Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

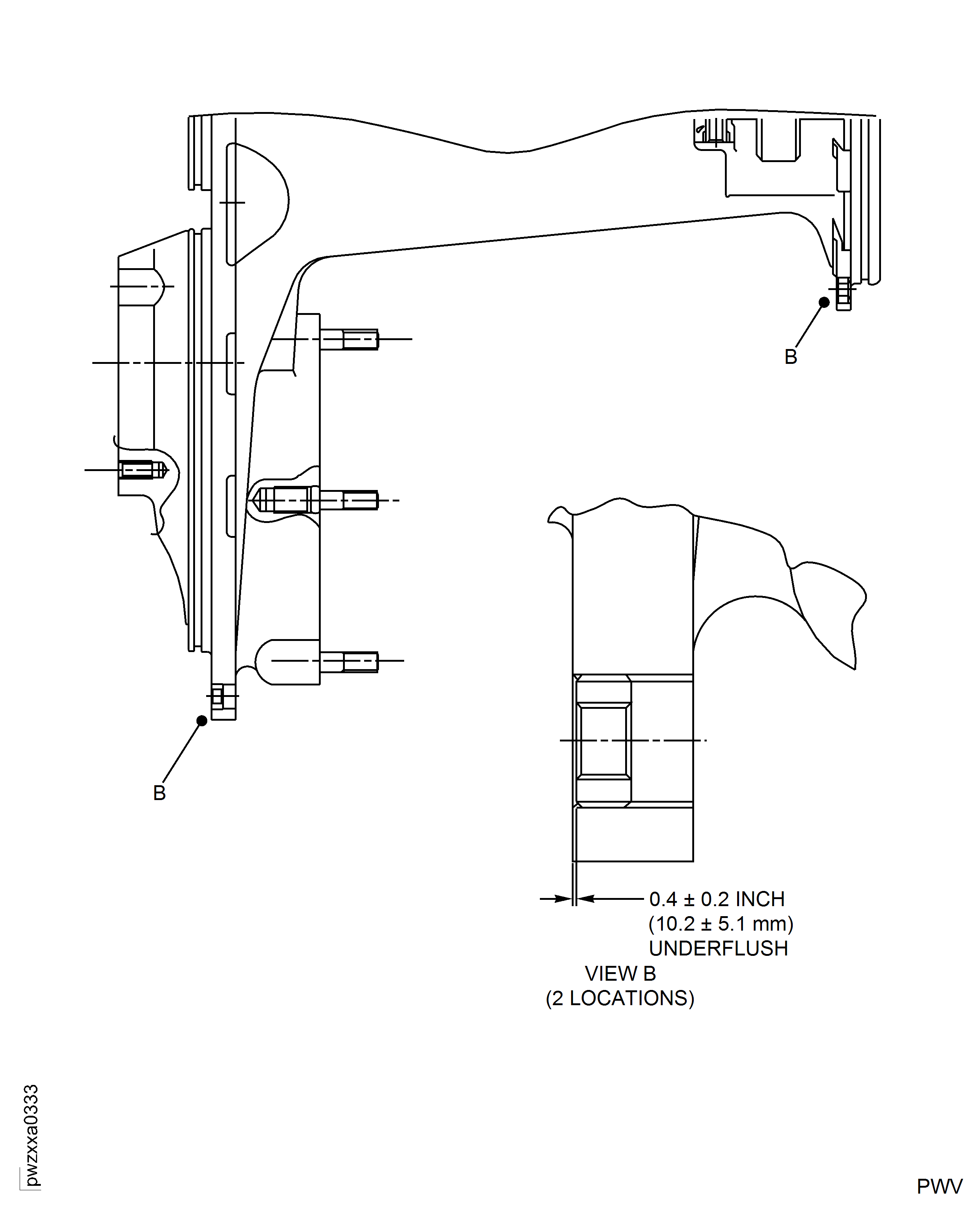

TASK 72-60-32-300-021 Replace the Damaged or Loose Screw Thread Inserts in the Angle Gearbox Support, Repair-021 (VRS5676)

General

Price and availability - none.

