Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 73-13-41-300-005 Fuel Nozzle And Support Assembly - Weld Repair The Fairing Cracks, Repair-005 (VRS3032)

Effectivity

FIG/ITEM | PART NO. |

01-020 | 2A0994 |

01-020 | 2A0994-001 |

01-020 | 2A1637 |

01-020 | 2A1637-001 |

01-020 | 2A2250 |

01-020 | 2A2250-001 |

01-020 | 2A3448 |

01-020 | 2A3448-001 |

01-020 | 2A3453 |

01-020 | 2A3453-001 |

Material of component

DESCRIPTION | SYMBOL | MATERIAL |

Fuel nozzle and support assembly | Corrosion and heat resistant alloy |

General

Price and Availability - Refer to IAE.

The practices and processes referred to in this procedure by TASK numbers are in the SPM.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Stainless steel wire brush | LOCAL | Stainless steel wire brush - no specific | ||

| Welding equipment | LOCAL | Welding equipment - no specific |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-209 WELDING FILLER WIRE, NiBASE 5% Cr | LOCAL | CoMat 03-209 | ||

| CoMat 03-286 WELDING WIRE | LOCAL | CoMat 03-286 | ||

| Silicon carbide abrasives | LOCAL | Silicon carbide abrasives - no specific |

Spares

NONESafety Requirements

NONEProcedure

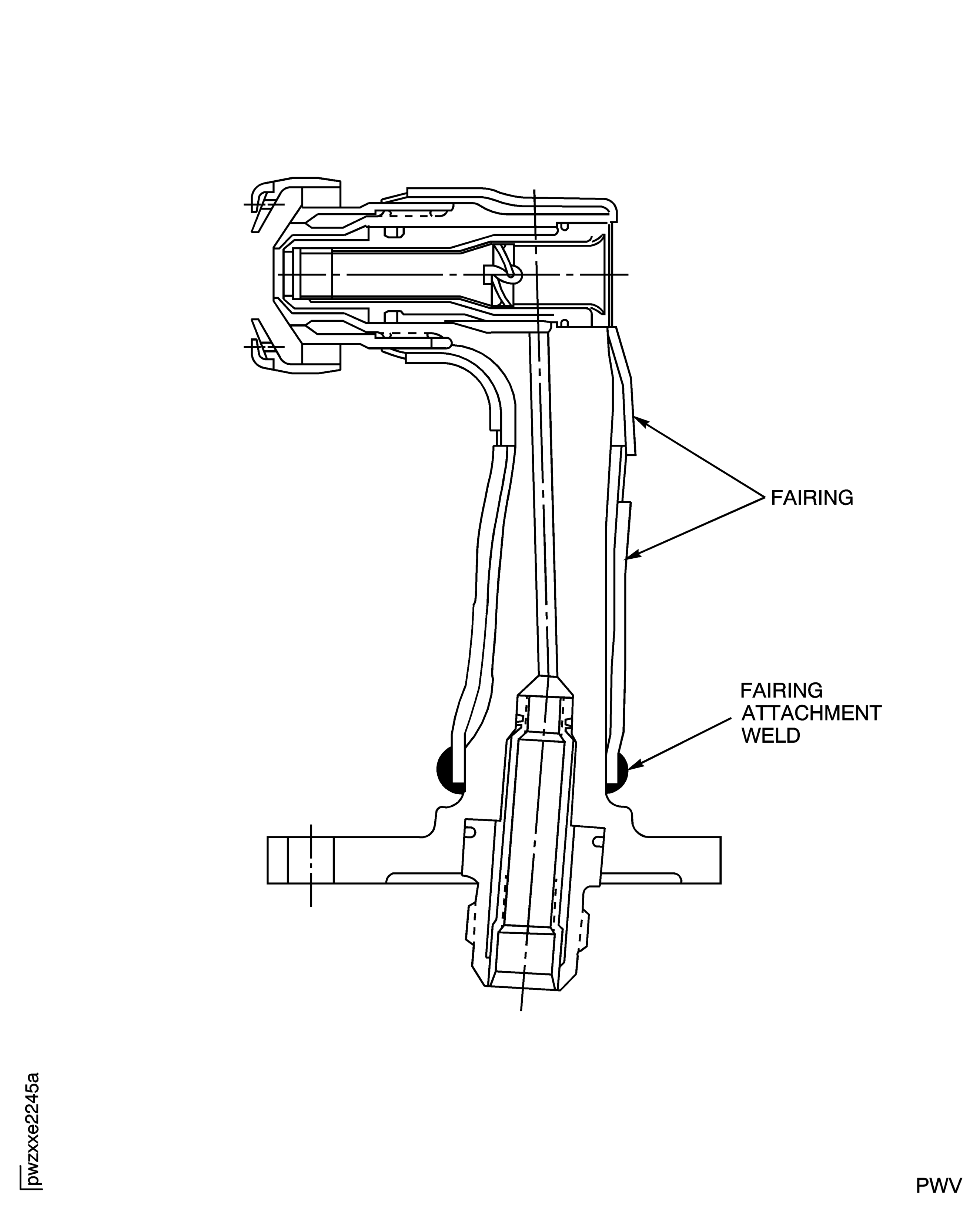

Refer to Figure to find the referenced weld area.

Refer to Testing-001 TASK 73-13-41-700-201 for leak/pressure test procedure and acceptance criteria.

If a crack is located in the fairing attachment weld area, do a leak/pressure test on the fuel nozzle to make sure any crack indications are not through cracks into the fuel passage.

SUBTASK 73-13-41-790-052 Do a Leak/Pressure Test of the Fuel Nozzle and Support Assembly

Refer to Figure.

CAUTION

BE CAREFUL WHEN YOU ROUTE OUT CRACKS SO YOU DO NOT CAUSE NICKS, GOUGES OR OTHER TOOL MARKS ON THE BASE METAL OF THE SUPPORT THAT IS ADJACENT TO OR BEHIND THE FAIRING.Route out cracks in the fairing.

