Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-50-53-300-075 Turbine Exhaust Case (TEC) - Blend Repair On The No. 5 Bearing Oil Tube Boss And Cover Bolt Boss Crack, Repair-075 (VRS3632)

Effectivity

FIG/ITEM | PART NO. |

|---|---|

21-300 | 2A1209-01 |

21-300 | 2A2620-01 |

21-300 | 2A3111-01 |

21-300 | 2A3183-01 |

21-300 | 2A3455-01 |

21-300 | 2A3183-101 |

21-300 | 2A4258-01 |

21-300 | 2A4263-01 |

Material of component

PART IDENT | SYMBOL | MATERIAL |

|---|---|---|

Turbine Exhaust Case Assembly | Corrosion and heat resistant steel |

General

Prices and Availability - Refer to IAE

The practices and processes referred to in the procedure by the TASK number are in the SPM.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Fluorescent Penetrant Inspection Equipment | LOCAL | Fluorescent penetrant inspection equipment | ||

| Welding equipment | LOCAL | Welding equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 06-064 FLUORESCENT PENETRANT (WATER WASHABLE MEDIUM SENSITIVITY) | LOCAL | CoMat 06-064 | ||

| CoMat 01-007 ETHYL ALCOHOL C2H5OH (DENATURED) | LOCAL | CoMat 01-007 | ||

| CoMat 02-099 LINT-FREE CLOTH | LOCAL | CoMat 02-099 | ||

| CoMat 03-378 WELDING WIRE | LOCAL | CoMat 03-378 |

Spares

NONESafety Requirements

NONEProcedure

Refer to Figure.

If the wall thickness of the bosses.

after routing is greater than or equal.

to 0.095 in. (2.41 mm), do a blend repair.

of the routed area Step.

If the wall thickness of the bosses.

after routing is less than or equal.

to 0.095 in. (2.41 mm), do a weld repair.

of the routed area Step.

SUBTASK 72-50-53-350-163 Rout the Repair Area to Repair the Cracks

Use a CoMat 02-099 LINT-FREE CLOTH and CoMat 01-007 ETHYL ALCOHOL C2H5OH (DENATURED). Refer to the SPM TASK 70-11-26-300-503.

Clean the routed area.

Refer to the SPM TASK 70-31-02-310-501. Use CoMat 03-378 WELDING WIRE. Apply sufficient material to make sure you can blend to the adjacent surfaces.

Weld the routed area manually.

SUBTASK 72-50-53-310-078 Weld Repair the Routed Repair Area to Keep the Minimum Wall thickness

Do a local fluorescent penetrant inspection procedure. Refer to the SPM TASK 70-23-05-230-501. Use CoMat 06-064 FLUORESCENT PENETRANT (WATER WASHABLE MEDIUM SENSITIVITY).

Inspect for cracks.

SUBTASK 72-50-53-230-110 Inspect for Cracks Using Fluorescent Penetrant Inspection

Refer to the SPM TASK 70-37-13-370-501. If furnace stress relief is used, remove the heat shields, 13 rear inner flange nut plates, 3 carbon seal flange nut plates, 19 bearing cover boss helical coil inserts, and 2 jumper tube boss helical coil inserts.

Do a local or furnace.

stress relieve.

SUBTASK 72-50-53-370-085 Stress Relieve the Turbine Exhaust Case/Weld Repair Areas

CAUTION

KEEP THE TIME BETWEEN WELD REPAIR AND STRESS RELIEF TO A MINIMUM TO DECREASE THE POSSIBILITY OF CRACKS.For a local fluorescent penetrant inspection, refer to the SPM TASK 70-23-05-230-501.

Inspect for cracks using local.

fluorescent penetrant inspection if a.

local stress relief was used.

Inspect for cracks on all of the.

turbine exhaust case if a furnace.

stress relief was used.

