Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

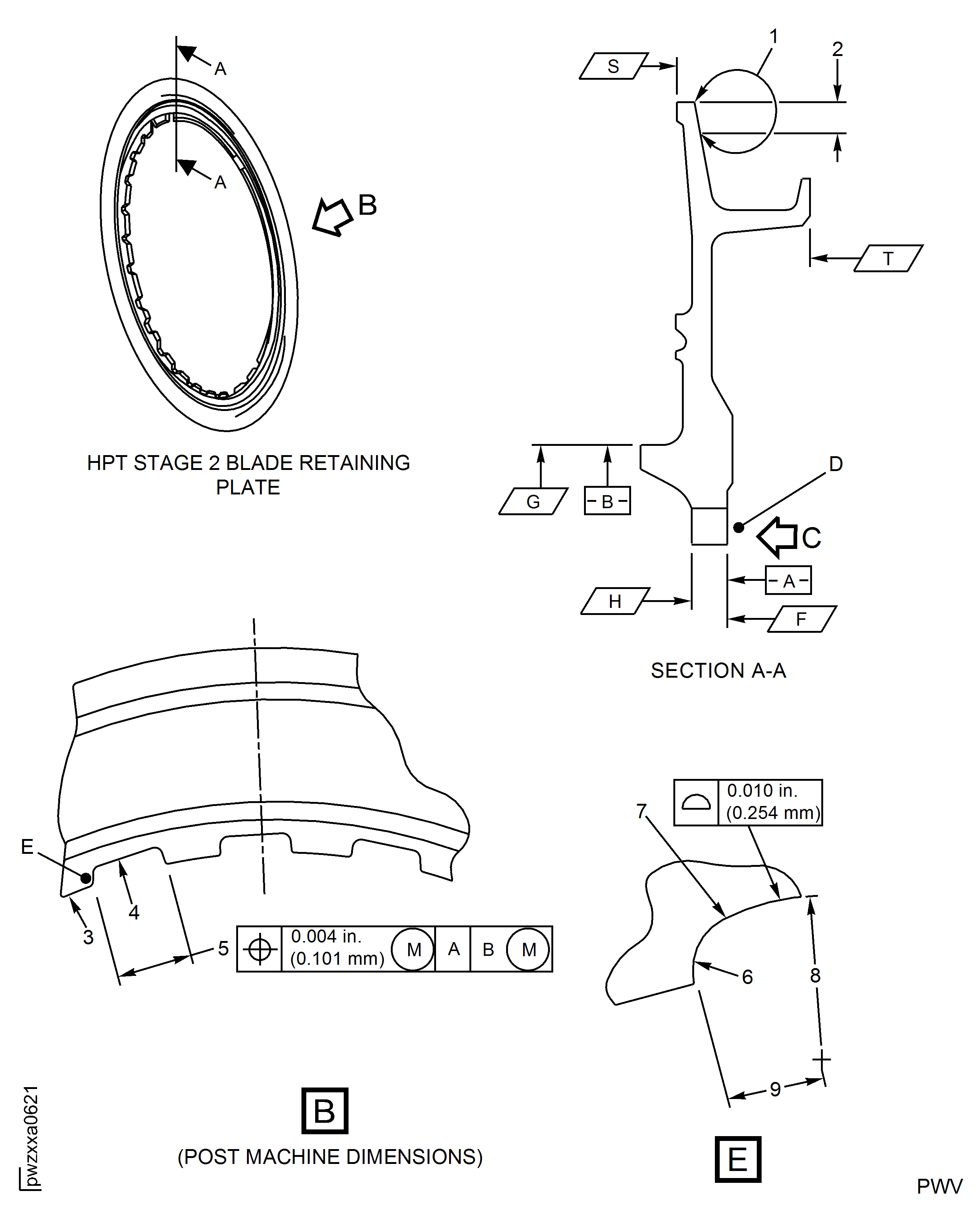

TASK 72-45-33-300-007 HPT Stage 2 Blade Retaining Plate - Bayonet Locking Slots, Machine Repair, Repair-007 (VRS3856)

Preliminary Requirements

Pre-Conditions

| Action/Condition | Data Module/Technical Publication |

|---|---|

| Make sure that the cleaning and inspection procedures are done before this repair. |

Support Equipment

NONEConsumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

Refer to Figure.

Remove an additional 0.002 in. - 0.003 in. (0.051 mm - 0.076 mm) of material more than depth of damage.

It is permissible to machine only two (2) bayonet locking slots in any 90 degree quadrant.

Break edges 0.003 in. - 0.015 in. (0.077 mm - 0.381 mm).

Surface texture 63 micro-inches (1.6 micro-meters) must be maintained.

No mismatch permitted in the machined slot(s).

Slot(s) to be machined symmetrically on both sides.

Machine the bayonet locking slot(s) of HPT stage 2 blade retaining plate to remove the damage(s) as follows. See Figure for the limits.

SUBTASK 72-45-33-320-059 Machine the Bayonet Locking Slot(s)

Refer to Figure.

Clean the repaired area(s) by SPM TASK 70-11-03-300-503.

