Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-50-32-300-037 LPT Stage 5 Blade - Restore Shroud Pre-Twists, Repair-037 (VRS4304)

General

Price and availability - none

The practices and processes referred to in the procedure by the TASK number are in the SPM.

Only one pre-twist repair is permitted per part. A "W" marking adjacent to the part number shows that the part was repaired before.

NOTE

For more equipment and materials necessary to do this repair, refer to:

Equivalent equipment can be used.

NOTE

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 3M14481 Fixture check and correct | 0AM53 | IAE 3M14481 | 1 | |

| IAE 3M14482 Blade holder | 0AM53 | IAE 3M14482 | 1 | or |

| IAE 3M14495 Bladeholder | 0AM53 | IAE 3M14495 | 1 | |

| IAE 3M14488 Handle twist | 0AM53 | IAE 3M14488 | 1 | |

| IAE 3M14493 Gage, inspection | 0AM53 | IAE 3M14493 | 1 | |

| IAE 3M14543 Gage, master | 0AM53 | IAE 3M14543 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 05-029 CAST STEEL SHOT, S110 | LOCAL | CoMat 05-029 | ||

| CoMat 05-030 CAST STEEL SHOT DELETED | 0AM53 | CoMat 05-030 | ||

| CoMat 05-031 CAST STEEL SHOT DELETED | 0AM53 | CoMat 05-031 | ||

| CoMat 05-138 SHOT, CAST STEEL, S110 | 11851 | CoMat 05-138 | ||

| CoMat 05-177 CUT WIRE SHOT,CW-14 | LOCAL | CoMat 05-177 |

Spares

NONESafety Requirements

NONEProcedure

Refer to Figure.

