Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 73-13-41-300-006 Fuel Nozzle And Support Assembly - Replace The Hardface On The Outer Swirler, Repair-006 (VRS3163)

Material of Component

PART IDENT | MATERIAL |

Fuel nozzle and support assembly | Corrosion and heat resistant alloy |

General

Price and Availability - Refer to IAE.

The practices and processes referred to in this procedure by TASK numbers are in the SPM.

NOTE

Preliminary Requirements

Pre-Conditions

| Action/Condition | Data Module/Technical Publication |

|---|---|

| Make sure all the necessary cleaning and inspection procedures are done before this repair. |

Support Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-066 METAL SPRAYING POWDER, 75 CHROMIUM CARBIDE/25 (80 NICKEL - 20 CHROMIUM ALLOY), FINE | DK026 | CoMat 03-066 | ||

| CoMat 03-096 PLASMA SPRAY POWDER | LOCAL | CoMat 03-096 |

Spares

NONESafety Requirements

NONEProcedure

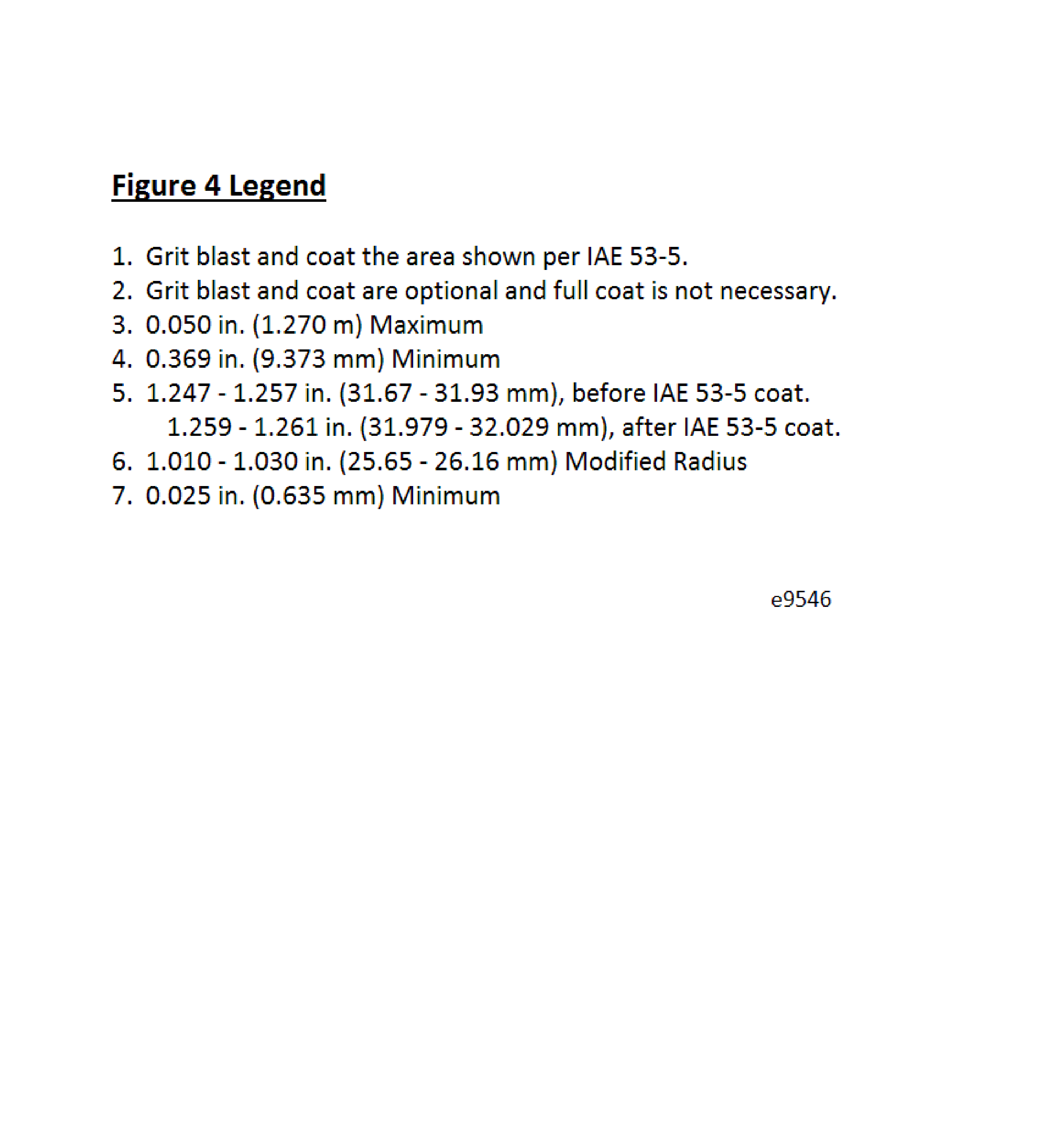

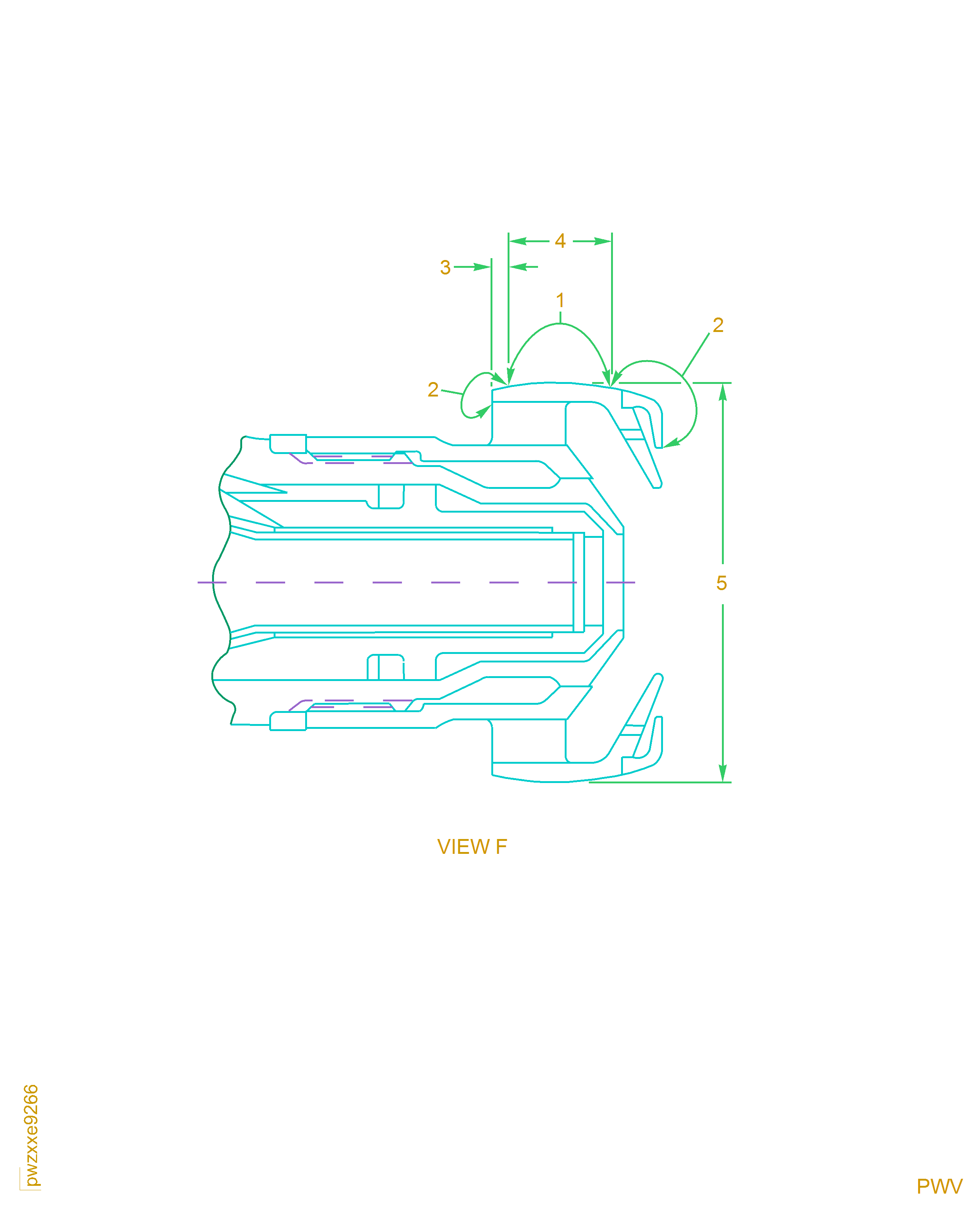

Refer to Figure for the areas to be masked and plugged to prevent the internal cavities of the nozzle assembly from being exposed to foreign materials.

