DMC:V2500-A0-72-60-2101-17A-664A-CIssue No:005.00Issue Date:2019-11-01

Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-60-21-300-030 Main Gearbox Casing - Repair The Support Bushings Of The Main Gearbox Casing - Repair-030 (VRS5295)

Effectivity

FIG/ITEM | PART NO. |

02-050 | 4B0053 |

02-050 | 4B0054 |

02-050 | 4B0055 |

02-050 | 4B0057 |

02-050 | 4B0400 |

02-050 | 4B0402 |

02-050 | 4B0423 |

General

NOTE

Consumable materials are given in the PCI.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Arbor Press | LOCAL | |||

| Bore Gage | LOCAL | |||

| Boring machine | LOCAL | |||

| Drilling equipment | LOCAL | |||

| Freezer | LOCAL | |||

| Fluorescent penetrant inspection equipment | LOCAL | Fluorescent Penetrant Inspection Equipment | ||

| Hot Air Gun | LOCAL | |||

| Vibrating Marking Pencil | LOCAL | Vibrating Marking Pencil | ||

| Workshop inspection equipment | LOCAL | Workshop inspection equipment |

Consumables, Materials and Expendables

NONESpares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Bush | LOCAL | 4P0128 | 2 | |

| Bush | LOCAL | 4P0128 | 2 | |

| Bush | LOCAL | 4P0128 | 2 |

Safety Requirements

NONEProcedure

Repair, VRS5709 TASK 72-60-21-300-057 (REPAIR-057).

If the diameter G is more than Step.

Inspect the diameter G of the bores of the casing.

SUBTASK 72-60-21-220-188 Inspect the Bores of the Support Bushes

WARNING

DO NOT TOUCH THE HOT PARTS WITHOUT PROTECTIVE GLOVES.

WARNING

HOT PARTS CAN CAUSE REDDENING AND BLISTERING OF THE SKIN IF THE HANDS ARE NOT PROTECTED.

WARNING

IMMERSE THE CONTACTED AREA IN COLD WATER FOR 10 MINUTES IF THE SKIN IS BURNED. IMMEDIATELY GET MEDICAL ATTENTION IF THE PAIN OR BLISTERING PERSIST.Refer to Figure.

SUBTASK 72-60-21-350-207 Install the Bushing

NOTE

The difference in temperature between the parts must be less than 250 deg F (120 deg C).Refer to SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

Make a mark VRS5295 adjacent to the part number.

