Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-50-10-430-011 LPT Case And Rotor Assembly - Balance The LPT Assembly, Assembly-011

General

Fig/item numbers in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

For standard torque data and procedures, refer to the SPM TASK 70-41-01-400-501 and SPM TASK 70-41-02-400-501.

Special torque data and assembly tolerances are included in the procedure.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS, unless other lubricants are referred to in the procedure.

To identify, lubricate and install seal rings, refer to TASK 70-44-01-400-501.

After assembly apply CoMat 07-038 AIR DRYING ENAMEL to any damaged surface protection, joint flanges and attach parts. Use the correct color of the air drying enamel. Refer to TASK 70-63-02-400-501.

The number for each radial location must be identified in a clockwise direction. These start at the engine top position when you look from the rear of the engine, unless stated differently in the procedure.

Refer to TASK 72-50-00-990-501 (DESCRIPTION AND OPERATION-001) for a sectional view of the LP turbine module.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Horizontal Balancing Machine | LOCAL | Schenck HL5U | ||

| Rack pallet | LOCAL | Rack pallet | ||

| IAE 1F10026 Hydraulic hand pump | 0AM53 | IAE 1F10026 | 1 | |

| IAE 1F10052 Two cables sling | 0AM53 | IAE 1F10052 | 2 | |

| IAE 6F10027 Heater control unit | 0AM53 | IAE 6F10027 | 1 | |