Refer to SPM TASK 70-38-24-380-501.

Apply a mask and plug as necessary.

SUBTASK 73-13-41-380-001 Prerequisites

Refer to SPM TASK 70-32-07-100-501. Remove minimum amount of material necessary to do the repair.

CAUTION

REMOVAL OF IAE 53-5 COAT BY MANUAL GRIT BLAST PROCEDURE IS NOT PERMITTED.Grind to remove IAE 53-5 plasma coating from the Outer Air Swirler.

The Source Demonstration requirements of this repair mean that any facility not authorized to accomplish this repair either utilize the Authorized Repair Vendors listed below or contact IAE Manager Maintenance Operations to determine if a qualification program can be initiated at their facility.

IAE - International Aero Engines AG

400 Main Street, Mail Stop 121-10

East Hartford, CT 06118

USA

Email: gpiaecomms@iaev2500.com

ATTN: Manager, Maintenance Operations

Authorized repair vendor for Repair VRS3163 is listed below:

Combustor Airmotive Services

10 Loyang Lane - Mail Stop 107-18

Singapore 508916

Tel: 65 65493811

Fax: 65 65421409

The designation by IAE of an authorized repair vendor indicates that the repair vendor has demonstrated the necessary capability to enable it to carry out the listed repair work. However, IAE makes no warranties or representations concerning the qualifications or quality standards of the repair vendors to carry out the repair work and accepts no responsibility whatsoever for any work that may be carried out by a repair vendor, other than when IAE is listed as the repair vendor. Authorized repair vendors do not act as agents or representatives of IAE.

Remove the IAE 53-5 coat from the Outer Air Swirler by using a fully automated grit blast process. Send the Fuel Nozzle and Support Assembly to an approved source given below for removal of IAE 53-5 coat by automated grit blast.