SUBTASK 72-50-53-230-111 Inspect for Cracks Using Fluorescent Penetrant Inspection

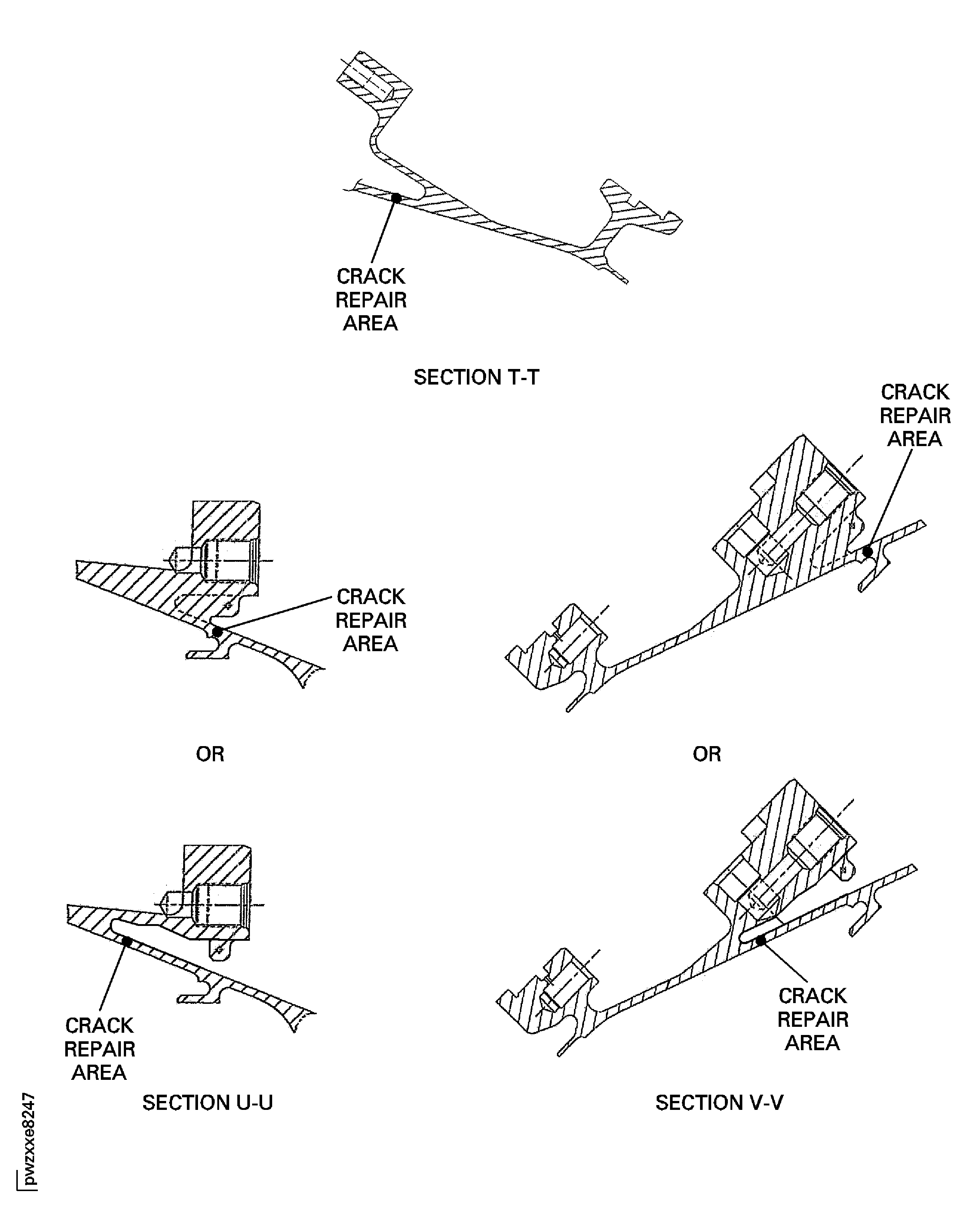

