Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-50-10-430-010 LPT Case And Rotor Assembly - Assemble The LPT Stage 7 Rotor Assembly To The LPT, Assembly-010

General

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

For standard torque data and procedures, refer to the SPM TASK 70-41-01-400-501 and SPM TASK 70-41-02-400-501.

Special torque data and assembly tolerances are included in the procedure.

The number for each radial location must be identified in a clockwise direction. These start at the engine top position when you look from the rear of the engine, unless stated differently in the procedure.

Use new rotor bolts and new nuts.

NOTE

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Straight edge | LOCAL | Straight edge | with blocks | |

| Depth gage | LOCAL | Depth gage | ||

| IAE 6F10027 Heater control unit | 0AM53 | IAE 6F10027 | 1 | |

| IAE 1M14000 Lifting fixture | 0AM53 | IAE 1M14000 | 1 | |

| IAE 1M14001 Support fixture | 0AM53 | IAE 1M14001 | 1 | |

| IAE 1M14009 Storage stand | 0AM53 | IAE 1M14009 | 1 | |

| IAE 1M14010 Assembly/Disassembly fixture | 0AM53 | IAE 1M14010 | 1 | |

| IAE 1M14030 Assembly trolley | 0AM53 | IAE 1M14030 | 1 | |

| IAE 1M14054 Torque wrench adapter | 0AM53 | IAE 1M14054 | 1 | |

| IAE 1M14055 Special wrench | 0AM53 | IAE 1M14055 | 1 | |

| IAE 1M14060 Lifting fixture | 0AM53 | IAE 1M14060 | 1 | |

| IAE 1M14463 Lifting fixture | 0AM53 | IAE 1M14463 | ||

| IAE 1M14063 Guide fixture | 0AM53 | IAE 1M14063 | 1 | |

| IAE 1M14067 Heating fixture | 0AM53 | IAE 1M14067 | 1 | |

| IAE 1M14074 Heating fixture carrier | 0AM53 | IAE 1M14074 | 1 | |

| IAE 1M14091 Position retainer | 0AM53 | IAE 1M14091 | 1 | |

| IAE 1M14110 Turnover stand | 0AM53 | IAE 1M14110 | 1 | |

| IAE 1M14124 Protector ring segment | 0AM53 | IAE 1M14124 | 3 | |

| IAE 1M14125 Guide pin | 0AM53 | IAE 1M14125 | 1 | |

| IAE 1M14131 Guide pin | 0AM53 | IAE 1M14131 | 1 | |

| IAE 1M14134 Installation bolt/nut | 0AM53 | IAE 1M14134 | 6 | |

| IAE 1M14155 Clamping ring | 0AM53 | IAE 1M14155 | 1 | |

| IAE 1M14156 Lifting fixture | 0AM53 | IAE 1M14156 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 10-129A ANTI-SEIZE PASTE | 71984 | CoMat 10-129A | ||

| CoMat 10-129 ANTI-SEIZE PASTE | 34568 | CoMat 10-129 |

Safety Requirements

WARNING

Procedure

Refer to: Figure

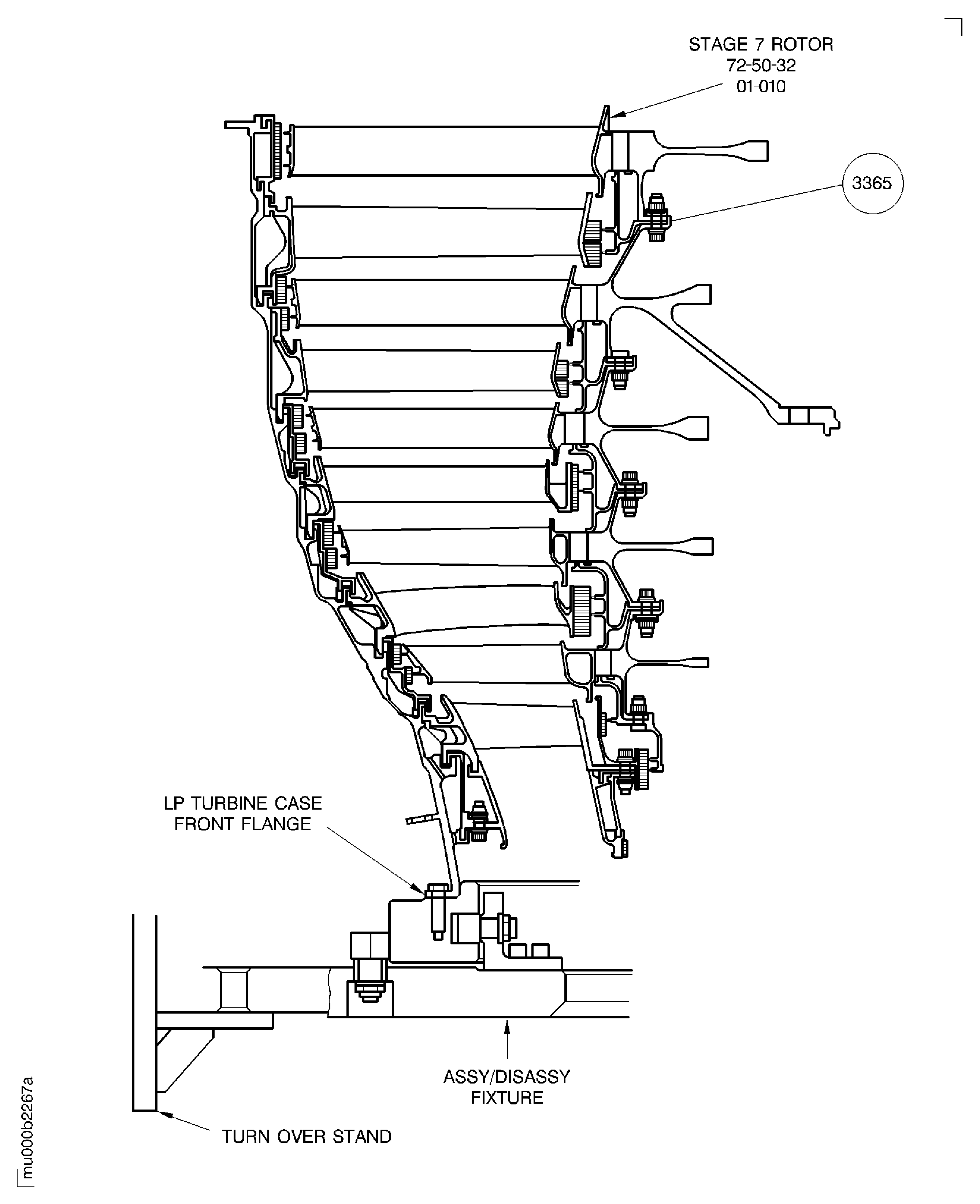

Calculate the clearance at location 3365.