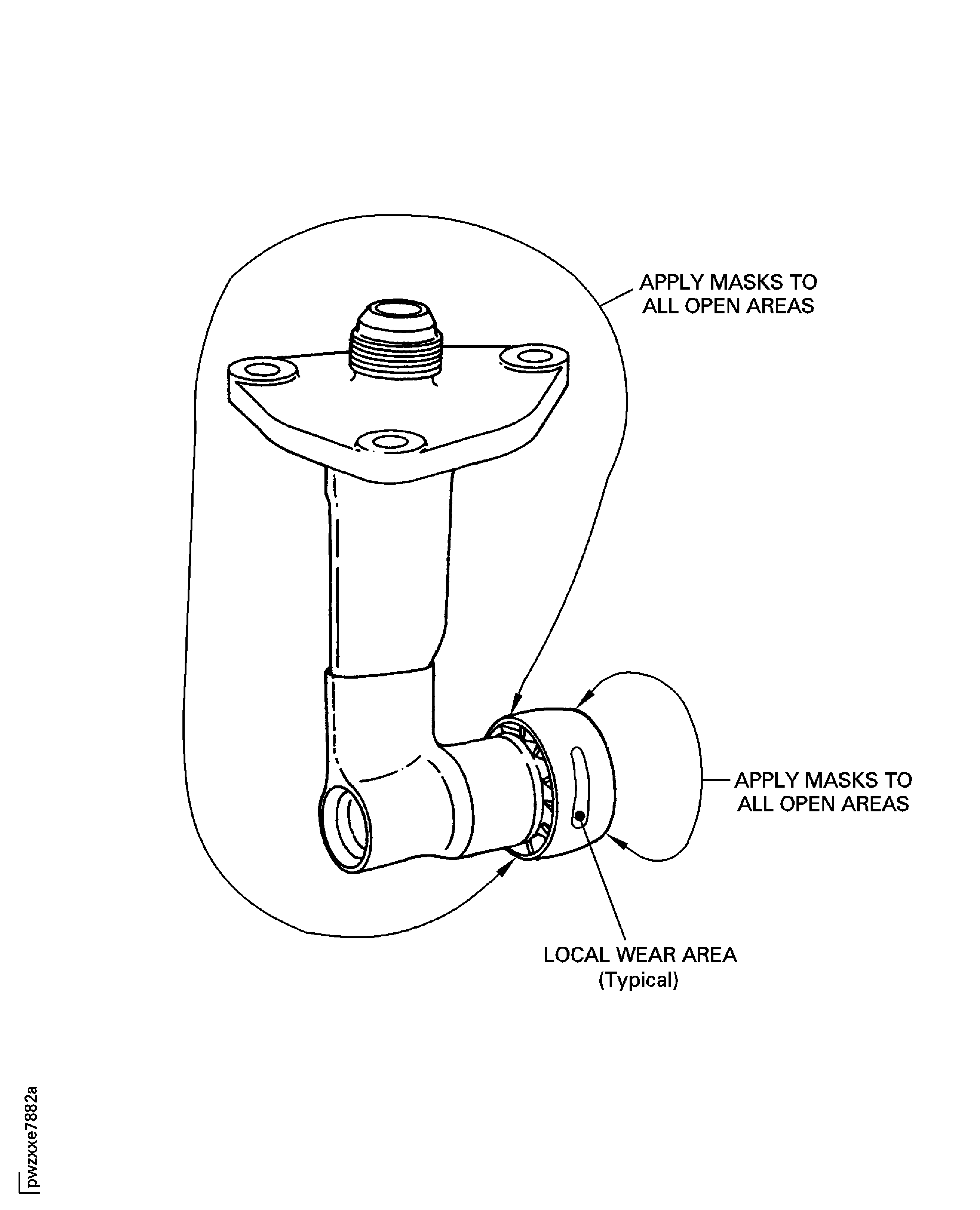

Remove all coat and wear from the Fuel Nozzle and Support Assembly Outer Air Swirler to the limits given in Figure and by one or more of the procedures that follow:

Refer to SPM TASK 70-32-07-100-501. Remove minimum amount of material necessary to do the repair.

If necessary, remove the remaining damage and base coat by machining or grind operation.

SUBTASK 73-13-41-330-001 Remove wear and/or existing coating from the Outer Air Swirler

Refer to SPM TASK 70-11-03-300-503.

Clean the Outer Air Swirler.

SUBTASK 73-13-41-110-001 Clean the Fuel Nozzle and Assembly

Refer to TASK 70-23-05-230-501.

Use medium sensitivity, water washable.

No cracks permitted.

If grinding was performed, do a fluorescent penetrant inspection of the repair area.

SUBTASK 73-13-41-230-001 Do a Fluorescent Penetrant Inspection of the Repair Area if Grinding was Performed

Inspect for complete removal of coat.

Do a visual inspection of the Outer Air Swirler.

