Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-60-21-300-059 Main Gearbox Casing - Double Helical Insert Repair at Lay Shaft Bearing Location, Repair-059 (VRS5711)

Effectivity

FIG/ITEM | PART NO. |

|---|---|

02-050 | 4B0053 |

02-050 | 4B0054 |

02-050 | 4B0055 |

02-050 | 4B0057 |

02-050 | 4B0400 |

02-050 | 4B0402 |

02-050 | 4B0423 |

Material of component

DESCRIPTION | RR SYMBOL | MATERIAL |

|---|---|---|

Casing, Main Gearbox | A357/T61 (AMS4219) | Aluminum alloy |

General

Price and availability - none

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

Kit PN 3178-4 consists of quantity 25 outer coils, quantity 25 inner coils, the tap, and tang break-off tools applicable for this repair.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Break-off tool (outer insert) | LOCAL | Break-off tool (4032-4) | ||

| Extracting tool (1227-6) | LOCAL | Extracting tool (1227-6) | ||

| Fluorescent Penetrant Inspection Equipment | LOCAL | Fluorescent penetrant inspection equipment | ||

| Helicoil Twinsert Kit Number 3178-4 | 01556 | Helicoil Twinsert Kit Number 3178-4 | ||

| Inserting tool (outer insert) | LOCAL | Inserting tool (2705-4) | ||

| Magnifying Glass | LOCAL | Magnifying Glass | ||

| Standard Workshop Equipment | LOCAL | Standard Workshop Equipment | ||

| Tap tool, double insert | LOCAL | Tap tool, double insert (3893-4) | ||

| Vibration peen equipment | LOCAL | Vibration peen equipment | ||

| Workshop Inspection Equipment | 0AM53 | Workshop Inspection Equipment |

Consumables, Materials and Expendables

NONESpares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| PLUG | AR | |||

| PLUG - EXPANSION, OVERSIZED | U1653 | AS3123-60 | AR | Double Helical Coil Insert |

| PIN | AR | |||

| Insert - Double Helical Coil | LOCAL | 2391-4CN375 | AR | Double Helical Coil Insert |

| Insert - Double Helical Coil | LOCAL | 4691-4CN339 | AR | Double Helical Coil Insert |

Safety Requirements

NONEProcedure

Refer to Figure.

Drive the Extracting tool (1227-6) into the insert at approximately a quarter of a coil from the end of the insert.

Apply the Extracting tool (1227-6) into the insert.

Hit the head of the tool lightly to dig the blade into the top of the coil of the insert. Use a hammer.

Arrange the Extracting tool (1227-6) into the insert.

Bear down hard on the handle of the tool.

Turn the tool slowly counterclockwise.

Maintain a hard pressure on the handle when the insert backs out.

Complete removal of the insert.

SUBTASK 72-60-21-350-216 Remove the Helical Insert

Use Helicoil Twinsert Kit Number 3178-4 or equivalent.