Table 1. Fits and Clearances (all dimensions are in inches) NEW PART

DIMENSIONS

WORN PART

DIMENSIONS

REJECT IF

PART IDENT

Size

Clearance

(Non-select)

MORE THAN

LOCATION 3365

Stage 3 to 6 turbine rotor to

the abutment diameter of

the stage 7 turbine rotor

LPT Stage 3, 4, 5, 6, 7 Blades (72-50-32,01-010)

Stage 6 disk diameter

17.7047

17.7008

Intf

0.0197

Intf

0.0216

Stage 7 disk diameter

17.6890

17.6850

0.0118

0.0079

Table 2. Fits and Clearances (all dimensions are in millimeters) NEW PART

DIMENSIONS

WORN PART

DIMENSIONS

REJECT IF

PART IDENT

Size

Clearance

(Non-select)

MORE THAN

LOCATION 3365

Stage 3 to 6 turbine rotor to

the abutment diameter of

the stage 7 turbine rotor

LPT Stage 3, 4, 5, 6, 7 Blades (72-50-32,01-010)

Stage 6 disk diameter

449.70

449.60

Intf

0.50

Intf

0.55

Stage 7 disk diameter

449.30

449.20

0.30

0.20

SUBTASK 72-50-10-220-098-A00 V2500-A1: Make Sure that the Fits and Clearances of the Stage 6 Turbine Disk and the Stage 7 Turbine Disk are in the Limits given at Location 3365 (Pre SBE 72-0138)

Refer to: Figure

SBE 72-0138: Rotor and stator assembly introduce new LP turbine blades and vanes

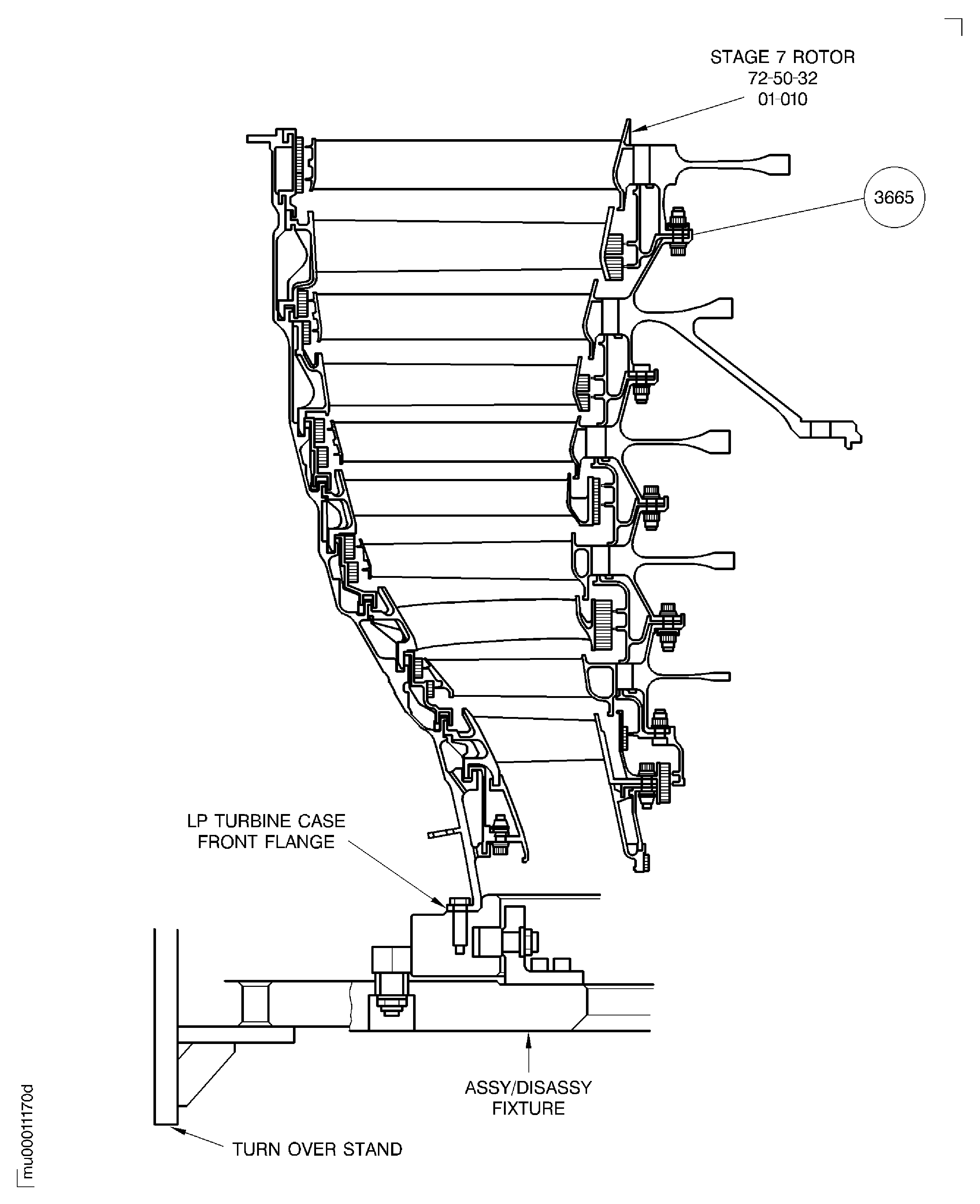

Calculate the clearance at location 3665.

Table 3. Fits and Clearances (all dimensions are in inches) NEW PART

DIMENSIONS

WORN PART

DIMENSIONS

REJECT IF

PART IDENT

Size

Clearance

(Non-select)

MORE THAN

LOCATION 3665

Stage 3 to 6 turbine rotor to

the abutment diameter of

the stage 7 turbine rotor

LPT Stage 3, 4, 5, 6, 7 Blades (72-50-32,01-010)

Stage 6 disk diameter

17.7047

17.7008

Intf

0.0197

Intf

0.0216

Stage 7 disk diameter

17.6890

17.6850

0.0118

0.0079

Table 4. Fits and Clearances (all dimensions are in millimeters) NEW PART

DIMENSIONS

WORN PART

DIMENSIONS

REJECT IF

PART IDENT

Size

Clearance

(Non-select)

MORE THAN

LOCATION 3665

Stage 3 to 6 turbine rotor to

the abutment diameter of

the stage 7 turbine rotor

LPT Stage 3, 4, 5, 6, 7 Blades (72-50-32,01-010)

Stage 6 disk diameter

449.70

449.60

Intf

0.50

Intf

0.55

Stage 7 disk diameter

449.30

449.20

0.30

0.20

SUBTASK 72-50-10-220-098-B00 V2500-A1: Make Sure that the Fits and Clearances of the Stage 6 Turbine Disk and the Stage 7 Turbine Disk are in the Limits given at Location 3665 (SBE 72-0138)