SUBTASK 73-13-41-220-095 Do a Visual Inspection of the Outer Air Swirler

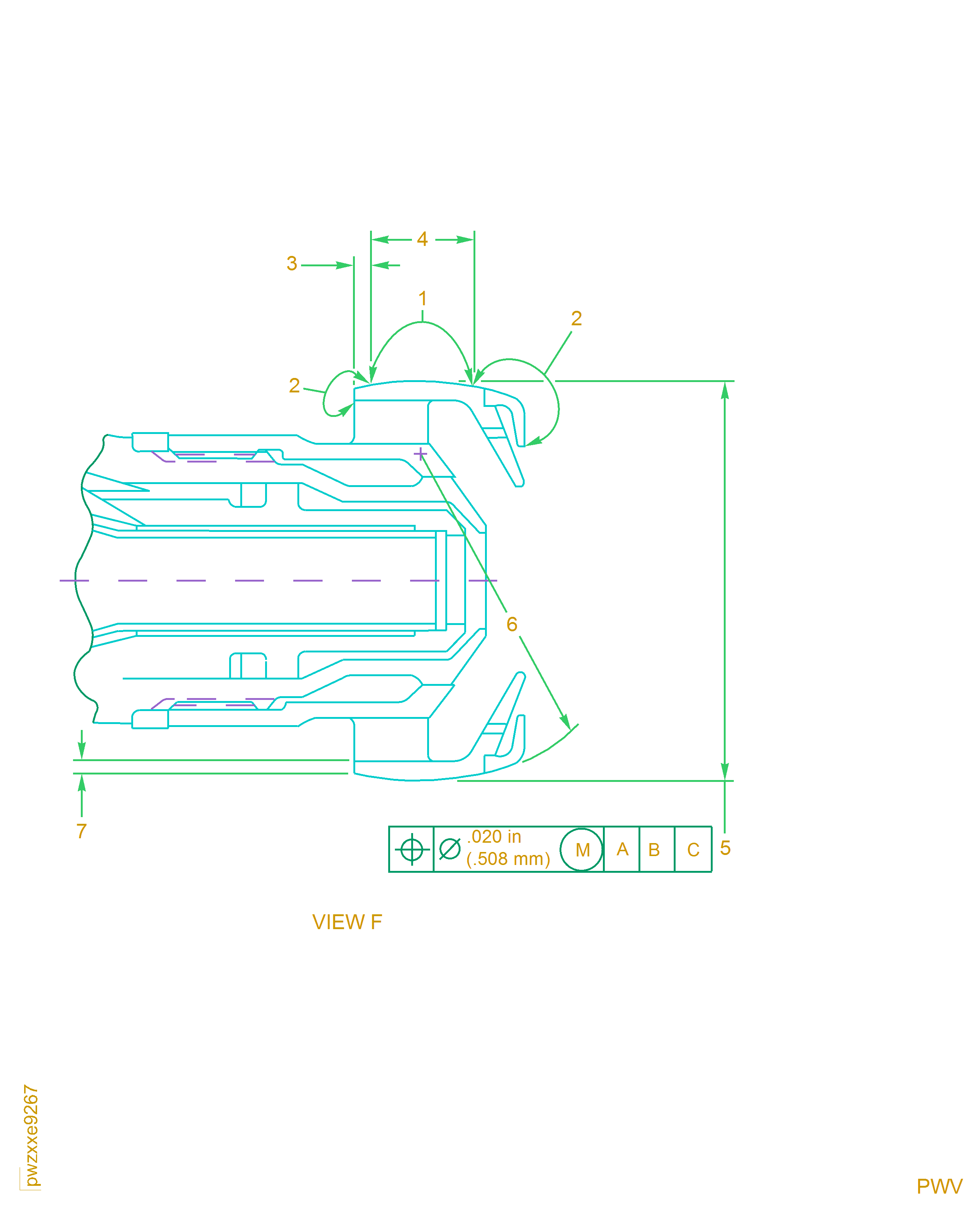

SUBTASK 73-13-41-220-002 Do a Dimensional Inspection of the Outer Air Swirler

Refer to SPM TASK 70-34-18-380-501.

Grit blast out of the repair area is not permitted. Use masks or maskants.

