Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-50-53-300-078 Turbine Exhaust Case (TEC) - Plasma Spray Repair The Rear Face Of The Rear Outer Flange, Repair-078 (VRS3732)

Effectivity

FIG/ITEM | PART NO. |

|---|---|

02-300 | 4B8060 |

02-300 | 4B8068 |

21-300 | 2A1209-01 |

21-300 | 2A2620-01 |

21-300 | 2A3111-01 |

21-300 | 2A3183-01 |

21-300 | 2A3455-01 |

21-300 | 2A3183-101 |

21-300 | 2A4258-01 |

21-300 | 2A4263-01 |

General

Price and availability - refer to IAE

The practices and processes referred to in this procedure by TASK numbers are in the SPM.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Workshop inspection equipment | LOCAL | Workshop inspection equipment | ||

| Furnace | LOCAL | Furnace |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-097 LINT-FREE GLOVES | LOCAL | CoMat 02-097 | ||

| CoMat 03-096 PLASMA SPRAY POWDER | LOCAL | CoMat 03-096 | ||

| CoMat 06-064 FLUORESCENT PENETRANT (WATER WASHABLE MEDIUM SENSITIVITY) | LOCAL | CoMat 06-064 |

Spares

NONESafety Requirements

NONEProcedure

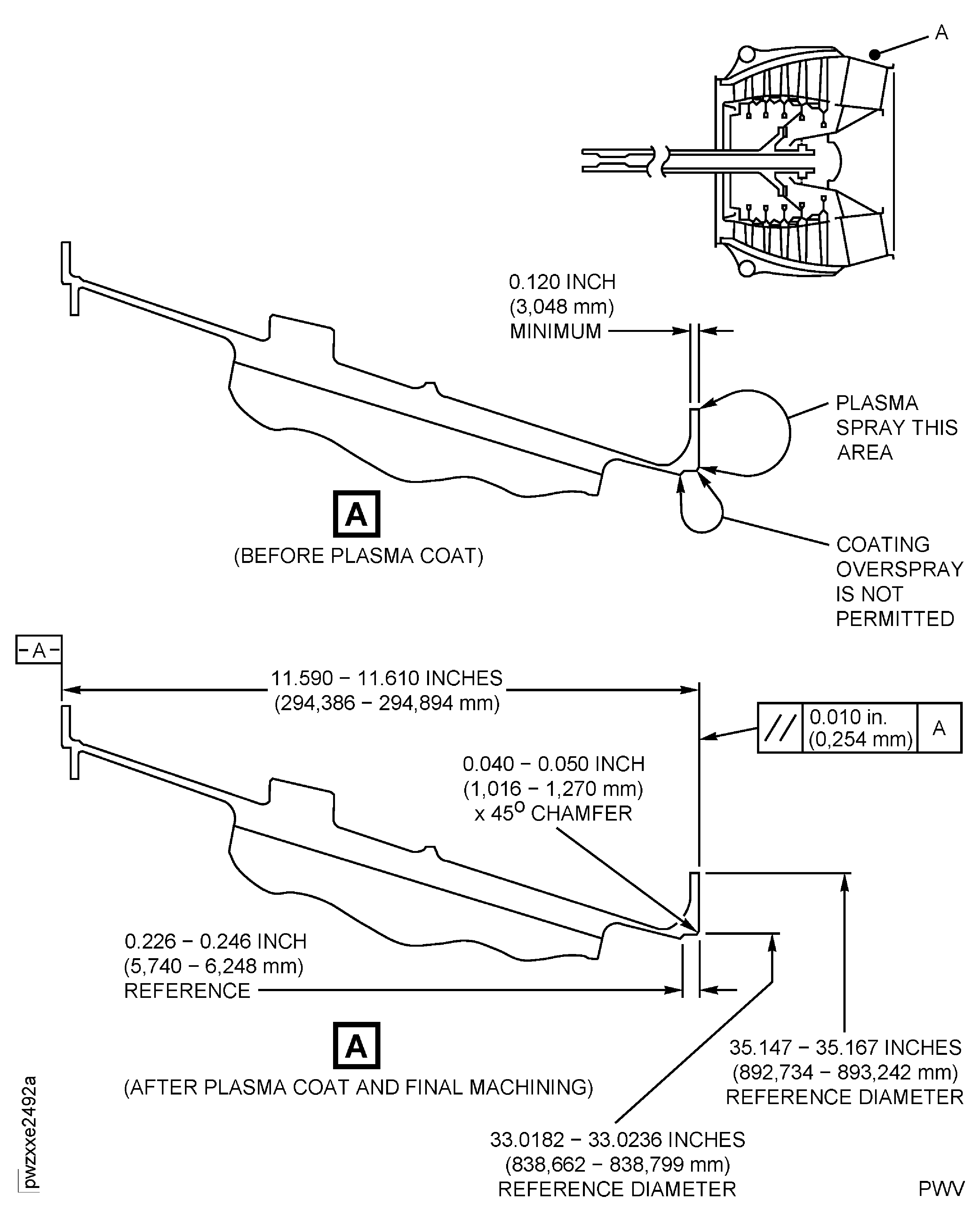

Refer to Figure.

SUBTASK 72-50-53-320-149 Machine the Rear Face of the Rear Outer Flange

Refer to the SPM TASK 70-23-05-230-501 using CoMat 06-064 FLUORESCENT PENETRANT (WATER WASHABLE MEDIUM SENSITIVITY) or SPM TASK 70-23-02-230-501.

No cracks are permitted.

NOTE

This step is required if the method of machining used in Step (4) was grinding. For all other methods, this step is optional.

Fluorescent penetrant inspect the turbine exhaust case.

SUBTASK 72-50-53-230-130 Examine the Turbine Exhaust Case

Refer to the SPM TASK 70-34-18-380-501.

Prepare surface for plasma and other thermal spray.

SUBTASK 72-50-53-340-054 Prepare the Rear Face of the Outer Flange for Coating

CAUTION

YOU MUST DO THE GRIT BLAST AGAIN IF YOU WAIT LONGER THAN TWO HOURS. IF YOU DO NOT SO PREPARED SURFACES CAN BE CONTAMINATED.Refer to Figure.

Refer to the SPM TASK 70-34-03-340-501.

Apply plasma spray to a sufficient thickness to permit finish machining.

No overspray is permitted.

Plasma spray the rear face of the rear outer flange.

SUBTASK 72-50-53-340-055 Plasma Spray the Rear Face of the Rear Outer Flange of the Turbine Exhaust Case

Refer to Figure.

SUBTASK 72-50-53-320-152 Finish Machine the Rear Face of the Rear Outer Flange

Refer to the SPM TASK 70-09-00-400-501.

Use vibration peen method with depth not more than 0.006 in. (0.15 mm).

Vibration peen VRS3070 adjacent to the part number.

SUBTASK 72-50-53-350-195 Identify the Repair

Figure: Repair Details and Dimensions

Repair Details and Dimensions