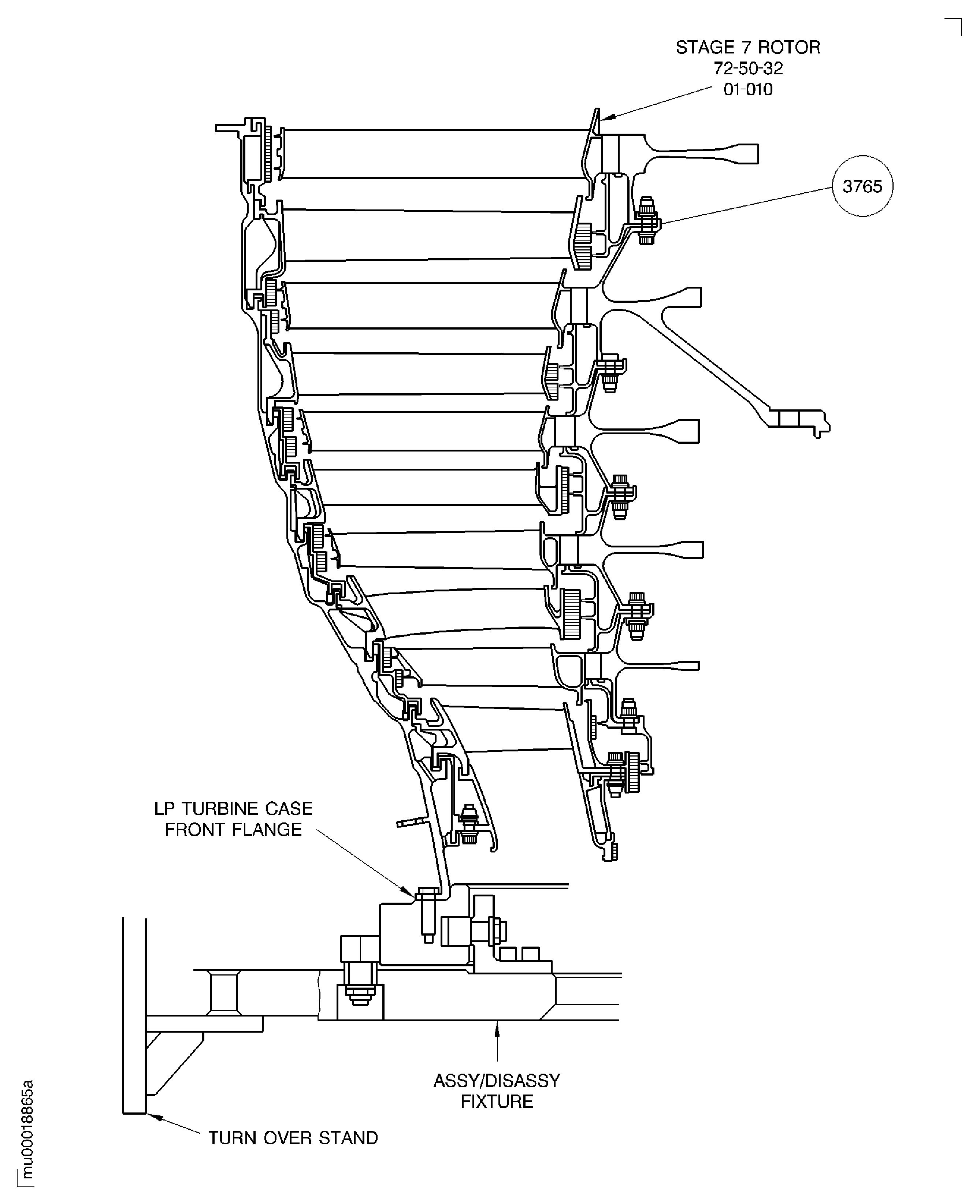

Refer to: Figure

Calculate the clearance at location 3765.

Table 5. Fits and Clearances (all dimensions are in inches) NEW PART

DIMENSIONS

WORN PART

DIMENSIONS

REJECT IF

PART IDENT

Size

Clearance

(Non-select)

MORE THAN

LOCATION 3765

Stage 3 to 6 turbine rotor to

the abutment diameter of

the stage 7 turbine rotor

LPT Stage 3, 4, 5, 6, 7 Blades (72-50-32,01-010)

Stage 6 disk diameter

17.7047

17.7008

Intf

0.0197

Intf

0.0216

Stage 7 disk diameter

17.6890

17.6850

0.0118

0.0079

Table 6. Fits and Clearances (all dimensions are in millimeters) NEW PART

DIMENSIONS

WORN PART

DIMENSIONS

REJECT IF

PART IDENT

Size

Clearance

(Non-select)

MORE THAN

LOCATION 3765

Stage 3 to 6 turbine rotor to

the abutment diameter of

the stage 7 turbine rotor

LPT Stage 3, 4, 5, 6, 7 Blades (72-50-32,01-010)

Stage 6 disk diameter

449.70

449.60

Intf

0.50

Intf

0.55

Stage 7 disk diameter

449.30

449.20

0.30

0.20

SUBTASK 72-50-10-220-098-C00 V2500-A5: Make Sure that the Fits and Clearances of the Stage 6 Turbine Disk and the Stage 7 Turbine Disk are in the Limits given at Location 3765

Refer to Figure.

