Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-50-53-300-089 Turbine Exhaust Case (TEC) - Nickel Plate The Seal Housing Bore, Repair-089 (VRS3854)

Preliminary Requirements

Pre-Conditions

| Action/Condition | Data Module/Technical Publication |

|---|---|

| Make sure that all the cleaning and inspection procedures are done before this repair. |

Support Equipment

NONEConsumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

Visually inspect the part markings for evidence of previous repair.

If the part is marked with VRS3112, refer to Repair, VRS3112 TASK 72-50-53-300-060 (REPAIR-060) for chromium plate removal instructions before proceeding with this repair.

If the part is marked with VRS3755, refer to Repair, VRS3755 TASK 72-50-53-300-084 (REPAIR-084) for coating removal instructions before proceeding with this repair.

If the part is marked with VRS3854 or has no VRS markings, proceed with Step of this repair.

SUBTASK 72-50-53-220-284 Visually Inspect the Part Markings

Remove the nickel plate by SPM TASK 70-33-06-300-503.

If there is nickel plate do one or more of the following:

SUBTASK 72-50-53-380-065 Prepare the Seal Housing Bore Diameter for Nickel Plating

Refer to SPM TASK 70-11-03-300-503.

Clean the Turbine Exhaust Case.

SUBTASK 72-50-53-110-214 Clean the Turbine Exhaust Case

Apply a mask to the areas of the turbine exhaust case that are not to be plated.

Refer to SPM TASK 70-38-24-300-503.

SUBTASK 72-50-53-380-066 Apply a Mask to the Turbine Exhaust Case

Part is a steel alloy. Hardness is between HRC 25 and HRC 40.

Part cannot be damaged if heated to 375 deg F (191 deg C).

Apply the plating to a sufficient thickness to allow for finish machining.

Plating outside the repair area is permitted but must be removed.

Refer to SPM TASK 70-33-06-300-503, Nickel Plating.

Treat as a 400 series stainless steel alloy. Hardness is between HRC 25 and HRC 40.

Part cannot be damaged if heated to 375 deg F.

Apply the plating to a sufficient thickness to allow for finish machining.

Plating outside the repair area is permitted but must be removed.

Refer to SPM TASK 70-33-28-300-503, Brush Nickel Plating.

Nickel Plate the seal housing bore by one of the following methods:

SUBTASK 72-50-53-330-071 Nickel Plate the Seal Housing Bore

Refer to SPM TASK 70-11-03-300-503.

Clean the turbine exhaust case.

SUBTASK 72-50-53-110-215 Clean the Turbine Exhaust Case

Remove high material caused by marking the number.

Make a permanent mark by the procedure given in SPM TASK 70-09-00-400-501.

Vibration peen VRS3854 on the repaired case adjacent to the part number.

