Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 73-13-41-300-008 Fuel Nozzle And Support Assembly - Replace The Fairing, Repair-008 (VRS3583)

Material of component

DESCRIPTION | SYMBOL | MATERIAL |

Fuel nozzle and support assembly | Corrosion and heat resistant alloy |

General

Price and Availability Refer to IAE.

The practices and processes referred to in this procedure by TASK numbers are in the SPM.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Welding equipment | LOCAL | Welding equipment |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-209 WELDING FILLER WIRE, NiBASE 5% Cr | LOCAL | CoMat 03-209 | ||

| CoMat 03-286 WELDING WIRE | LOCAL | CoMat 03-286 | ||

| CoMat 06-064 FLUORESCENT PENETRANT (WATER WASHABLE MEDIUM SENSITIVITY) | LOCAL | CoMat 06-064 |

Spares

NONESafety Requirements

NONEProcedure

CAUTION

DO NOT REMOVE ANY MORE PARENT MATERIAL THAN IS NECESSARY TO REMOVE THE WELD.If necessary, machine any remaining weld material from the support.

SUBTASK 73-13-41-320-004 Remove the Lower Right and Left Fairing from the Fuel Nozzle and Support Assembly

CAUTION

DO NOT REMOVE ANY MORE PARENT MATERIAL THAN IS NECESSARY TO REMOVE THE WELD.If necessary, machine any remaining weld material from the support.

SUBTASK 73-13-41-320-005 If Necessary, Remove the Upper Right and Left Fairing

SUBTASK 73-13-41-220-093 Dimensional Inspection

Do a fluorescent penetrant inspection of the support where the welds held the fairing Ref SPM TASK 70-23-05-230-501. Use CoMat 06-064 FLUORESCENT PENETRANT (WATER WASHABLE MEDIUM SENSITIVITY).

No cracks are permitted on the support.

SUBTASK 73-13-41-230-058 Examine the Fuel Nozzle and Support Assembly After Fairing Removal

Clean the repair of the fuel nozzle and support assembly and the replacement fairing. Refer to SPM TASK 70-11-26-300-503.

SUBTASK 73-13-41-110-059 Clean the Fuel Nozzle and Support Assembly and Replacement Fairing