SUBTASK 72-60-21-350-208 Identify the Repair

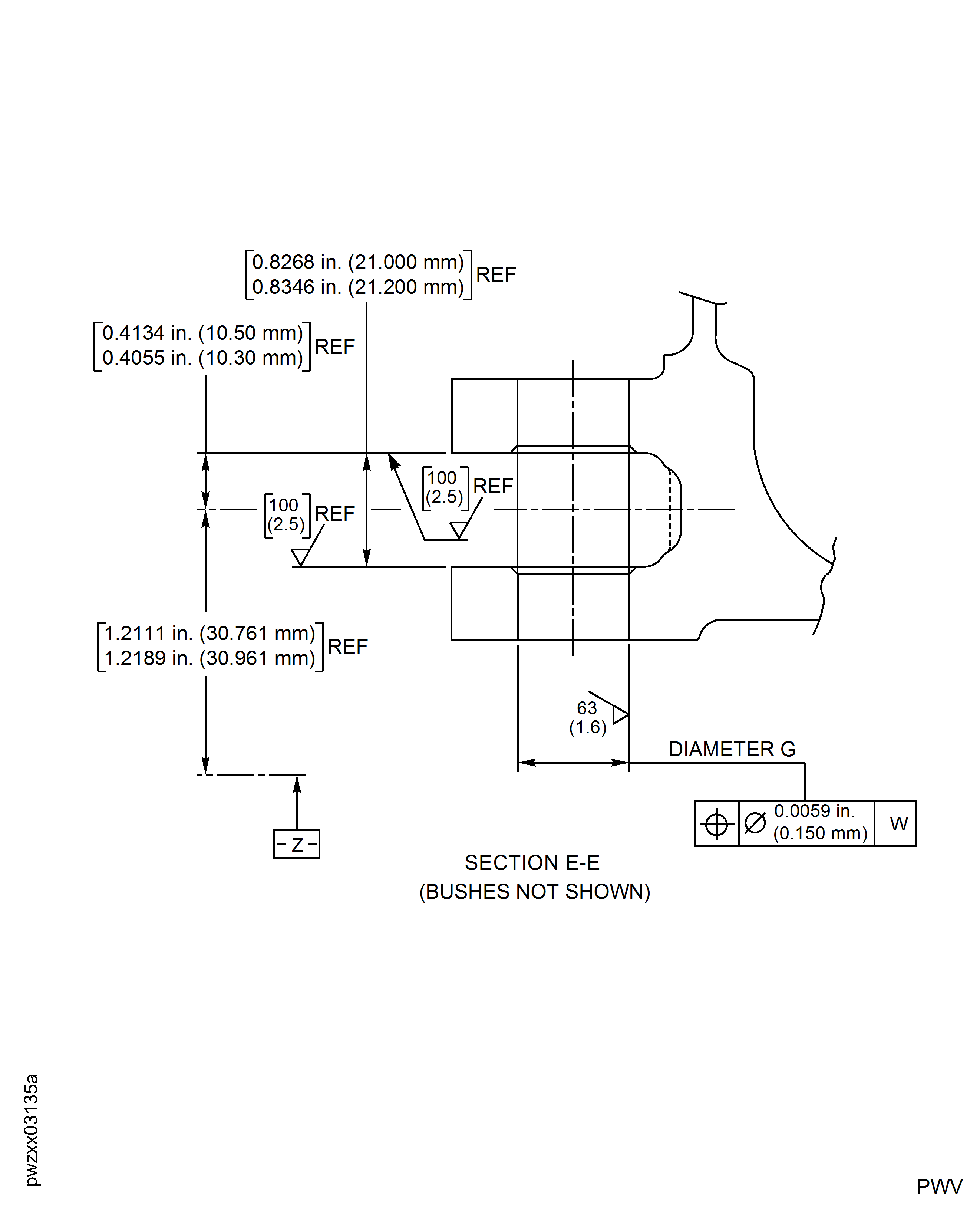

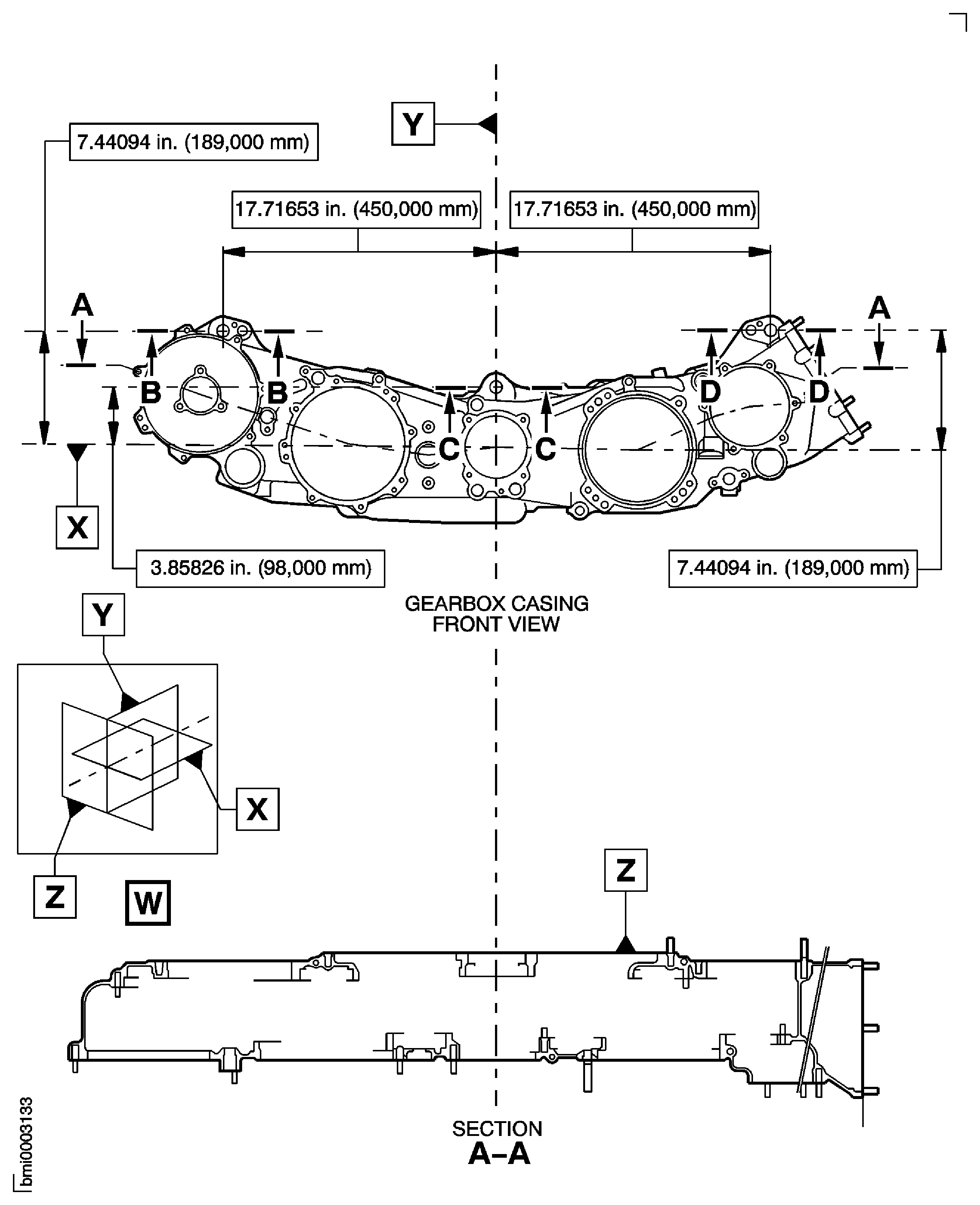