| IAE 1J12283 Expanding heater | 0AM53 | IAE 1J12283 | 1 | |

| IAE 1M14000 Lifting fixture | 0AM53 | IAE 1M14000 | 1 | |

| IAE 1M14001 Support fixture | 0AM53 | IAE 1M14001 | 1 | |

| IAE 1M14009 Storage stand | 0AM53 | IAE 1M14009 | 1 | |

| IAE 1M14012 Hydraulic puller- pusher | 0AM53 | IAE 1M14012 | 1 | |

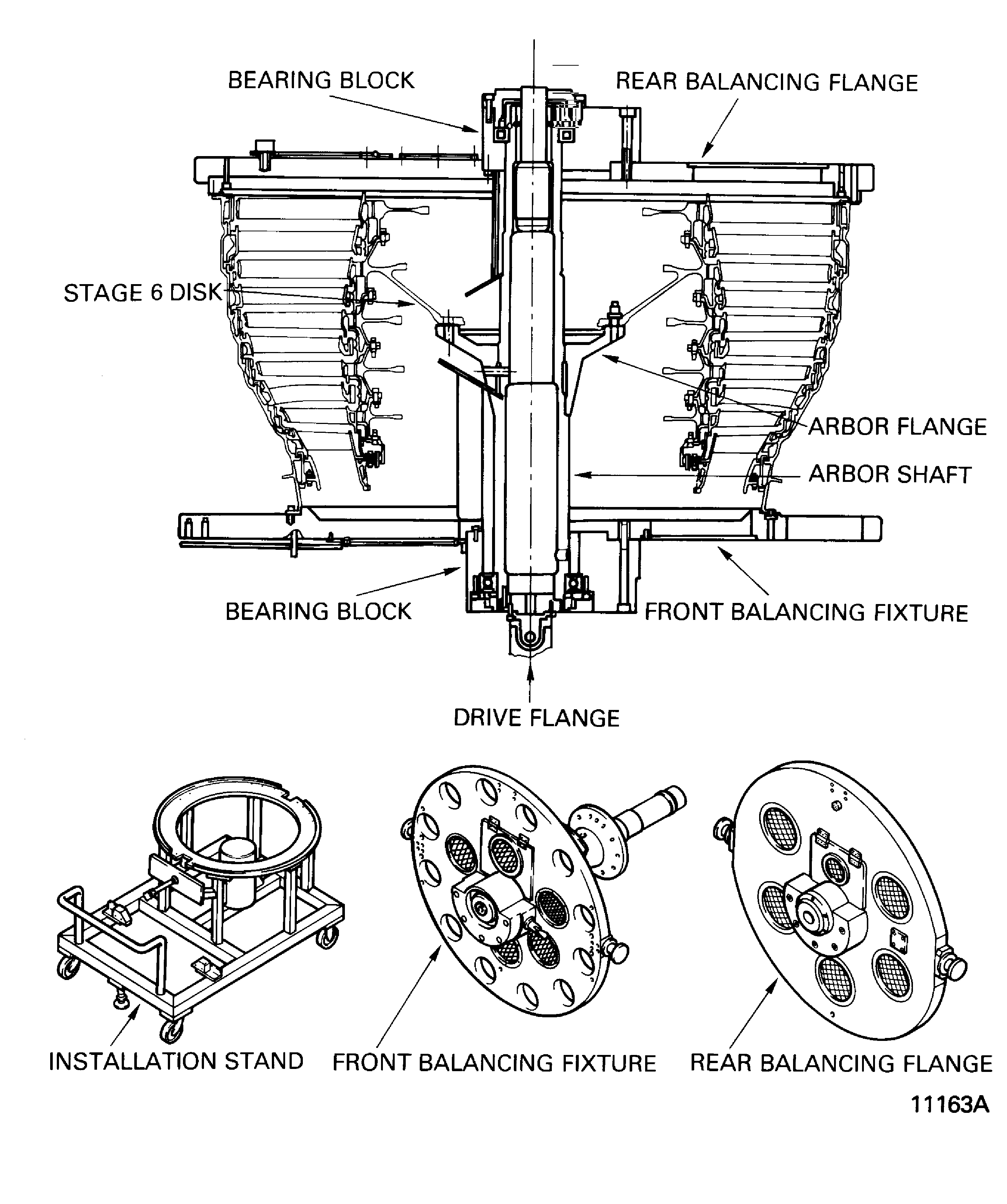

| IAE 1M14045 Installation stand | 0AM53 | IAE 1M14045 | 1 | |

| IAE 1M14047 Rear balancing flange | 0AM53 | IAE 1M14047 | 1 | |

| IAE 1M14048 Torque wrench adapter | 0AM53 | IAE 1M14048 | 1 | |

| IAE 1M14055 Special wrench | 0AM53 | IAE 1M14055 | 1 | |

| IAE 1M14057 Hydraulic basic fixture | 0AM53 | IAE 1M14057 | 1 | |

| IAE 1M14099 Front balancing fixture | 0AM53 | IAE 1M14099 | 1 | |

| IAE 1M14125 Guide pin | 0AM53 | IAE 1M14125 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-031 ACETONE (CH3)2CO | LOCAL | CoMat 01-031 | ||

| CoMat 02-069 DISPOSABLE CLEANING TISSUES | 33591 | CoMat 02-069 | ||

| CoMat 02-129 MARKER | IAE28 | CoMat 02-129 | ||

| CoMat 07-038 AIR DRYING ENAMEL | K3504 | CoMat 07-038 | ||

| CoMat 10-077 APPROVED ENGINE OILS | LOCAL | CoMat 10-077 |

Spares

NONESafety Requirements

NONEProcedure

Refer to: Figure

Use hoist equipment. Attach the IAE 1F10052 Two cables sling 1 off to the front balancing fixture.

Lift the IAE 1M14099 Front balancing fixture 1 off with the two cables sling from the installation stand.