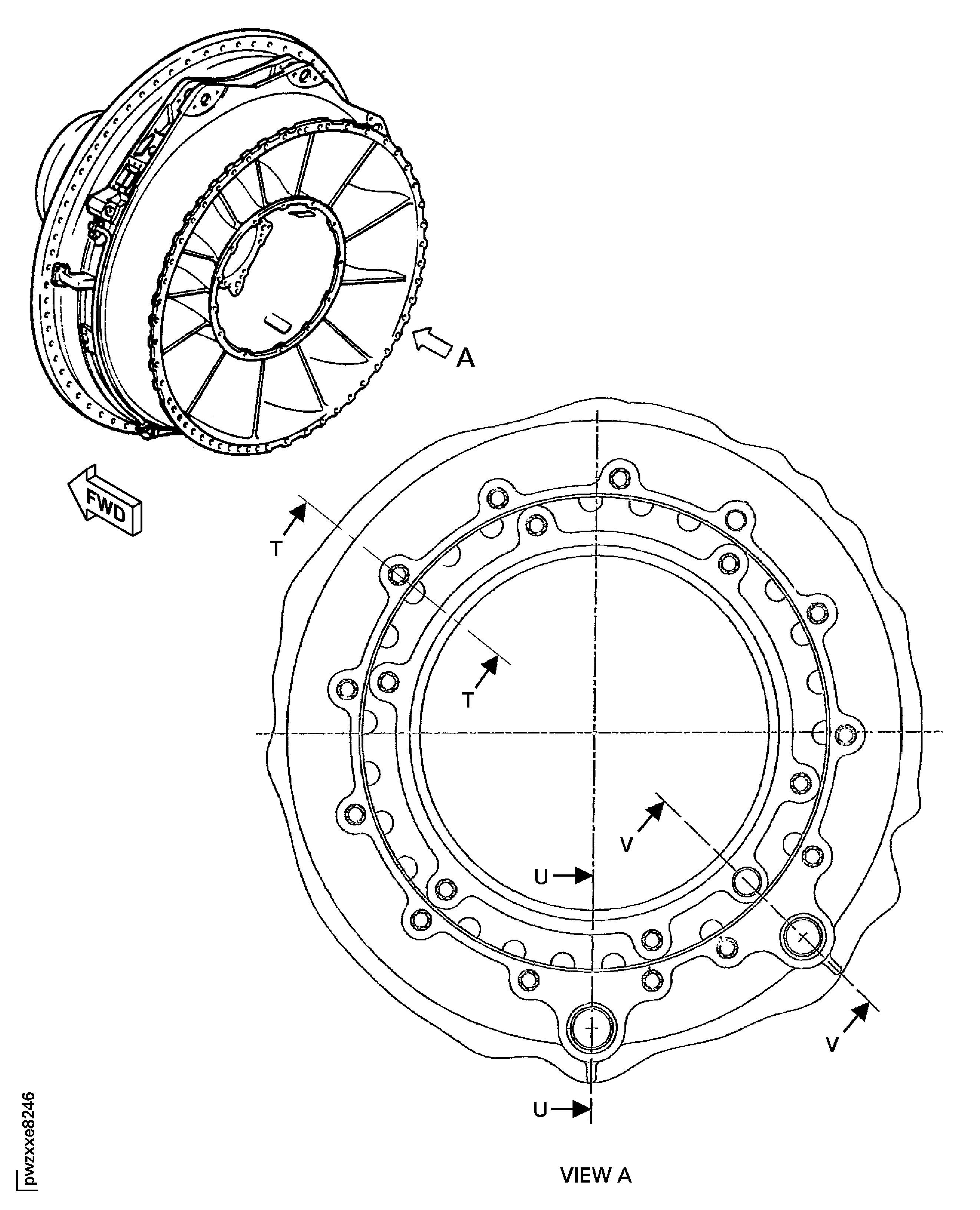

Figure: Repair Details and Dimensions

Sheet 1

Figure: Repair Details and Dimensions

Sheet 2