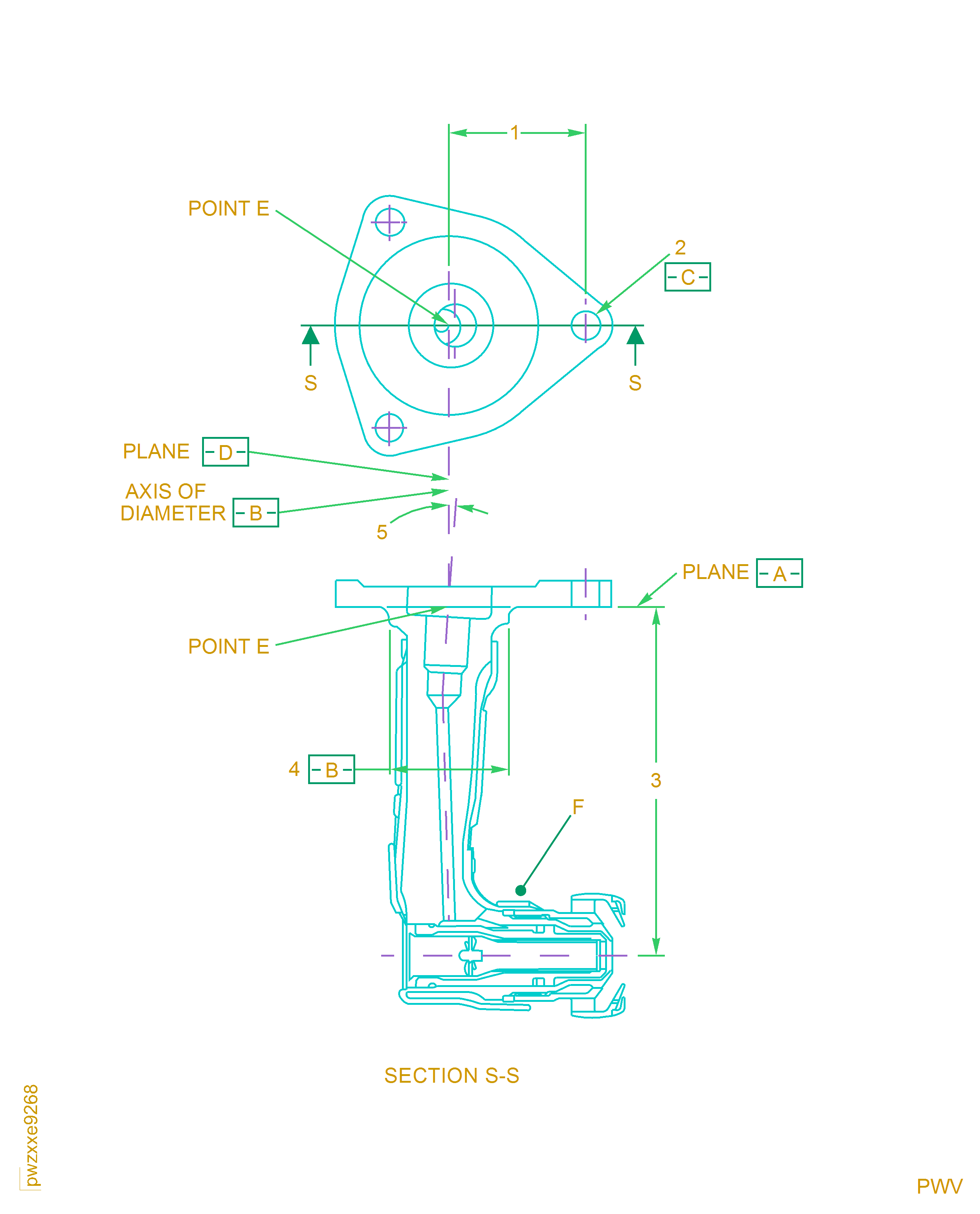

Prepare the repair area for base coat.

SUBTASK 73-13-41-380-002 Prepare the Outer Air Swirler for Base Coat

Refer to Figure.

Refer to SPM TASK 70-34-03-340-501. Use CoMat 03-096 PLASMA SPRAY POWDER.

Coat out of the repair area is not permitted. Coat to a sufficient thickness to allow for finishing.

Coat the repair area by IAE 53-47.

Refer to Figure.

Finish coat thickness must be 0.003 in. - 0.012 in. (0.077 mm - 0.304 mm) thick. Refer to SPM TASK 70-32-07-100-501. No cutting fluids are permitted. Blend edges of the build-up to the initial contour of the parent material.

Dry machine or dry grind the base coat.