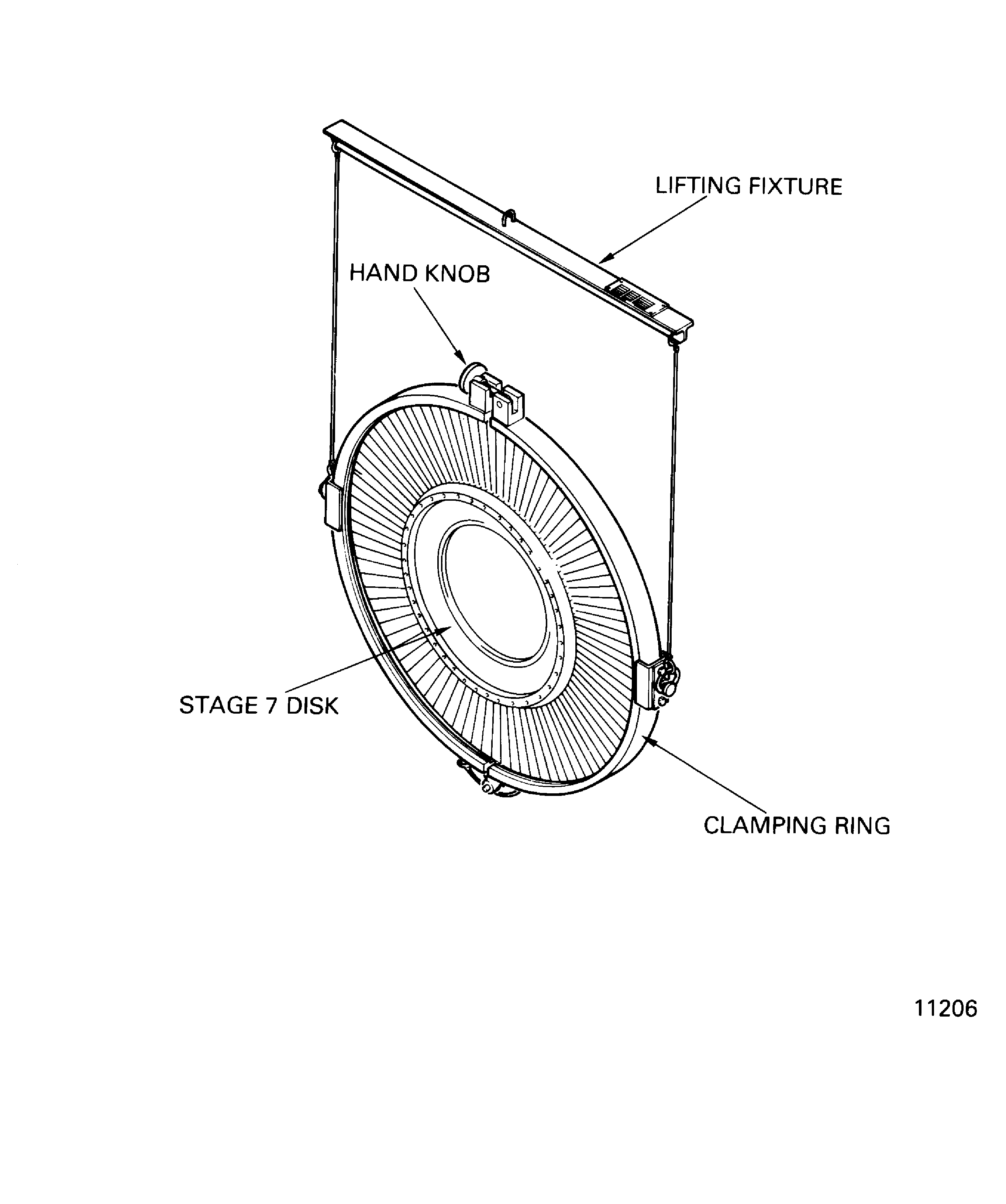

Install the two halves of the IAE 1M14155 Clamping ring 1 off to the stage 7 disk.

SUBTASK 72-50-10-430-158 Install the Clamping Ring to the Stage 7 Disk

Refer to Figure.

Use hoist equipment to install the IAE 1M14156 Lifting fixture 1 off to the clamping ring.

Put the stage 7 disk, front side down, on to the IAE 1M14030 Assembly trolley 1 off.

SUBTASK 72-50-10-430-159 Put the Stage 7 Disk on to the Assembly Trolley

Refer to: Figure

NOTE

Measure the inner hub diameter before you install the lifting fixture:NOTE

If the inner hub diameter is 12.595in. (319.9 mm) use IAE 1M14060 Lifting fixture.

If the inner hub diameter is 12.441in. (316 mm) use IAE 1M14463 Lifting fixture.

Use hoist equipment to install the IAE 1M14060 Lifting fixture 1 off or the IAE 1M14463 Lifting fixture 1 off. Make sure that the clamps of the lifting fixture are locked in the inner position.

SUBTASK 72-50-10-430-160 Attach the Lifting Fixture on to the Stage 7 Disk

Refer to: Figure

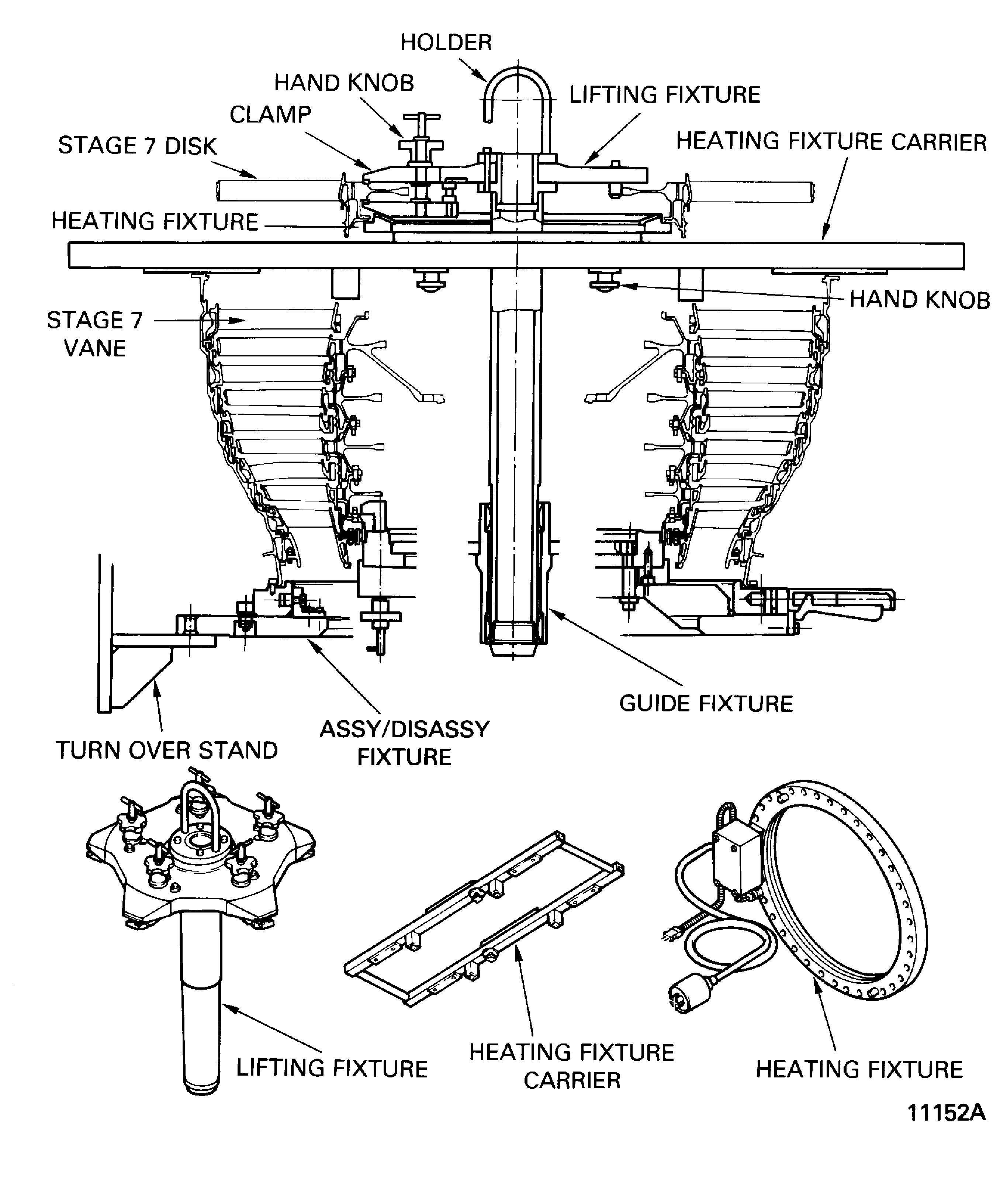

Put the IAE 1M14067 Heating fixture 1 off on to the IAE 1M14074 Heating fixture carrier 1 off. The two locating pins must engage to the bushings of the heating fixture carrier.