SUBTASK 72-50-53-350-225 Identify the Repair

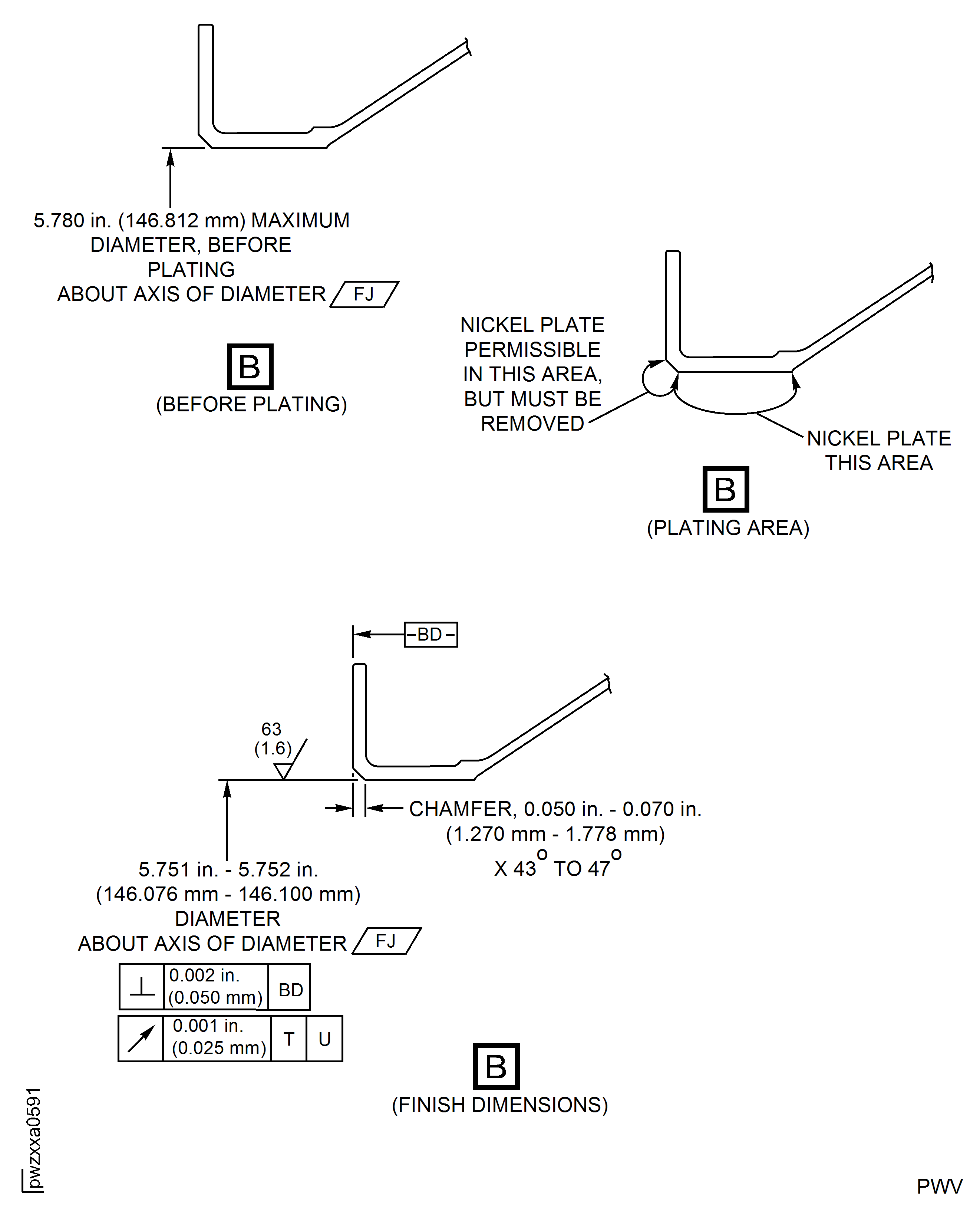

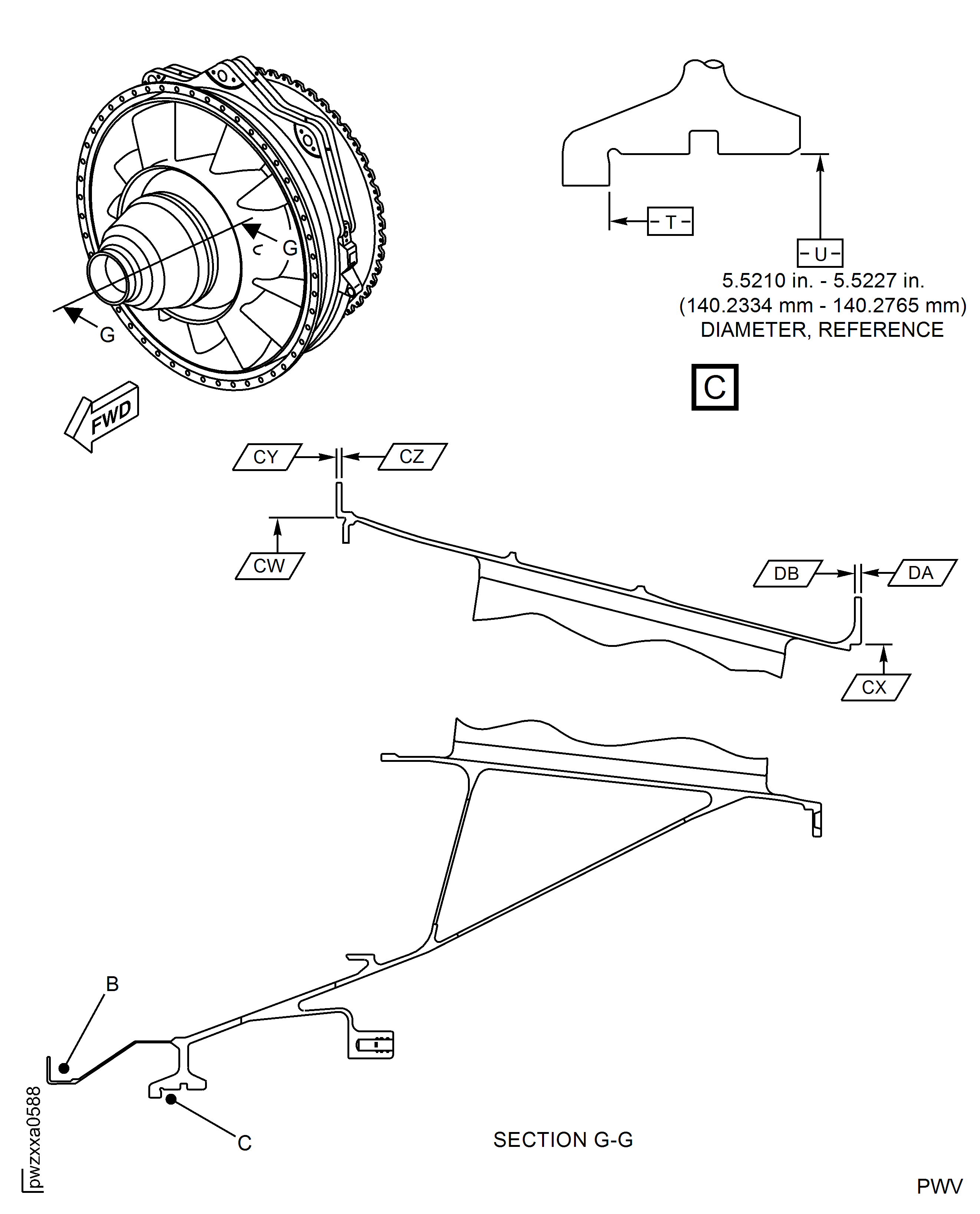

Figure: PN 2A1209-01 Only

PN 2A1209-01 Only

