Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-50-24-300-002 LPT Inner Diffuser Duct Segment - Replace The Air Seal, Repair-002 (VRS4065)

General

Price and availability - none

The practices and processes referred to in the procedure by the TASK number are in the SPM.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-148 BRAZING FILLER POWDER | LOCAL | CoMat 03-148 | ||

| CoMat 03-151 HIGH TEMP. BRAZING FILLERPOWDER | LOCAL | CoMat 03-151 | ||

| CoMat 03-227 WHITE STOP OFF | D3309 | CoMat 03-227 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Air seal | 3A2429 | 1 |

Safety Requirements

NONEProcedure

Electrical discharge machine according to the SPM TASK 70-32-03-320-501 is permitted.

Refer to Figure.

Do not remove parent material.

Traces of braze can stay to get required dimension.

Machine off the worn air seal.

SUBTASK 72-50-24-325-057 Remove the Worn Air Seal

Refer to the SPM TASK 70-11-34-300-503.

Aqueous degrease.

SUBTASK 72-50-24-110-076 Clean the Inner Duct Segment

Refer to Figure.

Use CoMat 03-151 HIGH TEMP. BRAZING FILLERPOWDER, CoMat 03-148 BRAZING FILLER POWDER and CoMat 03-227 WHITE STOP OFF.

Braze run-off in location X is permitted.

For braze cycles refer to TASK 70-31-07-310-501.

Vacuum-braze the air seal in position.

SUBTASK 72-50-24-310-056 Braze in the New Air Seal

Refer to the SPM TASK 70-11-34-300-503.

Aqueous degrease.