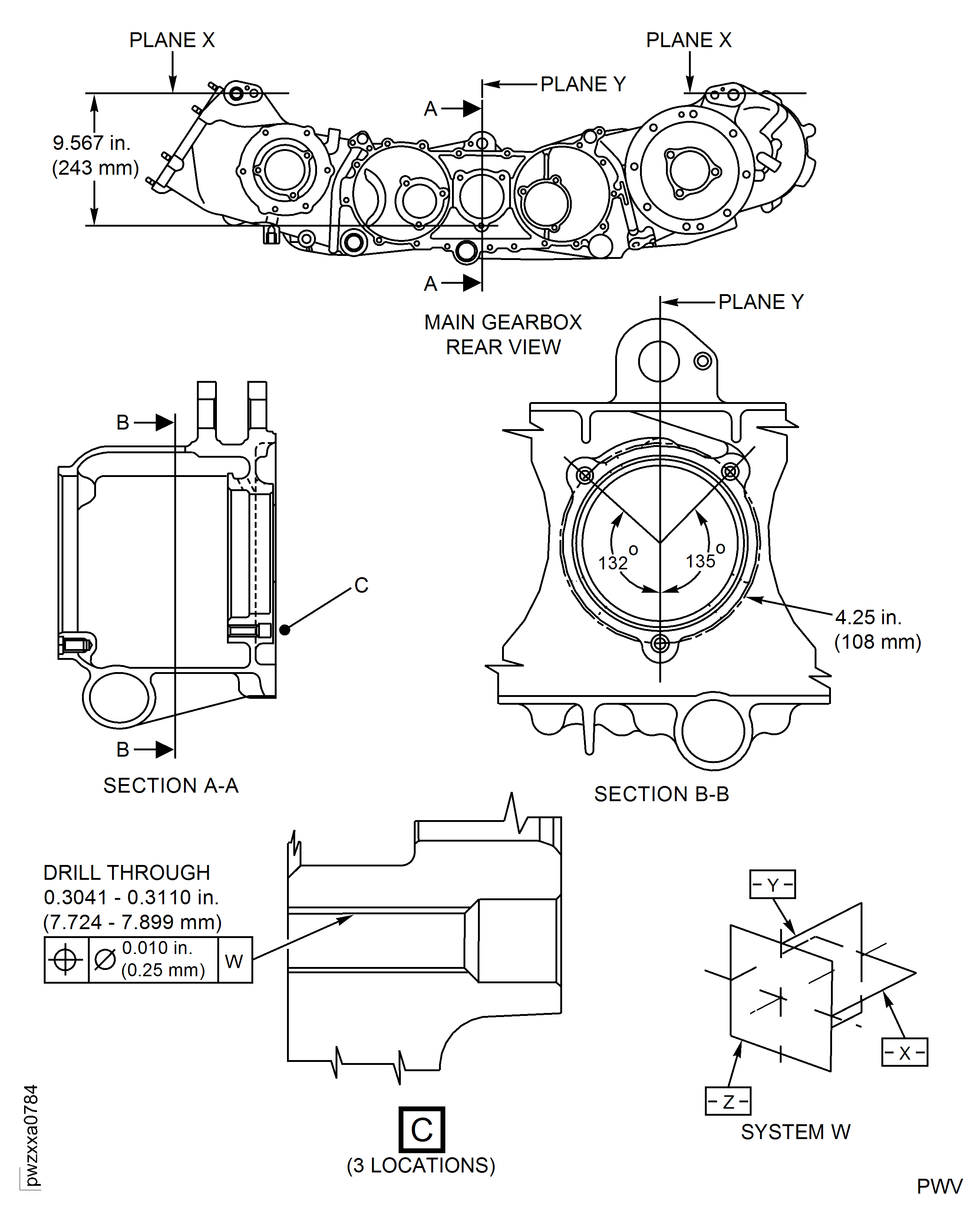

Drill hole to a minor diameter of 0.3041 in. - 0.3110 in. (7.724 mm - 7.899 mm).

Tap the hole using Tap tool, double insert. Tap the entire depth of the hole.

Refer to Figure.

