Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-50-10-030-010 LPT Case And Rotor Assembly - Disassemble The LPT Stage 3 Rotor Assembly From The LPT, Disassembly-010

General

Refer to TASK 72-50-10-030-001 (DISASSEMBLY-001) before you do this TASK.

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

Apply the approved penetrating oil before the removal of threaded parts and parts with an interference fit. Let the parts soak before removal. For the approved oils and procedures, refer to SPM TASK 70-64-00-640-501.

Remove and discard the lockwire before parts are disconnected or removed.

Discard all rubber seal rings, cotter pins and keywashers removed in this procedure.

Refer to TASK 72-50-00-990-501 (DESCRIPTION AND OPERATION-001) for a sectional view of the LP turbine module.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Rack pallet | LOCAL | Rack pallet | ||

| Basket | LOCAL | Basket | For blades and vanes | |

| IAE 1M14010 Assembly/Disassembly fixture | 0AM53 | IAE 1M14010 | 1 | |

| IAE 1M14030 Assembly trolley | 0AM53 | IAE 1M14030 | 1 | |

| IAE 1M14059 Lifting fixture | 0AM53 | IAE 1M14059 | 1 | |

| IAE 1M14063 Guide fixture | 0AM53 | IAE 1M14063 | 1 | |

| IAE 1M14078 Clamping ring | 0AM53 | IAE 1M14078 | 1 | |

| IAE 1M14130 Removal puller | 0AM53 | IAE 1M14130 | 1 | |

| IAE 1M14142 Clamping ring | 0AM53 | IAE 1M14142 | 1 | |

| IAE 1M14156 Lifting fixture | 0AM53 | IAE 1M14156 | 1 |

Consumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

Refer to: Figure

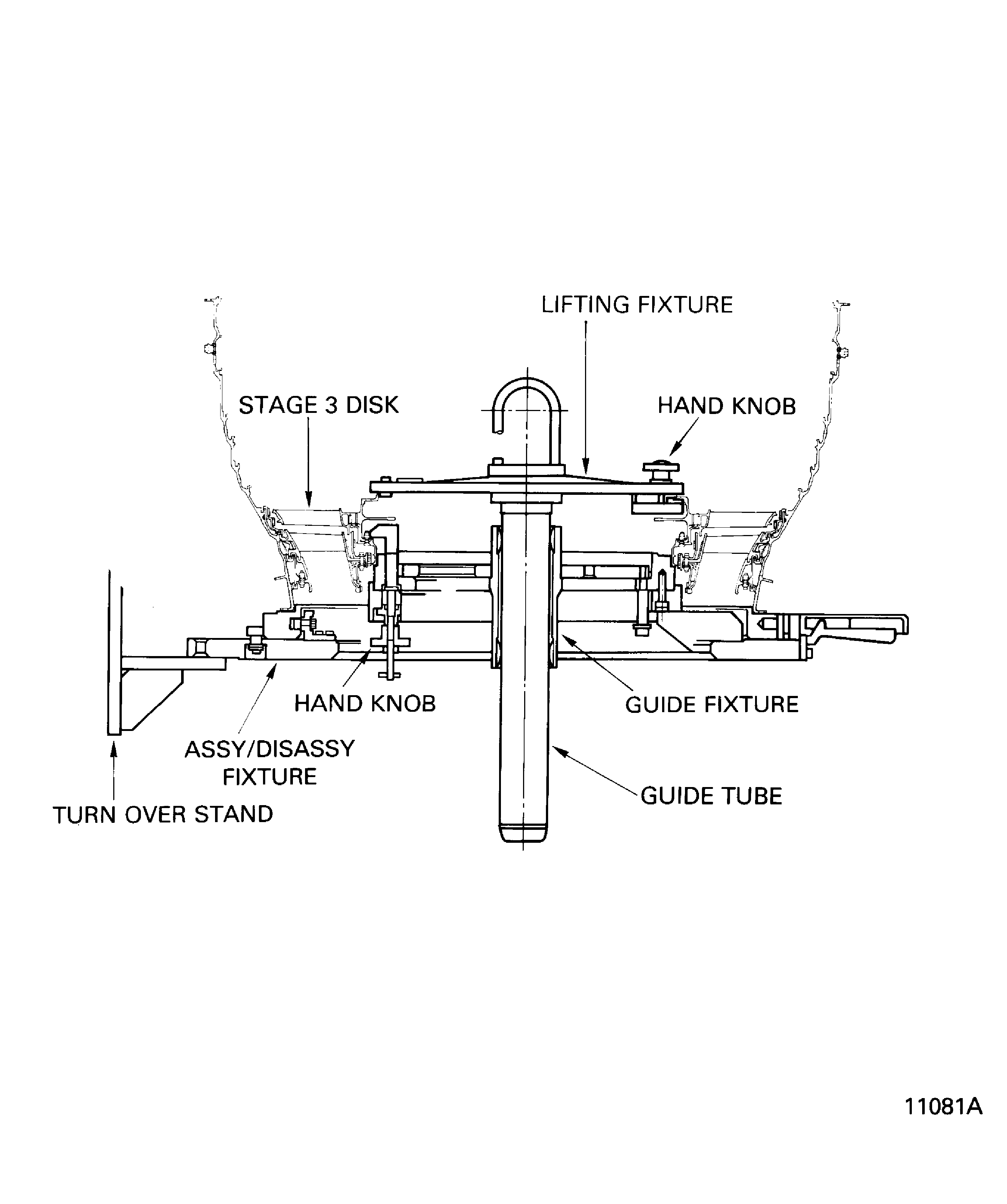

Release the hand knobs of the six clamps of the IAE 1M14010 Assembly/Disassembly fixture 1 off which attach the stage 3 disk to the fixture.