SUBTASK 73-13-41-340-001 Apply Base Coat to the Outer Air Swirler

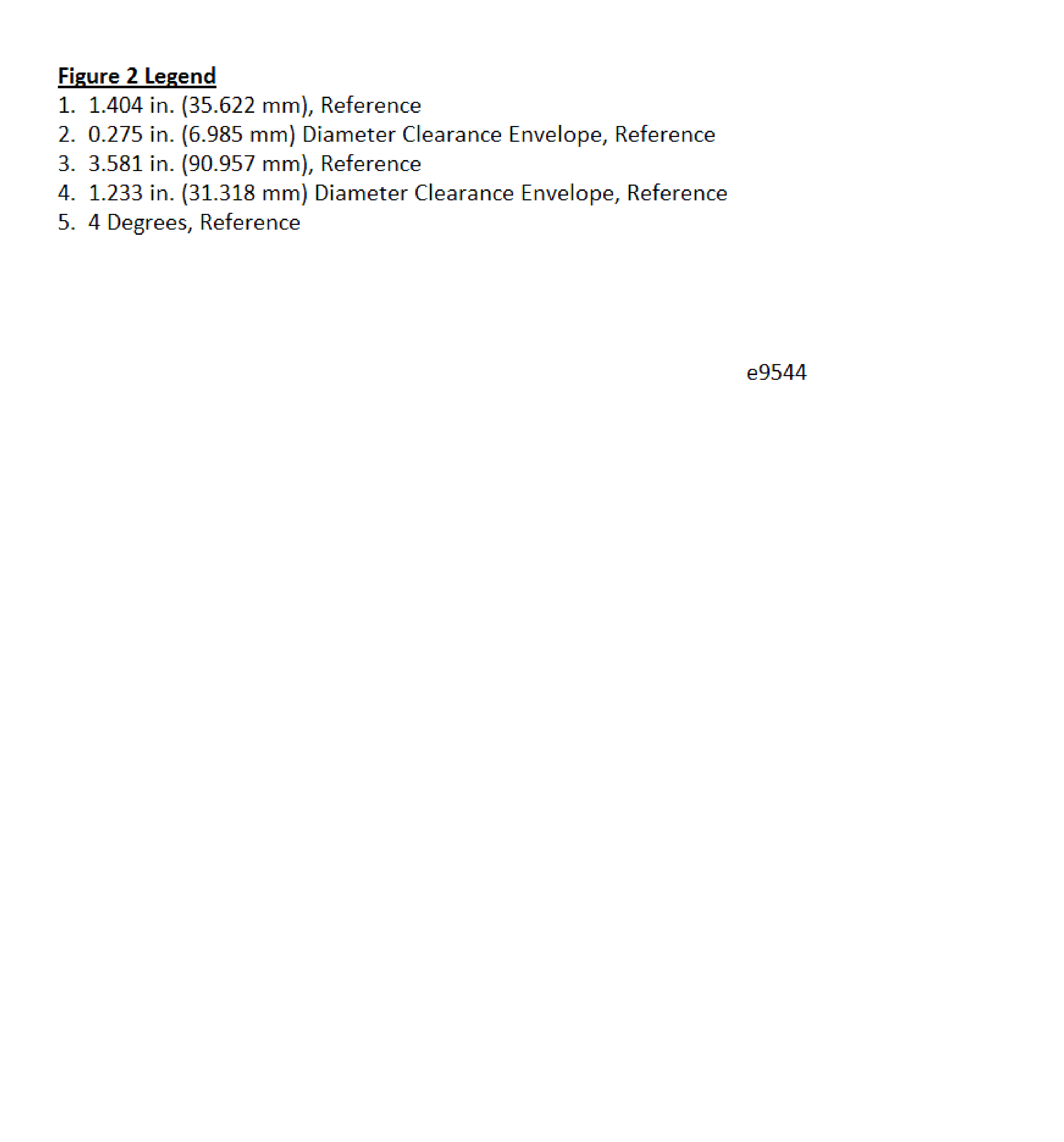

Refer to SPM TASK 70-34-18-380-501.

Grit blast out of the repair area is not permitted. Use masks or maskants.

Prepare the repair area for coat.

Refer to Figure.

Coat out of the repair area is not permitted. Coat to a sufficient thickness to allow for finishing.

Coat the repair area by IAE 53-5.

Refer to Figure.

Finish coating thickness must be 0.002 - 0.006 inch (0.051 - 0.152 mm). Refer to SPM TASK 70-32-07-100-501.

Finish grind the repaired area.

SUBTASK 73-13-41-340-002 Apply Top Coat to the Outer Air Swirler

Remove masks or maskants by SPM TASK 70-34-18-380-501.

SUBTASK 73-13-41-110-002 Remove Masks or Maskants or Plugs from the Outer Air Swirler

Refer to SPM TASK 70-11-03-300-503.

Clean the Outer Air Swirler.

SUBTASK 73-13-41-110-003 Clean the Outer Air Swirler

Refer to SPM TASK 70-34-03-340-501.

Examine the coating after repair by IAE 53.

SUBTASK 73-13-41-220-002 Examine the Plasma Coating on the Outer Air Swirler

Refer to TASK 73-13-41-200-200 (INSPECTION-000).

Do a dimensional inspection of the Fuel Nozzle and Support Assembly.

SUBTASK 73-13-41-220-003 Do a Dimensional Inspection of the Fuel Nozzle and Support Assembly

Figure: Mask the Fuel Nozzle and Support Assembly

Mask the Fuel Nozzle and Support Assembly

Figure: Fuel Nozzle and Support Datums

Fuel Nozzle and Support Datums

Fuel Nozzle and Support Datums

Figure: Apply Base Coat On The Outer Air Swirler

Apply Base Coat On The Outer Air Swirler

Apply Base Coat On The Outer Air Swirler

Figure: Apply Topcoat IAE 53-5 On The Outer Air Swirler

Apply Topcoat IAE 53-5 On The Outer Air Swirler

Apply Topcoat IAE 53-5 On The Outer Air Swirler