SUBTASK 72-50-24-110-077 Clean the Inner Duct Segment

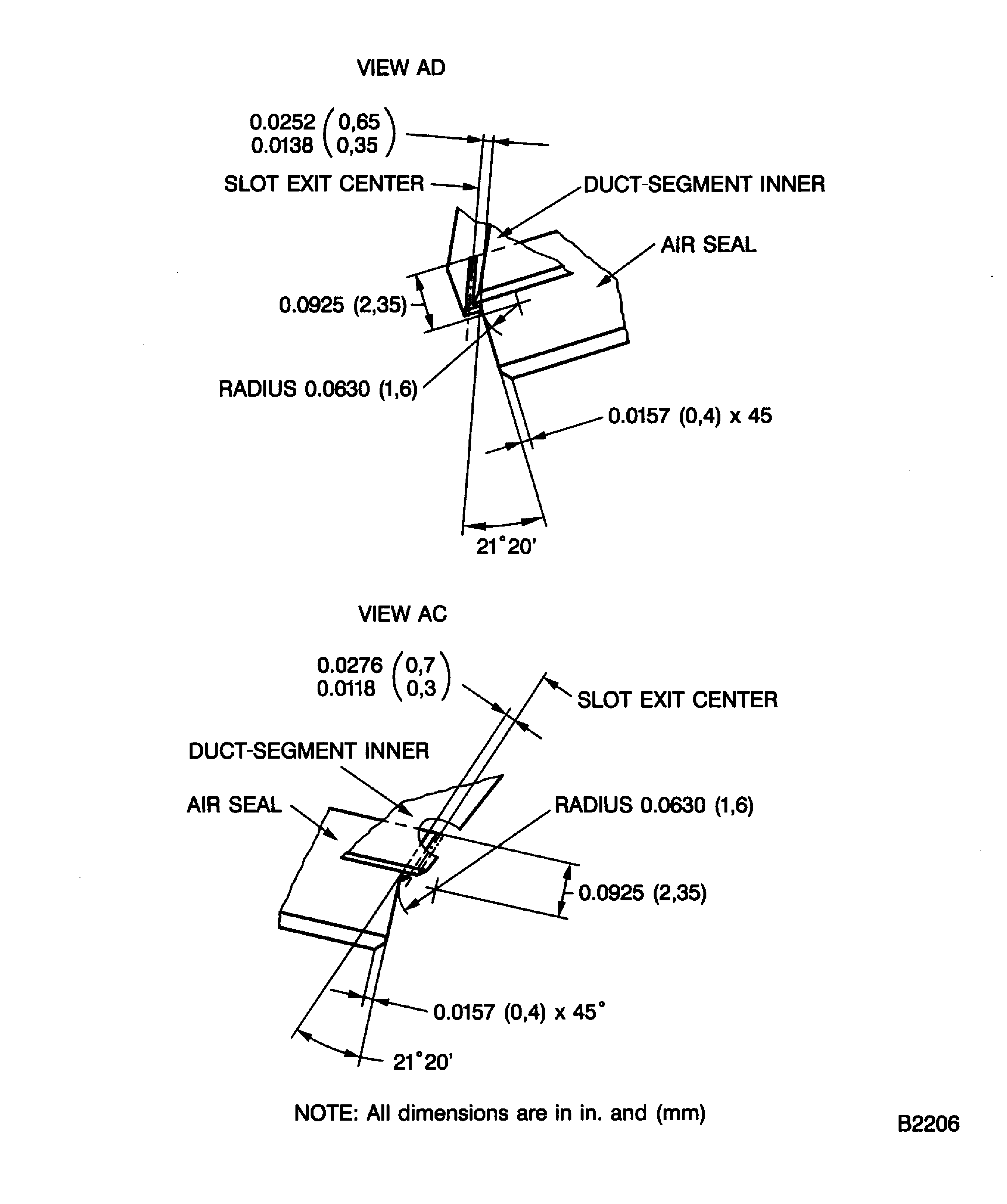

Refer to Figure for finishing dimension.

Machine inner duct.

SUBTASK 72-50-24-350-063 Machine the Inner Duct after Brazing

Refer to the finished dimensions in Figure.

Dimensionally examine.

SUBTASK 72-50-24-220-109 Examine the Brazed Air Seal

Refer to the SPM TASK 70-31-07-310-501 for acceptance standards.

Visually examine the honeycomb for completed braze.

