DMC:V2500-A0-72-50-2401-01A-609A-CIssue No:002.00Issue Date:2013-11-01

Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-50-24-300-004 LPT Inner Diffuser Duct Segment - Touch-Up Coating After Blend Repair, Repair-004 (VRS4111)

General

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

Price and availability - none

NOTE

For equipment and materials necessary to do this repair refer to the SPM TASK 70-38-14-380-501, SPM TASK 70-09-00-400-501.

Equivalent equipment may be used.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Furnace | LOCAL | Furnace | ||

| Illuminated comparator magnifier | LOCAL | Illuminated comparator magnifier | ||

| Vibrating marking pencil | LOCAL | Vibrating marking pencil | ||

| Vapor blast cabinet | LOCAL | Vapor blast cabinet |

Consumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

Refer to the SPM TASK 70-38-14-380-501.

Do the touch-up coating.

SUBTASK 72-50-24-380-052 Touch-Up Coating after Blend Repair of the Inner Duct Segment

NOTE

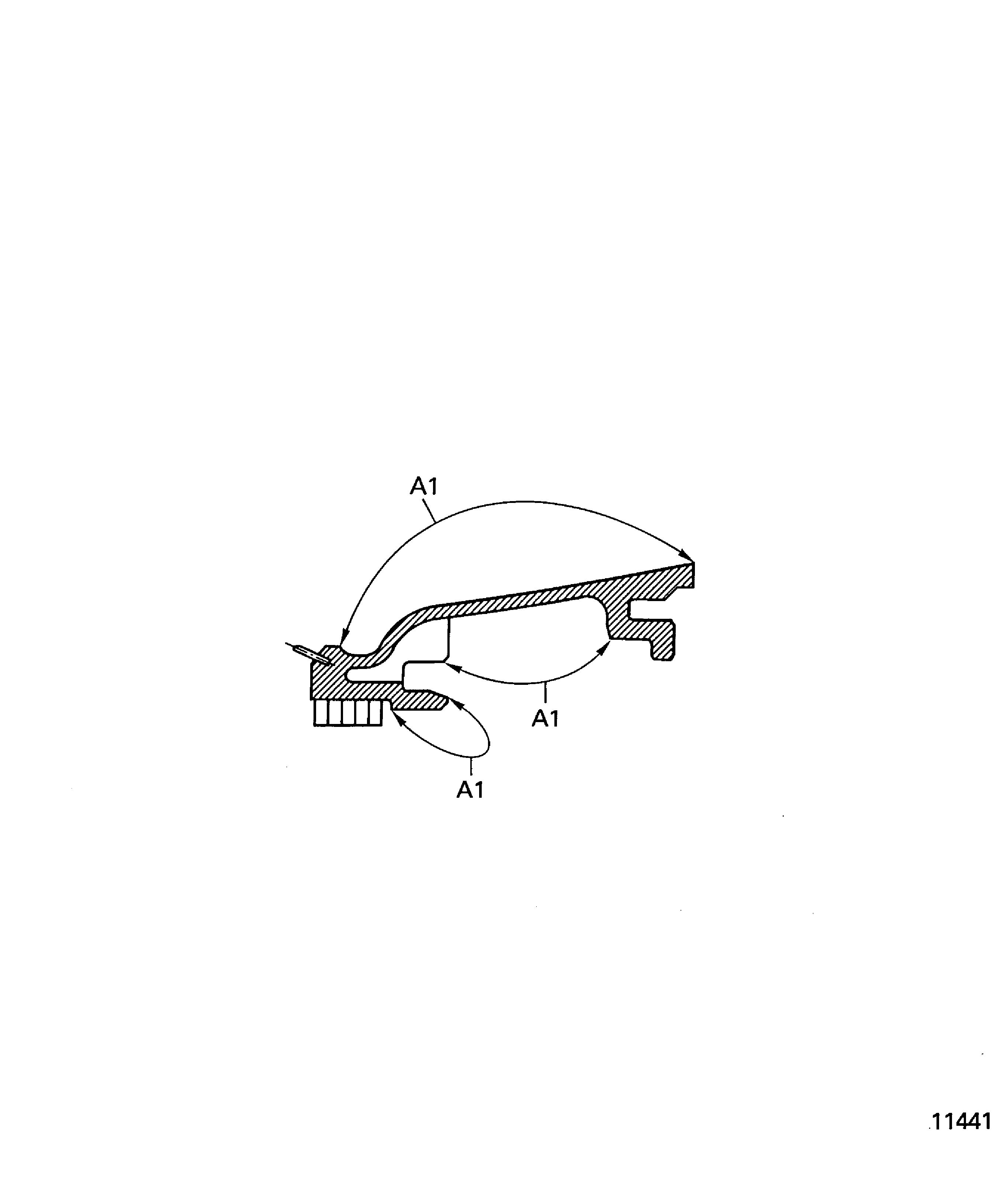

This repair is only permitted in conjunction with Repair VRS4110, TASK 72-50-24-300-003 (REPAIR-003).If the coating is badly damaged, then refer to Repair, VRS4116, TASK 72-50-24-300-010 (REPAIR-010) or Repair, VRS4117, TASK 72-50-24-300-011 (REPAIR-011).If honeycomb Repair VRS4115, TASK 72-50-24-300-009 (REPAIR-009) is to be carried out also, and the honeycomb segment is already removed, then standard diffusion heat treatment temperature at between 1950 and 2000 deg F (1066 and 1094 deg C) can be used.Touch-up is only permitted in area A1, refer to Figure.Refer to the SPM TASK 70-38-14-380-501 except diffusion heat treatment at between 1575 and 1625 deg F (857 and 885 deg C).

Use a furnace.

Diffuse the coated inner duct segment by heat treatment.

SUBTASK 72-50-24-370-051 Diffusion Heat Treatment of the Coated Inner Duct Segment

Refer to the SPM TASK 70-09-00-400-501.

Position the touch-up symbol (T) adjacent to the part number.

Use the vibration-peening method and vibration marking pencil.

Make a mark on the touched-up inner duct segment.

SUBTASK 72-50-24-380-053 Make a Mark on the Touched-Up Inner Duct Segment with a Touch-Up Symbol (T)

Figure: Touch-up coating of the inner duct segment

Touch-up coating of the inner duct segment