SUBTASK 72-50-10-030-113 Release the Clamps of the Assembly/Disassembly Fixture

Refer to: Figure

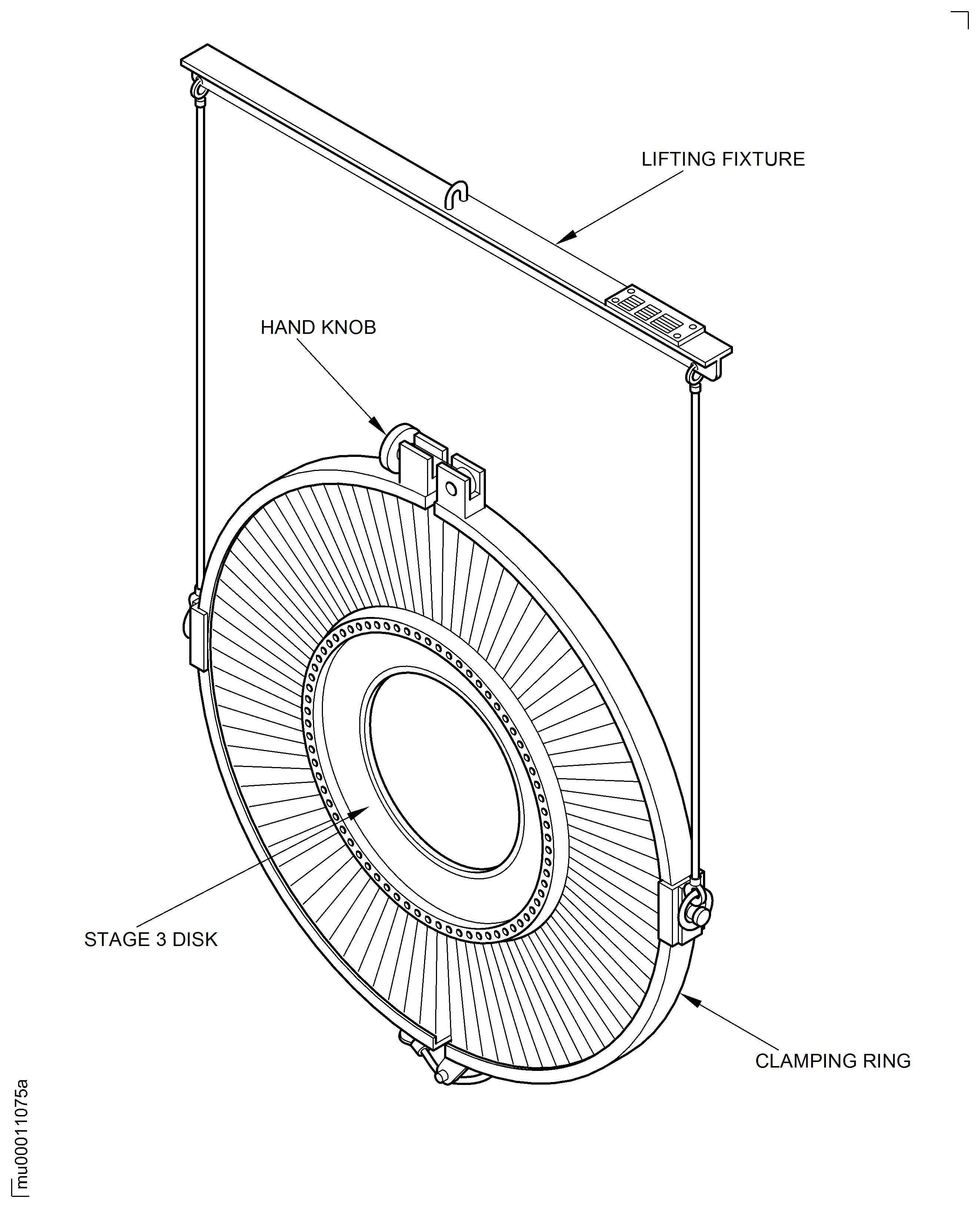

Use hoist equipment to install the IAE 1M14059 Lifting fixture 1 off. Make sure that the clamps of the lifting fixture are locked in the inner position. Install the three teflon bolts into the holes which are marked with the stage number of the disk to be removed.

Lower the lifting fixture carefully on to the stage 3 disk, engage the front end of the guide tube through the IAE 1M14063 Guide fixture 1 off.

SUBTASK 72-50-10-030-114 Attach the Lifting Fixture on to the Stage 3 Disk

Refer to: Figure

Lower the stage 3 disk on the IAE 1M14030 Assembly trolley 1 off.

SUBTASK 72-50-10-030-115 Remove the Stage 3 Disk

Refer to: Figure

Install the two halves of the IAE 1M14078 Clamping ring 1 off to the stage 3 disk.

SUBTASK 72-50-10-030-116-A00 V2500-A1: Install the Clamping Ring to the Stage 3 Disk

Refer to: Figure

Install the two halves of the IAE 1M14142 Clamping ring 1 off to the stage 3 disk.

SUBTASK 72-50-10-030-116-B00 V2500-A5: Install the Clamping Ring to the Stage 3 Disk

Use hoist equipment to install the IAE 1M14156 Lifting fixture 1 off to the clamping ring.

