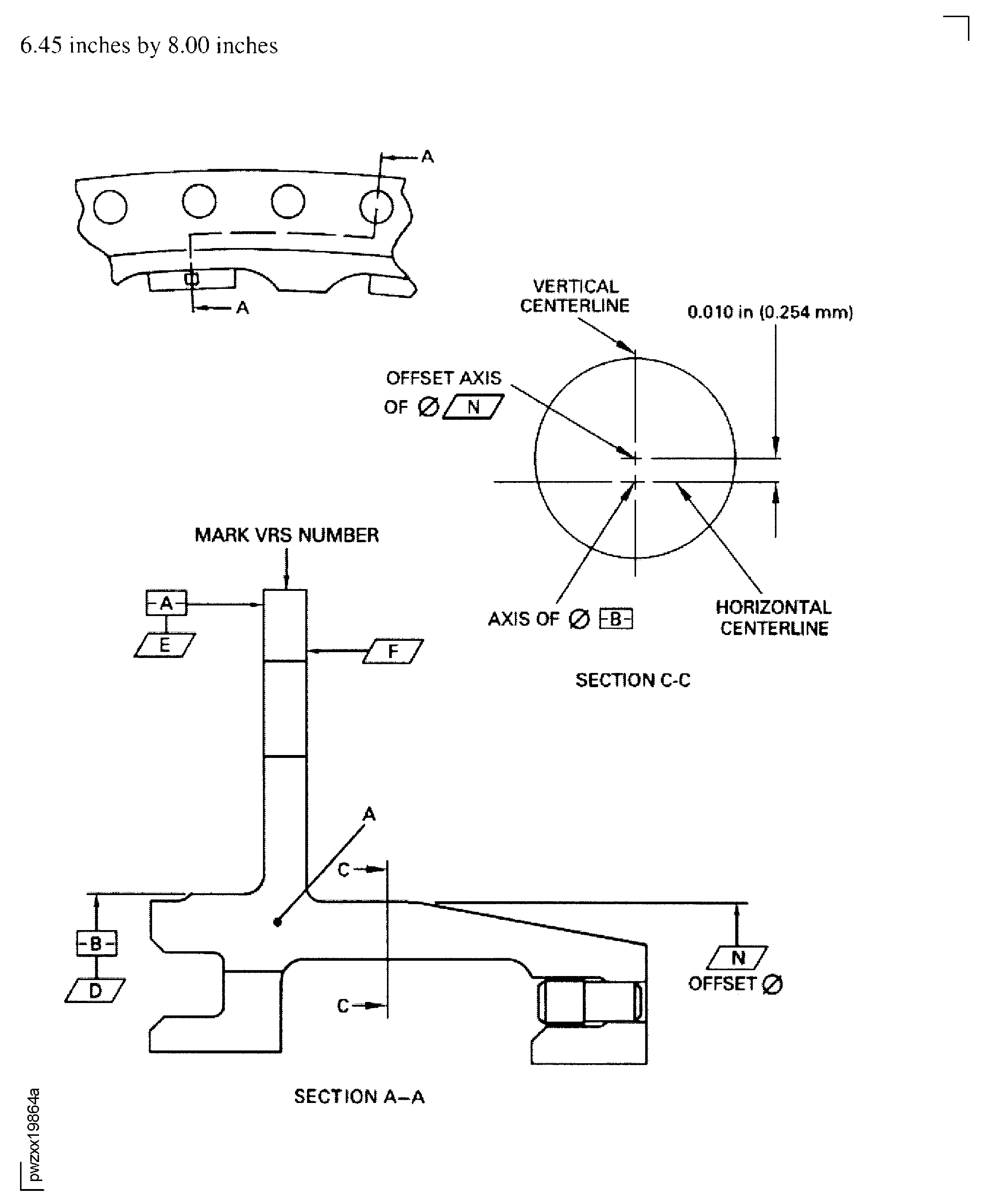

Figure: Repair Details And Dimensions (PN 2A1360 and 2A1713)

Repair Details And Dimensions (PN 2A1360 and 2A1713)

Figure: Repair Details And Dimensions (PN 2A1360 and 2A1713)

Repair Details And Dimensions (PN 2A1360 and 2A1713)

Figure: Repair Details And Dimensions (PN 2A1713)

Repair Details And Dimensions (PN 2A1713)

Figure: Repair Details And Dimensions (PN 2A1360)

Repair Details And Dimensions (PN 2A1360)