PN 2A1209-01 Only

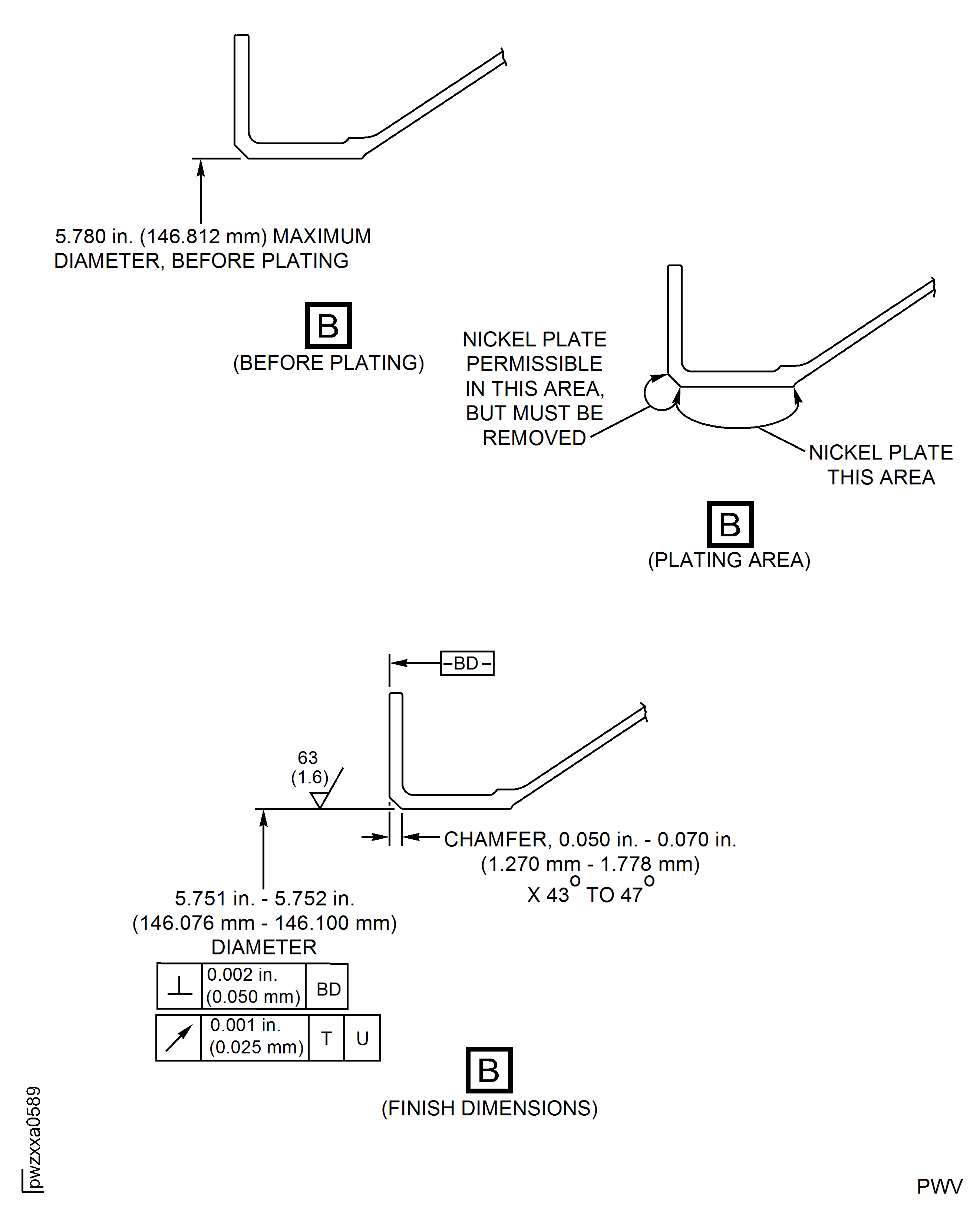

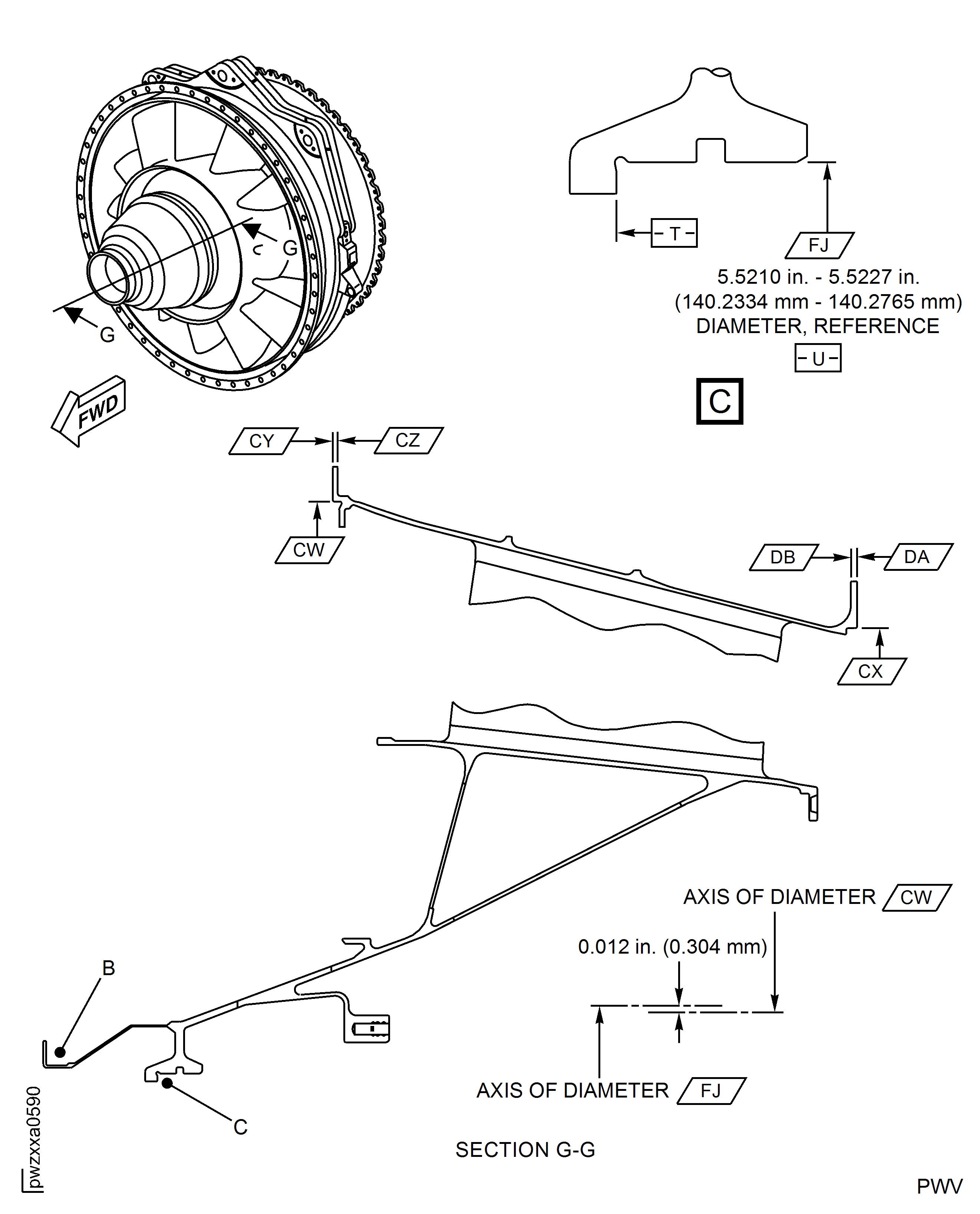

Figure: PN's 2A2620-01, 2A3111-01, 2A3183-01, 2A3183-101, 2A3455-01, 2A4258-01, 2A4263-01

PN's 2A2620-01, 2A3111-01, 2A3183-01, 2A3183-101, 2A3455-01, 2A4258-01, 2A4263-01

PN's 2A2620-01, 2A3111-01, 2A3183-01, 2A3183-101, 2A3455-01, 2A4258-01, 2A4263-01