Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 73-13-41-300-002 Fuel Nozzle And Support Assembly - Remove And Install, Or Replace The Fuel Strainer Element And/Or Metering Plug, Repair-002 (VRS3458)

Material of component

DESCRIPTION | SYMBOL | MATERIAL |

Fuel metering plug | Corrosion and heat resistant alloy | |

Support | Corrosion and heat resistant alloy | |

Strainer element | Corrosion and heat resistant alloy |

General

Price and Availability - Refer to IAE for the items that follow:

Tools

Repair parts

Repair of spares

The practices and processes referred to in this procedure by TASK numbers are in the SPM.

To identify the consumable materials, refer to the PCI.

Related repairs - none

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Allen wrench | LOCAL | Allen wrench | 0.126 in. (3.20 mm) hexagonal head | |

| Oven | LOCAL | Oven | With range of 500 deg F (260 deg C) | |

| Power arm vise | LOCAL | Power arm vise | ||

| IAE 1P16167 Holding plate | 0AM53 | IAE 1P16167 | 1 off |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 04-008 ANAEROBIC COMPOUND SEALANT | 05972 | CoMat 04-008 | ||

| CoMat 04-010 ACTIVATOR/PRIMER | LOCAL | CoMat 04-010 |

Spares

NONESafety Requirements

NONEProcedure

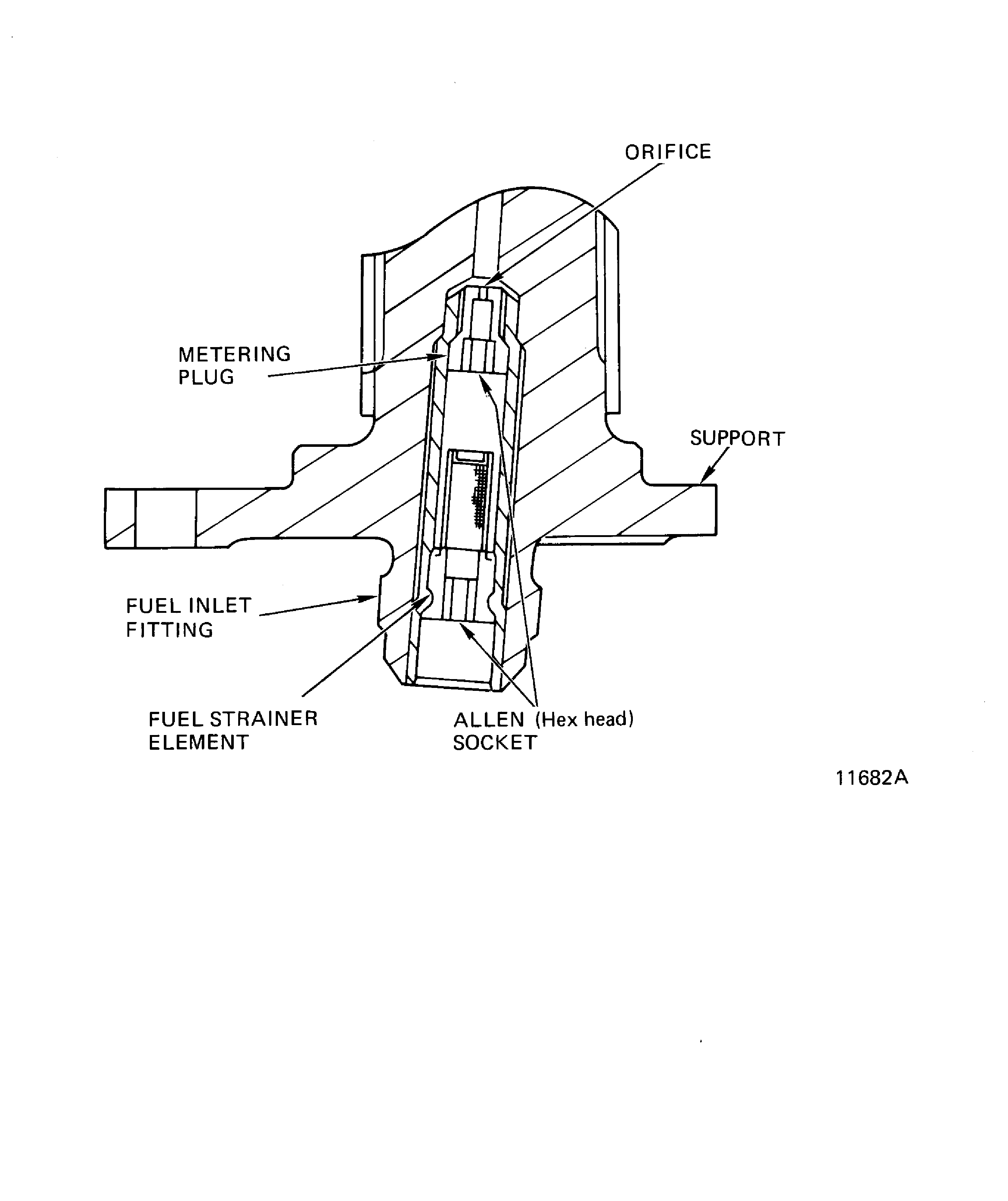

Refer to Figure.

Put the fuel nozzle and support assembly onto the IAE 1P16167 Holding plate 1 off and connect to the Power arm vise.

Use an Allen wrench.

Remove the fuel strainer element and/or the metering plug.

Increase the temperature of the oven to 500 deg F (260 deg C).

WARNING

FOR PROTECTION FROM HIGH TEMPERATURES, WEAR A FACE SHIELD AND PROTECTIVE CLOTHING.Put the assembly in the oven.

Use an Allen wrench.

WARNING

WEAR PROTECTIVE GLOVES.

CAUTION

THE FUEL METERING PLUG AND SUPPORT ASSEMBLY ARE A MATCHED SET AND MUST BE KEPT TOGETHER.While the assembly is hot, connect it to the power arm vise. Remove the strainer element or the metering plug

If the wrench does not loosen the strainer element or the metering plug do the following:

Remove the fuel nozzle and support assembly from Power arm vise and IAE 1P16167 Holding plate.

Refer to Cleaning-004 TASK 73-13-41-100-204.

Flush the assembly

SUBTASK 73-13-41-350-051 Remove the Fuel Strainer Element and/or the Fuel Metering Plug

Refer to Figure.

CAUTION

THE FUEL METERING PLUG AND THE SUPPORT ASSEMBLY ARE A MATCHED SET AND MUST BE KEPT TOGETHER.NOTE

