Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 75-24-48-300-006 HPT ACC Air Manifold - Replace the Joint, Repair-006 (VRS1536)

Material of component

DESCRIPTION | RR SYMBOL | MATERIAL |

Turbine CLG manifold assembly | 18Cr-10.5Ni-0.4Ti steel | |

Turbine CLG manifold assembly (Joint) | 18Cr-10.5Ni-0.4Ti steel |

General

Price and availability - none.

The practices and processes referred to in the procedure by the TASK number are in the SPM.

For the method to clean the parts, refer to Cleaning 000 TASK 75-24-48-100-100.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| TIG welding equipment | LOCAL | TIG welding equipment | ||

| Grinder, Hand held pneumatic | LOCAL | Grinder, Hand held pneumatic | ||

| Fluorescent Penetrant Inspection Equipment | LOCAL | Fluorescent Penetrant Inspection Equipment | ||

| IAE 3J13515 Fixture, joint replacement | 0AM53 | IAE 3J13515 | 1 off |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-031 ACETONE (CH3)2CO | LOCAL | CoMat 01-031 | ||

| CoMat 02-099 LINT-FREE CLOTH | LOCAL | CoMat 02-099 | ||

| CoMat 03-204 WELDING FILLER WIRE | LOCAL | CoMat 03-204 | ||

| CoMat 05-020 WATERPROOF SILICON CARBIDE | LOCAL | CoMat 05-020 | ||

| CoMat 05-021 WATERPROOF SILICON CARBIDE | 44197 | CoMat 05-021 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| JOINT - TCC MANIFOLD | 0AM53 | 2A0205 | 1 off |

Safety Requirements

NONEProcedure

Refer to VRS1532 (Repair-001) TASK 75-24-48-300-001.

Weld cracks on turbine CLG manifold assembly.

Refer to VRS1529 (Repair-010) TASK 75-24-48-300-010.

Replace the bracket, if required.

