Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-50-24-300-056 LPT Inner Diffuser Duct Support Ring - Weld Repair Front Faces, Repair-056 (VRS4499)

General

Price and availability - none

The practices and the processes referred to in the procedure by the TASK number are in the SPM.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Turning lathe | LOCAL | Turning lathe | ||

| Grinding machine | LOCAL | Grinding machine |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-184 WELDING FILLER WIRE, NICKEL | LOCAL | CoMat 03-184 |

Spares

NONESafety Requirements

NONEProcedure

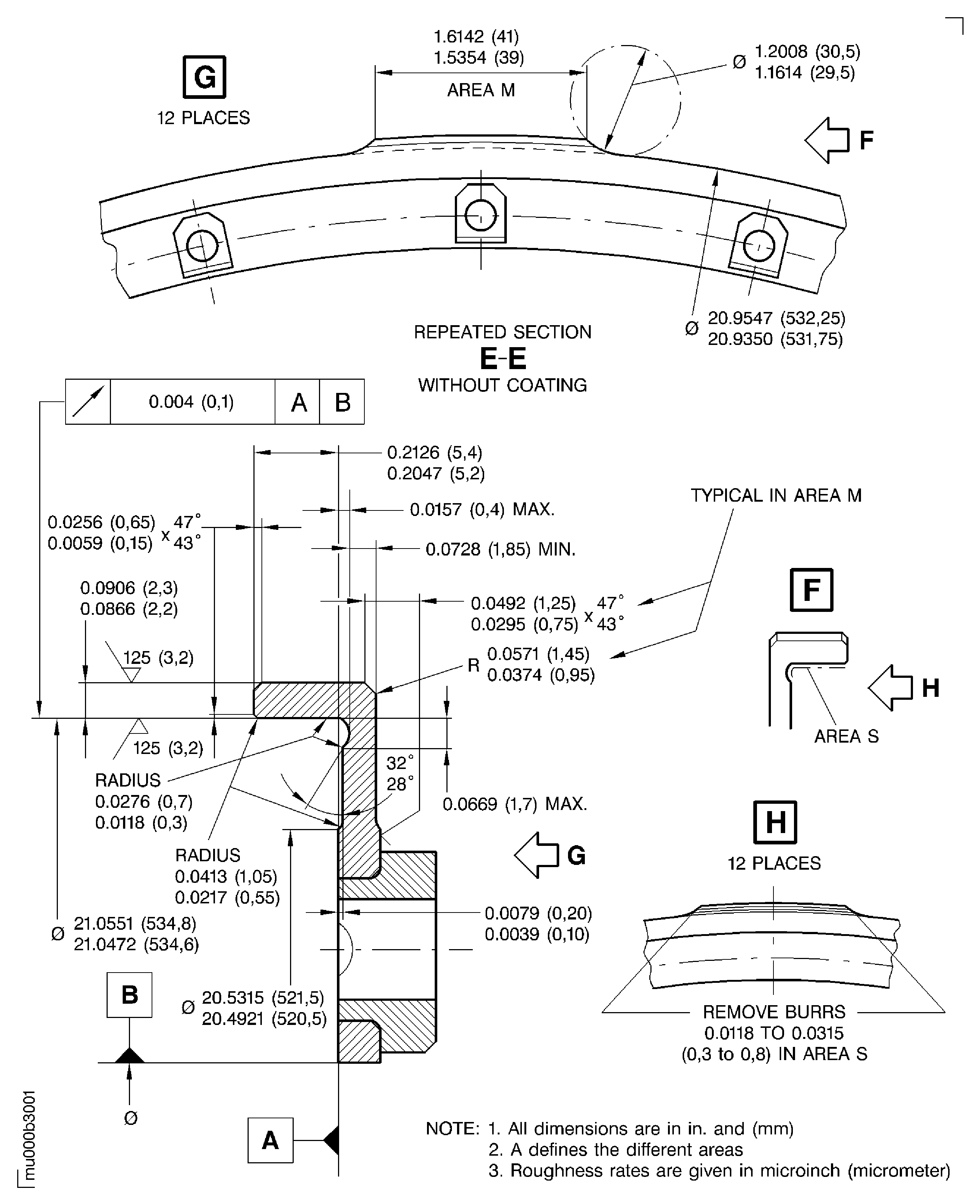

Refer to Figure.

Remove the old coating fully. Refer to VRS4309 TASK 72-50-24-300-039 (REPAIR-039).

Remove the old coating fully. Refer to VRS4466 TASK 72-50-24-300-053 (REPAIR-053).

SUBTASK 72-50-24-320-074 Remove the Coating

Refer to the SPM TASK 70-11-34-300-503.

SUBTASK 72-50-24-110-162 Clean the Support Ring Assembly

Refer to Figure.

Refer to the SPM TASK 70-31-13-310-501. Use CoMat 03-184 WELDING FILLER WIRE, NICKEL. Make sure that there is sufficient material to do last machining. To prevent distortion, several weld passes should be made. Prevent too much temperature build-up.