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Standard workshop equipment | LOCAL | Standard workshop equipment | ||

| Drilling machine | LOCAL | Drilling machine | ||

| Drill | LOCAL | Drill | 0.354 in. (9.0 mm) Diameter | |

| Drill puller | LOCAL | Drill puller | ||

| Vibration peen equipment | LOCAL | Vibration peen equipment |

Consumables, Materials and Expendables

NONESpares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

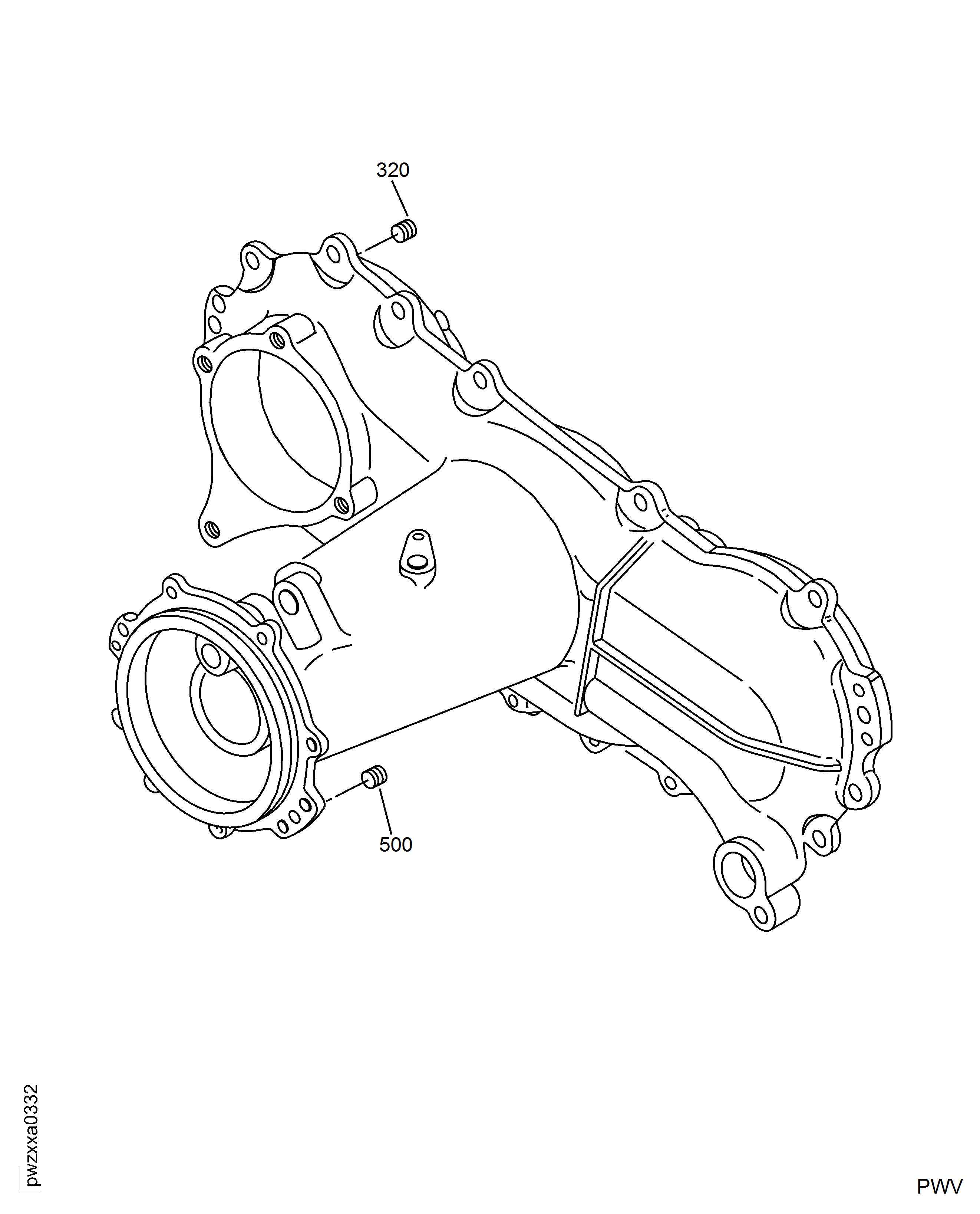

| INSERT - SCREW THREAD | 0AM53 | 4T0318 | AR | 01-320 |

| INSERT - SCREW THREAD | 0AM53 | 4T0318 | AR | 01-500 |

Safety Requirements

NONEProcedure

Refer to Figure.