NOTE

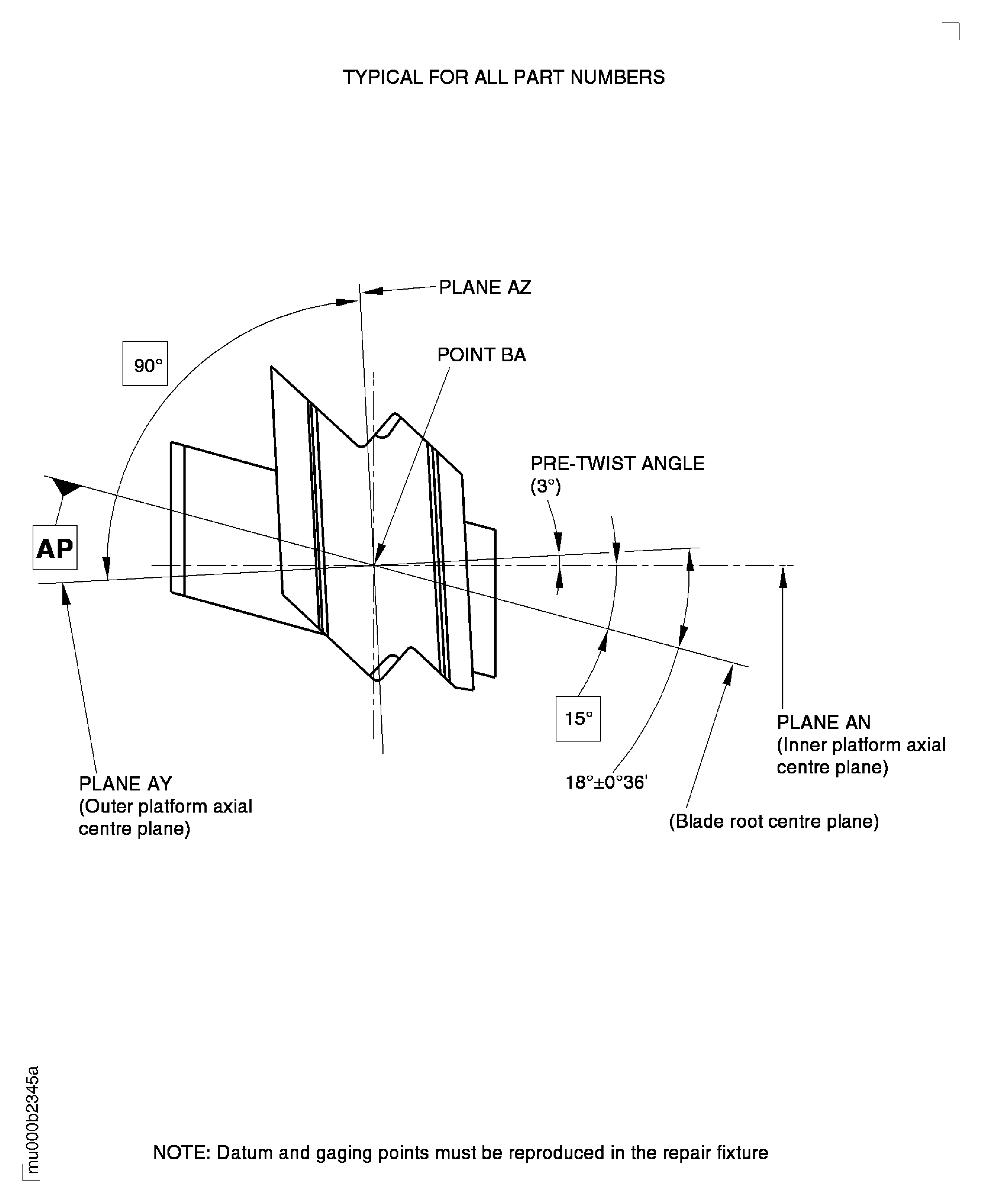

Use a test piece to evaluate amount of twist necessary to get a permanent set of necessary pre-twist value. Twist-back of outer shroud is not permitted if achieved pre-twist is out of limits.Use IAE 3M14481 Fixture check and correct 1 off, IAE 3M14482 Blade holder 1 off or IAE 3M14495 Bladeholder 1 off, IAE 3M14488 Handle twist 1 off, IAE 3M14493 Gage, inspection 1 off and IAE 3M14543 Gage, master 1 off.

Do not bend outer shroud and airfoil section axially or circumferentially.

Twist the stage 5 turbine blade.

SUBTASK 72-50-32-350-111 Restore Pre-Twist on Outer Shroud

Refer to the SPM TASK 70-37-10-370-501, Stress-Relief Cycle 5.

Stress relieve the turbine blade.

SUBTASK 72-50-32-370-074 Heat Treatment after Twisting

NOTE

Do the stress-relief after all weld operations.Refer to the SPM TASK 70-11-03-300-503.

Aqueous cleaning.

SUBTASK 72-50-32-110-102 Clean the Stage 5 Turbine Blade

Refer to the SPM TASK 70-38-13-380-501.

Use CoMat 05-029 CAST STEEL SHOT, S110 or CoMat 05-138 SHOT, CAST STEEL, S110 or CoMat 05-177 CUT WIRE SHOT,CW-14 to an intensity of 6A.

