Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-60-24-300-013 Input Gearshaft - Chromium Plate The Front Bearing Shoulder, Repair-013 (VRS5143)

General

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Grinding machine | LOCAL | Grinding machine | ||

| Hot oil tank | LOCAL | Hot oil tank | ||

| Pressure shotpeen system | LOCAL | Pressure shotpeen system | ||

| Process Plating Tanks | LOCAL | Process plating tanks | ||

| Oven | LOCAL | Oven | ||

| Magnifying glass, 5x | LOCAL | Magnifying glass, 5x | ||

| Vibrating marking pencil | LOCAL | Vibrating marking pencil |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-001 SOLVENT, DELETED | 0AM53 | CoMat 01-001 | ||

| CoMat 02-017 WAX | LOCAL | CoMat 02-017 | ||

| CoMat 02-034 METALLIC MASKING TAPE(LEAD FOIL) | 76381 | CoMat 02-034 | ||

| CoMat 05-030 CAST STEEL SHOT DELETED | 0AM53 | CoMat 05-030 |

Spares

NONESafety Requirements

NONEProcedure

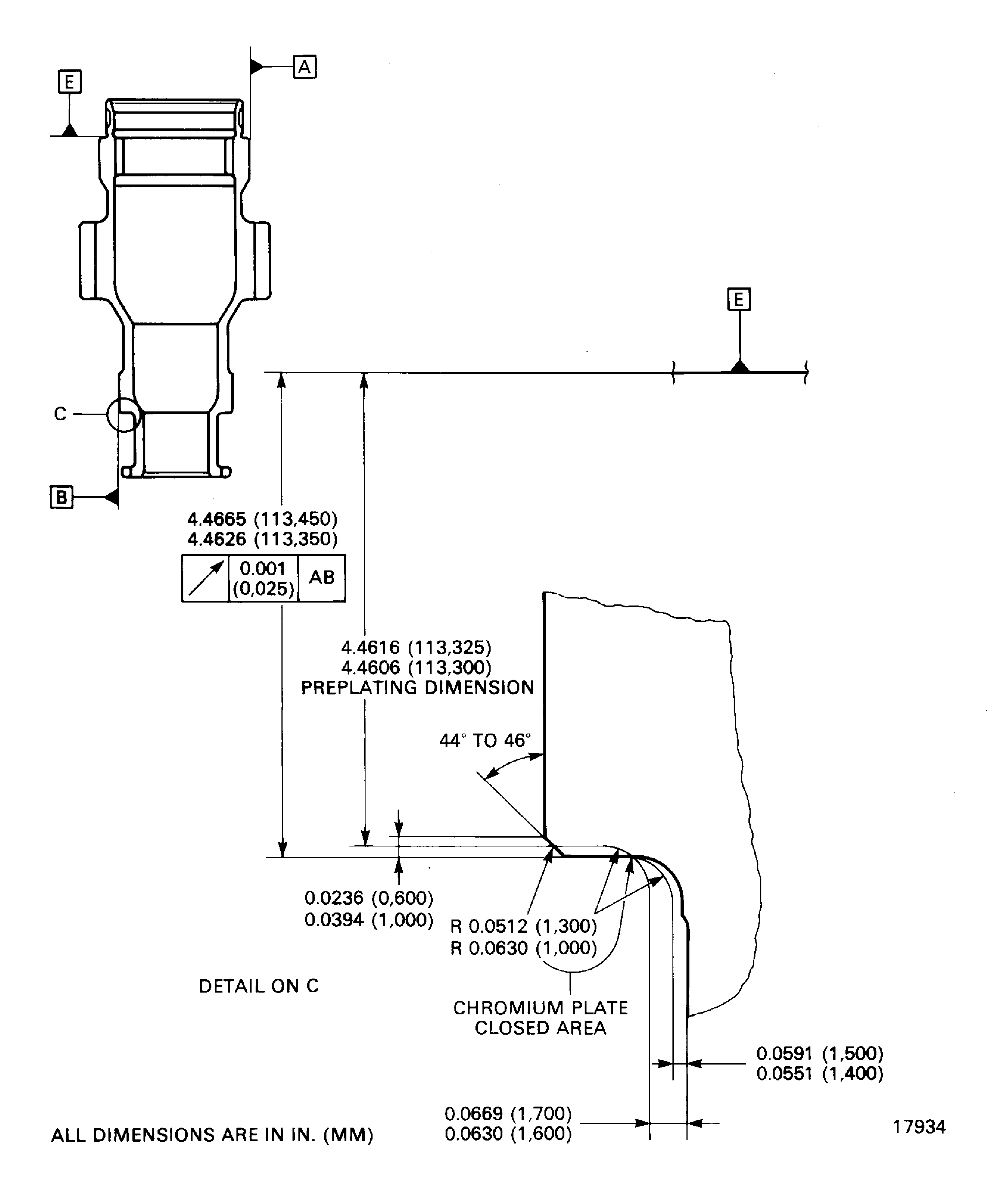

Refer to Figure.

Keep the removal of material to the minimum necessary to remove the damage.

Do not remove more than 0.005 in. (0.127 mm) of material.

The preplating dimensions must be between 4.4616 to 4.4606 in. (113.325 to 113.300 mm).

Surface roughness must be 32 microin. (0.8 micron) before plating.

Use grinding machine.

Machine the front bearing shoulder.

SUBTASK 72-60-24-320-062 Machine the Front Bearing Shoulder of the Gearshaft

Refer to the SPM TASK 70-24-01-240-501.

Cracks are not permitted.

Do the magnetic particle inspection for cracks.

SUBTASK 72-60-24-240-055 Examine the Gearshaft

Refer to the SPM TASK 70-21-02-210-501.

Machine the front bearing shoulder if there are signs of burnt metal.

Keep the removal of material to the minimum necessary to remove the damage.

Do the nital etch on the front bearing shoulder to find signs of burnt metal.

SUBTASK 72-60-24-210-054 Nital Etch the Front Bearing Shoulder

Refer to the SPM TASK 70-38-04-300-503.

Use pressure shotpeen system.

Shot-peen the front bearing shoulder surface to an intensity of 0.006 A to 0.008 Ain.

SUBTASK 72-60-24-380-054 Shot-peen the Front Bearing Shoulder

Refer to the SPM TASK 70-11-01-300-503.

Vapour degrease the gearshaft.

SUBTASK 72-60-24-110-054 Clean the Gearshaft

Refer to Figure.

Use CoMat 02-017 WAX.

Mask the areas of the gear not to be plated.

Refer to the SPM TASK 70-33-02-330-501.

Plate to a sufficient thickness to permit the machining to the last dimensions.

The plating out of the front bearing shoulder area is permitted but must be removed.

Use process plating tanks.

Chromium plate the front bearing shoulder.

SUBTASK 72-60-24-330-057 Chromium Plate the Front Bearing Shoulder of the Gearshaft

Refer to Figure.

SUBTASK 72-60-24-320-063 Machine the Front Bearing Shoulder of the Gearshaft

Refer to Figure.

SUBTASK 72-60-24-220-081 Examine the Chromium Plated Area

Figure: Chromium plate the front bearing shoulder of the gearshaft

Chromium plate the front bearing shoulder of the gearshaft