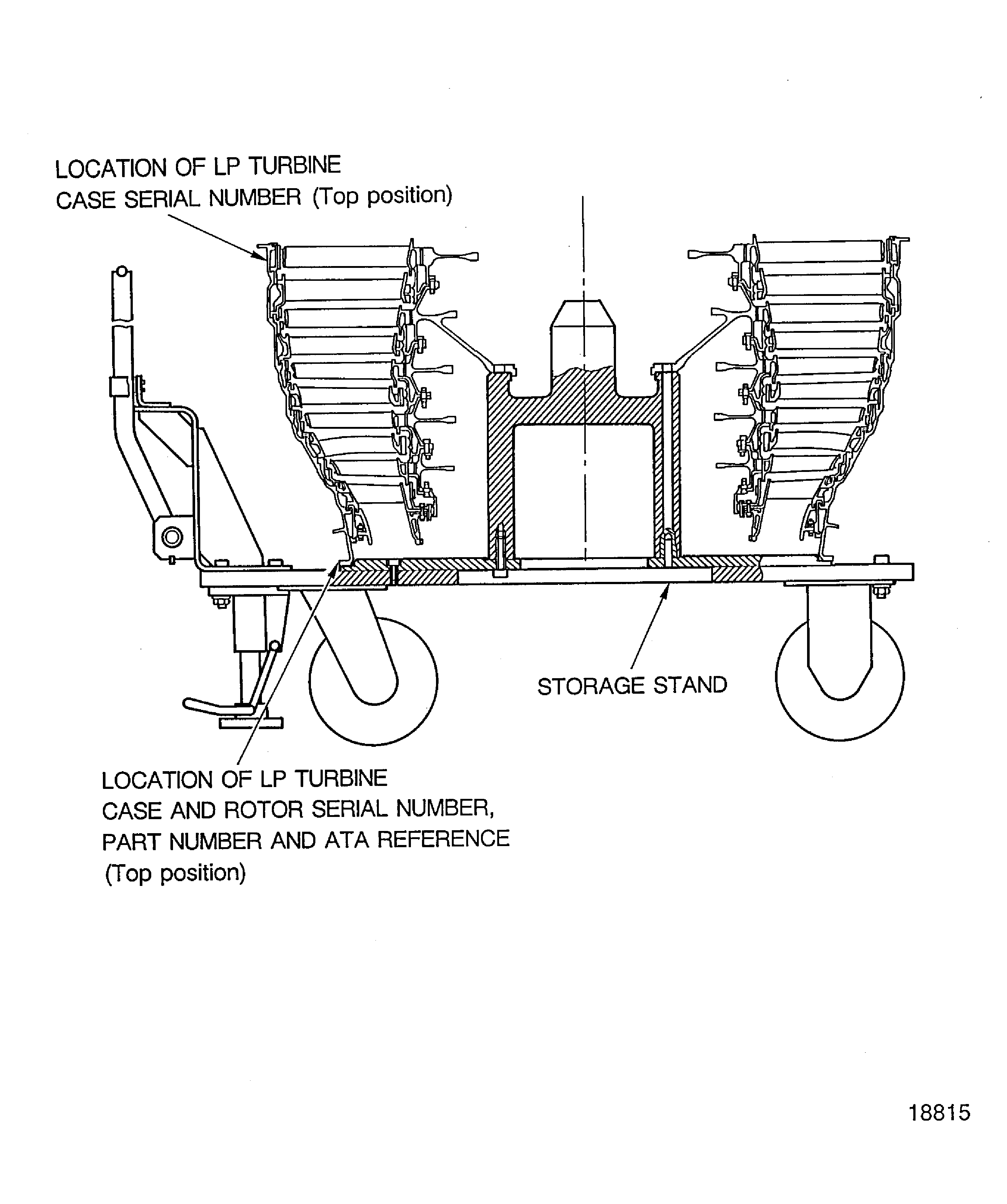

Place the IAE 1M14009 Storage stand 1 off near to the installation stand.

SUBTASK 72-50-10-430-180 Install the Front Balancing Fixture on to the Installation Stand

CAUTION

SAFETY THE IAE 1M14045 Installation stand 1 OFF WITH THE FLOOR LOCK.Install the IAE 1J12283 Expanding heater 1 off on to the arbor flange.

Increase the temperature of the arbor flange with the expanding heater to get a maximum temperature of 248.0 deg F (120.0 deg C). Increase the temperature for 15 minutes. Use the IAE 6F10027 Heater control unit 1 off.

