Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-50-32-300-073 LPT Stage 3 Blade - Weld Build Up Repair Of Outer Shroud Hardfacing, Repair-073 (VRS4512)

General

Price and availability - none

The practices and processes referred to in the procedure by the TASK number are in the SPM.

NOTE

NOTE

NOTE

NOTE

If repair of pre-twist is also required, then do VRS4511 TASK 72-50-32-300-065 (REPAIR-065) first, before start of this repair.

Touch-up of aluminide coating in repaired areas is not required.

Before repair, write down turbine part number and serial number.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Rockwell hardness tester | LOCAL | Rockwell hardness tester | ||

| 10X Illuminated magnifier | LOCAL | 10X Illuminated magnifier | ||

| Hand grinder | LOCAL | Hand grinder | ||

| IAE 2M14188 Inspection gage | 0AM53 | IAE 2M14188 | 1 | |

| IAE 3M14496 Welding mounting block | 0AM53 | IAE 3M14496 | 1 | |

| IAE 3M14497 Grinding fixture (convex/concave side) | 0AM53 | IAE 3M14497 | 1 | |

| IAE 3M14498 Welding fixture | 0AM53 | IAE 3M14498 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-283 COATING ALLOY | 0CZB2 | CoMat 03-283 | ||

| CoMat 05-029 CAST STEEL SHOT, S110 | LOCAL | CoMat 05-029 | ||

| CoMat 05-030 CAST STEEL SHOT DELETED | 0AM53 | CoMat 05-030 | ||

| CoMat 05-031 CAST STEEL SHOT DELETED | 0AM53 | CoMat 05-031 | ||

| CoMat 05-075 WATERPROOF SILICON CARBIDE | IE241 | CoMat 05-075 | ||

| CoMat 05-138 SHOT, CAST STEEL, S110 | 81349 | CoMat 05-138 | ||

| CoMat 05-177 CUT WIRE SHOT,CW-14 | LOCAL | CoMat 05-177 |

Spares

NONESafety Requirements

NONEProcedure

Use CoMat 05-075 WATERPROOF SILICON CARBIDE or similar.

Remove the aluminide coating locally.

SUBTASK 72-50-32-326-005 Remove the Coating Locally

Refer to the SPM TASK 70-11-03-300-503.

Aqueous cleaning.

