Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 73-22-48-300-002 P2/T2 Sensor Air Tube - Repair A Dent, Repair-002 (VRS2900)

General

This repair can be done on the P2/T2 tube during overhaul.

Make a jig that is the same shape as the P2/T2 tube. Use a new or serviceable P2/T2 tube as an aid.

The practices and processes referred to in the procedure by the TASK numbers are in the (SPM).

To identify the consumable materials refer to the (PCI).

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Nylon Hammer | LOCAL | Nylon Hammer | ||

| Ball Mandrel (stainless steel) | LOCAL | Ball Mandrel (stainless steel) |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-076 METHYL ETHYL KETONE | LOCAL | CoMat 01-076 | ||

| CoMat 02-099 LINT-FREE CLOTH | LOCAL | CoMat 02-099 |

Spares

NONESafety Requirements

NONEProcedure

If there is an access, apply the lanolin lubricant directly on the damaged area.

CAUTION

DO NOT PULL THE MANDREL WITH TOO MUCH FORCE. THIS CAN CAUSE DAMAGE TO THE TUBE AND CAN CAUSE THE MANDREL TO BE CAUGHT IN THE TUBE.Put the lanolin lubricant in the P2/T2 tube

Put the P2/T2 tube in the jig.

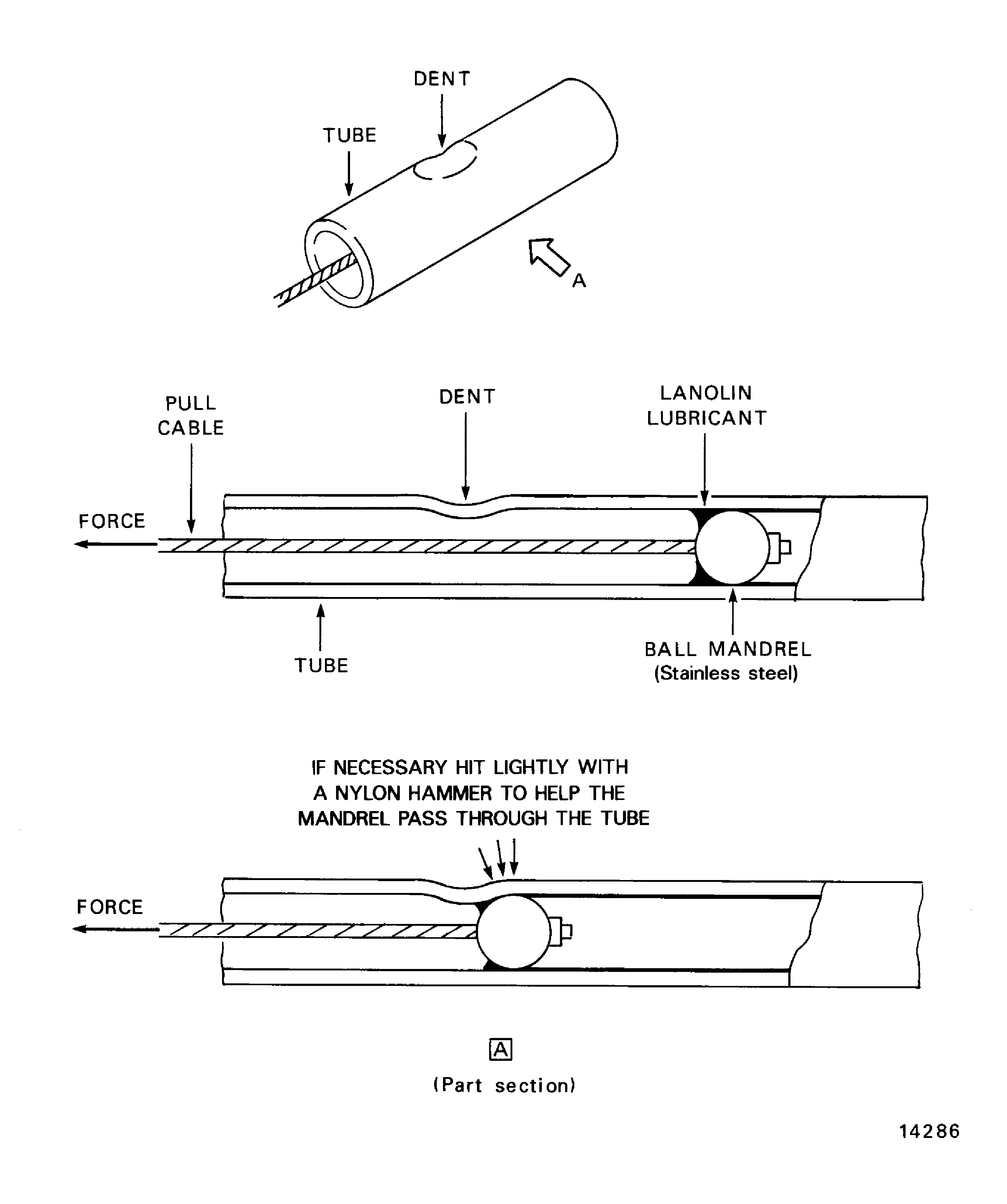

Refer to Figure. Make sure that there is a bead of lanolin lubricant in front of the mandrel during the repair. Feed the cable of the mandrel through the P2/T2 tube.

Put the mandrel into the P2/T2 tube.

Pull the mandrel through the P2/T2 tube until it touches the damaged area.

Pull the mandrel through the damaged area without too much force. If necessary, hit the damaged area lightly with the nylon hammer as the mandrel goes through the damaged area.

This will help to move the mandrel.

Repair the tube wall.

Remove the mandrel from the P2/T2 tube.

SUBTASK 73-22-48-350-053 Prepare the Tube Wall

Use the CoMat 01-076 METHYL ETHYL KETONE and the CoMat 02-099 LINT-FREE CLOTH. Remove the lanolin lubricant with the fluid. Make the tube clean with a clean piece of lint-free cloth before the fluid dries.

WARNING

DO NOT GET THE CLEANING FLUID ON YOUR SKIN OR IN YOUR EYES. PUT ON PROTECTIVE CLOTHING, GLOVES, GOGGLES AND A MASK. USE THE FLUID IN A CORRECTLY VENTILATED AREA. DO NOT BREATHE THE GAS. IF YOU GET THE FLUID ON YOUR SKIN OR IN YOUR EYES, FLUSH IT AWAY WITH WATER. GET MEDICAL AID IF YOUR SKIN OR EYES BECOME IRRITATED.Clean the tube

SUBTASK 73-22-48-110-053 Clean the P2/T2 Tube

Make sure that the repairs are satisfactory. Crack and distortion are not permitted. The shape of the tube must be parallel in the internal diameter and the external diameter.

Examine the P2/T2 tube.

SUBTASK 73-22-48-220-056 Examine the P2/T2 Tube

Refer to SPM TASK 70-23-00-230-501.

Do a dye-penetrant test on the P2/T2 tube.

SUBTASK 73-22-48-230-053 Examine the P2/T2 Tube

Refer to Testing-000 TASK 73-22-48-700-100.

Do a pressure test on the P2/T2 tube.

SUBTASK 73-22-48-780-054 Pressure Test the P2/T2 Tube

Refer to SPM TASK 70-09-00-400-501.

Mark the repair scheme number VRS2900 on the P2/T2 tube adjacent to the part number, with an electro-etch method.

SUBTASK 73-22-48-850-052 Put the Repair Scheme Number on the P2/T2 Tube

Figure: P2/T2 Tube Repair

P2/T2 Tube Repair