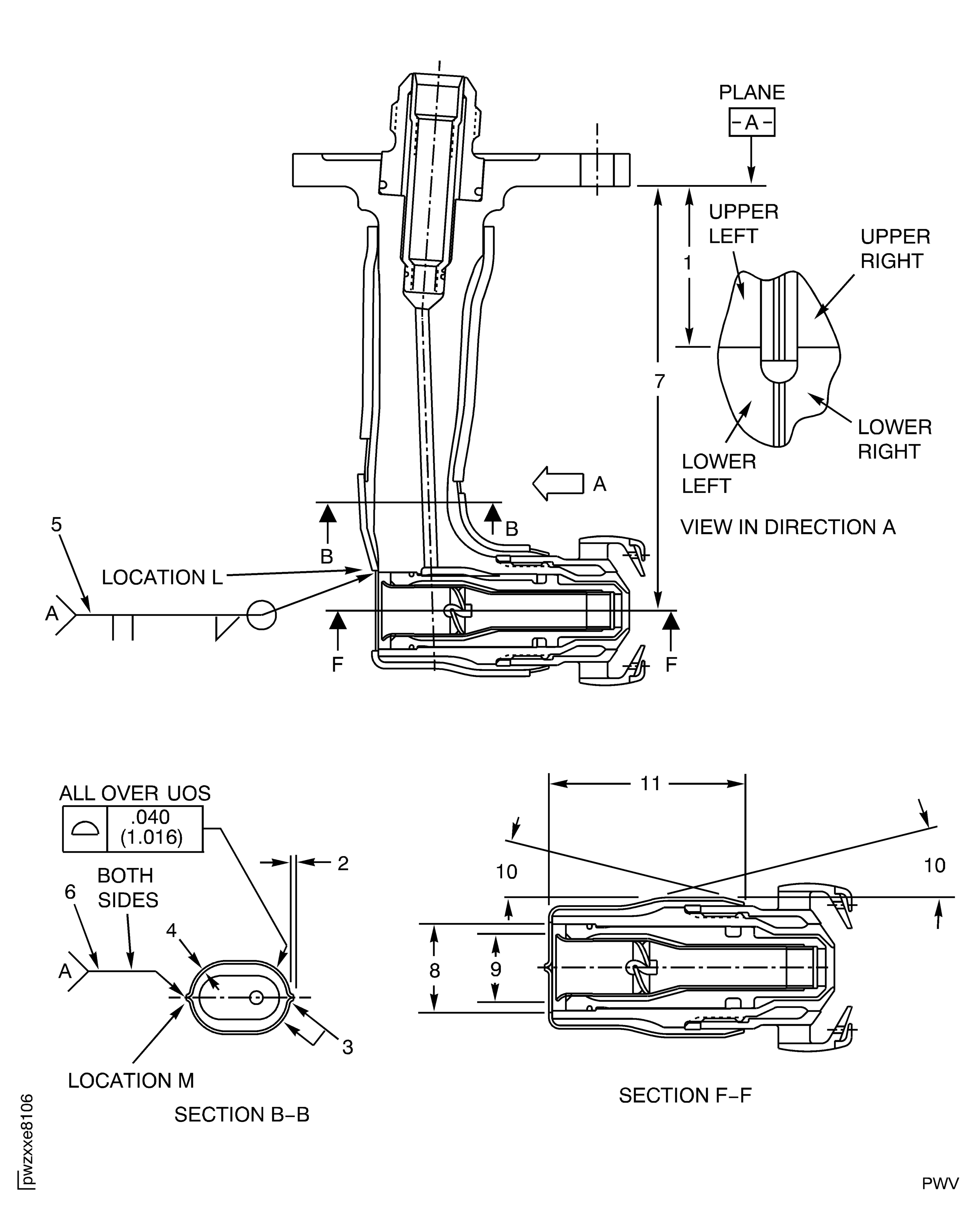

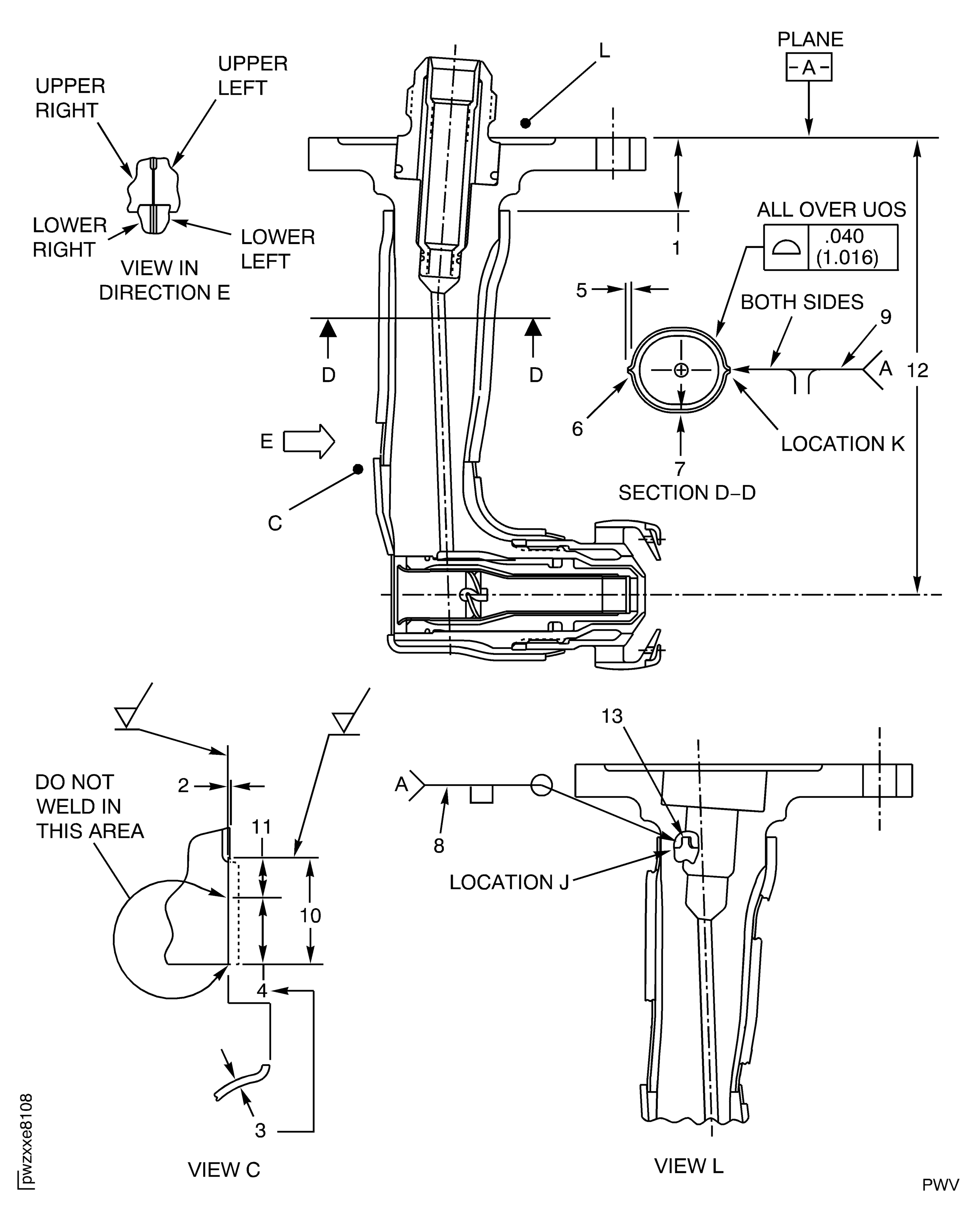

Make sure that the fairing contact the support at Location J.

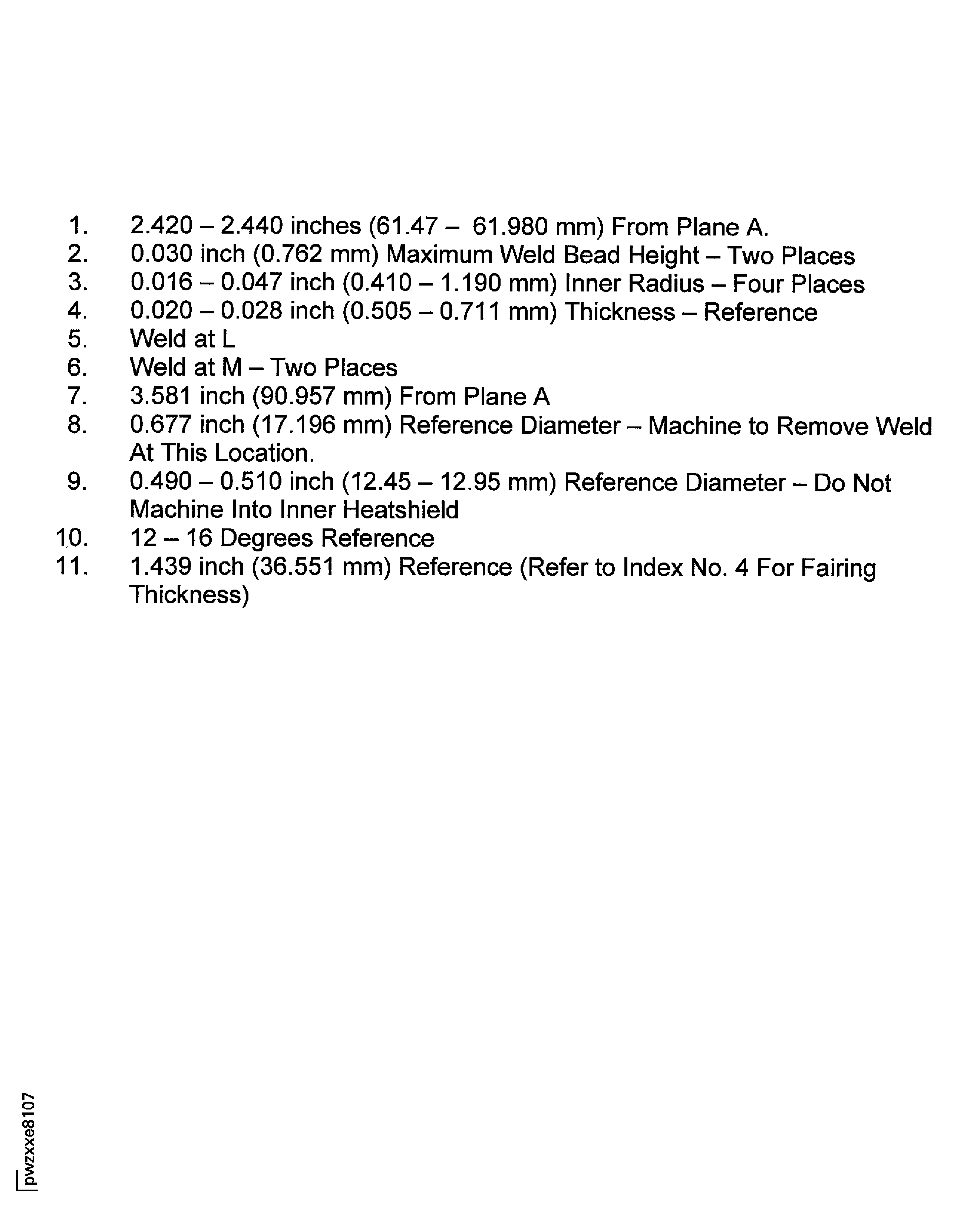

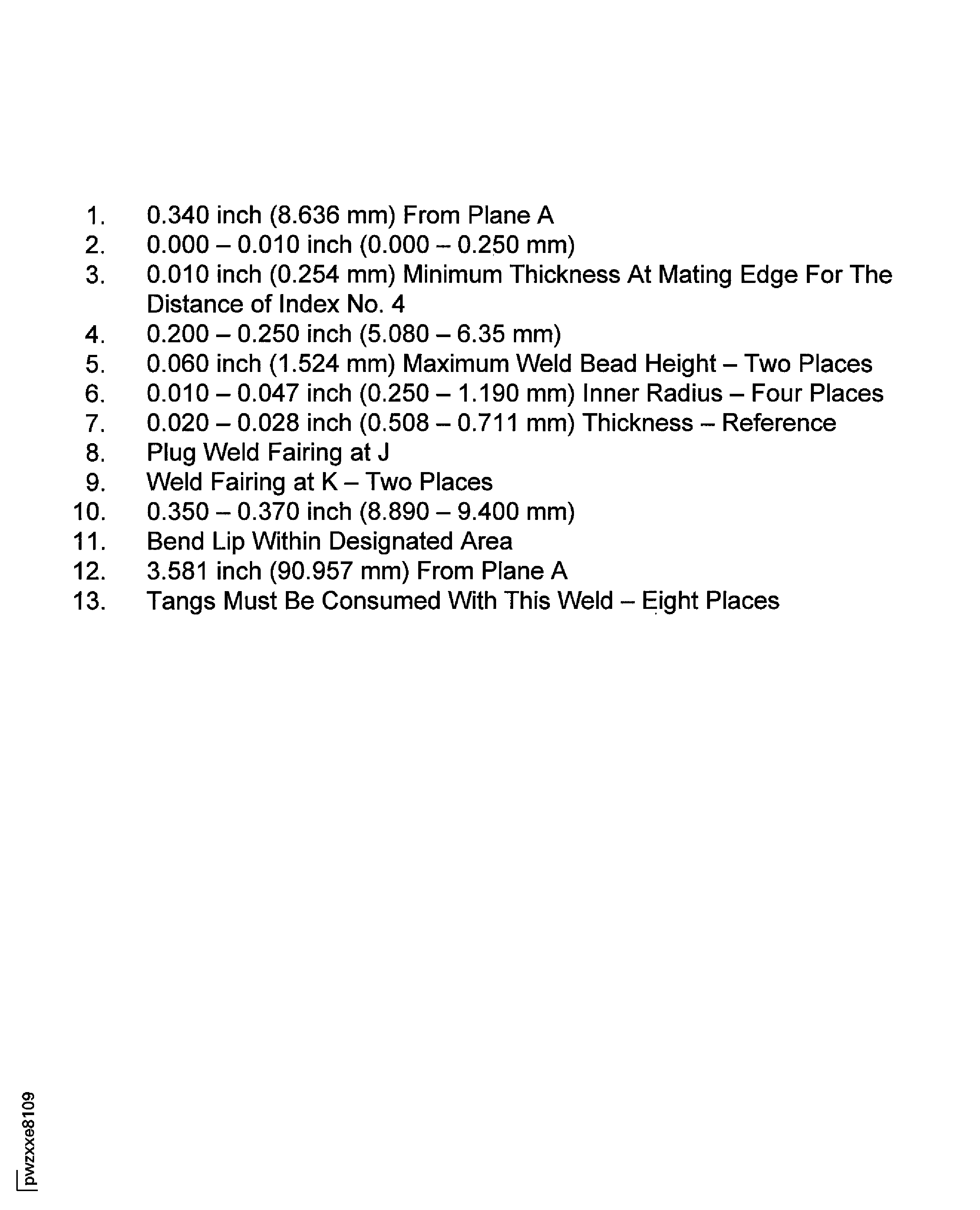

Locate the upper edges of the upper fairing from Plane A as shown by Index 1.

Position the new fairing on the support.

Weld by the manual gas tungsten arc method (IAE 16A) in SPM TASK 70-31-13-310-501.

The eight tangs must be consumed by the weld.

NOTE

The tangs may move during the weld procedure.

Plug weld the fairing at Location J.

Weld by the manual gas tungsten arc method (IAE 16A) per SPM TASK 70-31-13-310-501.

Weld beads may be 0.060 in. (1,524 mm) maximum above the contour.

Weld the fairing at Location K in two places (both sides of fairing).

SUBTASK 73-13-41-310-053 If Necessary, Weld the Replacement Upper Right and Left Fairings to the Fuel Nozzle and Support Assembly

NOTE

If the upper fairings do not need to be replaced, go to Step.Weld by the manual gas tungsten arc method (IAE 16A) in SPM TASK 70-31-13-310-501.

Weld the fairing at Location L.

Weld by the manual gas tungsten arc method (IAE 16A) in SPM TASK 70-31-13-310-501.

A weld head of 0.030 in. (0,762 mm) maximum above contour is permitted.

Weld the fairing at Location M, two places.

SUBTASK 73-13-41-310-054 Weld the Replacement Lower Right and Left Fairing to the Fuel Nozzle and Support Assembly

Examine the fuel nozzle and support assembly by fluorescent penetrant inspection method where the fairings were replaced.

No cracks are permitted.

Do a Fluorescent penetrant inspection of the fuel nozzle and support assembly after the fairing weld replacement.

SUBTASK 73-13-41-230-059 Examine the Fuel Nozzle and Support Assembly After Repair

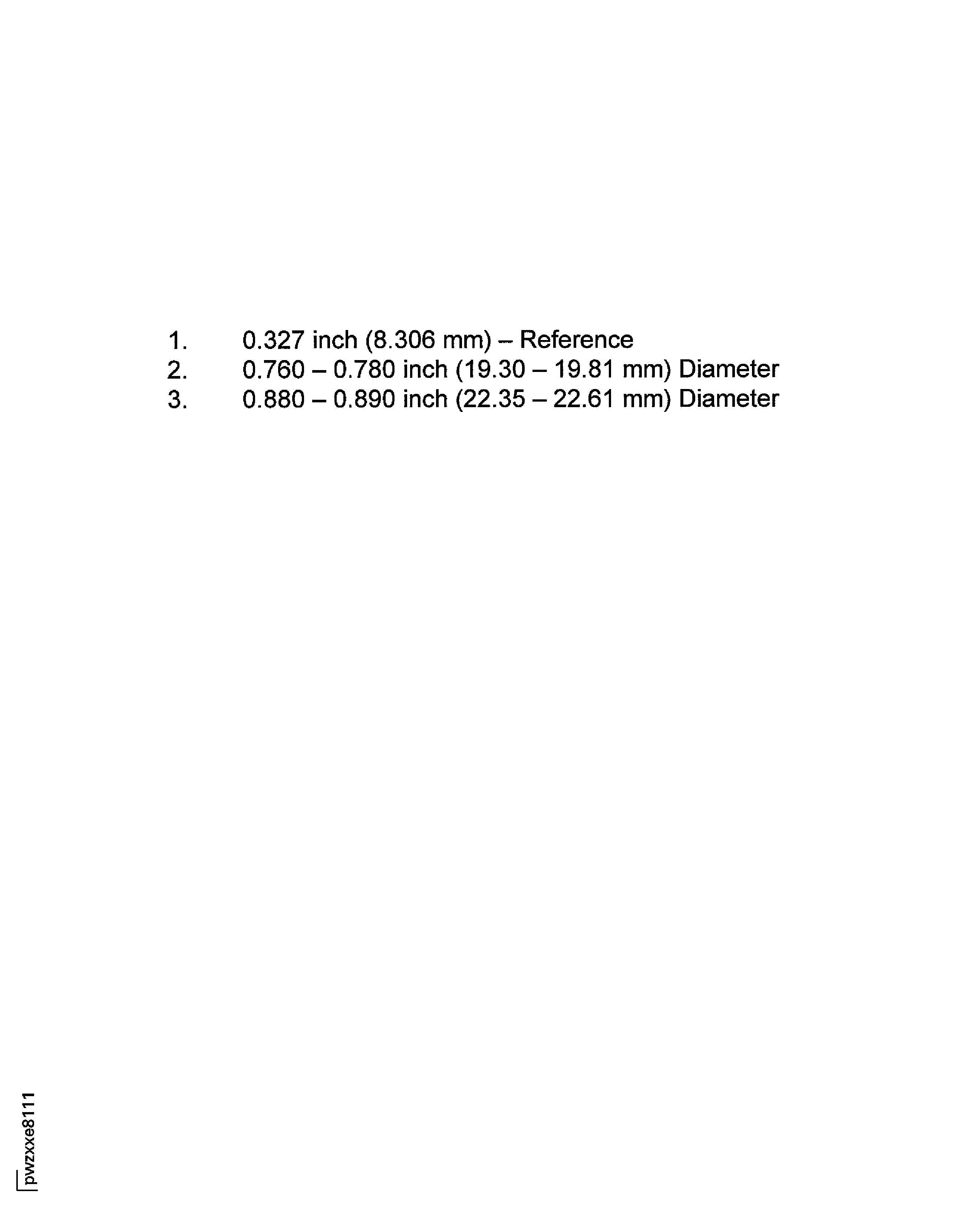

Figure: Replacement of Lower Right and Left Fairing

Replacement of Lower Right and Left Fairing

Replacement of Lower Right and Left Fairing

Figure: Replacement of Upper Right and Left Fairing

Replacement of Upper Right and Left Fairing

Replacement of Upper Right and Left Fairing

Figure: Replacement of Upper Right and Left Fairing

Replacement of Upper Right and Left Fairing

Replacement of Upper Right and Left Fairing