Metering plugs are sold with an orifice that is smaller than necessary. It will be necessary to ream out the orifice to the appropriate diameter to meet the flow requirements that are specified in the Testing section.However, it is not permitted to try to adjust for fuel passage coking or blockage by changing the orifice diameter because if the blockage was subsequently removed the nozzle flow would be too high, possibly resulting in increased hot section distress. Service-run nozzles that cannot meet minimum flow requirements after cleaning must be returned to the vendor for replacement or repair.Install the assembly on to the holding plate and secure to the Power arm vise.

Refer to Figure.

Torque the plug to 10 to 20 lbfin (1.13 to 2.26 Nm).

Torque the strainer element to 15 to 35 lbfin (1.70 to 3.95 Nm).

Torque the metering plug and the fuel strainer element into the passage through the fuel inlet fitting

Remove the assembly from the Power arm vise and the IAE 1P16167 Holding plate

Refer to Testing-001 TASK 73-13-41-700-201.

Do the fuel flow test

Refer to Figure.

Put the fuel nozzle and support assembly onto the IAE 1P16167 Holding plate 1 off and connect to the Power arm vise.

Use an Allen wrench.

Remove the fuel strainer element and/or the metering plug

Refer to Cleaning-005 TASK 73-13-41-100-205.

Clean the strainer element and/or the metering plug

Use CoMat 04-010 ACTIVATOR/PRIMER primer T.

Apply primer to threads of the fuel strainer element and the metering plug

Apply compound to threads of the strainer element and the metering plug

Refer to Figure.

Torque the metering plug to 10 to 20 lbfin (1.13 to 2.26 Nm).

Torque the strainer element to 15 to 35 lbfin (1.70 to 3.95 Nm).

Torque the metering plug and the fuel strainer element into passage through the fuel inlet fitting

Remove the assembly from the Power arm vise and IAE 1P16167 Holding plate.

Cure at room temperature for a minimum of 24 hours or bake for 15 to 30 minutes at 215 deg F (101.6 deg C).

Refer to Testing-001 TASK 73-13-41-700-201.

Do the fuel flow test

SUBTASK 73-13-41-350-052 Install the Fuel Strainer Element and/or the Fuel Metering Plug

Figure: Replace the Fuel Nozzle and Support Assembly Fuel Strainer Element or Metering Plug

Replace the Fuel Nozzle and Support Assembly Fuel Strainer Element or Metering Plug