SUBTASK 72-60-21-350-217 Repair the Helical Insert Holes

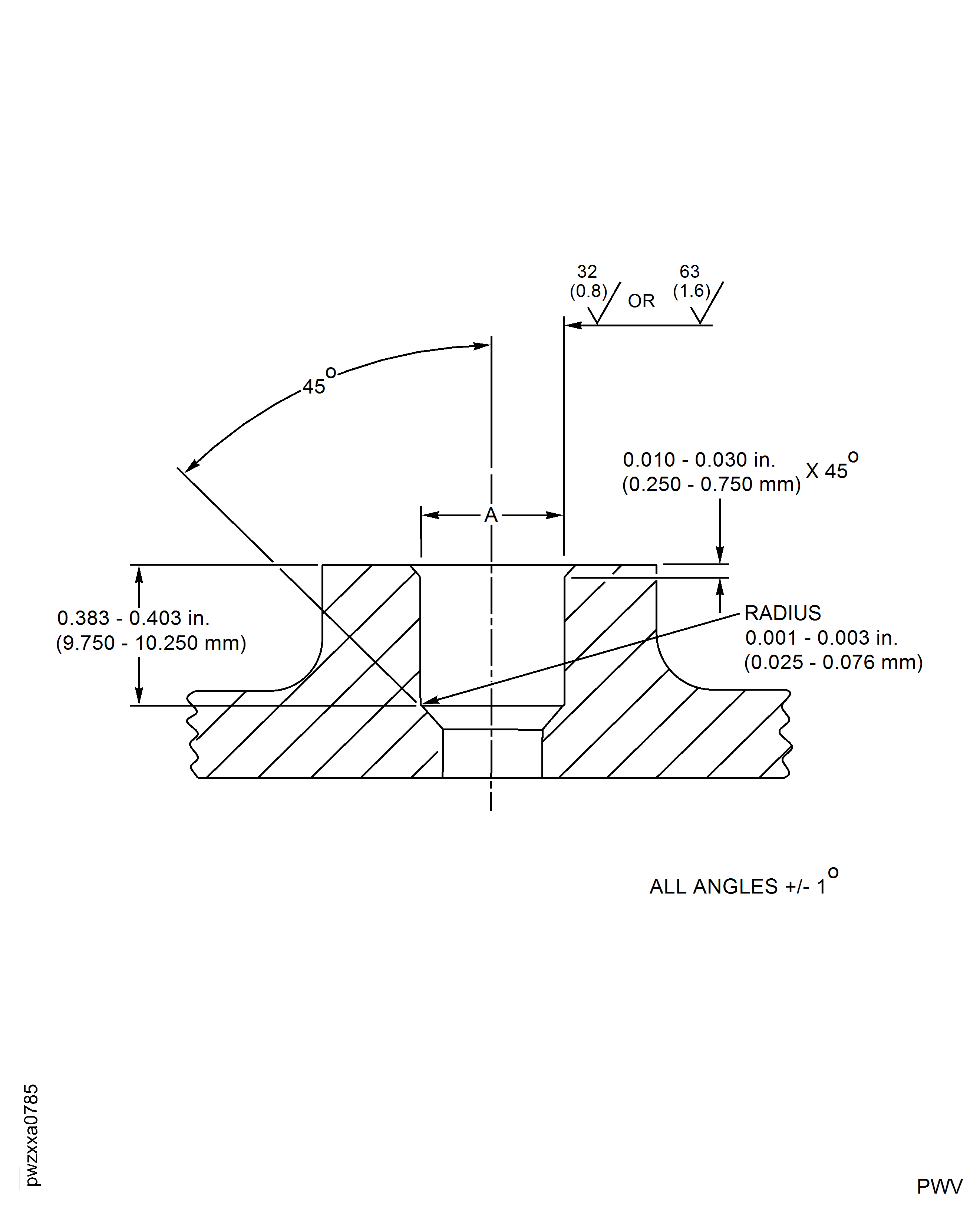

Refer to Figure.

Proceed to the next step. Use the expansion plug. Additional machining is not necessary.

Between 0.4687 in. - 0.4712 in. (11.900 mm - 11.965 mm).

Replace the Surface Protection with SPM TASK 70-38-02-300-503.

Damaged or more than 0.4712 in. (11.965 mm).

Diameter A

SUBTASK 72-60-21-220-199 Check the Bore Dimensions

Refer to Figure.

Refer to SPM TASK 70-35-27-300-501, paragraph C.

Install the2391-4CN375 0.25 in. - 0.50 in. (6.35 mm - 12.70 mm) pitch below the inside surface of the Gearbox Casing. Use the Inserting tool (outer insert).

Install the 4691-4CN339 so that the end of the last coil is flush with the end of the outer insert. Use the Inserting tool (outer insert).

Install the double helical coil threaded insert.

Break off the installation tangs at the notch using Break-off tool (outer insert).

Collect and remove all broken tangs.

