Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-50-22-300-018 LPT Stage 5 Vane - Replace The Locating Key, Repair-018 (VRS4056)

Material of component

DESCRIPTION | RR SYMBOL | MATERIAL |

Stage 3 turbine vane | Inconel 713C | |

Locating key | Hastelloy X |

General

Price and availability - none

The practices and processes referred to in the procedure by the TASK number are in the SPM.

NOTE

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Dial caliper | LOCAL | Dial caliper | ||

| Radius gage set | LOCAL | Radius gage set | ||

| Vernier caliper | LOCAL | Vernier caliper | ||

| IAE 3M14272 Clamping fixture | 0AM53 | IAE 3M14272 | 1 | |

| IAE 3M14540 Fixture, Grinding | 0AM53 | IAE 3M14540 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-151 HIGH TEMP. BRAZING FILLERPOWDER | LOCAL | CoMat 03-151 | ||

| CoMat 03-227 WHITE STOP OFF | D3309 | CoMat 03-227 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Locating Key | 3A0002 | 1 |

Safety Requirements

NONEProcedure

Use IAE 3M14540 Fixture, Grinding 1 off.

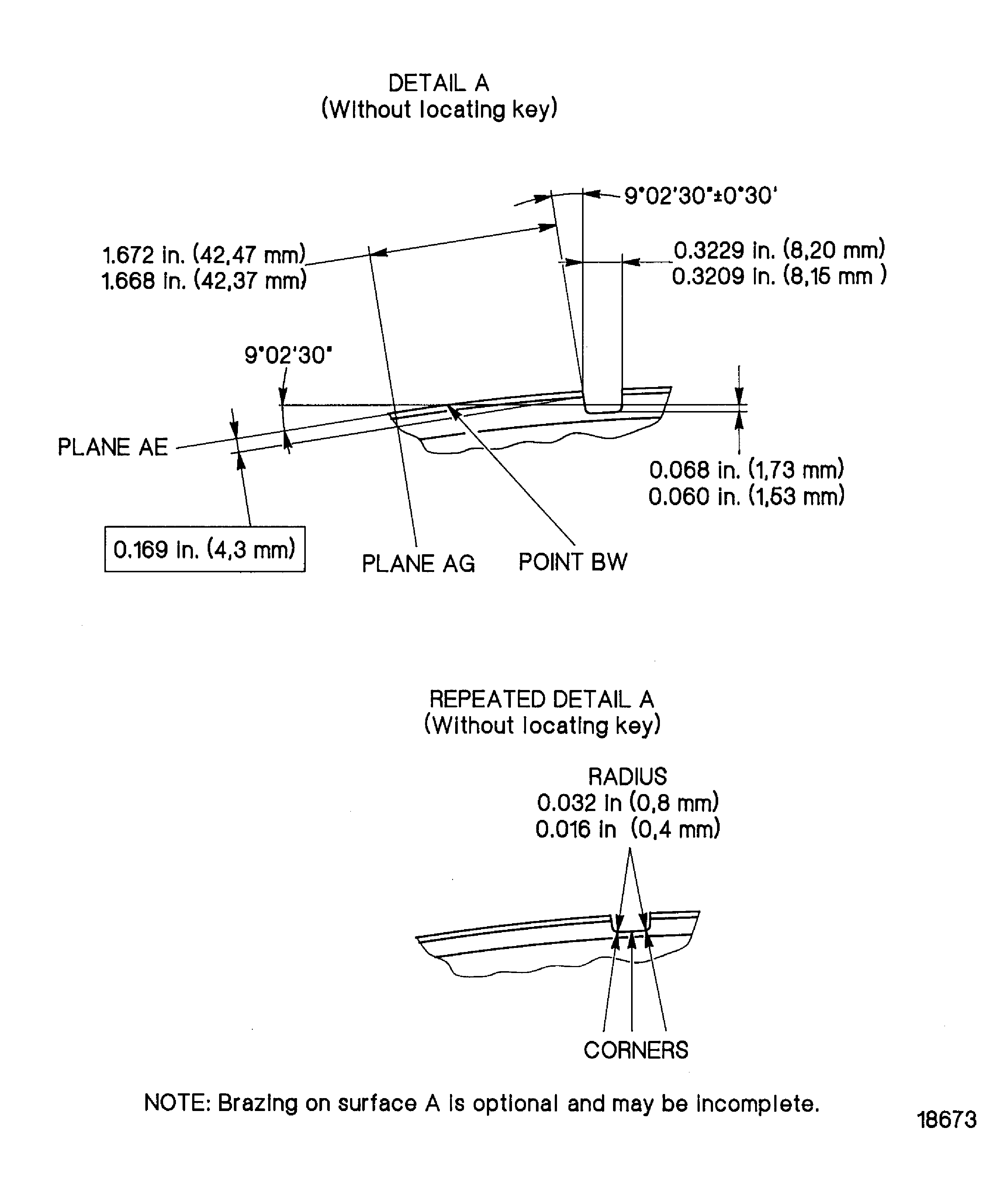

Electrical discharge machine according to the SPM TASK 70-32-03-320-501 is permitted. Refer to Figure. Do not remove parent material. To get the slot dimensions traces of braze may stay.

Machine off the worn locating key.

SUBTASK 72-50-22-326-053 Remove the Worn Locating Key

Refer to the SPM TASK 70-11-01-300-503.

Vapor degrease.

SUBTASK 72-50-22-110-072 Clean the Turbine Vane

For dimensions refer to Figure. Use radius gage set and dial caliper.

Dimensionally examine the machined areas.

SUBTASK 72-50-22-220-118 Examine the Turbine Vane

Refer to the SPM TASK 70-23-05-230-501. No cracks are permitted.

Do the test for cracks.

SUBTASK 72-50-22-230-071 Examine the Machined Surfaces for Cracks

Refer to the SPM TASK 70-11-01-300-503.

Vapor degrease.

SUBTASK 72-50-22-110-073 Clean the Turbine Vane

Nickel plate is permitted to make the following braze cycle easier. Refer to the SPM TASK 70-33-06-300-503.

Make sure that the coating thickness is 0.0001 to 0.0003 in. (0.003 to 0.008 mm).

Nickel plate the connecting surfaces if necessary.