SUBTASK 72-50-24-220-110 Examine the Honeycomb Braze Condition

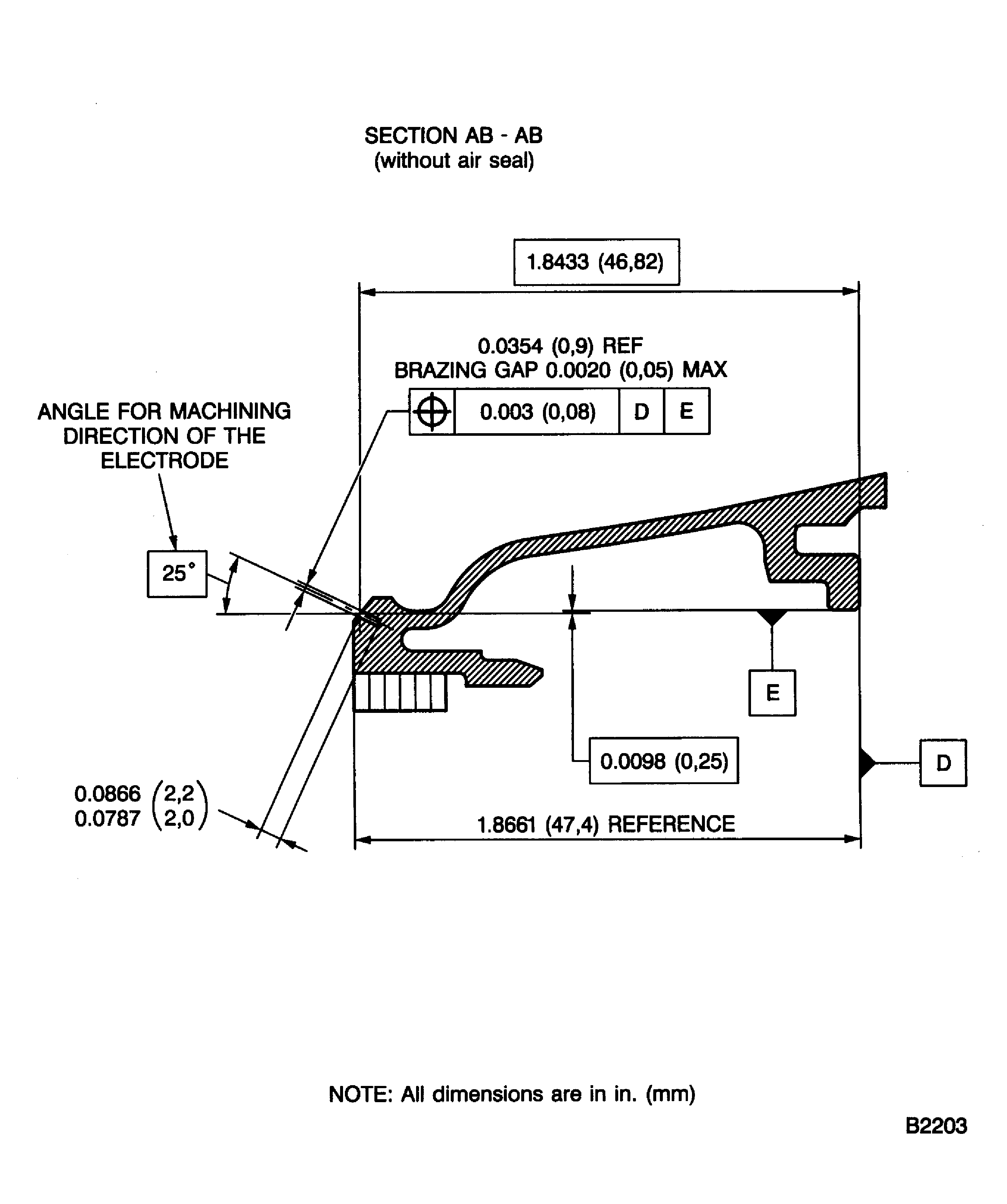

Figure: Dimensions for machining the air seal of the inner duct

Dimensions for machining the air seal of the inner duct

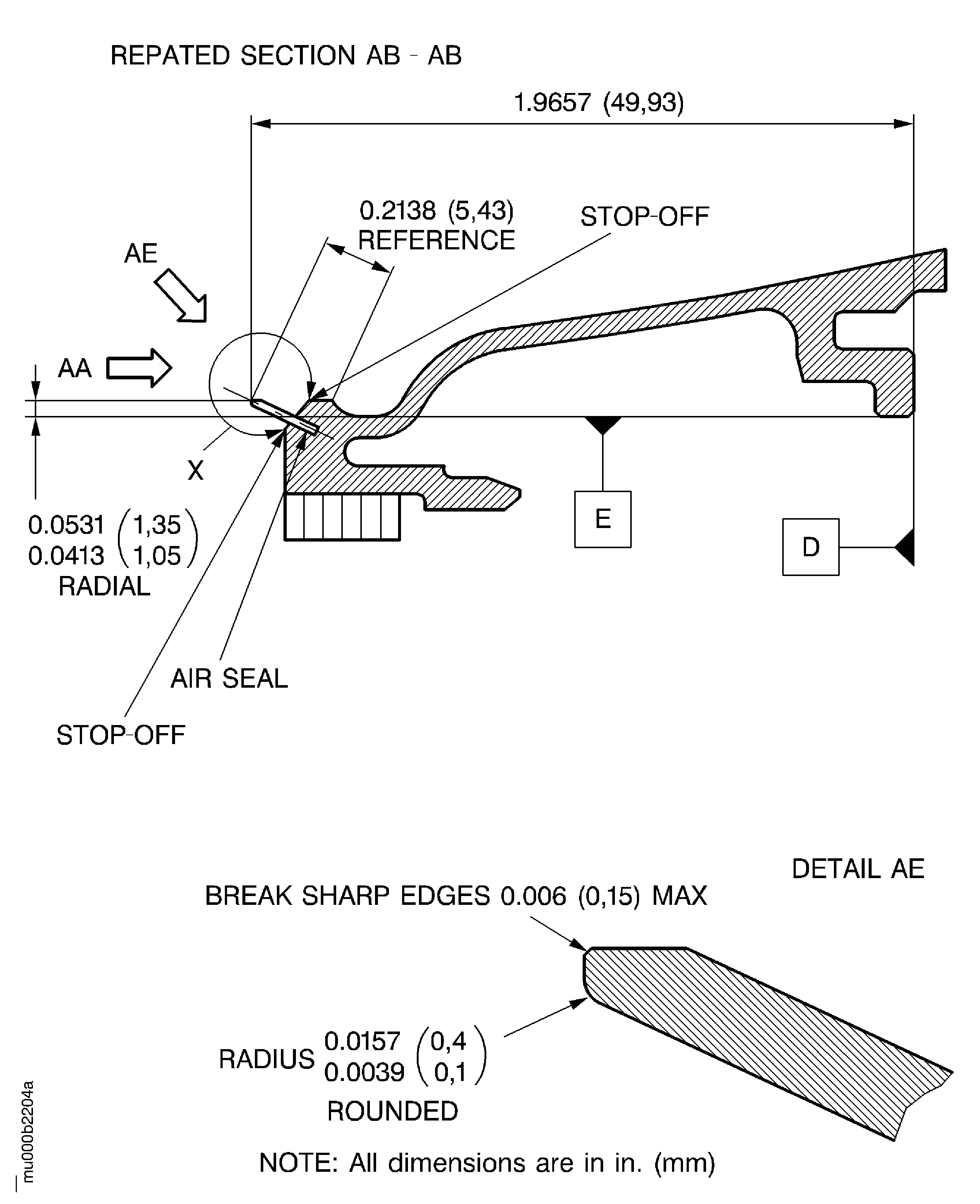