SUBTASK 72-45-33-110-062 Clean the Repaired Area(s)

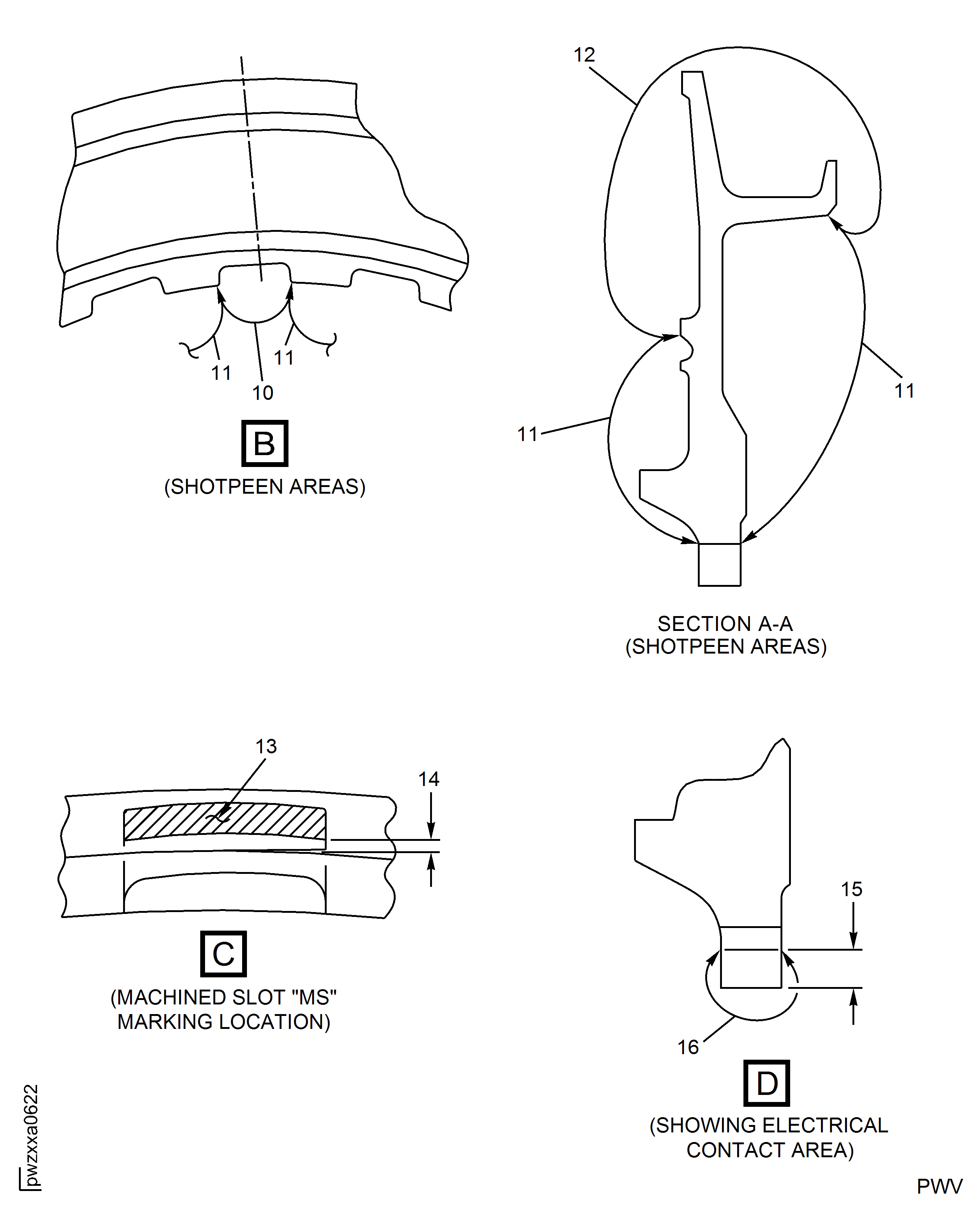

Refer to Figure.

No cracks are allowed.

SPM TASK 70-23-05-230-501, use ultra-high sensitivity.

No cracks are allowed.

TASK 72-45-33-200-000 and applicable part number.

Do a fluorescent penetrant inspection of the repaired area(s) by one of the methods that follow:

SUBTASK 72-45-33-230-066 Do a Fluorescent Penetrant Inspection of the Repaired Area(s)

Refer to Figure.

Use an intensity of 4A and S-170 maximum shot size.

Shotpeen is not permitted on any finish coated surfaces and marking location.

No rolled edges or sharp lines of demarcation are permitted.

Shotpeen the repaired area(s) on HPT stage 2 blade retaining plate by SPM TASK 70-38-13-380-501.

SUBTASK 72-45-33-380-058 Shotpeen the Repaired Area(s)

Do a dimensional inspection of the machined bayonet locking slot(s) of HPT stage 2 blade retaining plate to the limits specified in Figure.

SUBTASK 72-45-33-220-101 Do a Dimensional Inspection

Mark the machined bayonet slot(s) with an "MS" in area indicated in Figure.

Make a permanent mark by the procedure given in SPM TASK 70-09-00-400-501.

Marking must be accomplished with only deep electrolytic etch, vibration peen, or deep dot peen.

Do not mark over previously repaired area(s).

SUBTASK 72-45-33-350-062 Mark the Machined Bayonet Slot(s)

Refer to Figure.

Make a permanent mark by the procedure given in SPM TASK 70-09-00-400-501.

Marking must be accomplished with only deep electrolytic etch, vibration peen, or deep dot peen.

Mark VRS3856 adjacent to the part number.

SUBTASK 72-45-33-350-063 Mark the Part

Figure: HPT Stage 2 Blade Retaining Plate - Bayonet Locking Slots, Machine Repair, Repair-006 (VRS3856)

VRS Marking Location

0.250 Inch (6.350 mm) Maximum

NOTEAll dimensions apply when Surface F is flat within 0.001 Inch (0.026 mm) and Diameter G Maintains a clearance envelope of diameter 17.215 Inch (437.261 mm) in free state or constrained. Constraint contact allowed only on Surfaces F, H, S, T and Diameter G. |