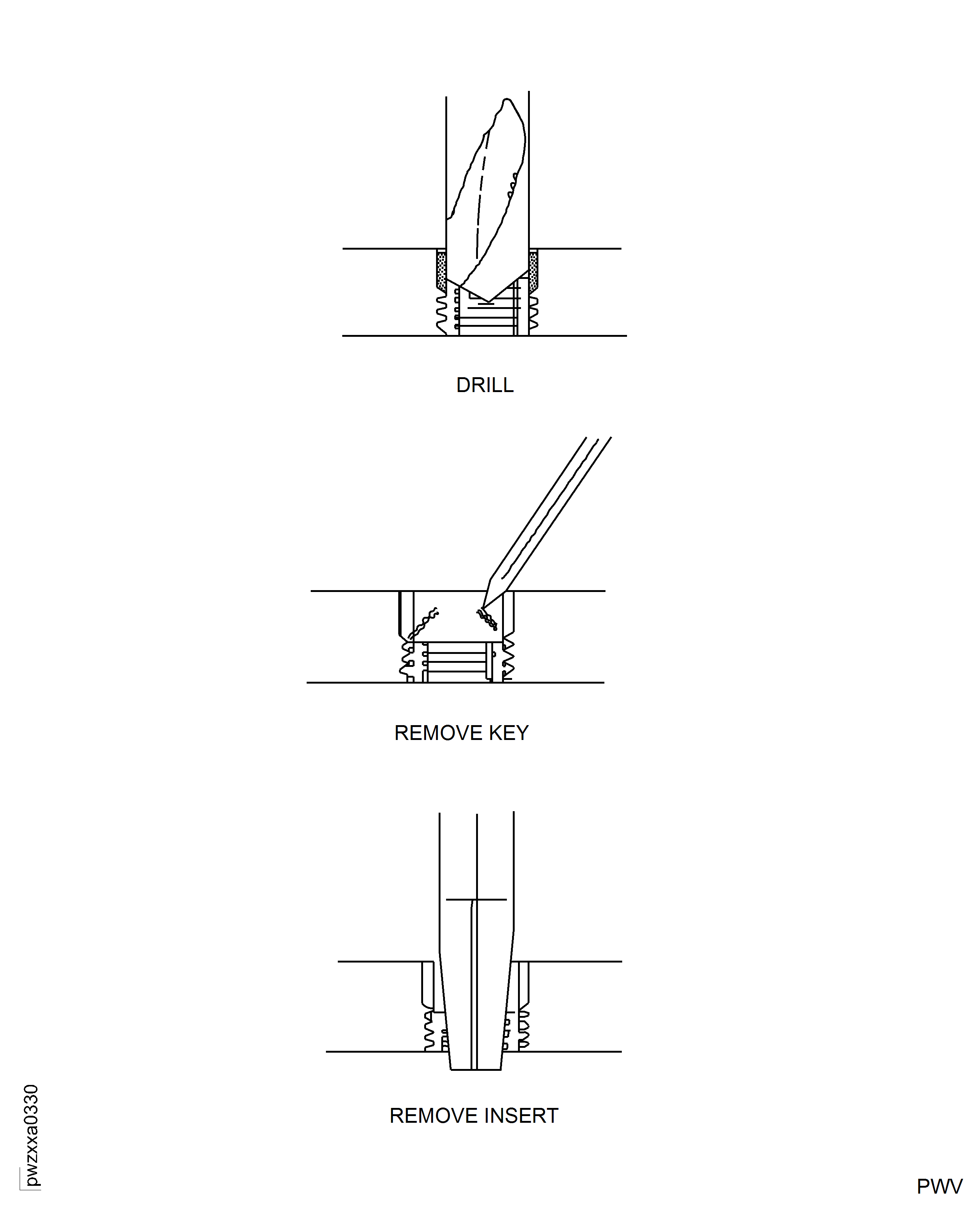

Drill the inner diameter of the insert between the keys and the internal thread for not more than 0.102 in. (2.6 mm) depth. Use a 0.354 in. (9.0 mm) Drill.

Bend with a punch and remove the keys. Use a Drill puller to remove the insert.

Remove the damaged insert(s).

SUBTASK 72-60-32-350-086 Remove the Insert

Use a clean dry air blast to remove all swarf.

Clean the thread.

SUBTASK 72-60-32-100-003 Clean the part

Ensure that the threads are clean and free from damage and swarf.

Reject if damage is found.

Visually examine the part.

SUBTASK 72-60-32-200-002 Examine the Part after the Insert Removal

Do the touch up process if the anodic treatment has been damaged by insert removal.

Refer to TASK 70-38-02-300-503.

Check the surface.