SUBTASK 72-50-32-110-151 Clean the Stage 3 Turbine Blade

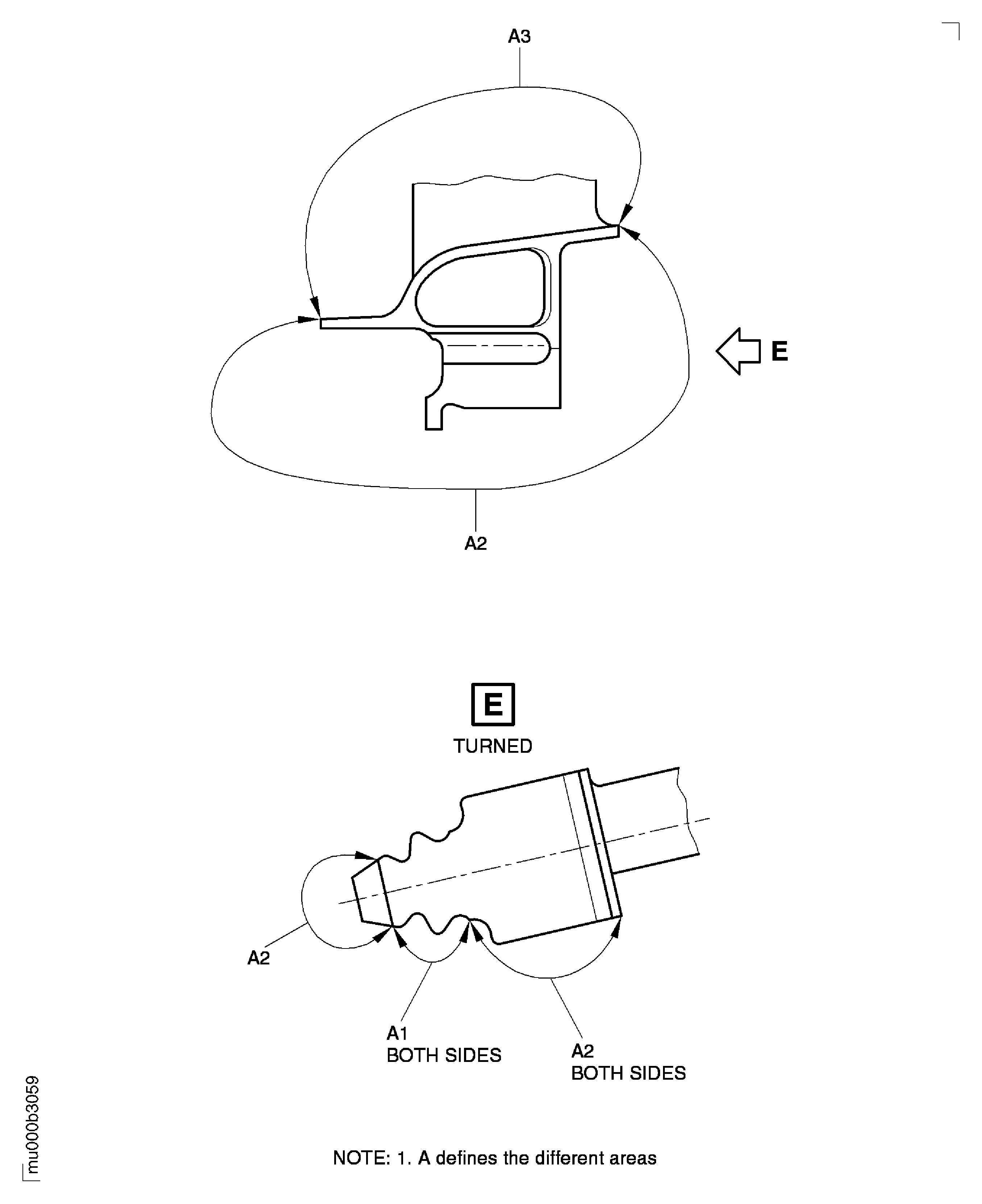

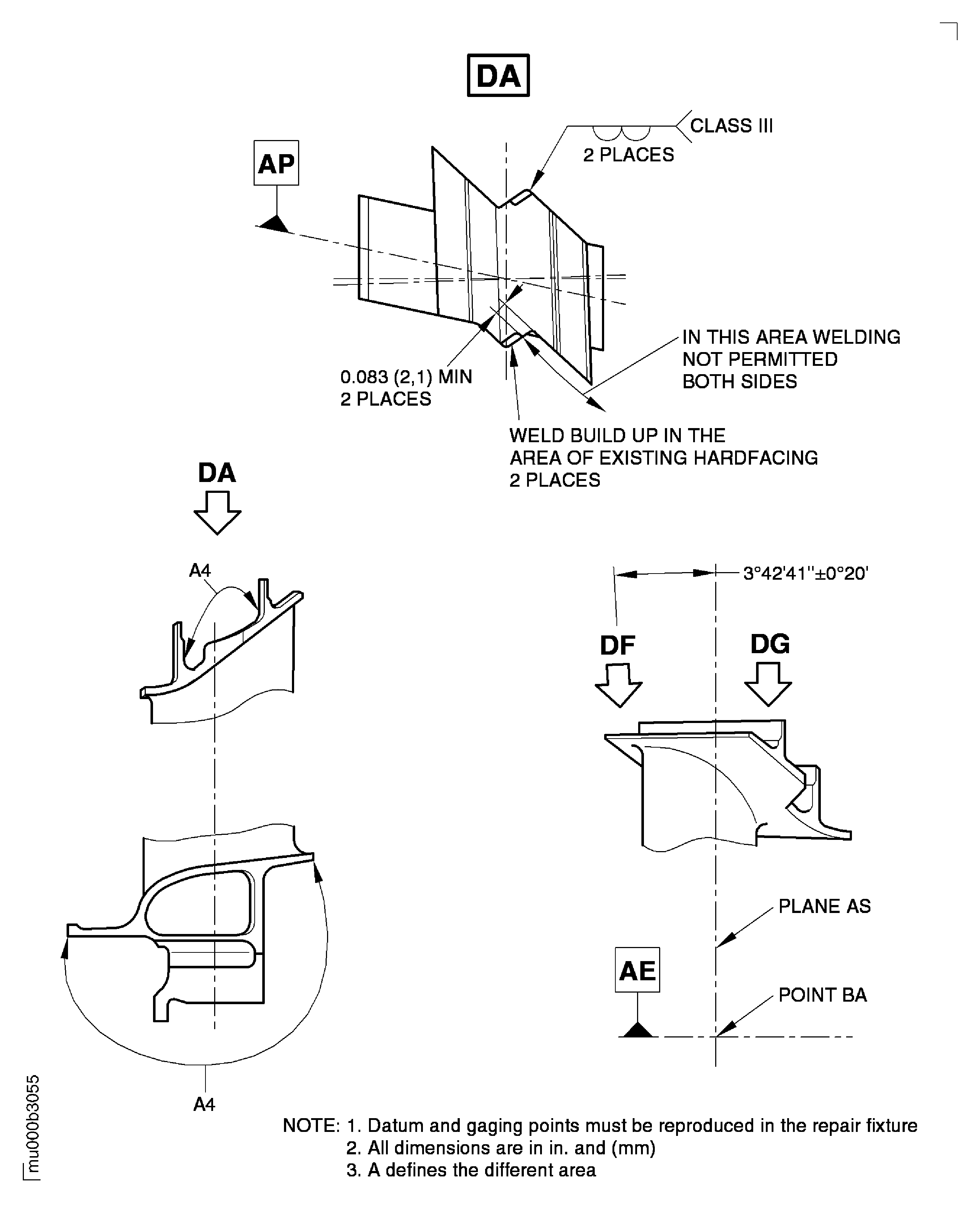

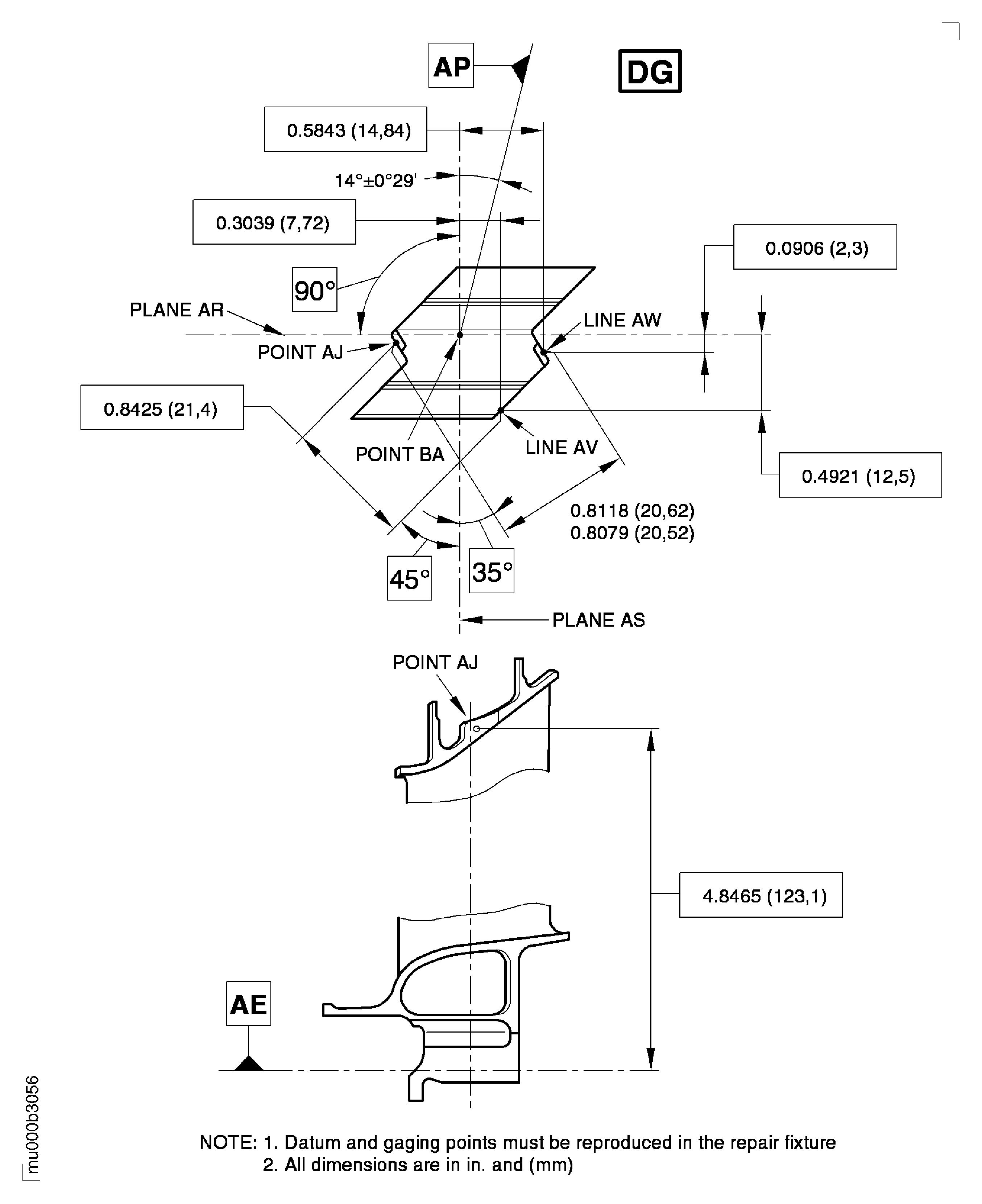

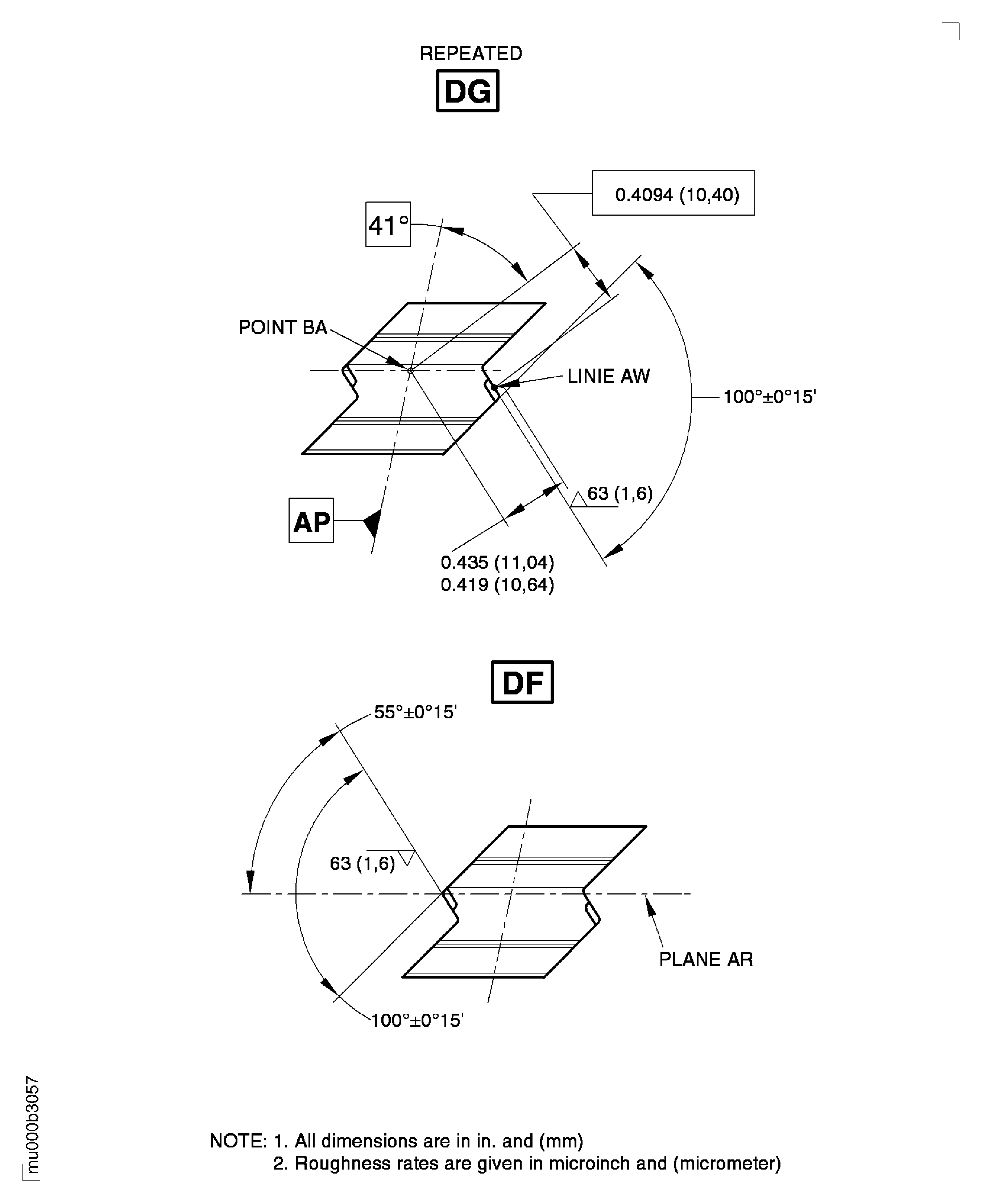

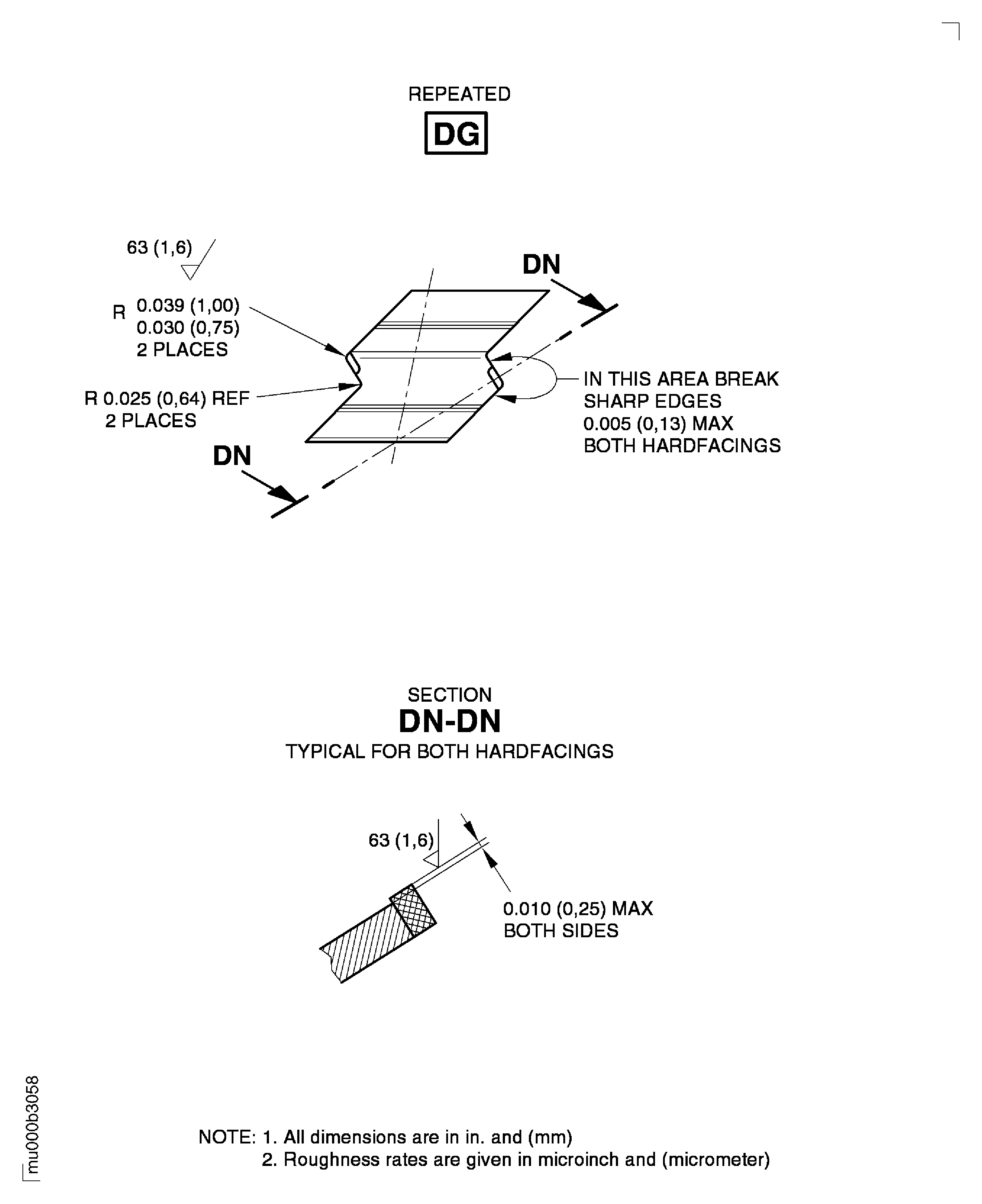

Refer to Figure.

Refer to the SPM TASK 70-31-08-310-501.

Use IAE 3M14498 Welding fixture 1 off and IAE 3M14496 Welding mounting block 1 off.

Make sure that there is sufficient material to do last machining.