SUBTASK 75-24-48-350-076 Weld Cracks on Turbine CLG Manifold Assembly

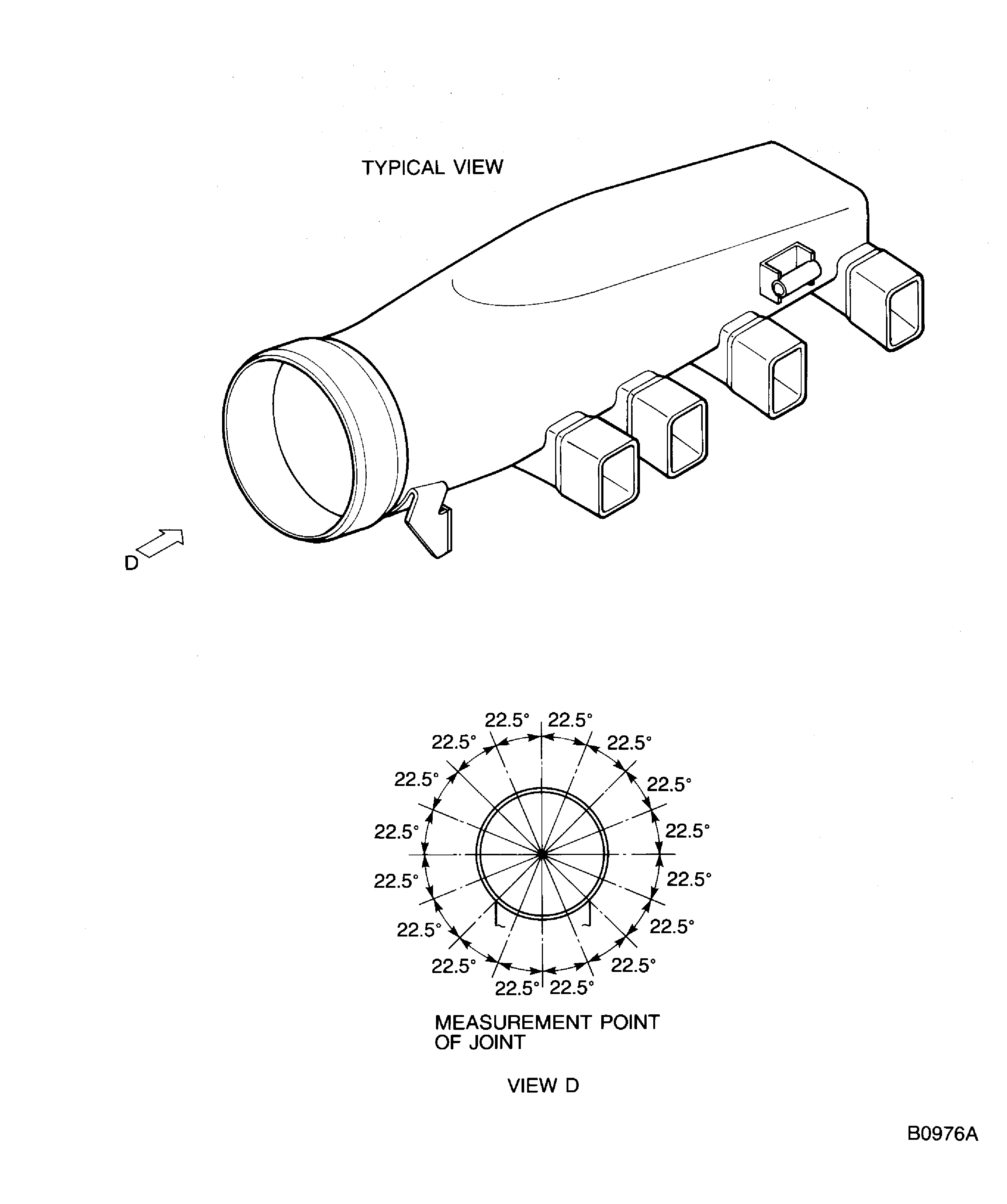

Refer to Figure.

Use the IAE 3J13515 Fixture, joint replacement 1 off.

Set the turbine CLG manifold assembly to the fixture.

Refer to Figure.

Cut off the joint from the turbine CLG manifold assembly.

Remove the turbine CLG manifold assembly from the fixture.

SUBTASK 75-24-48-350-061 Cut off the Joint

Refer to the Cleaning-000 TASK 75-24-48-100-100.

Remove all the oxides, hydrocarbon, grit and scale from the surface to be welded and adjacent area by local cleaning.

SUBTASK 75-24-48-110-059 Remove All the Soil from the Surface

Refer to Figure.

Use the IAE 3J13515 Fixture, joint replacement 1 off.

Set the joint and the turbine CLG manifold assembly to the fixture.