SUBTASK 72-50-10-430-162 Install the Heating Fixture on to the Heating Fixture Carrier

Refer to: Figure

SUBTASK 72-50-10-430-163 Install the Heating Fixture Carrier with the Heating Fixture on to the LP Turbine Case

Refer to: Figure

NOTE

Make sure that the temperature feeler of the heating fixture touches the stage 7 air seal.

SUBTASK 72-50-10-430-164 Install the Stage 7 Disk to the Heating Fixture

Refer to: Figure

NOTE

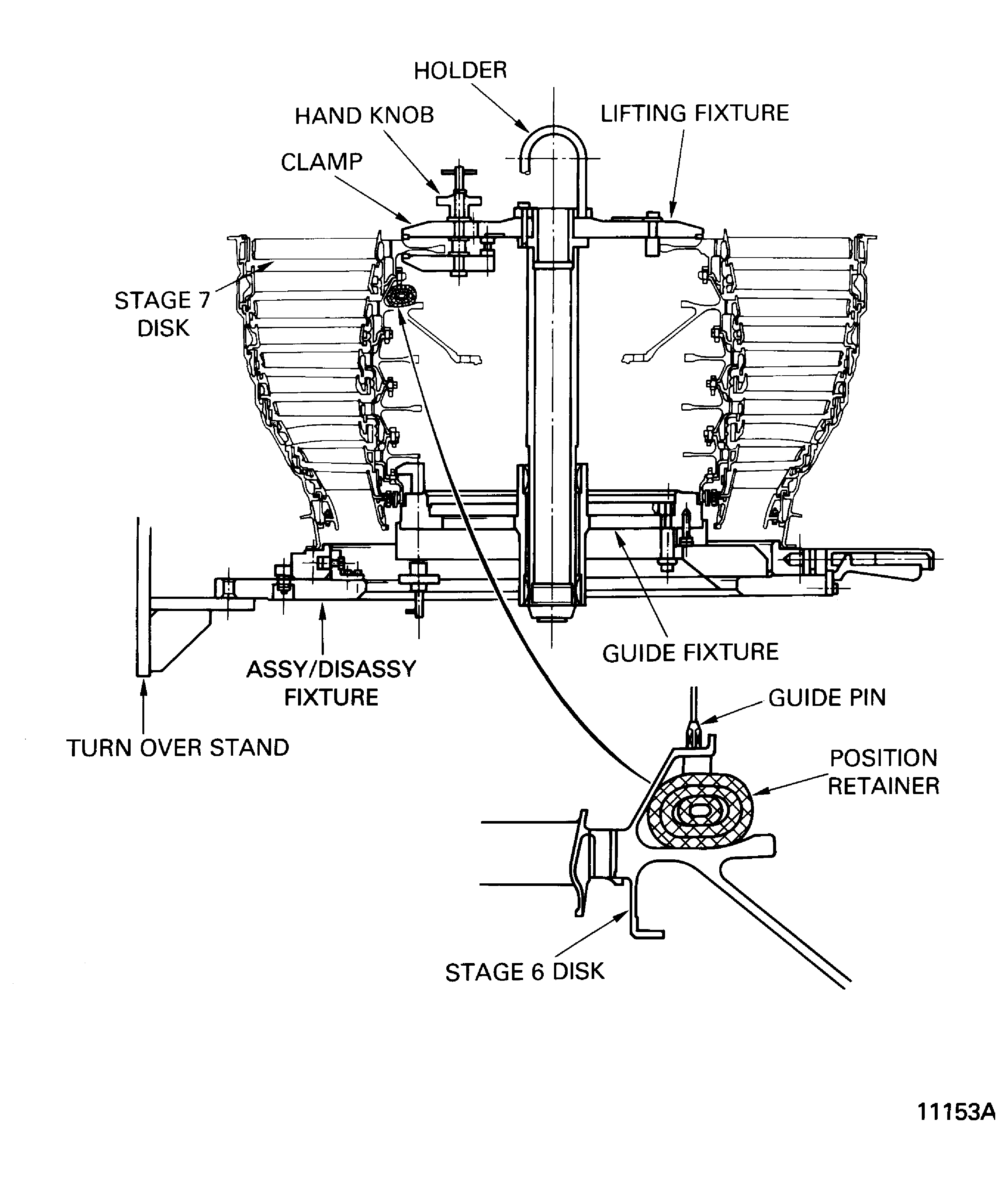

The high point position of the stage 6 rotor is marked on the disk hub by a circled dash symbol. Refer to TASK 72-50-30-440-004.Engage the guide cable, part of the IAE 1M14131 Guide pin 1 off, through a hole 175 to 185 degrees apart of the marked highpoint position of the stage 6 rear flange.

Compress the IAE 1M14091 Position retainer 1 off and put it under the guide pin.

SUBTASK 72-50-10-430-165 Install the Guide Pin to the Stage 6 Disk

Refer to: Figure

Increase the temperature of the stage 7 disk front flange with the heating fixture. Use the IAE 6F10027 Heater control unit 1 off.

NOTE

The temperature of the stage 7 parts must not have more than 464.0 deg F (240.0 deg C).

SUBTASK 72-50-10-430-166 Increase the Temperature of the Stage 7 Disk Front Flange

Refer to: Figure

SUBTASK 72-50-10-430-167 Remove the Heating Fixture from the LP Turbine Case

Refer to: Figure

CAUTION

MAKE SURE THAT THE IAE 1M14124 Protector ring segment 3 OFF ARE NOT INSTALLED.NOTE

The high point position of the stage 7 rotor is marked on the disk hub by a circled dash symbol. Refer to TASK 72-50-30-440-005 (ASSEMBLY-005, CONFIG-001, CONFIG-002).Engage the guide cable through a hole near the marked high point position of the stage 7 disk.

SUBTASK 72-50-10-430-168 Install the Stage 7 Disk on to the Stage 6 Disk Rear Flange

Refer to Figure.

SUBTASK 72-50-10-430-169 Remove the Lifting Fixture from the Stage 7 Disk

Refer to: Figure

SUBTASK 72-50-10-430-170 Remove the Guide Pin

Refer to Figure.