SUBTASK 72-50-24-310-073 Weld Repair the Support Ring Assembly

Refer to Figure.

SUBTASK 72-50-24-320-075 Machine the Welded Area

Refer to the SPM TASK 70-37-00-370-501. Put the part in an oven for eight hours at 1450 to 1500 deg F (788 to 816 deg C). Use argon or vacuum. Cooling rate equivalent to air cooling.

SUBTASK 72-50-24-370-068 Heat Treatment after Weld Repair

Refer to the SPM TASK 70-23-05-230-501. Use medium sensivity level. No cracks are permitted.

SUBTASK 72-50-24-230-121 Examine the Welded Areas for Cracks

Refer to Figure.

SUBTASK 72-50-24-220-228 Examine the Machined Areas

Refer to VRS4309 TASK 72-50-24-300-039 (REPAIR-039).

Refer to VRS4466 TASK 72-50-24-300-053 (REPAIR-053).

SUBTASK 72-50-24-350-099 Do the Post Repair

Figure: Repair Details and Dimensions

Repair Details and Dimensions

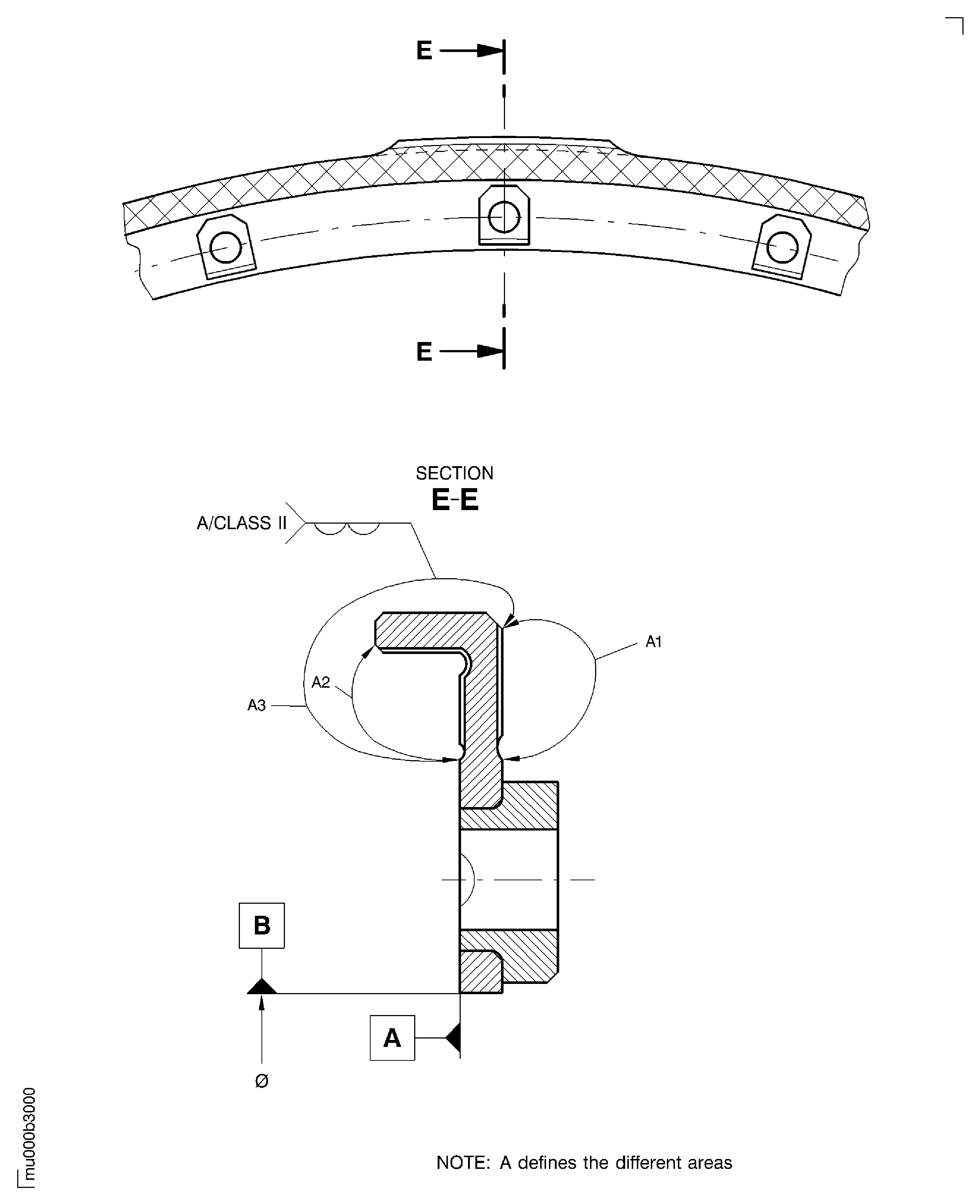

Figure: Repair Details and Dimensions

Repair Details and Dimensions