SUBTASK 72-50-10-430-181 Increase the Temperature of the Arbor Flange with the Expanding Heater

Engage the IAE 1M14000 Lifting fixture 1 off on to the IAE 1M14001 Support fixture 1 off. Turn back the three guide sleeves, part of the lifting fixture, until the support fixture touches the lifting fixture.

SUBTASK 72-50-10-430-297 Install the Support Fixture into the Lifting Fixture

Refer to: Figure

Use a hoist equipment and lift the assembled fixture with the chain shackles. Install the IAE 1M14125 Guide pin 1 off on to the assembled fixture.

SUBTASK 72-50-10-430-298 Install the Assembled Fixture on to the LP Turbine Case and Rotor

Refer to: Figure

SUBTASK 72-50-10-430-185 Install the LP Turbine Case and Rotor on to the Front Balancing Fixture

CAUTION

MAKE SURE THAT THE LP TURBINE INNER DIFFUSER SUPPORT FIXTURE ON THE FRONT BALANCING FIXTURE IS IN THE RETRACTED POSITION. THE KNURLED SCREW MUST BE TIGHTENED AS FAR AS POSSIBLE INTO THE SPECIAL NUT. WITHOUT THIS PROCEDURE, THE LP TURBINE DIFFUSER CAN BE DAMAGED DURING INSTALLATION ON THE FRONT BALANCING FIXTURE.Refer to: Figure

Turn the IAE 1M14012 Hydraulic puller- pusher 1 off in to the front balancing fixture.

Install the flange, part of the IAE 1M14057 Hydraulic basic fixture 1 off. The word ASSEMBLY is up.

SUBTASK 72-50-10-430-186 Install the Hydraulic Basic Fixture on to the Front Balancing Fixture

Connect the IAE 1F10026 Hydraulic hand pump 1 off to the hydraulic basic fixture.

SUBTASK 72-50-10-430-187 Press the Stage 6 Disk on to the Arbor Flange of the Front Balancing Fixture

Refer to: Figure

SUBTASK 72-50-10-430-188 Remove the Hydraulic Basic Fixture

Refer to: Figure

SUBTASK 72-50-10-430-190 Attach the LP Turbine Case Front Flange on to the Front Balancing Fixture

Refer to: Figure

Use CoMat 02-129 MARKER. Make a mark to the arbor flange, part of the front balancing fixture, and the stage 6 disk flange to identify the assembly position.

SUBTASK 72-50-10-430-191 Attach the Stage 6 Disk on to the Arbor Flange of the Front Balancing Fixture

Refer to: Figure

Remove the hand knob and the washer which secure the IAE 1M14047 Rear balancing flange 1 off to the installation stand.

Use hoist equipment and the IAE 1F10052 Two cables sling 1 off. Remove the rear balancing flange from the installation stand.

SUBTASK 72-50-10-430-192 Install the Rear Balancing Flange on to the LP Turbine Case Rear Flange

Use a second hoist equipment. Attach a second IAE 1F10052 Two cables sling 1 off on the trunnion spools of the front balancing fixture.

SUBTASK 72-50-10-430-194 Install the LP Turbine Case and Rotor into the Bearing Pedestals

Attach the link shaft to the drive flange, part of the front balancing fixture, with the six hex head cap screws. Tighten the screws. Use CoMat 02-129 MARKER. Identify on the link shaft and the arbor shaft the assembly position.

SUBTASK 72-50-10-430-195 Attach the Link Shaft to the Balancing Machine and to the Front Balancing Fixture

Use two hoist equipments and the IAE 1F10052 Two cables sling 2 off.