Figure: Brazing and examination limits for the new air seal of the inner duct

Sheet 1

Figure: Brazing and examination limits for the new air seal of the inner duct

Sheet 2

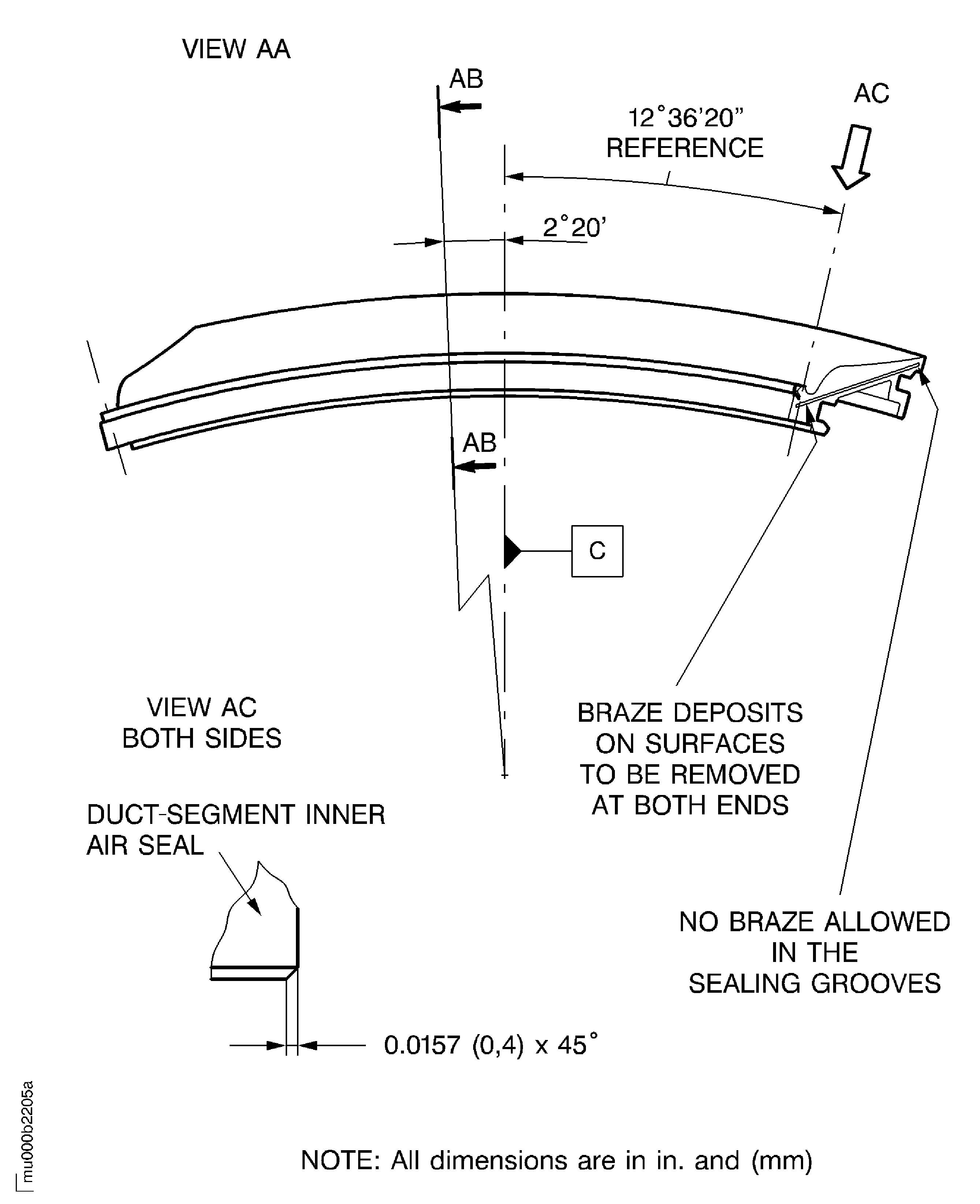

