Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-60-33-300-015 PMA Support - Chromium Plate The Stator Seat, Repair-015 (VRS5188)

General

Price and availability - none

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Workshop inspection equipment | LOCAL | Workshop inspection equipment | ||

| Grinding machine | LOCAL | Grinding machine | ||

| Magnetizing unit | LOCAL | Magnetizing unit | ||

| Demagnetizing unit | LOCAL | Demagnetizing unit | ||

| Pressure shotpeen system | LOCAL | Pressure shotpeen system | ||

| Basket | LOCAL | Basket | ||

| Vapor degreaser | LOCAL | Vapor degreaser | ||

| Process Plating Tanks | LOCAL | Process plating tanks | ||

| Furnace | LOCAL | Furnace | ||

| Magnifying glass, 5x | LOCAL | Magnifying glass, 5x | ||

| Vibrating marking pencil | LOCAL | Vibrating marking pencil |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-001 SOLVENT, DELETED | 0AM53 | CoMat 01-001 | ||

| CoMat 01-022 SODIUM HYDROXIDE NaOH (SOLID) | LOCAL | CoMat 01-022 | ||

| CoMat 01-023 CHROMIUM TRIOXIDE CrO3(CHROM.ACID) | LOCAL | CoMat 01-023 | ||

| CoMat 02-017 WAX | LOCAL | CoMat 02-017 | ||

| CoMat 02-034 METALLIC MASKING TAPE(LEAD FOIL) | 76381 | CoMat 02-034 | ||

| CoMat 05-030 CAST STEEL SHOT DELETED | 0AM53 | CoMat 05-030 |

Spares

NONESafety Requirements

NONEProcedure

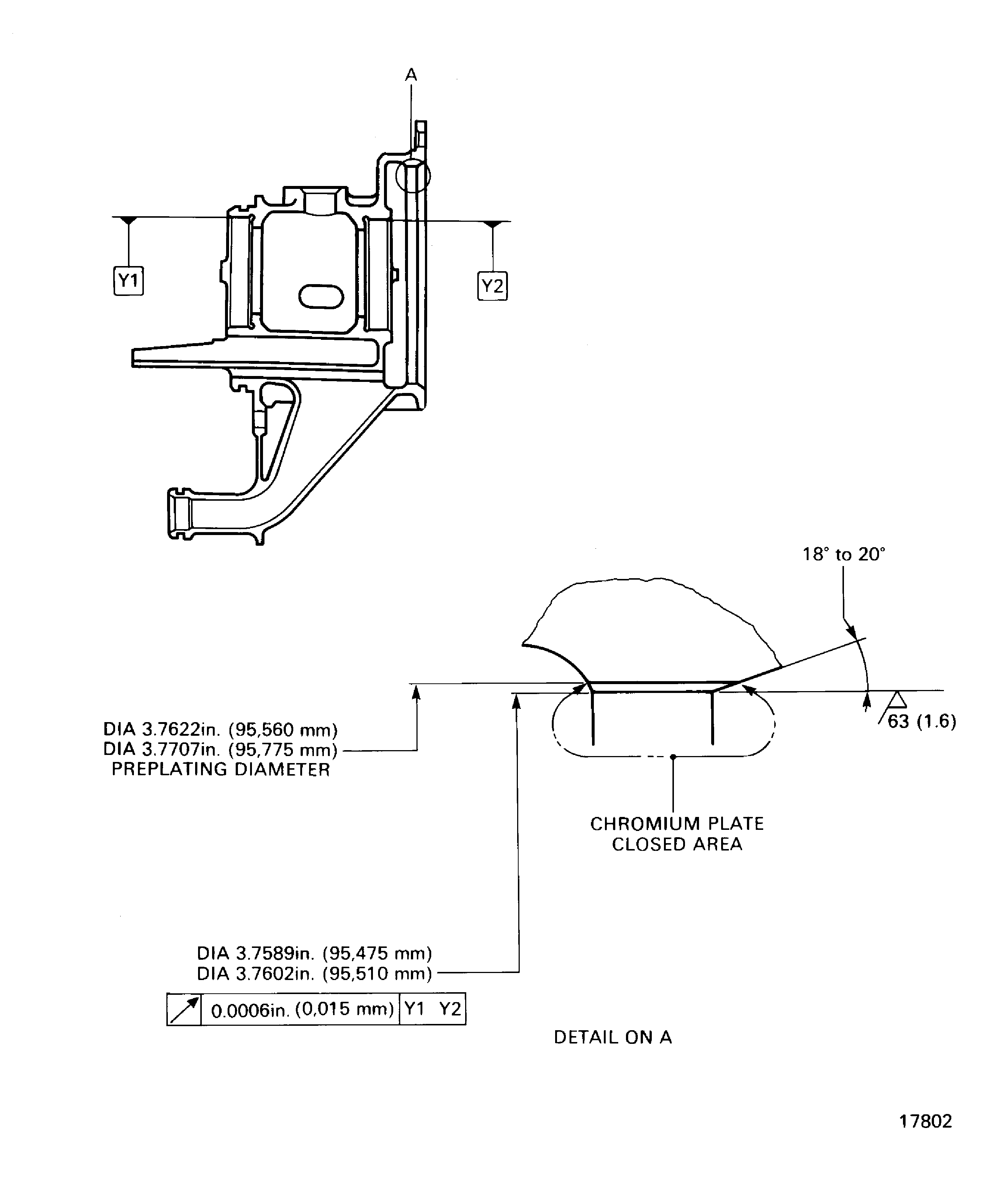

Refer to Figure.

SUBTASK 72-60-33-320-061 Machine the Stator Seat

Refer to the SPM TASK 70-24-01-240-501.

No cracks are permitted.

Do the magnetic particle inspection for cracks.

SUBTASK 72-60-33-240-058 Examine the PMA Support

Refer to the SPM TASK 70-38-04-300-503.

Shot-peen the stator seat to an intensity of 0.006A to 0.008A in.

SUBTASK 72-60-33-380-055 Shot-peen the Stator Seat

Refer to the SPM TASK 70-11-01-300-503.

Do the vapor degreasing.

SUBTASK 72-60-33-110-058 Clean the PMA Support

Refer to Figure.

Use CoMat 02-017 WAX.

Mask the areas not to be plated.

Refer to the SPM TASK 70-33-02-330-501.

Plate to a sufficient thickness to permit the machining to the last dimensions.

The plate out of the stator seat area is permitted but must be removed.

Do the chromium plate.

SUBTASK 72-60-33-330-056 Chromium Plate the Stator Seat

Refer to Figure.

SUBTASK 72-60-33-320-062 Machine the Stator Seat

Use a Magnifying glass, 5x.

The natural network crack, emphasized by grinding, is permitted.

Do the visual inspection of chromium plated areas for cracks and adhesion.

SUBTASK 72-60-33-220-085 Examine the Chromium Plated Area

Use the Vibrating marking pencil.

Remove the metal lifted by marking the number.

Vibro engrave VRS5188 adjacent to the part number.

SUBTASK 72-60-33-350-057 Record the Repair

Figure: Chromium plate the stator seat

Chromium plate the stator seat