SUBTASK 72-50-10-430-198 Remove the LP Turbine Case and Rotor from the Bearing Pedestals

Refer to: Figure

SUBTASK 72-50-10-430-199 Attach the Front Balancing Fixture in to the Installation Stand

Refer to: Figure

SUBTASK 72-50-10-430-200 Remove the Rear Balancing Flange from the LP Turbine Case Rear Flange

Refer to: Figure

SUBTASK 72-50-10-430-201 Remove the Nuts from the Arbor Flange of the Front Balancing Fixture

Refer to: Figure

SUBTASK 72-50-10-430-202 Remove the Bolts from the LP Turbine Case Front Flange

Refer to: Figure

SUBTASK 72-50-10-430-203 Install the Assembled Fixture on to the LP Turbine Case and Rotor

CAUTION

MAKE SURE THE SUPPORT FIXTURE IS CORRECTLY LOCKED ON THE LIFTING FIXTURE. IF THE FIXTURES ARE NOT CORRECTLY LOCKED, THE LP TURBINE CASE AND ROTOR PARTS CAN BE DAMAGED DURING HANDLING OF THE LP TURBINE ASSEMBLY.Refer to: Figure

Turn the IAE 1M14012 Hydraulic puller- pusher 1 off into the front balancing fixture.

Install the flange, part of the IAE 1M14057 Hydraulic basic fixture 1 off. The word DISASSEMBLY is up.

SUBTASK 72-50-10-430-204 Install the Hydraulic Basic Fixture on to the Front Balancing Fixture

Connect the IAE 1F10026 Hydraulic hand pump 1 off to the hydraulic basic fixture.

SUBTASK 72-50-10-430-205 Remove the LP Turbine Case and Rotor from the Front Balancing Fixture

CAUTION

MAKE SURE THAT THE LP TURBINE INNER DIFFUSER SUPPORT FIXTURE ON THE FRONT BALANCING FIXTURE IS IN THE RETRACTED POSITION. THE KNURLED SCREW MUST BE TIGHTENED AS FAR AS POSSIBLE INTO THE SPECIAL NUT. WITHOUT THIS PROCEDURE, THE LP TURBINE INNER DIFFUSER CAN BE DAMAGED DURING REMOVAL FROM THE FRONT BALANCING FIXTURE.Refer to: Figure

SUBTASK 72-50-10-430-206 Remove the Hydraulic Basic Fixture

Refer to: Figure

SUBTASK 72-50-10-430-207 Remove the LP Turbine Case and Rotor with the Assembled Fixture from the Installation Stand

Install the IAE 1J12283 Expanding heater 1 off on to the arbor flange.

Increase the temperature of the arbor flange with the expanding heater to get a maximum temperature of 248.0 deg F (120.0 deg C). Increase the temperature for 15 minutes. Use the IAE 6F10027 Heater control unit 1 off.

SUBTASK 72-50-10-430-209 Increase the Temperature of the Arbor Flange with the Expanding Heater

Refer to: Figure

SUBTASK 72-50-10-430-212 Install the LP Turbine Case and Rotor on to the Front Balancing Fixture

CAUTION

MAKE SURE THAT THE LP TURBINE INNER DIFFUSER SUPPORT FIXTURE ON THE FRONT BALANCING FIXTURE IS IN THE RETRACTED POSITION. THE KNURLED SCREW MUST BE TIGHTENED AS FAR AS POSSIBLE INTO THE SPECIAL NUT. WITHOUT THIS PROCEDURE, THE LP TURBINE INNER DIFFUSER CAN BE DAMAGED DURING INSTALLATION ON THE FRONT BALANCING FIXTURE.Refer to: Figure

Turn the IAE 1M14012 Hydraulic puller- pusher 1 off into the front balancing fixture.

Install the flange, part of the IAE 1M14057 Hydraulic basic fixture 1 off. The word ASSEMBLY is up.

SUBTASK 72-50-10-430-213 Install the Hydraulic Basic Fixture on to the Front Balancing Fixture

Connect the IAE 1F10026 Hydraulic hand pump 1 off to the hydraulic basic fixture.