NOTE

If the crack looks like it goes through the fairing outside of the weld area, it is not necessary to break through the fairing during routing.

SUBTASK 73-13-41-350-059 Remove the Cracks from the Fairing of the Fuel Nozzle and Support Assembly

Use a Stainless steel wire brush or Silicon carbide abrasives to mechanically clean around the crack repair area.

Clean the area to be welded to remove surface oxides from the fairing.

SUBTASK 73-13-41-110-056 Clean the Repair Area of the Fuel Nozzle and Support Assembly

Refer to SPM .TASK 70-11-01-300-503.

Clean the fuel nozzle and support assembly

SUBTASK 73-13-41-110-057 Clean the Fuel Nozzle and Support Assembly

Heat the nozzle and support assembly to 300 deg F (148.9 deg C) for a minimum of 20 minutes.

Provide an argon gas backup (flow argon gas behind the heatshield during the weld repair).

Refer to Figure and SPM TASK 70-31-13-310-501

Manual gas tungsten arc weld (IAE 16A) the cracks in the fairing.

Use CoMat 03-286 WELDING WIRE or CoMat 03-209 WELDING FILLER WIRE, NiBASE 5% Cr that is 0.031 in. (0.79 mm) in diameter.

The maximum height of the weld must be 0.020 in. (0.51 mm).

Do not remove material from the weld.

Weld the cracks in the fairing

Let the weld area become cool slowly after repair.

NOTE

Stress-relief is not necessary.

SUBTASK 73-13-41-310-051 Weld the Cracks in the Fairing

Refer to Figure.

Refer to SPM TASK 70-23-05-230-501.

No cracks are permitted.

Fluorescent penetrant inspection is necessary on the complete fairing.

Fluorescent penetrant inspect the weld repairs and the base metal of the support that is adjacent to the fairing.

SUBTASK 73-13-41-230-055 Examine the Fuel Nozzle and Support Assembly after Weld Repair

Figure: Repair Details and Dimensions

Repair Details and Dimensions