Figure: Brazing and examination limits for the new air seal of the inner duct

Brazing and examination limits for the new air seal of the inner duct

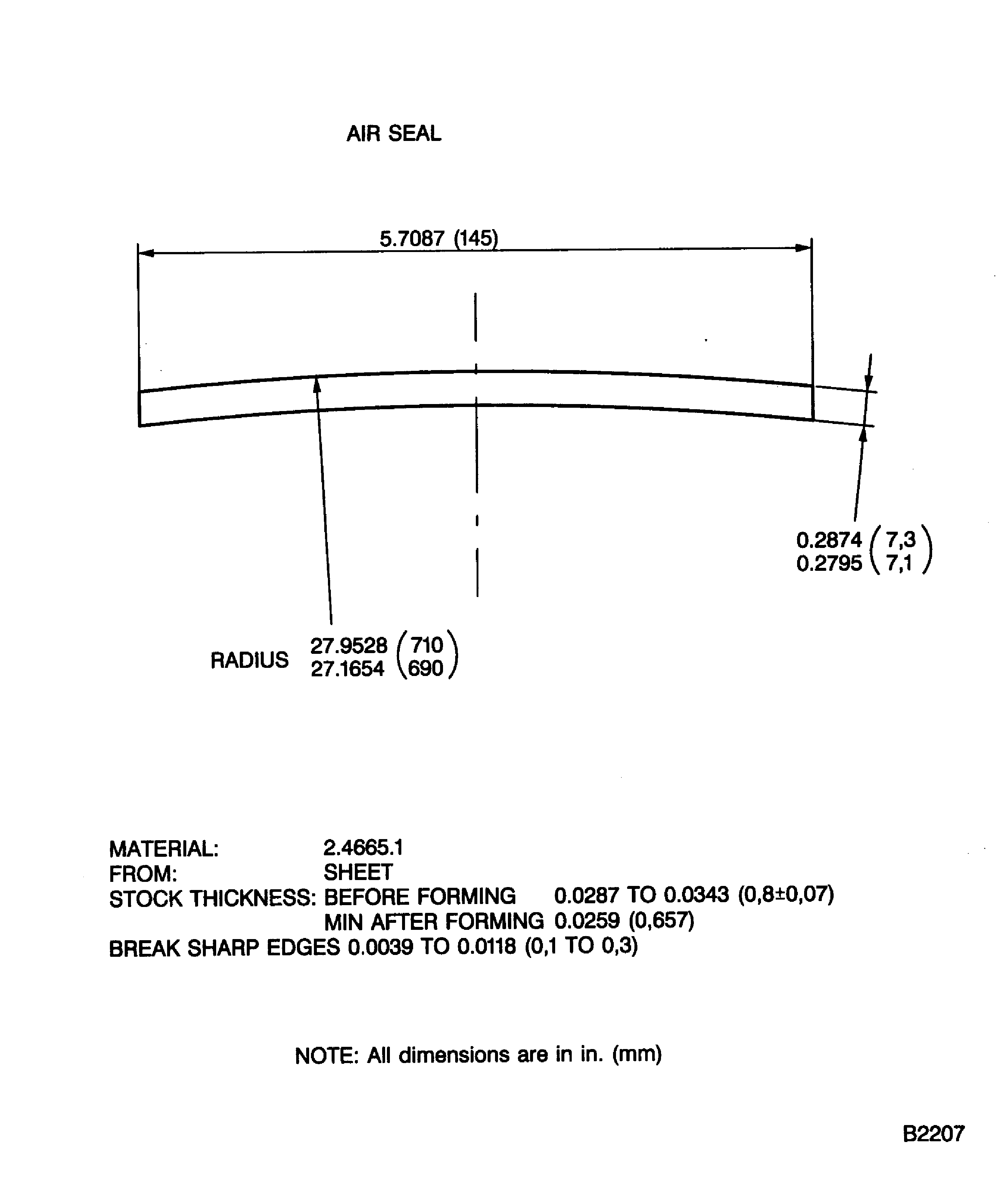

Figure: Repair Part new air seal of the inner duct

Repair Part new air seal of the inner duct