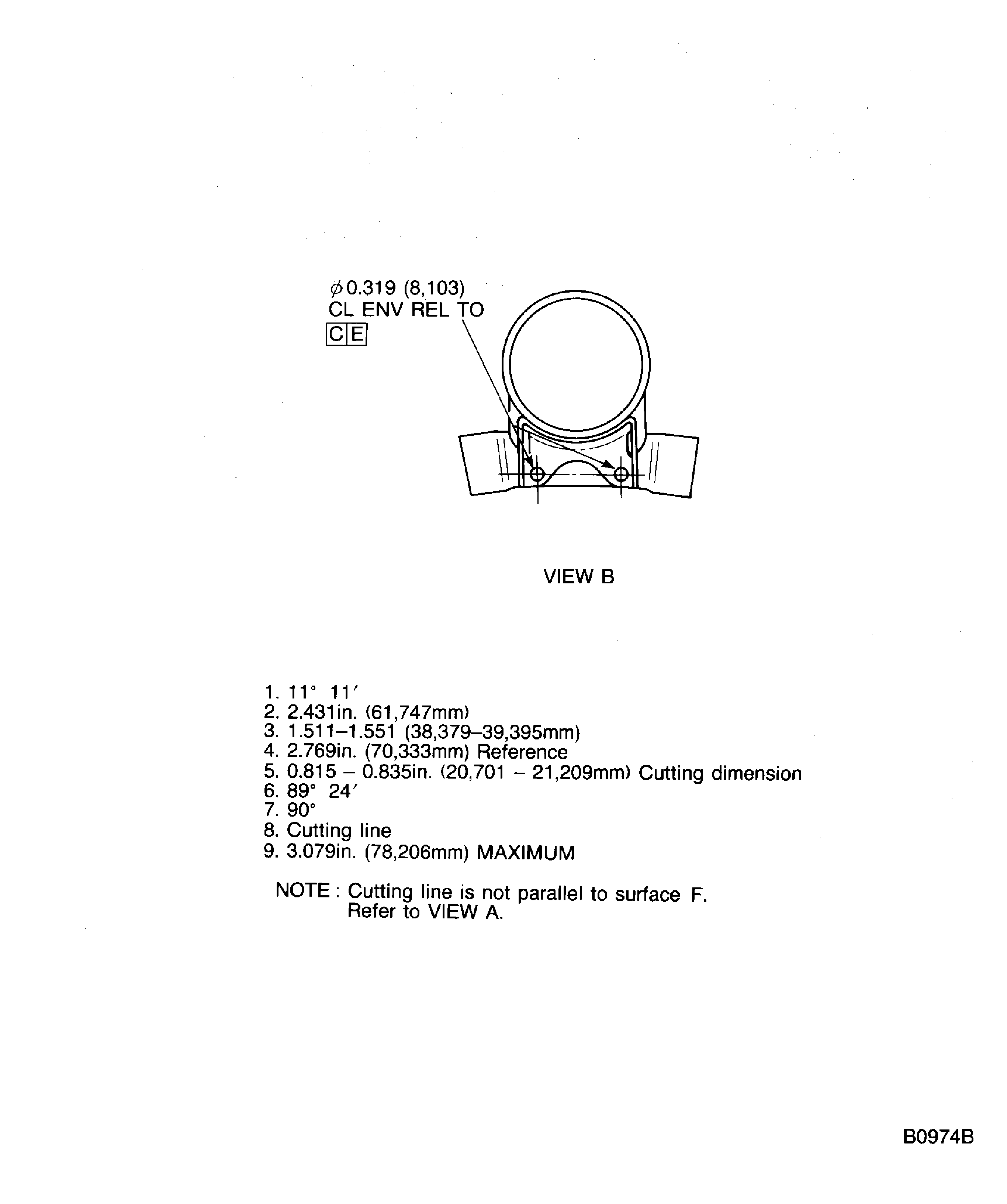

Finish the cutting surface of turbine CLG manifold assembly to fit the joint.

Refer to Figure.

Refer to TASK 70-31-02-310-501.

Use a TIG welding equipment.

Tack weld the joint at 12 point.

Refer to Figure.

Refer to TASK 70-31-02-310-501.

Use a TIG welding equipment.

Weld the joint by tungsten inert gas (TIG) weld.

Remove the turbine CLG manifold assembly from the fixture.

SUBTASK 75-24-48-310-052 Weld the Joint on the Turbine CLG Manifold Assembly

Refer to Cleaning-000 TASK 75-24-48-100-100.

Chemically clean the required area.

SUBTASK 75-24-48-110-060 Chemically Clean the Repaired Area

Refer to Figure.

Refer to Figure.

Outside diameter should be within a maximum of 3.079 in. (78.206 mm).

Measure the outside diameter of joint at 8 point for the thermal deformation.

Refer to SPM TASK 70-23-05-230-501.

Penetrant examine the repaired area.

Use a 8X magnifying glass.

Refer to Inspection-000 TASK 75-23-48-100-100.

Visually examine the repaired area.

Use a plastic mallet.

Hammer the joint to keep the roundness.

Refer to SPM TASK 70-23-05-230-501.

Penetrant examine the turbine CLG manifold assembly.

If outside diameter maximum is out of 3.079 in. (78.206 mm).

SUBTASK 75-24-48-350-062 Examine the Repaired Area for Cracks and Deformation

Refer to Cleaning-000 TASK 75-24-48-100-100.

Chemically clean the repaired area.

SUBTASK 75-24-48-110-061 Chemically Clean the Repaired Area

Stress relieve at 1175 to 1225 deg F (635 to 663 deg C) for one hour.

Heat treat the turbine CLG manifold assembly.

SUBTASK 75-24-48-310-054 Heat Treat the Turbine CLG Manifold Assembly

Vibro engrave VRS1536 near to part number.

SUBTASK 75-24-48-350-063 Vibro Engrave VRS1536

Figure: Replacement of the Joint

Replacement of the Joint

Replacement of the Joint

Replacement of the Joint

Replacement of the Joint