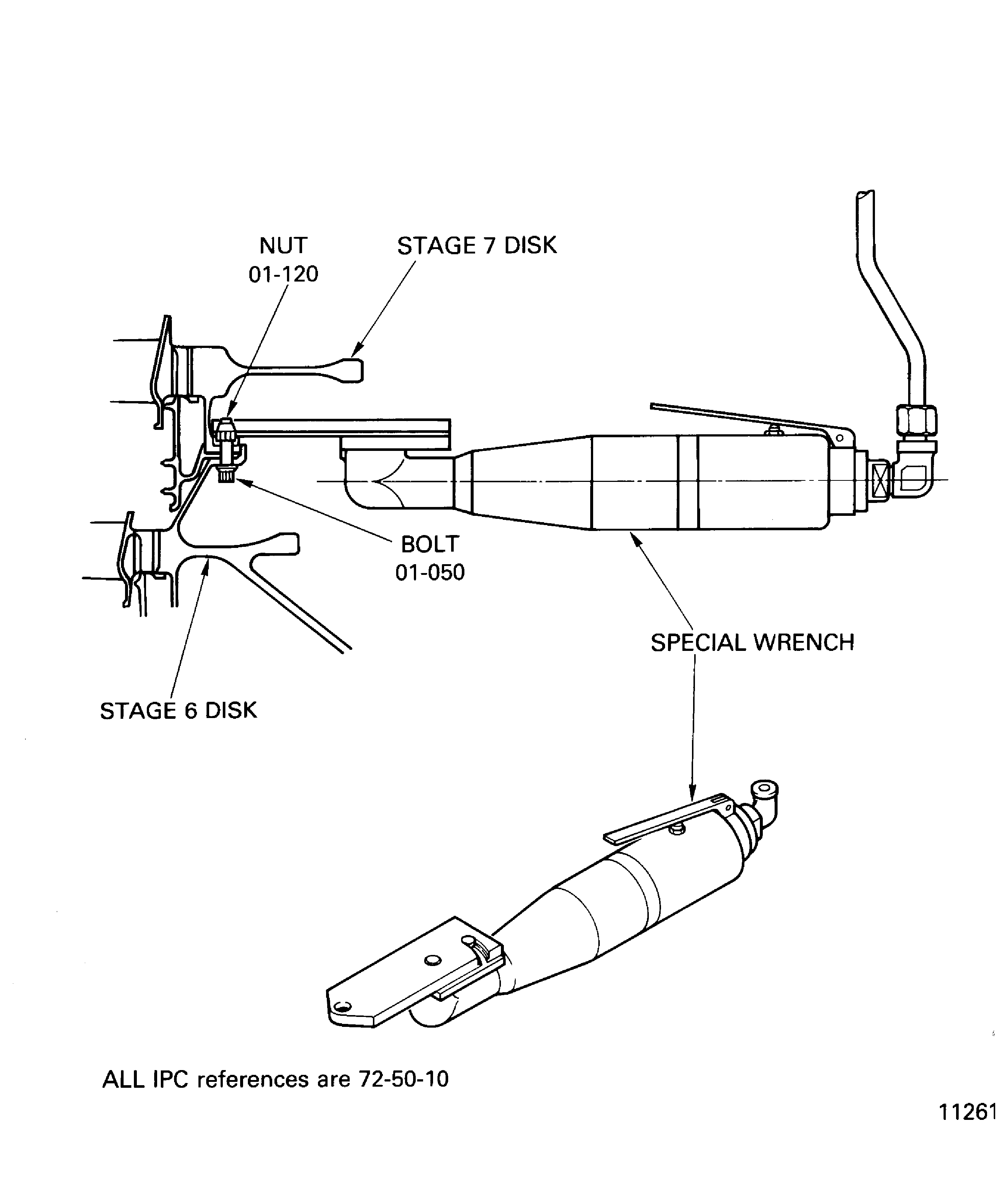

Install 60 degrees apart 6 installation bolts with the head up and 6 installation nuts, parts of the IAE 1M14134 Installation bolt/nut 6 off, to the disk flanges.

Tighten the installation nuts. Use the IAE 1M14055 Special wrench 1 off.

Torque the installation nuts from 119.0 to 133.0 lbfin (13.5 to 15 Nm). Use the IAE 1M14054 Torque wrench adapter 1 off.

SUBTASK 72-50-10-430-171 Attach the Disk Flanges

CAUTION

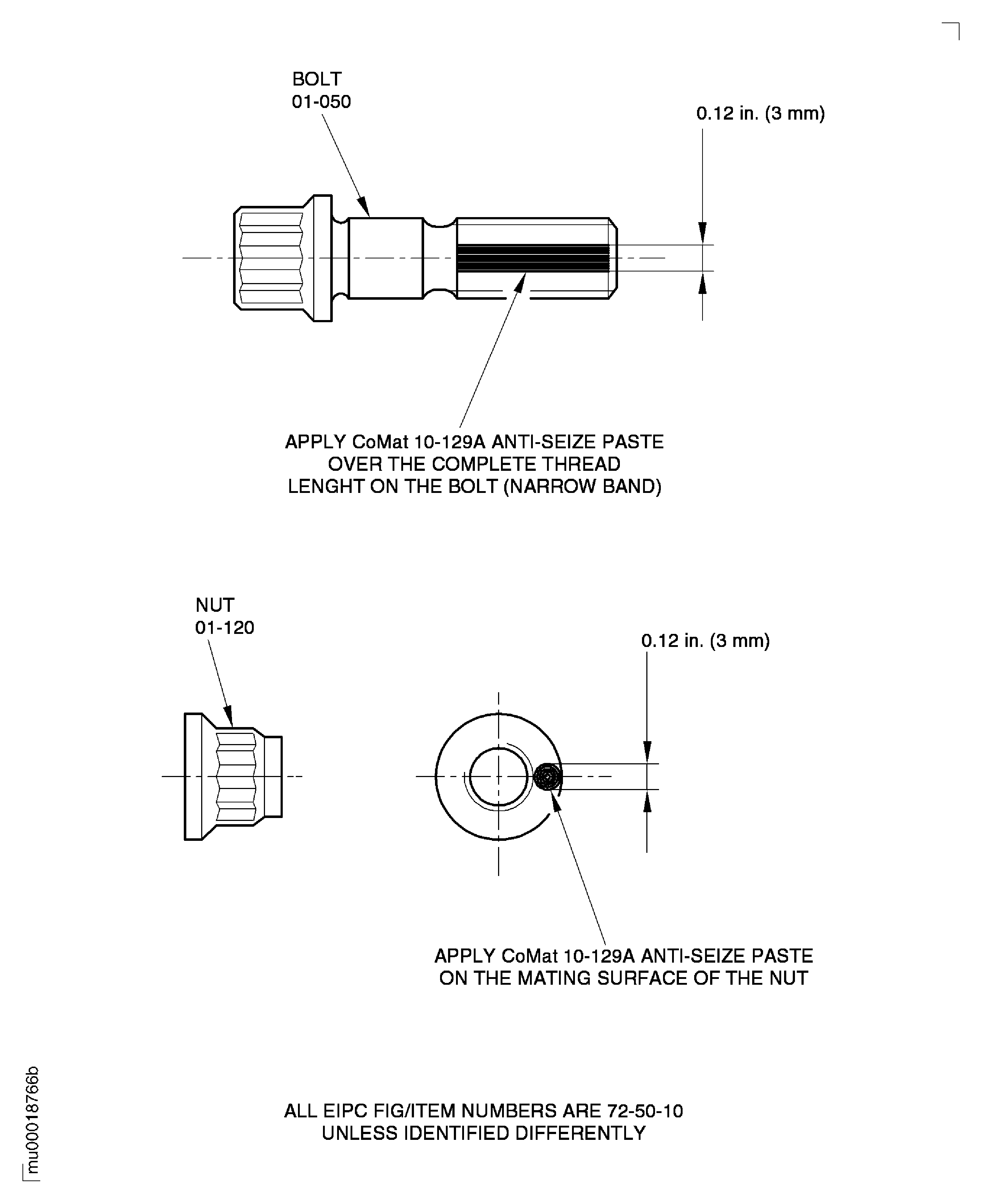

HOLD THE INSTALLATION BOLTS IN THEIR POSITION WHEN YOU INSTALL THE INSTALLATION NUTS ON TO THE INSTALLATION BOLTS. DO NOT TURN THE INSTALLATION BOLTS OR MAKE TO-AND-FRO MOVEMENTS. THE DISK-/INNER AIR SEAL FLANGES CAN BE DAMAGED BY SCORES.Lubricate all new bolts and new nuts with CoMat 10-129 ANTI-SEIZE PASTEA as follows:

CAUTION

HOLD THE BOLTS IN THEIR POSITION WHEN YOU INSTALL/REMOVE THE NUTS ON TO/FROM THE BOLTS. DO NOT TURN THE BOLTS OR MAKE TO-AND-FRO MOVEMENTS. THE DISK-/INNER AIR SEAL FLANGES AND/OR THE BOLTS CAN BE DAMAGED BY SCORES.MAKE SURE THAT THE LOCKING TORQUE OF THE NUTS IS BETWEEN 3.5 AND 30.0 LBFIN (0.4 AND 3.4 NM). TURN THE NUTS DOWN ON TO THE BOLTS UNTIL FINGER TIGHT. CONTINUE TO TURN THE NUTS WITH A WRENCH. MAKE SURE THAT THE NUTS GIVE SUFFICIENT RESISTANCE. IT SHOWS THAT THE SELF LOCKING PROPERTY IS STILL AVAILABLE.IT IS PERMITTED TO USE POWER TOOLS TO TURN THE NUTS ON TO THE REMAINING BOLT THREADS. MAKE SURE THAT THE POWER TOOL IS SET TO A TORQUE VALUE WHICH IS NOT MORE THAN 50 PERCENT TO THE FINAL TORQUE VALUE. THE SPEED MUST BE SLOW TO PREVENT INCREASE OF HEAT, WHICH CAN CAUSE THREAD PICK-UP AND SEIZURE.Install 30 new bolts with the head down and the new nuts to the disk flanges. Tighten the nuts on to the bolts with the IAE 1M14055 Special wrench 1 off.

Remove the installation nuts and installation bolts. Use the IAE 1M14055 Special wrench 1 off to remove the installation nuts.

Install the remaining six new bolts with the head down and the six new nuts. Tighten the nuts on to the bolts with the IAE 1M14055 Special wrench 1 off.

CAUTION

MAKE SURE THAT ALL INSTALLATION BOLTS AND INSTALLATION NUTS ARE REPLACED.NOTE

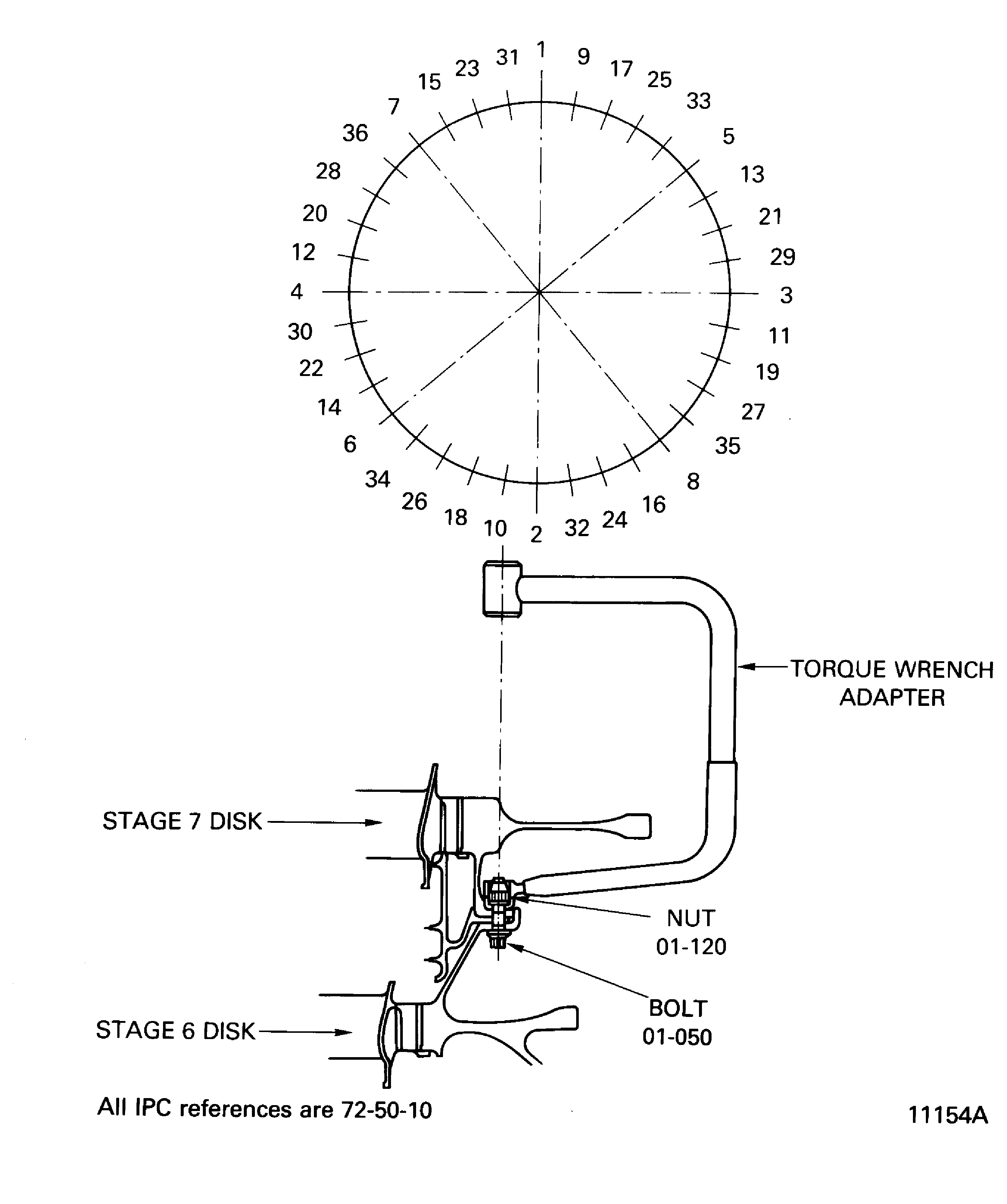

The tightening torque valve includes the self locking torque valve.Torque the nuts with the IAE 1M14054 Torque wrench adapter 1 off in two steps. For the torque sequence, refer to Figure.

Check all nuts again in clockwise direction for final torque. Use the IAE 1M14054 Torque wrench adapter 1 off.

SUBTASK 72-50-10-430-172 Attach the Stage 6 Disk and the Stage 7 Disk with the Bolts and the Nuts

Refer to: Figure

Remove the IAE 1M14063 Guide fixture from the IAE 1M14010 Assembly/Disassembly fixture.