SUBTASK 72-50-10-030-117 Turn the Stage 3 Disk

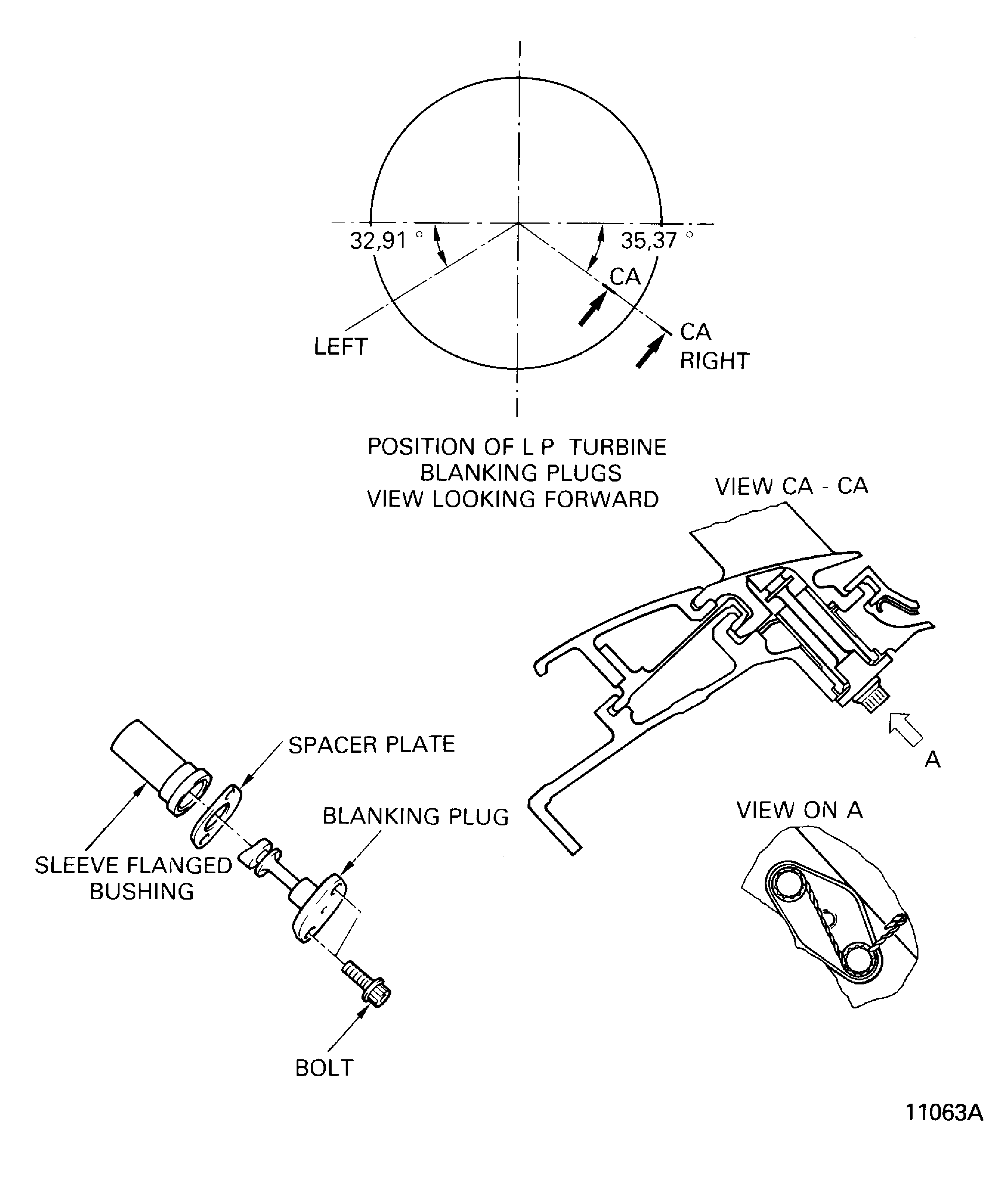

Refer to Figure.

WARNING

DURING DISASSEMBLY DO NOT BREATHE DUST OF THE LOOSENED BOLTS. PREVENT SKIN AND EYE CONTACT WITH RELEASED DUST. THE DUST CONTAINS NICKEL PARTICLES WHICH CAN POSE A HEALTH HAZARD. BEFORE DISASSEMBLY LUBRICATE ACCESSIBLE BOLTS AND BOLT HEADS, NUTS AND EXPOSED THREADS WITH AN APPROVED, SUITABLE PENETRANT OIL. WEAR A FACE MASK AND GOGGLES. DO NOT REMOVE DUST DEPOSITS WITH COMPRESSED AIR. REMOVE ANY SURFACE DUST PARTICLES WITH A DISPOSABLE DAMP RAG OR SIMILAR. AFTER END OF THIS PROCEDURE CLEAN YOUR HANDS AND EXPOSED SKIN WHERE POSSIBLE.Loosen and remove the two bolts, which secure the blanking plug.

SUBTASK 72-50-10-030-187 Remove the Blanking Plugs of the LP Turbine Borescope Ports