SUBTASK 72-60-21-350-218 Insert Double Helical Coil Threaded Insert

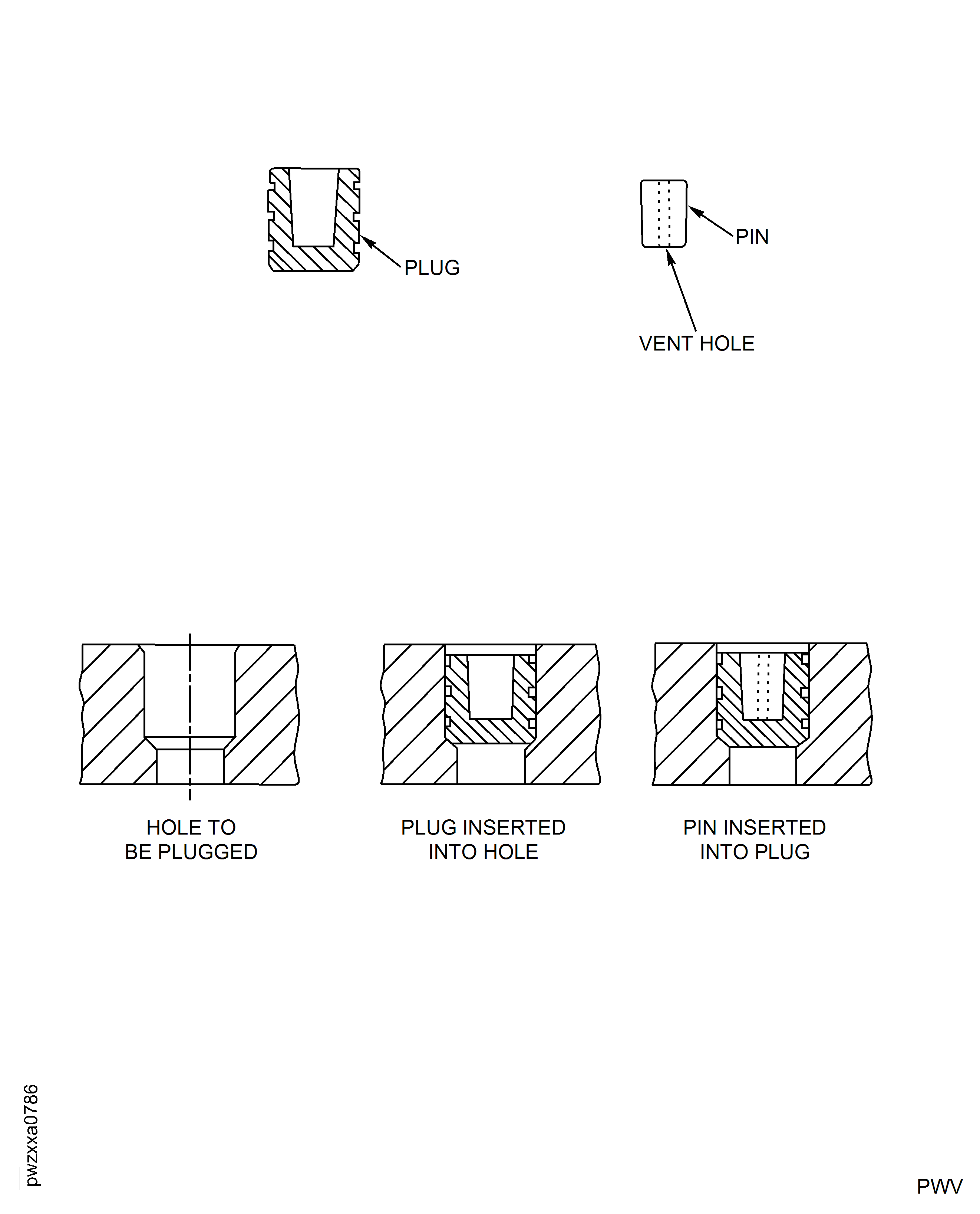

Refer to Figure.

PLUG, if the bore dimension is between 0.4687 in. - 0.4712 in. (11.900 mm - 11.965 mm).

AS3123-60 PLUG - EXPANSION, OVERSIZED, if the bore was machined to accept the oversized plug in Step.

PIN with both PLUG and AS3123-60 PLUG - EXPANSION, OVERSIZED.

Use the following parts:

Apply an axial load of 50 lbs - 100 lbs (23 kg - 45 kg) or tap the plug lightly with a punch to seat the plug in the bottom of the hole.

The plug must be at least 0.010 in. (0.25 mm) below the surface of the part.

Insert the plug into hole until it is firmly seated on the shoulder at the bottom of the hole.

Insert the pin small end first.

Do not degrease the pin. Supplementary lubricant must not be used.

Press or drive the pin using a vented driver until the large end of the pin is 0.005 in. (0.125 mm) above to 0.003 in. (0.076 mm) below the end of the plug.

Insert the pin into the installed plug.

SUBTASK 72-60-21-350-219 Install the new Plugs and Pins

Refer to SPM TASK 70-09-00-400-501.

Vibro-engrave VRS5711 adjacent to the part number.

SUBTASK 72-60-21-350-220 Identify the Repair

Figure: Helical Insert Locations

Helical Insert Locations

Figure: Hole Preparation

Hole Preparation

Figure: Installation Of Plug And Pin

Installation Of Plug And Pin