SUBTASK 72-60-32-330-003 Restore the Damaged Anodic Treatment

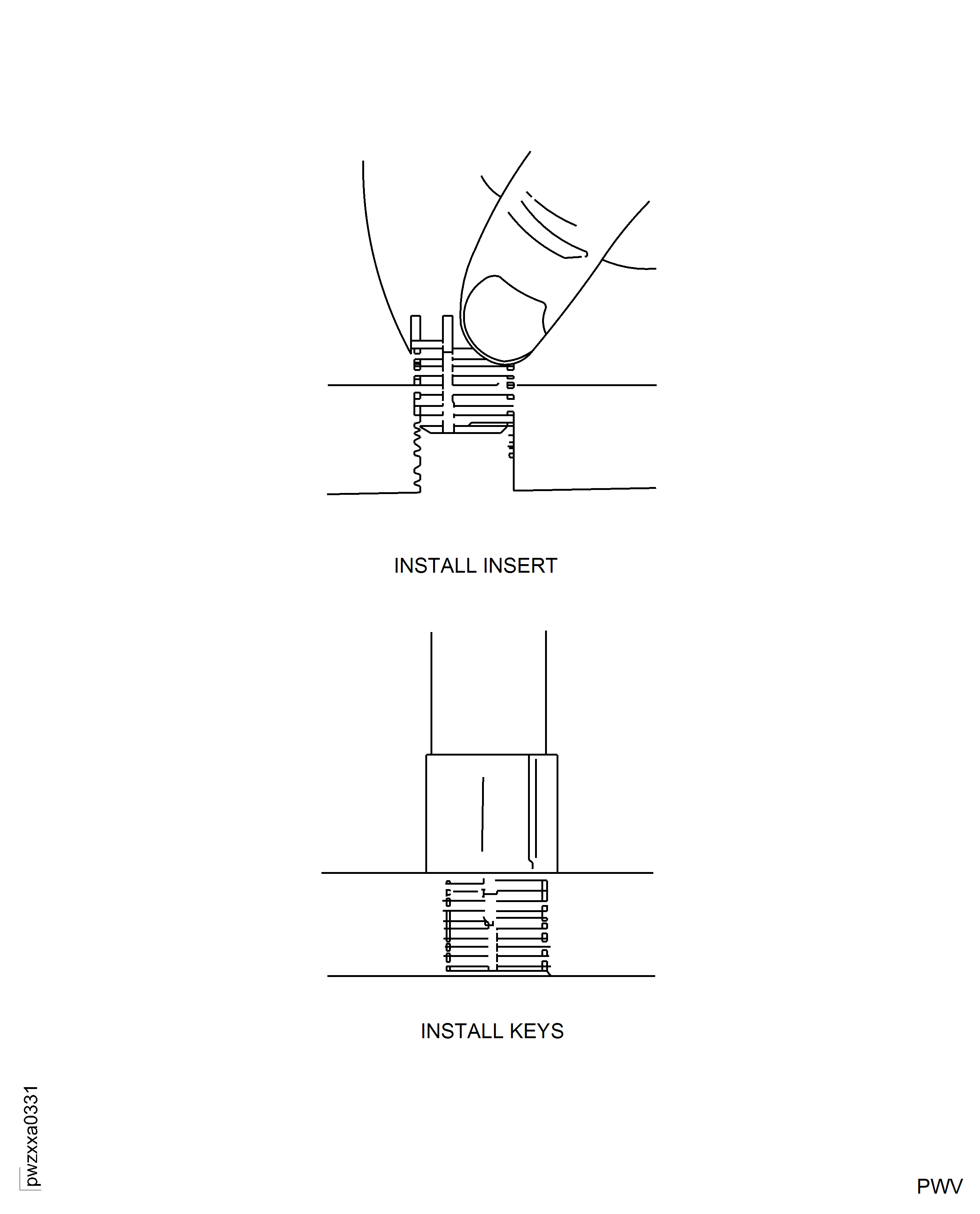

Refer to Figure.

Screw in by hand the new insert in the adapter threaded hole.

Align the keys with the broach seats on the adapter.

Make sure that the insert is flush both side of the flange.

Push the keys into the broached seats.

Install the insert.

SUBTASK 72-60-32-350-087 Install the New Insert

Do the touch up process if the anodic treatment has been damaged by insert installation.

Refer to TASK 70-38-02-300-503.

Check the surface.

SUBTASK 72-60-32-330-004 Restore the Damaged Anodic Treatment

Refer to TASK 72-60-32-200-001.

Do an inspection of the new insert.

SUBTASK 72-60-32-220-003 Inspect the Insert

Refer to SPM TASK 70-09-00-400-501, SUBTASK 70-09-00-400-001.

Vibration peen VRS5676 adjacent to the part number.

SUBTASK 72-60-32-350-088 Identify the Repair

Do the touch up process on the marking area.

Refer to TASK 70-38-02-300-503.

Check the surface.

SUBTASK 72-60-32-330-005 Restore the Damaged Anodic Treatment

Figure: Replace Damaged or Loose Inserts

Replace Damaged or Loose Inserts

Figure: Replace Damaged or Loose Inserts

Replace Damaged or Loose Inserts

Figure: Replace Damaged or Loose Inserts

Replace Damaged or Loose Inserts

Figure: Replace Damaged or Loose Inserts

Replace Damaged or Loose Inserts