SUBTASK 72-50-10-430-214 Press the Stage 6 Disk on to the Arbor Flange of the Front Balancing Fixture

Refer to: Figure

SUBTASK 72-50-10-430-215 Remove the Hydraulic Basic Fixture

Refer to: Figure

SUBTASK 72-50-10-430-217 Attach the LP Turbine Case Front Flange on to the Front Balancing Fixture

Refer to: Figure

SUBTASK 72-50-10-430-218 Attach the Stage 6 Disk on to the Arbor Flange of the Front Balancing Fixture

Refer to: Figure

Use the hoist equipment and the IAE 1F10052 Two cables sling 1 off. Remove the rear balancing flange from the installation stand.

Lift the IAE 1M14047 Rear balancing flange with the two cables sling above the LP turbine case.

SUBTASK 72-50-10-430-219 Install the Rear Balancing Flange on to the LP Turbine Case Rear Flange

Refer to: Figure

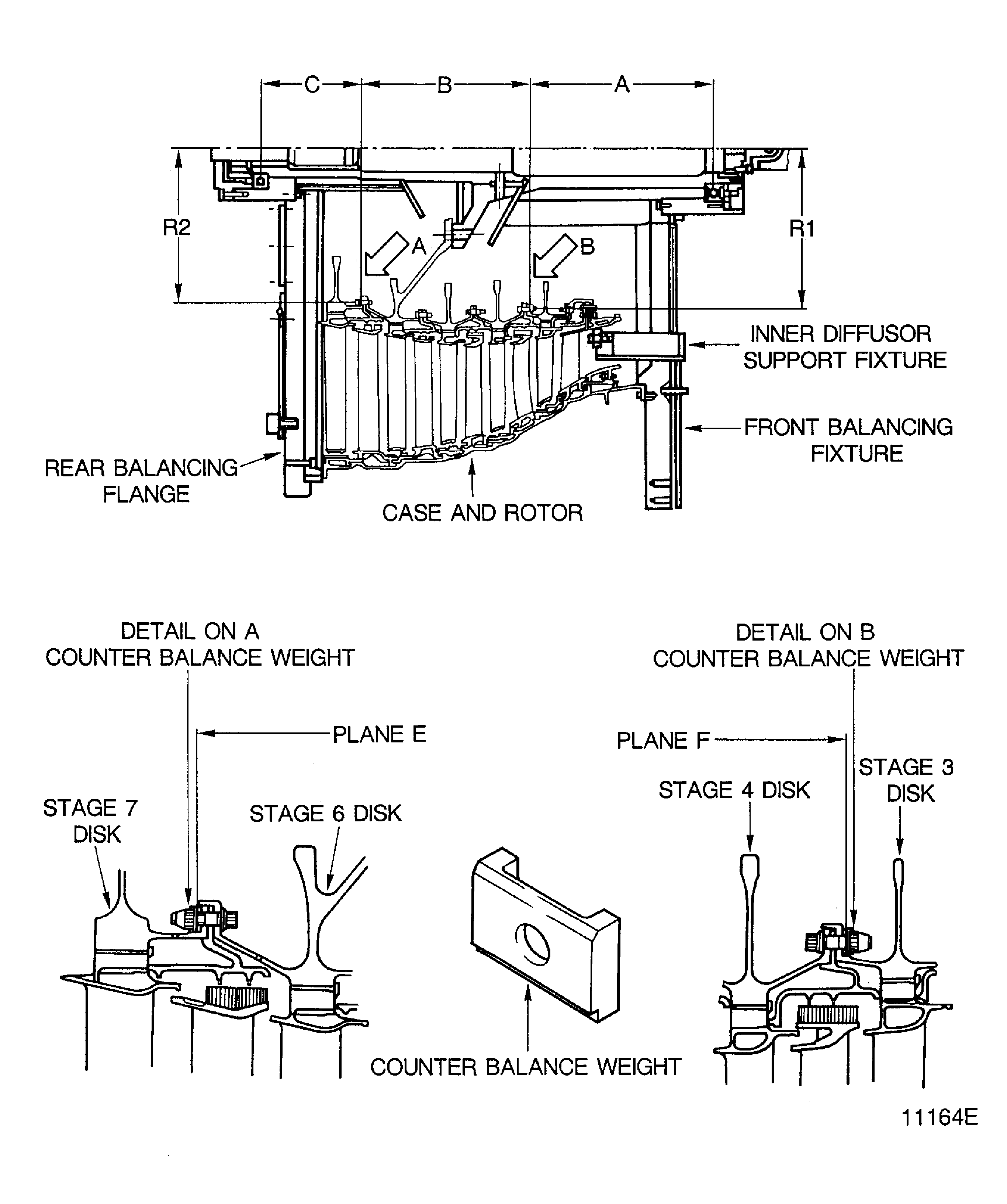

SUBTASK 72-50-10-430-300 Adjust the Dimensions of the LP Turbine Case and Rotor

Use a second hoist equipment. Attach a second IAE 1F10052 Two cables sling 1 off on the trunnion spools of the front balancing fixture.

SUBTASK 72-50-10-430-220 Install the LP Turbine Case and Rotor in to the Bearing Pedestals

Refer to: Figure

NOTE

The initial unbalance must not be more than 12 ozin (8640 gmm) per plane. The initial unbalance must not be more than 6 ozin (4320 gmm) per plane if unbalance vectors are in 30 degrees of each other. The remaining unbalance must not be more than 0.40 ozin (288 gmm) per plane.

SUBTASK 72-50-10-430-222 Balance the Turbine Rotor Assembly

Add counterweights under the nuts at the stage 3 disk location (Plane E) and under the nuts at the stage 7 disk (Plane F) to correct the unbalance.

A maximum of seven washer type counterweights can be used per plane, but a maximum of five counterweights one after the other.

Refer to: Figure