SUBTASK 72-50-22-330-053 Nickel Plate the Machined Surfaces

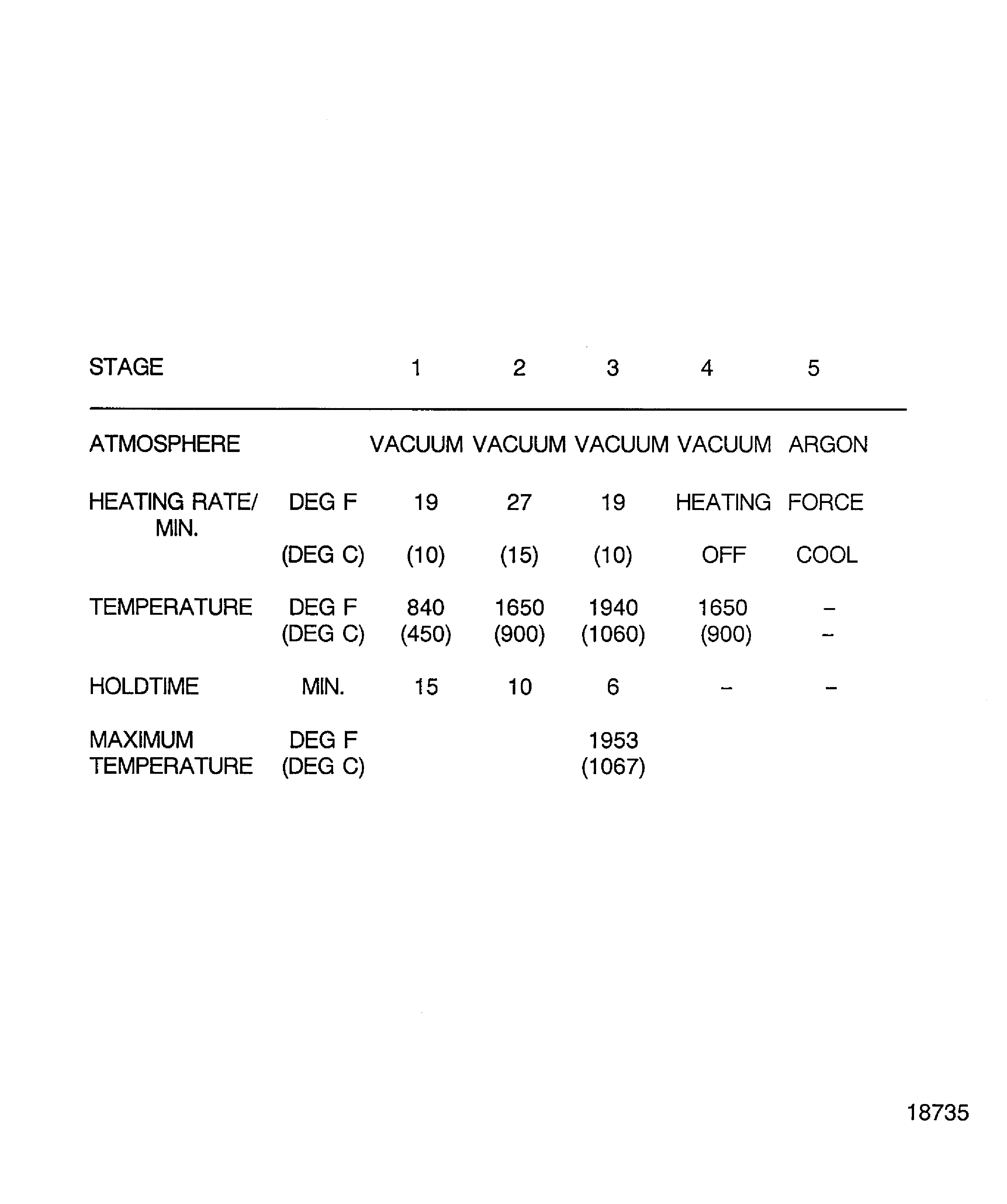

Clamp the locating key to prevent movement. Use IAE 3M14272 Clamping fixture 1 off. Spot welding of locating key to facilitate brazing is permitted. Use CoMat 03-151 HIGH TEMP. BRAZING FILLERPOWDER and CoMat 03-227 WHITE STOP OFF. For braze cycles refer to Figure and to the SPM TASK 70-31-09-310-501.

Braze the locating key in position.

SUBTASK 72-50-22-310-059 Braze in the New Locating Key

Refer to the SPM TASK 70-11-01-300-503.

Vapor degrease.

SUBTASK 72-50-22-110-074 Clean the Turbine Vane

Refer to the SPM TASK 70-31-09-310-501. Remove too much braze material.

Examine the reworked areas for completed braze.

For finish dimensions refer to Figure. Use dial caliper and vernier caliper.

Dimensionally examine the new locating key.

SUBTASK 72-50-22-220-119 Do the Post Repair Inspection

Refrer to the SPM TASK 70-23-04-230-501 or SPM TASK 70-23-08-230-501. No cracks are permitted.

Do the test for cracks.

SUBTASK 72-50-22-230-081 Do the Post Repair Inspection for Cracks

Refer to the SPM TASK 70-31-07-310-501 for acceptance standards.

Visually examine the honeycomb for completed braze.

SUBTASK 72-50-22-220-120 Examine the Honeycomb Braze Condition

Figure: Replace the locating key of the turbine vane

Replace the locating key of the turbine vane

Figure: Replace the locating key of the turbine vane

Replace the locating key of the turbine vane

Figure: Braze cycles to braze in the locating key

Braze cycles to braze in the locating key