Decrease temperature of the turbine blade to reduce heat affected zone to a minimum.

In area A4 electrical contact is permitted.

No burning, pitting or selective attack is permitted.

Gas tungsten arc weld surfaces.

SUBTASK 72-50-32-310-091 Weld Build-Up Repair the Worn Surfaces

Use IAE 2M14188 Inspection gage 1 off.

Examine the machined areas dimensionally.

SUBTASK 72-50-32-220-456 Examine the Machined Outer Shroud Hardfacing

Do the stress-relief after all weld and coating operations.

This SUBTASK is optional if aluminide coating will be completely removed and re-applied per VRS4300 TASK 70-50-32-300-049 (REPAIR-049) after weld repair.

Refer to the SPM TASK 70-37-10-370-501, Stress-Relief Cycle 5.

Stress-relieve the turbine blade.

SUBTASK 72-50-32-370-106 Heat Treatment after Machining

NOTE

Refer to the SPM TASK 70-23-08-230-501.

The maximum permitted length of discontinuities is 0.016 in. (0.4 mm) in the repaired areas.

Do the test for cracks.

SUBTASK 72-50-32-230-208 Examine the Machined Areas for Cracks

Refer to the SPM TASK 70-11-03-300-503.

Aqueous cleaning.

SUBTASK 72-50-32-110-152 Clean the Stage 3 Turbine Blade

Refer to the SPM TASK 70-38-13-380-501.

Use CoMat 05-029 CAST STEEL SHOT, S110 or CoMat 05-030 CAST STEEL SHOT DELETED or CoMat 05-031 CAST STEEL SHOT DELETED or CoMat 05-138 SHOT, CAST STEEL, S110 or CoMat 05-177 CUT WIRE SHOT,CW-14 to an intensity of 6A.

Shotpeen blade root flanks plus corner radii to end faces.

Shotpeening is permitted in area A2.

Shotpeen area A1.

SUBTASK 72-50-32-380-103 Shotpeen the Surface A1 of the Stage 3 Turbine Blade

If you cannot read any of these, make new marks.

Use the roll stamp method.

Refer to the SPM TASK 70-09-00-400-501.

Examine the markings of part number and serial number.

SUBTASK 72-50-32-220-457 Examine the Stage 3 Turbine Blade Markings

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Sheet 1

Figure: Repair Details and Dimensions

Sheet 2

Figure: Repair Details and Dimensions

Repair Details and Dimensions