Install the identified nuts at the same position as previously. Tighten the nuts. Use the IAE 1M14055 Special wrench 1 off.

NOTE

The tightening torque value includes the self locking torque value.Torque the nuts with the IAE 1M14048 Torque wrench adapter 1 off in two steps.

SUBTASK 72-50-10-430-223 Correct the Unbalance with Counterweights

CAUTION

HOLD THE BOLTS IN THEIR POSITION IF YOU LOOSEN AND REMOVE THE NUTS FROM THE BOLTS. DO NOT TURN THE BOLTS OR MAKE TO-AND-FRO MOVEMENTS. THE DISK/INNER AIR SEAL FLANGES AND/OR THE BOLTS CAN BE DAMAGED BY SCORES. DO THE SAME PROCEDURE IF YOU INSTALL THE NUTS ON TO THE BOLTS.NOTE

Do the check for the remaining unbalance, refer to Step steps B., C., D. and E.

Remove all the identification marks and high point position marks in the rotor drum. Use CoMat 02-069 DISPOSABLE CLEANING TISSUESs or clean cloth and CoMat 01-031 ACETONE (CH3)2CO.

SUBTASK 72-50-10-430-301 Do the Check for the Remaining Unbalance

NOTE

If the remaining unbalance is more than 0.40 ozin (288 gmm) per plane, correct the unbalance as per Step.Use two hoist equipments and the IAE 1F10052 Two cables sling 2 off.

SUBTASK 72-50-10-430-225 Remove the LP Turbine Case and Rotor from the Bearing Pedestals

Refer to: Figure

SUBTASK 72-50-10-430-226 Attach the Front Balancing Fixture in to the Installation Stand

Refer to: Figure

SUBTASK 72-50-10-430-227 Remove the Rear Balancing Flange from the LP Turbine Case Rear Flange

Refer to: Figure

SUBTASK 72-50-10-430-228 Remove the Nuts from the Arbor Flange of the Front Balancing Fixture

Refer to: Figure

SUBTASK 72-50-10-430-229 Remove the Bolts from the LP Turbine Case Front Flange

Refer to: Figure

SUBTASK 72-50-10-430-230 Install the Assembled Fixture on to the LP Turbine Case and Rotor