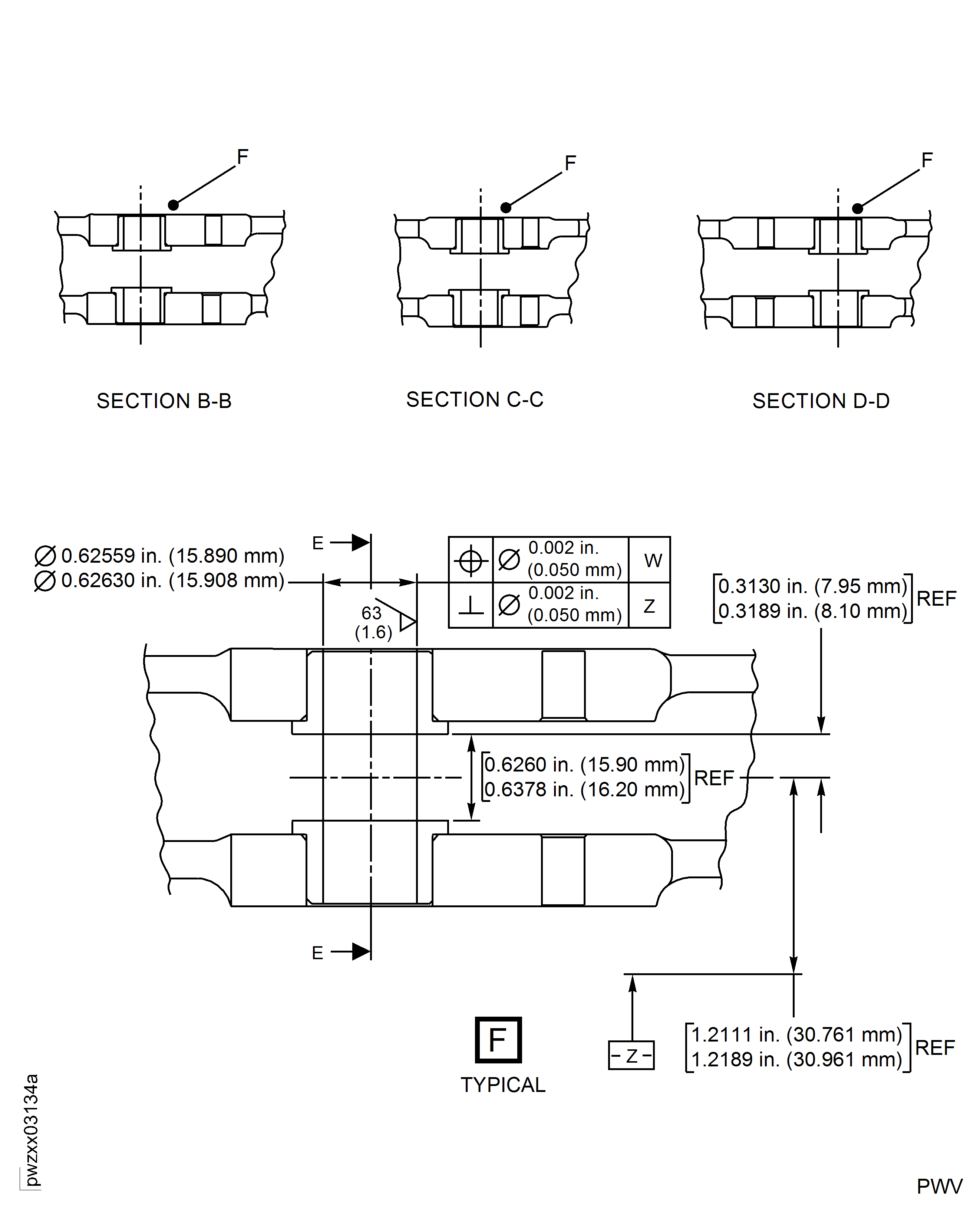

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Figure: Repair Details and Dimensions

Repair Details and Dimensions