SUBTASK 72-50-10-430-173 Remove the Guide Fixture from the Assembly/Disassembly Fixture

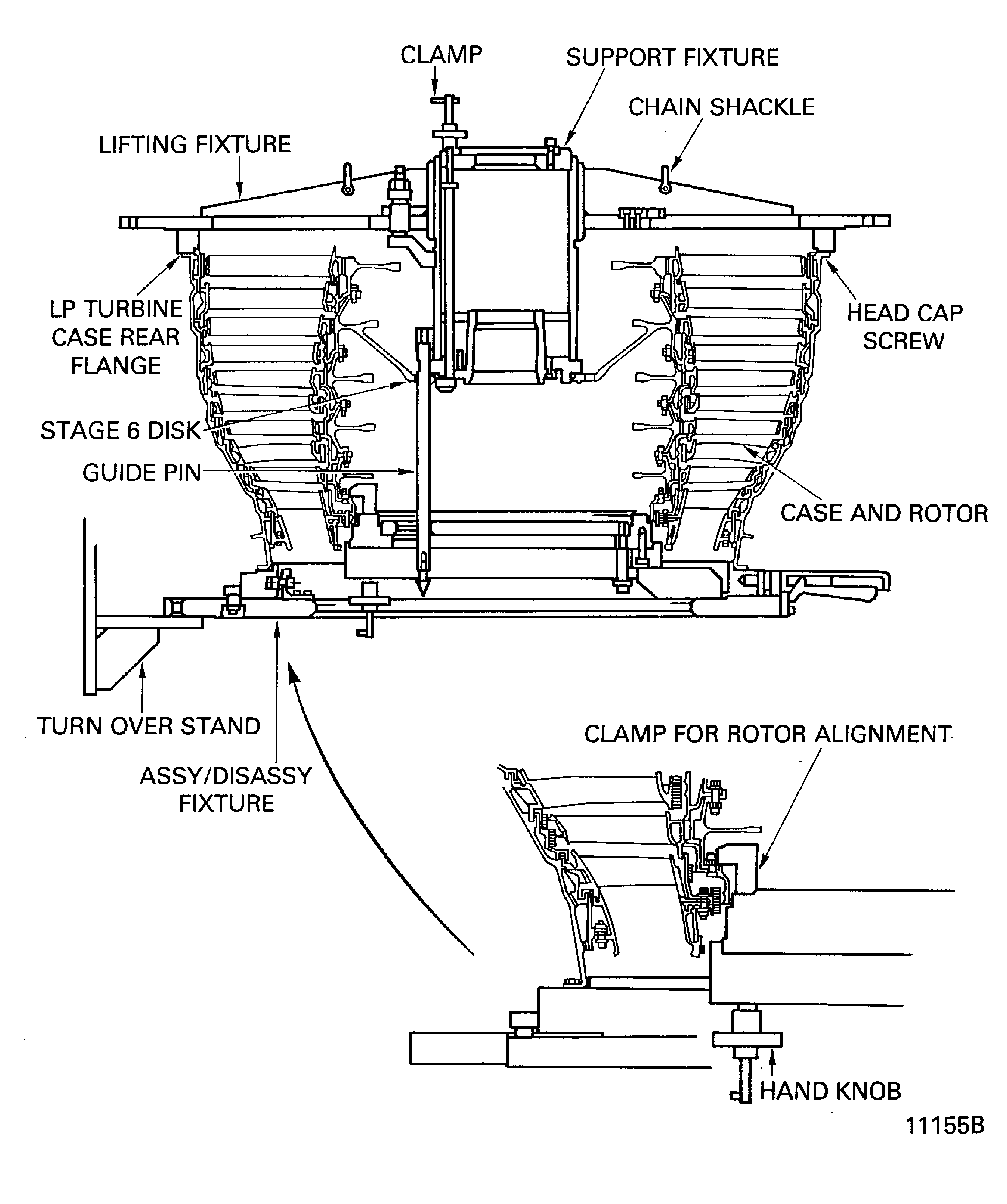

Engage the IAE 1M14000 Lifting fixture 1 off on to the IAE 1M14001 Support fixture 1 off. Turn back the three guide sleeves, part of the lifting fixture, until the support fixture touches the lifting fixture.

Lift the complete assembly and install the IAE 1M14125 Guide pin 1 off to the retaining dog at the side of the support fixture.

SUBTASK 72-50-10-430-174 Install the Support Fixture in to the Lifting Fixture

Refer to Figure.

CAUTION

MAKE SURE THE SUPPORT FIXTURE IS CORRECTLY LOCKED ON THE LIFTING FIXTURE. IF THE FIXTURES ARE NOT CORRECTLY LOCKED, THE LP TURBINE CASE AND ROTOR PARTS CAN BE DAMAGED DURING HANDLING OF THE LP TURBINE ASSEMBLY.Tighten the three nuts of the IAE 1M14001 Support fixture.

SUBTASK 72-50-10-430-175 Install the Assembled Fixture on to the LP Turbine Case and Rotor

Refer to: Figure

CAUTION

SAFETY THE STORAGE STAND WITH THE FLOOR LOCK.Install the LP turbine case and rotor in to the IAE 1M14009 Storage stand 1 off.

SUBTASK 72-50-10-430-176 Remove the LP Turbine Case and Rotor from the Assembly/Disassembly Fixture

Refer to: Figure

Loosen and remove the eight bolts and nuts which attach the assembly/disassembly fixture to the IAE 1M14110 Turnover stand.

SUBTASK 72-50-10-430-177 Remove the Assembly/Disassembly Fixture from the Turnover Stand

Figure: Lift and Turn the Stage 7 with the Clamping Ring

Lift and Turn the Stage 7 with the Clamping Ring

Figure: Increase the Temperature of the Stage 7 with the Heating Fixture

Increase the Temperature of the Stage 7 with the Heating Fixture

Figure: Install the Stage 7 Disk

Install the Stage 7 Disk

Figure: Torque Sequence of the Nuts which Attach the Stage 6 Disk and the Stage 7 Disk

Torque Sequence of the Nuts which Attach the Stage 6 Disk and the Stage 7 Disk

Figure: Remove the LP Turbine Case and Rotor from the Assembly/Disassembly Fixture

Remove the LP Turbine Case and Rotor from the Assembly/Disassembly Fixture

Figure: Pre SBE 72-0138 V2500-A1: Fits and Clearances of the Stage 7 Rotor

Sheet 1

Figure: SBE 72-0138 V2500-A1: Fits and Clearances of the Stage 7 Rotor

Sheet 2

Figure: V2500-A5: Fits and Clearances of the Stage 7 Rotor

V2500-A5: Fits and Clearances of the Stage 7 Rotor

Figure: Tighten the Nuts with the Special Wrench

Tighten the Nuts with the Special Wrench

Figure: Lubrication of the Bolt Thread and the Nut Mating Surface

Lubrication of the Bolt Thread and the Nut Mating Surface