Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 73-11-41-300-003 Fuel Nozzle Supply Fuel Manifolds - End Fittings For Conical Seat Machine Repair, Repair-003 (VRS3844)

Effectivity

FIG/ITEM | PART NO. |

|---|---|

01-060 | 2A0504-01 |

01-060 | 2A0508-01 |

01-060 | 2A3229-01 |

01-060 | 2A3229-001 |

01-060 | 2A3256-01 |

01-160 | 2A3230-01 |

01-160 | 2A3230-001 |

01-160 | 2A3257-01 |

01-260 | 2A0509-01 |

01-260 | 2A3231-01 |

01-260 | 2A3231-001 |

01-260 | 2A3258-01 |

02-060 | 2A3232-001 |

02-160 | 2A0511-01 |

02-160 | 2A3232-01 |

02-160 | 2A3233-01 |

02-160 | 2A3260-01 |

02-260 | 2A0510-01 |

02-260 | 2A0516-01 |

02-260 | 2A3236-01 |

02-260 | 2A3236-001 |

02-260 | 2A3259-01 |

02-260 | 2A3261-01 |

03-060 | 2A0515-01 |

03-060 | 2A3235-01 |

03-060 | 2A3263-01 |

03-160 | 2A1229-01 |

03-160 | 2A3237-01 |

03-160 | 2A3264-01 |

03-260 | 2A0513-01 |

03-260 | 2A3234-01 |

03-260 | 2A3265-01 |

03-360 | 2A1389-01 |

03-360 | 2A3238-01 |

03-360 | 2A3266-01 |

Material of component

DESCRIPTION | SYMBOL | MATERIAL |

|---|---|---|

Fuel Manifold Conical End Fitting | - | Iron or Nickel Alloy |

General

Price and availability - Refer to IAE.

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

Equipment IAE 3P16640 and IAE 3P16641 are available from:

Pratt & Whitney

Tool Support Services (TSS)

411 Silver Lane

East Hartford, CT 06118

Phone: (860) 610-2675

FAX: (860) 610-2670

E-Mail: pwtools@pweh.com

Preliminary Requirements

Pre-Conditions

| Action/Condition | Data Module/Technical Publication |

|---|---|

| Make sure that all the necessary cleaning and inspection procedures are done before this repair. |

Support Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 3P16640 Facer - Conical Fitting Repair .500 x .750-16 | 0AM53 | IAE 3P16640 | ||

| IAE 3P16641 Facer - Conical Fitting Repair .4375 x .625-18 | 0AM53 | IAE 3P16641 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 05-056 COMPOUND, LAPPING, SILICON CARBIDE (240 GRAIN SIZE) | 05972 | CoMat 05-056 | AR | (PMC 3014) 240 Grain Size |

Spares

NONESafety Requirements

NONEProcedure

CAUTION

OPERATORS MUST WEAR CLEAN, LINT-FREE GLOVES WHEN THEY TOUCH REWORKED FITTINGS TO PREVENT STAINS ON FINISHED CONICAL SEAT SURFACES.Refer to Figure.