Refer to: Figure

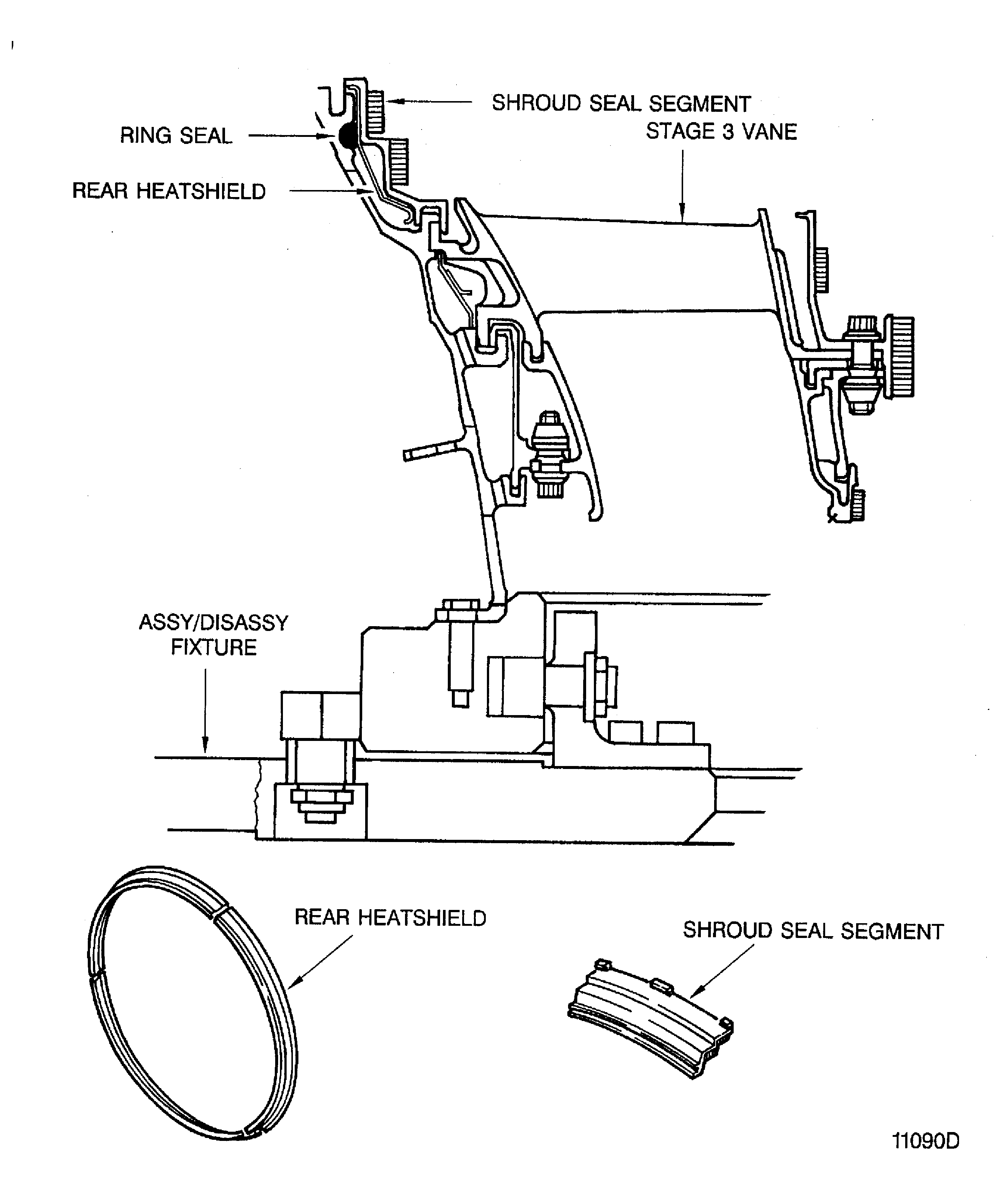

Loosen the shroud seal segments with the IAE 1M14130 Removal puller 1 off.