CAUTION

MAKE SURE THE SUPPORT FIXTURE IS CORRECTLY LOCKED ON THE LIFTING FIXTURE. IF THE FIXTURES ARE NOT CORRECTLY LOCKED, THE LP TURBINE CASE AND ROTOR PARTS CAN BE DAMAGED DURING HANDLING OF THE LP TURBINE ASSEMBLY.Refer to: Figure

Turn the IAE 1M14012 Hydraulic puller- pusher 1 off into the front balancing fixture.

Install the flange, part of the IAE 1M14057 Hydraulic basic fixture 1 off. The word DISASSEMBLY is up.

SUBTASK 72-50-10-430-231 Install the Hydraulic Basic Fixture on to the Front Balancing Fixture

Connect the IAE 1F10026 Hydraulic hand pump 1 off to the hydraulic basic fixture.

SUBTASK 72-50-10-430-232 Pull off the Stage 6 Disk from the Arbor Flange

CAUTION

MAKE SURE THAT THE LP TURBINE INNER DIFFUSER SUPPORT FIXTURE ON THE FRONT BALANCING FIXTURE IS IN THE RETRACTED POSITION. THE KNURLED SCREW MUST BE TIGHTENED AS FAR AS POSSIBLE INTO THE SPECIAL NUT. WITHOUT THIS PROCEDURE, THE LP TURBINE INNER DIFFUSER CAN BE DAMAGED DURING REMOVAL OF THE FRONT BALANCING FIXTURE.Refer to: Figure

SUBTASK 72-50-10-430-233 Remove the Hydraulic Basic Fixture

Refer to: Figure

Put the LP turbine case and rotor on the IAE 1M14009 Storage stand 1 off.

SUBTASK 72-50-10-430-234 Remove the LP Turbine Case and Rotor with the Assembled Fixture from the Front Balancing Fixture

Refer to: Figure

Use a hoist and install the IAE 1F10052 Two cables sling 1 off to the trunnion spools of the front balancing fixture.

SUBTASK 72-50-10-430-236 Remove the Front Balancing Fixture from the Installation Stand

Refer to: Figure

NOTE

The LP turbine case and rotor assemblies are identified by a serial number, part number and the ATA reference 72-50-10. The identification marks are on the LP turbine case front flange outer diameter in the TOP position. During production assembly, the LP turbine case and rotor assemblies are identified by the same serial number as the LP turbine case serial number. The serial number of the LP turbine case is on the rear end of the LP turbine case in the TOP position.

After overhaul of the LP turbine case and rotor, the new assembly must be identified by the serial number of the original LP turbine case and rotor assembly.

If a new LP turbine case is used, vibro-peen the serial number, the part number and the ATA reference 72-50-10 from off the old LP turbine case and rotor assembly on to the new LP turbine case front flange outer diameter in the TOP position. Refer to the SPM TASK 70-09-00-400-501 and to Figure.

If a LP turbine case from a different original LP turbine case and rotor assembly is used, cross out the serial number. Vibro-peen the correct serial number adjacent to the old identification mark. Refer to the SPM TASK 70-09-00-400-501 and to Figure.

Identify the LP turbine case and rotor assembly as follows:

SUBTASK 72-50-10-430-244 Identify the LP Turbine Case and Rotor

Figure: Press on and Pull off the LP Turbine Rotor Assembly

Press on and Pull off the LP Turbine Rotor Assembly

Figure: Balancing Tools for the LP Turbine Assembly

Balancing Tools for the LP Turbine Assembly

Figure: Balancing of the LP Turbine Assembly

Balancing of the LP Turbine Assembly

Figure: Counterweights for Balance of the LP Turbine Assembly

Counterweights for Balance of the LP Turbine Assembly

Figure: Identify the LP Turbine Case and Rotor

Identify the LP Turbine Case and Rotor