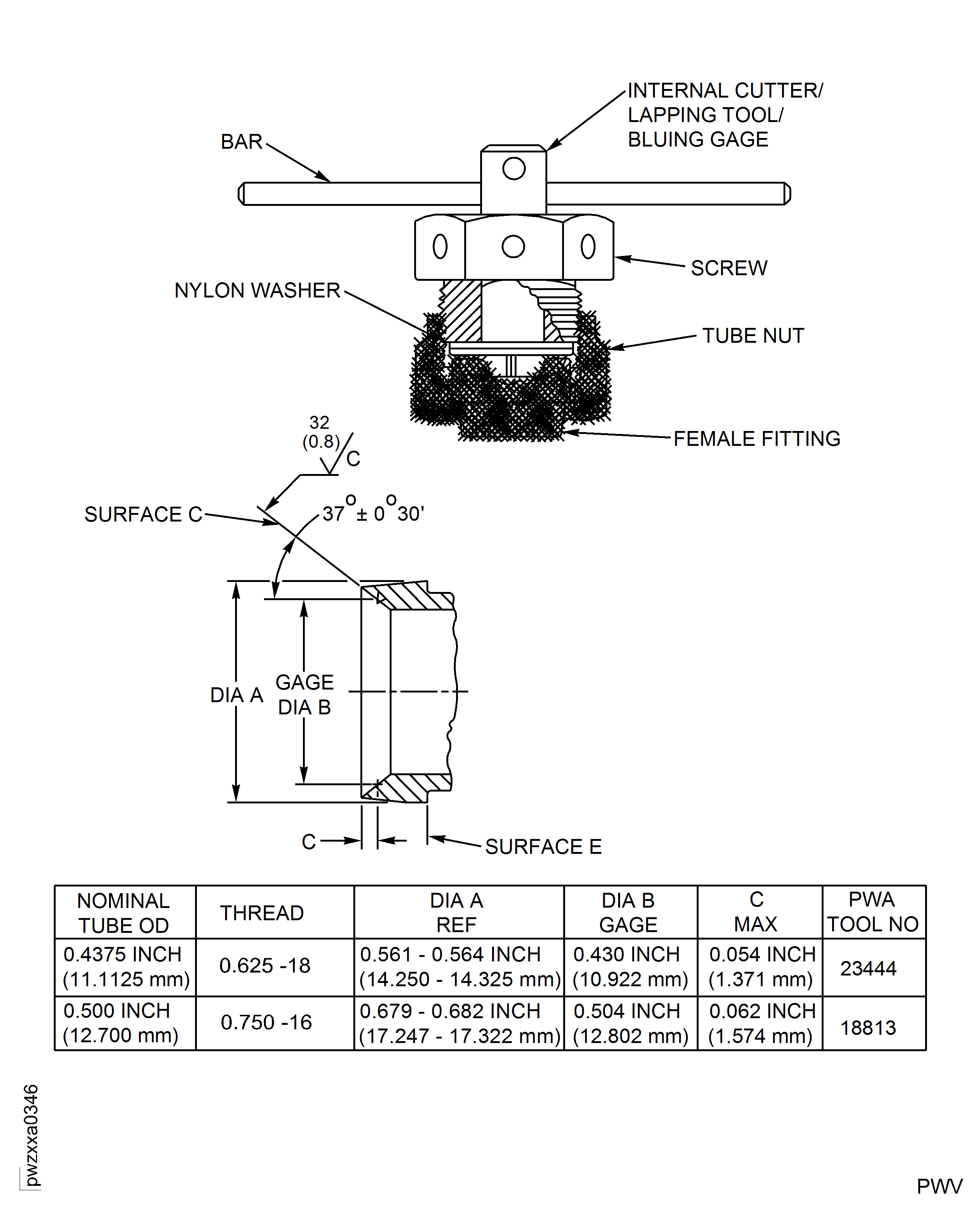

Select applicable IAE 3P16640 Facer - Conical Fitting Repair .500 x .750-16 or IAE 3P16641 Facer - Conical Fitting Repair .4375 x .625-18 tool to machine the conical seat.

Install the cutter detail of the applicable tool through the screw.

Insert the bar detail through the hole in the cutter detail.

Assemble the screw to the tube nut.

SUBTASK 73-11-41-430-001 Install End Fitting into the Machining Fixture

Machine conical seat up to the dimensions given in the Figure.

NOTE

Remove minimum amount of material to clean up conical seat surface. Do not exceed the maximum dimension.

Rotate the cutter detail to remove damage.

SUBTASK 73-11-41-350-052 Repair the Conical Seat of the End Fitting by Machining

Remove screw from tube nut.

Refer to TASK 73-11-41-200-101-A00 (INSPECTION-001), SUBTASK 73-11-41-220-052.

Inspect the seat for additional damage.

SUBTASK 73-11-41-110-057 Remove End Fitting from Machining Fixture

Insert the bar through the hole in the lap detail.

Refer to SPM TASK 70-11-26-300-503.

Clean seat surface.

Prepare lap detail.

Assemble the screw detail to the tube nut.

Lap conical seat up to the dimensions given in the Figure.

NOTE

Remove minimum amount of material to clean up conical seat surface. Do not exceed the maximum dimension.

Lap the conical seat.

Remove the screw detail from the tube nut.

Refer to TASK 73-11-41-200-101-A00 (INSPECTION-001), SUBTASK 73-11-41-220-052.

Inspect the seat for additional damage.

Lap conical seat of the end fitting per Step.

If satisfactory seat is not achieved.

Refer to SPM TASK 70-11-26-300-503.

If lapping was used make sure there is no lapping compound on the end fitting or tube.

Clean seat surface.

SUBTASK 73-11-41-350-053 Repair the Conical Seat of the End Fitting by Lapping

Figure: Repair the Conical Seat of the End Fitting

Repair the Conical Seat of the End Fitting