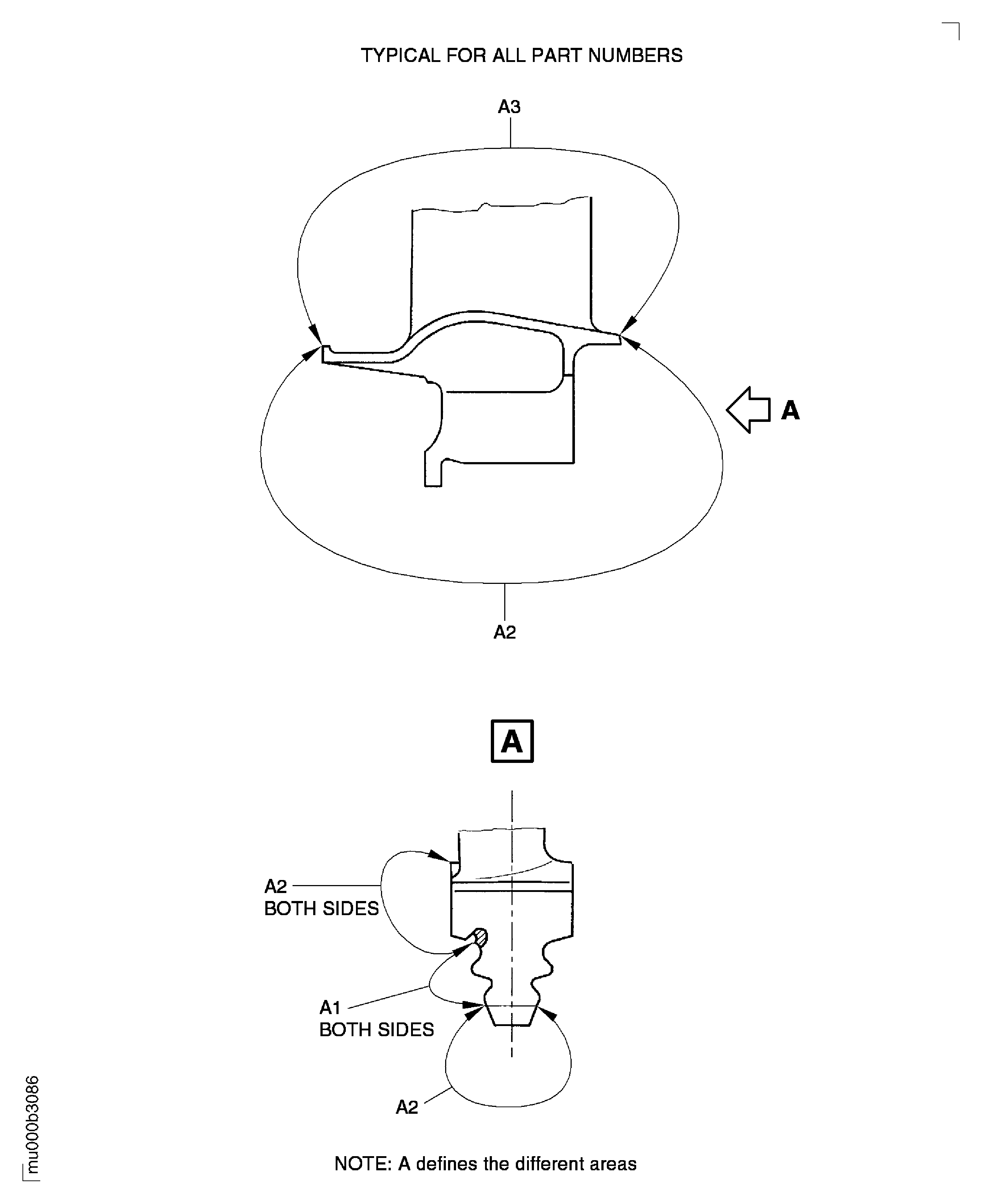

Shotpeen blade root flanks plus corner radii to end faces.

Shotpeening is permitted in Use area A2.

Shotpeen area A1.

SUBTASK 72-50-32-380-086 Shotpeen the Surface A1 of the Stage 5 Turbine Blade

If you cannot read the markings, make new marks.

Use the roll stamp method.

Refer to the SPM TASK 70-09-00-400-501.

Examine the markings of part number and serial number.

SUBTASK 72-50-32-220-214 Examine the Stage 5 Turbine Blade Markings

Refer to the SPM TASK 70-09-00-400-501.

Vibropeen VRS4304 and symbol "W" adjacent to the part number.

SUBTASK 72-50-32-350-112 Make a Mark to Identify the Repair

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions