Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 75-24-47-300-004 HPT/LPT Active Clearance Control (ACC) Ducts - Related Parts - Weld Repair Cracks And Worn Areas Of The Heat Shield Assembly, Repair-004 (VRS1510)

Material of Component

DESCRIPTION | RR SYMBOL | MATERIAL |

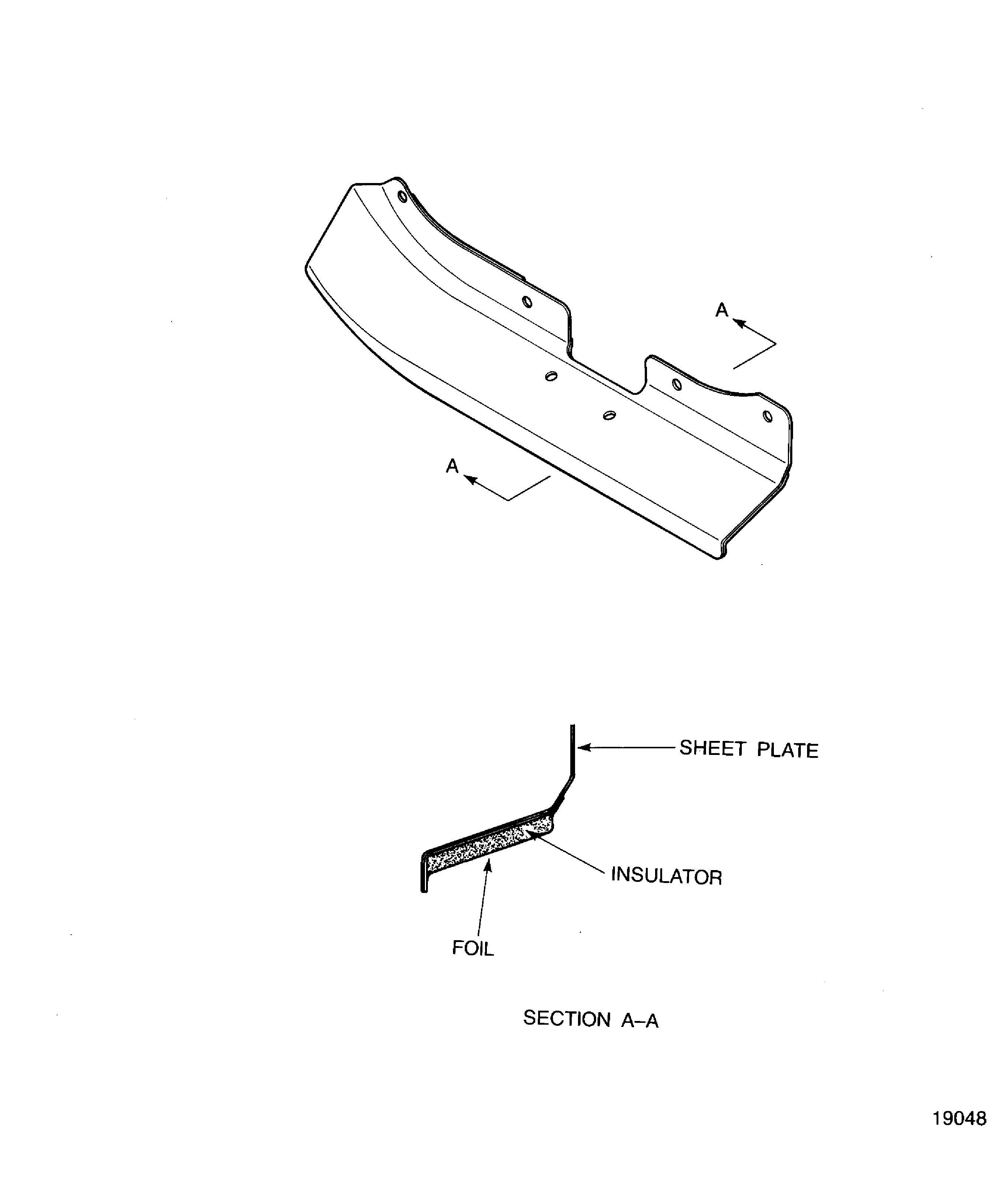

Heat shield assembly (Sheet plate) | 18Cr-10.5Ni-0.4Ti Steel | |

Heat shield assembly (Foil) | 18Cr-10.5Ni-0.4Ti Steel |

General

Price and availability - none

The practices and processes referred to in the procedure by the TASK number are in the SPM.

For the method to clean the parts, refer to Cleaning-002 TASK 75-24-47-100-402.

This repair scheme contains the following repair procedures:

Welding repair

Welding repair procedure is allowed at heat shield assembly if total foil and/or insulator missing areas are less than or equal to 20 percent of surface.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Tungsten inert gas system (TIG) | LOCAL | Tungsten inert gas system (TIG) | ||

| Spot welding machine | LOCAL | Spot welding machine | ||

| Hand Held Pneumatic Grinder | LOCAL | Hand Held Pneumatic Grinder | ||

| Magnifying glass, 8x | LOCAL | Magnifying glass, 8x |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-031 ACETONE (CH3)2CO | LOCAL | CoMat 01-031 | ||

| CoMat 02-099 LINT-FREE CLOTH | LOCAL | CoMat 02-099 | ||

| CoMat 03-204 WELDING FILLER WIRE | LOCAL | CoMat 03-204 |

Spares

NONESafety Requirements

NONEProcedure

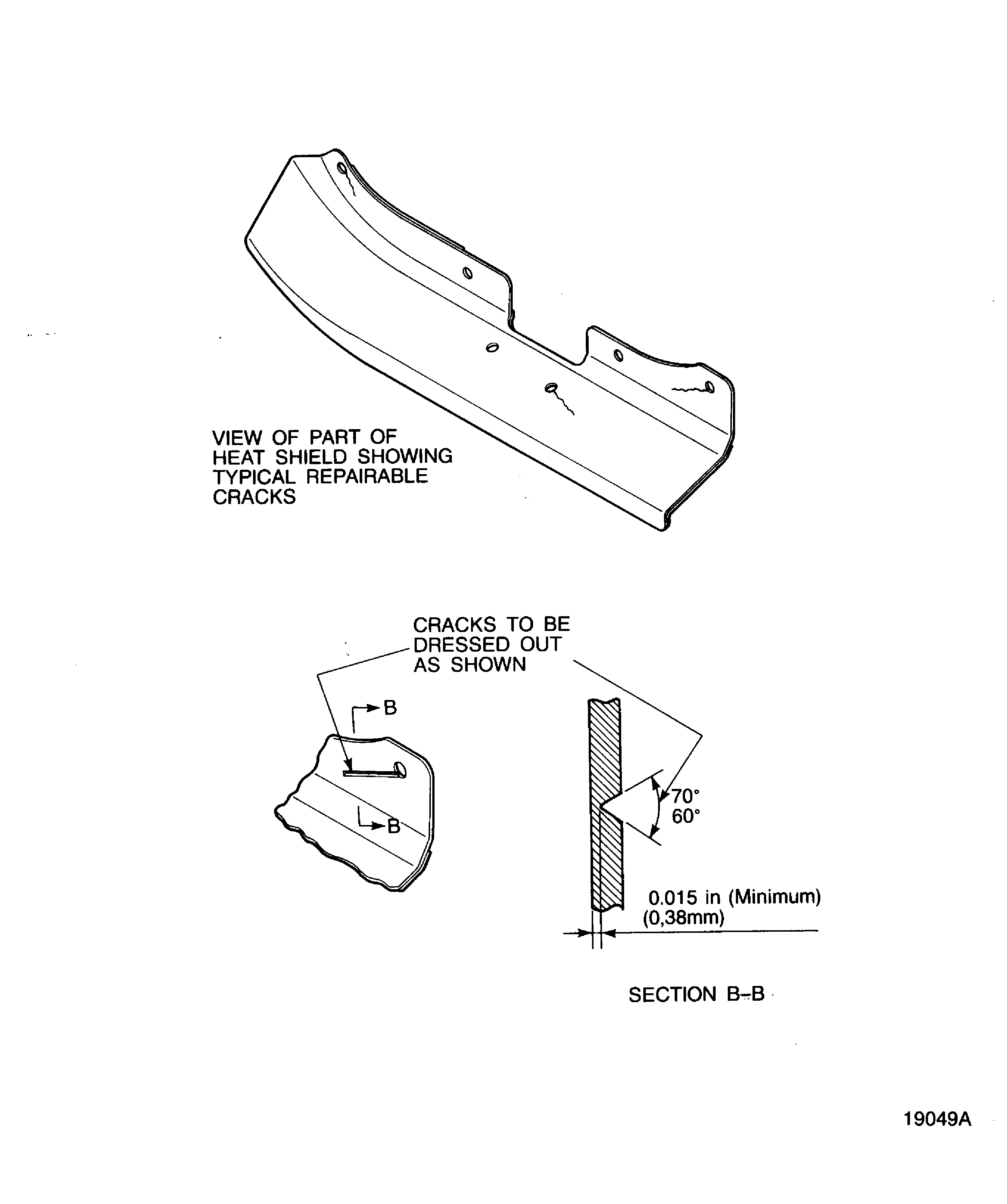

Use a Hand Held Pneumatic Grinder.

Ensure that the crack is completely removed from the sheet plate.

SUBTASK 75-24-47-350-053 Dress Out the Crack

Refer to the Cleaning-000 TASK 75-24-47-100-400.

Remove all the oxides, hydrocarbon, grit and scale from the surface to be welded and adjacent area by local cleaning.

SUBTASK 75-24-47-110-060 Remove all the Unwanted Material from the Surface of the Sheet Plate

Refer to SPM TASK 70-31-02-310-501-001.

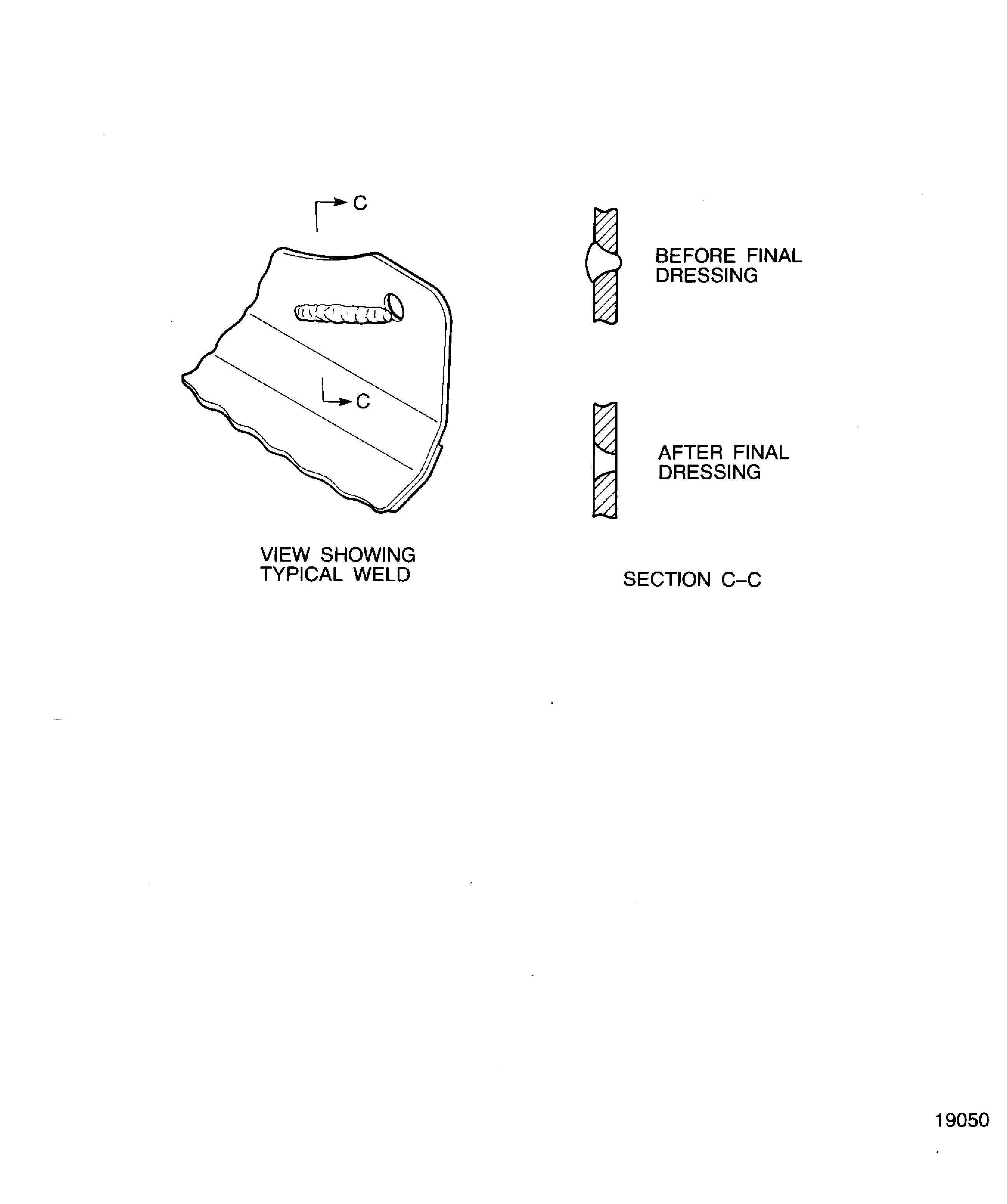

Weld dressed cracks manually by tungsten inert gas (TIG) weld.

Refer to SPM TASK 70-31-02-310-501-001.

Use AMS5510 patch material (0.022 to 0.027 in. (0.56 to 0.71 mm) thickness.

Weld cracks and worn areas of sheet plate using patch welding repair, if necessary.

Use a Hand Held Pneumatic Grinder.

In contact area, remove excess weld and dress flush with adjacent area.

SUBTASK 75-24-47-310-051 Weld the Dressed Cracks on the Sheet Plate

Refer to SPM TASK 70-23-05-230-501.

Penetrant examine the repaired area.

Use 8X magnifying glass.

Refer to Inspection-000 TASK 75-24-47-200-400.

Visually examine the repaired area.

SUBTASK 75-24-47-230-054 Examine the Welded Area for Cracks

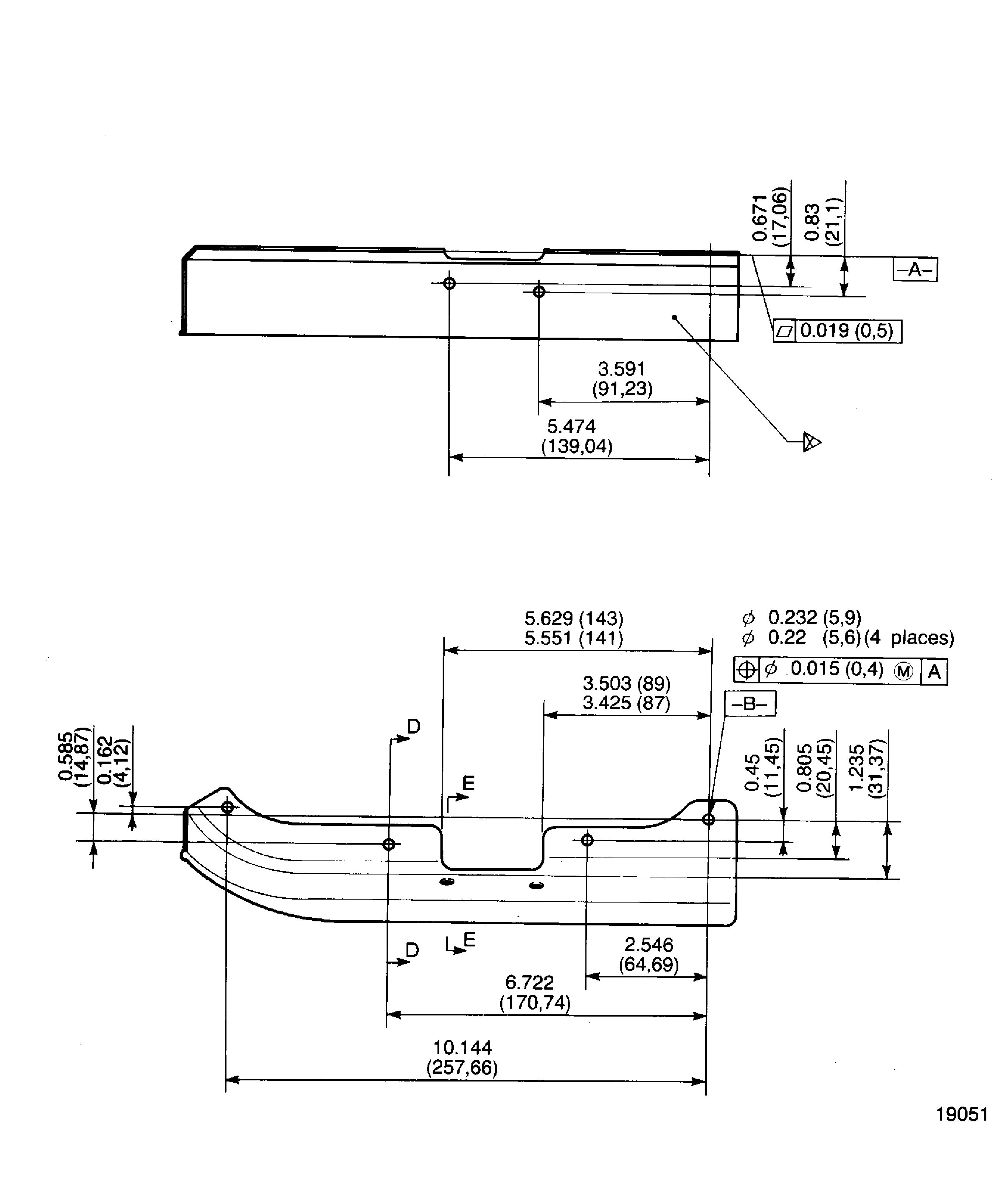

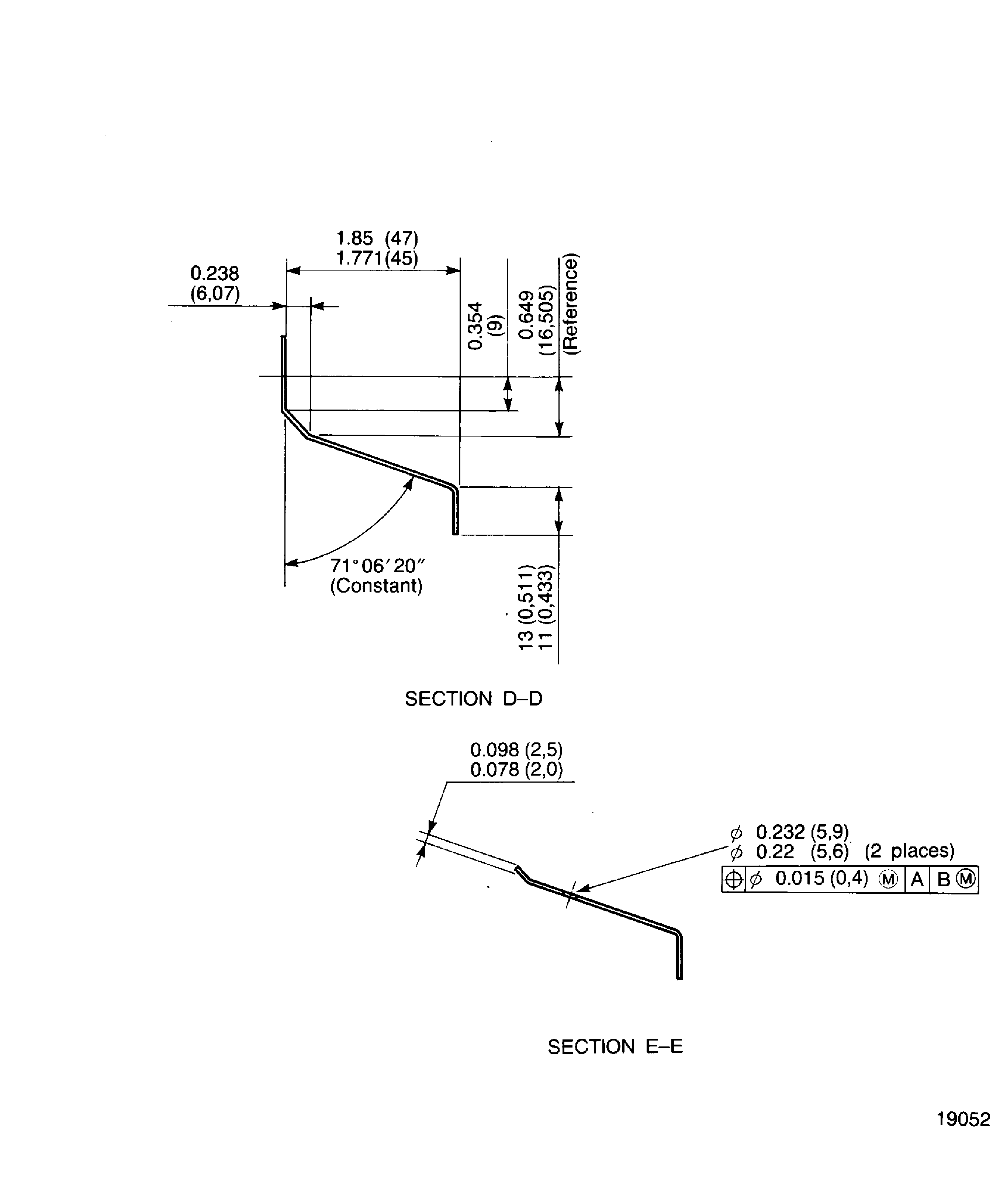

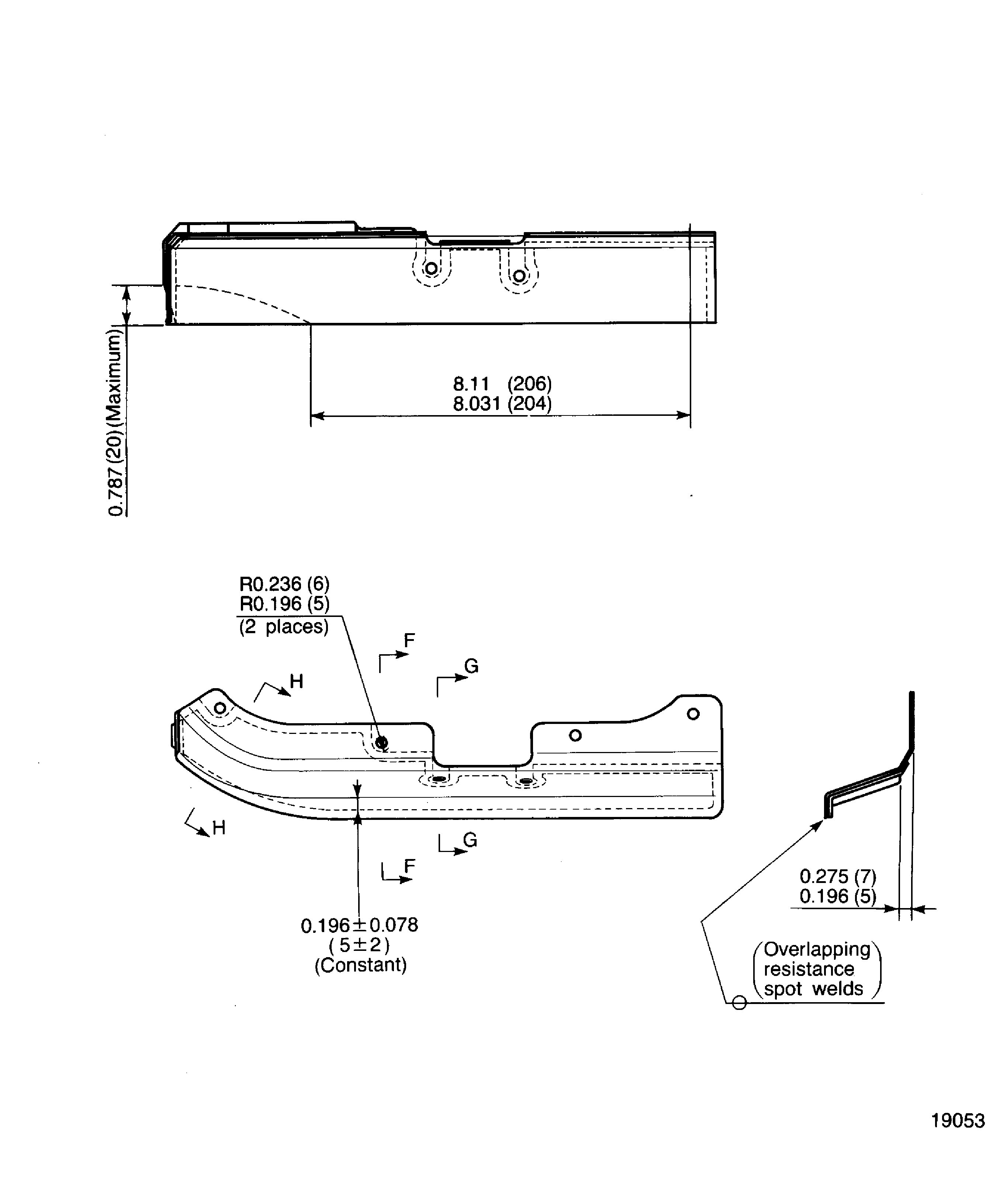

Refer to Figure.

Use a spot welding machine.

Refer to SPM TASK 70-31-10-310-501

NOTE

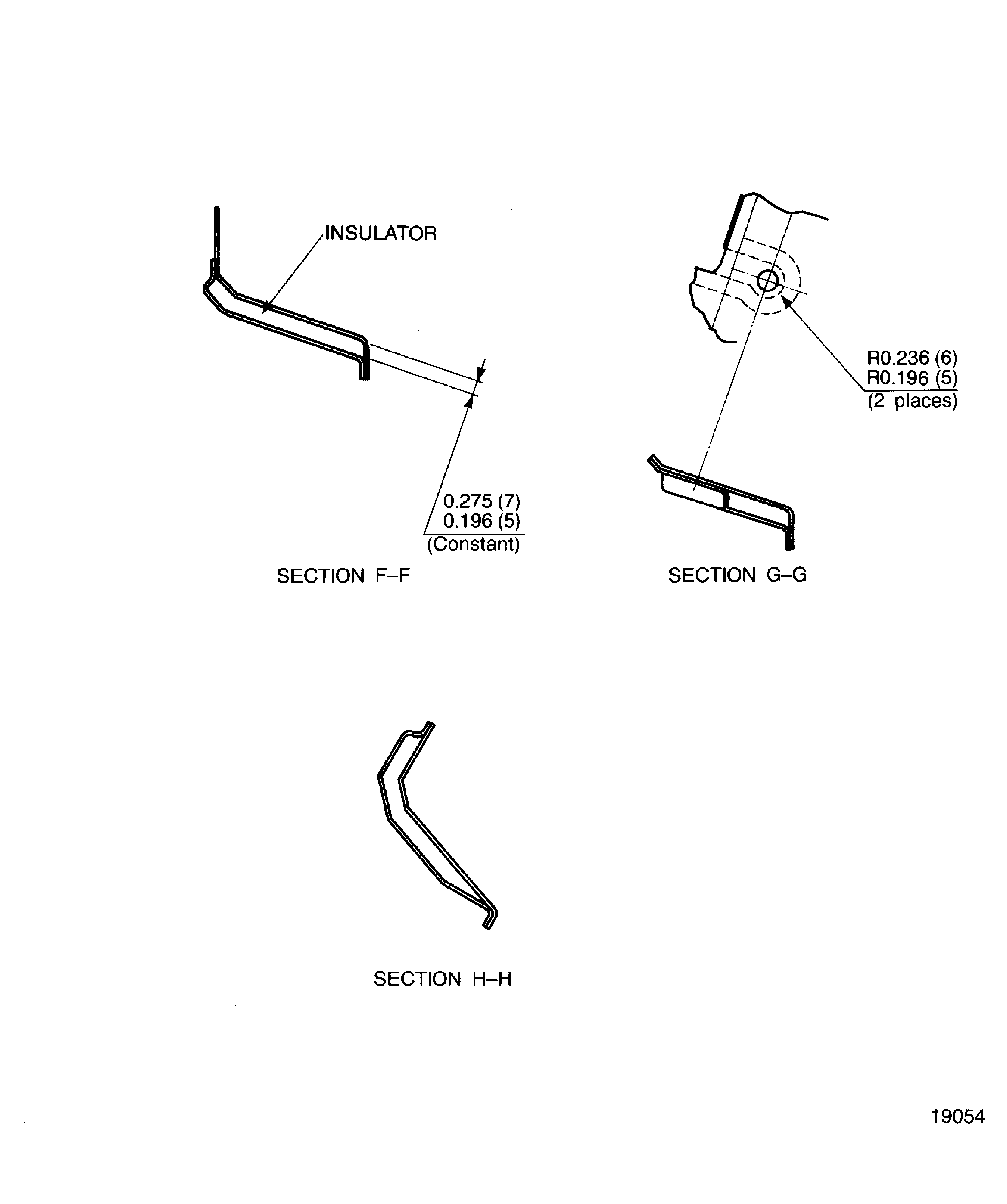

Make sure that the foil contains insulator perfectly.

Weld the foil to the sheet plate.

SUBTASK 75-24-47-310-052 Weld the Foil to the Sheet Plate

Refer to Inspection-000 TASK 75-24-47-200-400.

Visually examine the repaired area.

SUBTASK 75-24-47-230-055 Examine the Welded Area for Breakage

Refer to TASK 75-24-47-100-400.

Remove the oxides, hydrocarbon, grit, and scale from the cracks on the foil and adjacent area by local cleaning.

75-24-47-110-069 Remove all the Unwanted Material from the Surface of the Foil

Refer to SPM TASK 70-31-10-310-501.

Use a spot welding machine.

Use AMS5510 patch material (0.004 to 0.007 in. (0.10 to 0.20 mm) thickness for foil.

Weld cracks of foil using patch welding repair.

75-24-47-310-055 Weld the Cracks on the Foil

Refer to SPM TASK 70-23-05-230-501.

Penetrant examine the repaired area.

Use 8X magnifying glass.

Refer to Inspection-000 TASK 75-24-47-200-400.

Visually examine the repaired area.

75-24-47-230-068 Examine the Welded Area for Cracks

Figure: Weld of the Heat Shield Assembly

Weld of the Heat Shield Assembly

Weld of the Heat Shield Assembly

Weld of the Heat Shield Assembly

Weld of the Heat Shield Assembly

Weld of the Heat Shield Assembly

Weld of the Heat Shield Assembly

Weld of the Heat Shield Assembly