SUBTASK 72-50-10-030-118 Remove the Shroud Seal Segments of the Stage 3

Refer to: Figure

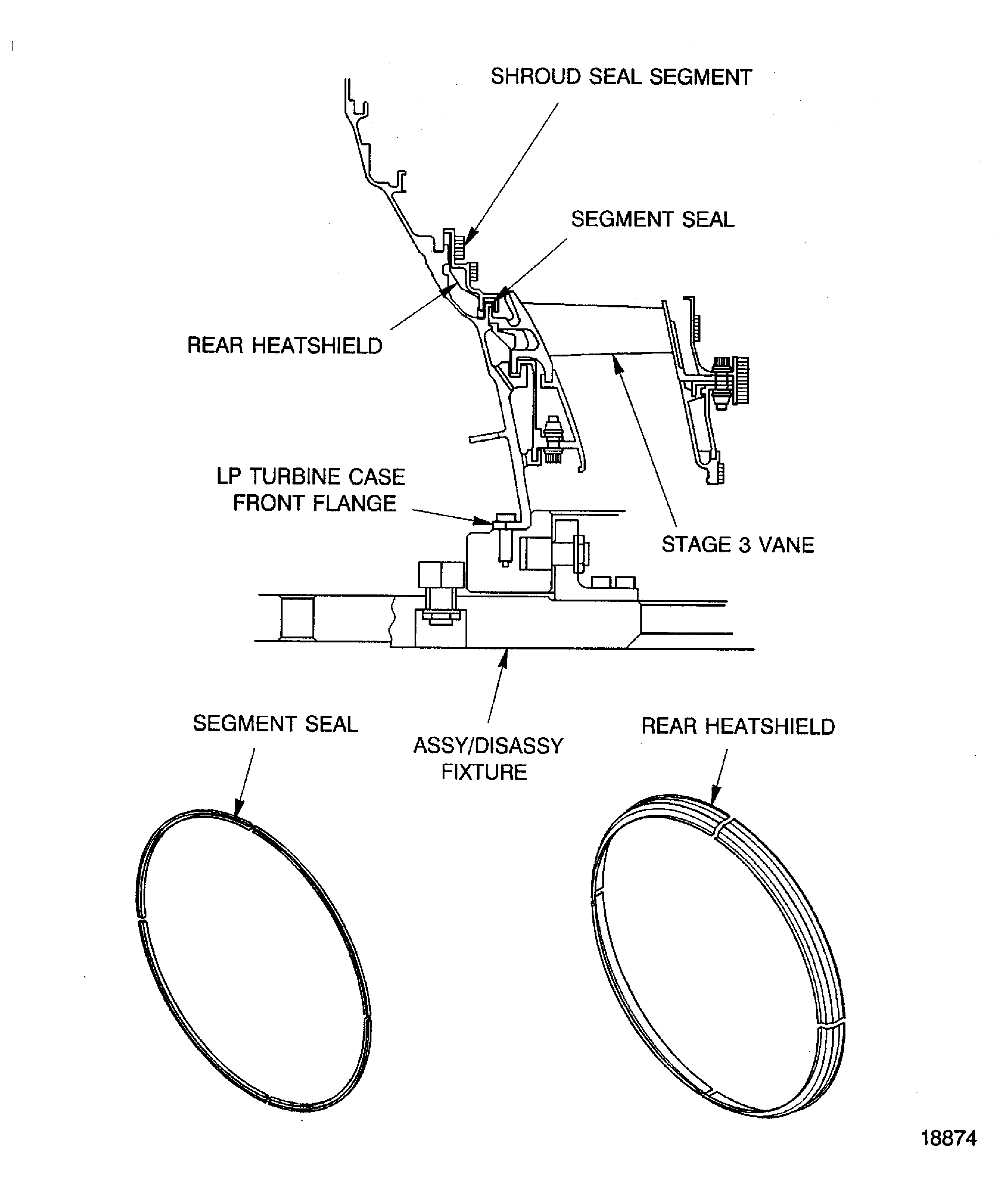

SUBTASK 72-50-10-030-119-A00 V2500-A1: Remove the Stage 3 Rear Heatshield Segments

Refer to: Figure

SUBTASK 72-50-10-030-119-B00 V2500-A5: Remove the stage 3 Rear Heatshields

Refer to: Figure

SUBTASK 72-50-10-030-119-188 V2500-A5: Remove the Stage 3 Segment Seals

Refer to: Figure

SUBTASK 72-50-10-030-120 V2500-A1: Remove the Ring Seal

Refer to: Figure

SUBTASK 72-50-10-030-153 Remove the Guide Fixture from the Assembly/Disassembly Fixture

Figure: Remove the Stage 3 Disk

Remove the Stage 3 Disk

Figure: Remove the Stage 3 LP Turbine Borescope Port

Remove the Stage 3 LP Turbine Borescope Port

Figure: V2500-A1: Remove the Segments Seals, the Rear Heatshield Segments and the Ring Seal

V2500-A1: Remove the Segments Seals, the Rear Heatshield Segments and the Ring Seal

Figure: Lift and Turn the Stage 3 Disk with the Clamping Ring

Lift and Turn the Stage 3 Disk with the Clamping Ring

Figure: V2500-A5 Remove the Segment Seals, the Rear Heatshields and the Shroud Seal Segments

V2500-A5 Remove the Segment Seals, the Rear Heatshields and the Shroud Seal Segments