Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 75-24-49-840-002 LPT ACC Cooling Air Ducts - Replace The Titanium Tubes, Rework-002 - SBE 75-0084

General

Price and availability - none.

The practices and processes referred to in the procedure by the TASK number are in the SPM.

NOTE

NOTE

Expendable parts

FIG/ITEM | PART IDENT | QTY |

75-24-49, 02-880 | Tube A/O | 1 off |

75-24-49, 02-890 | Tube A/O | 1 off |

75-24-49, 02-900 | Tube A/O | 1 off |

75-24-49, 02-910 | Tube A/O | 1 off |

75-24-49, 02-920 | Tube A/O | 1 off |

75-24-49, 02-930 | Tube A/O | 1 off |

75-24-49, 02-940 | Tube A/O | 1 off |

75-24-49, 02-950 | Tube A/O | 1 off |

75-24-49, 02-800 | Tube A/O | 1 off |

75-24-49, 02-810 | Tube A/O | 1 off |

75-24-49, 02-820 | Tube A/O | 1 off |

75-24-49, 02-830 | Tube A/O | 1 off |

75-24-49, 02-840 | Tube A/O | 1 off |

75-24-49, 02-850 | Tube A/O | 1 off |

75-24-49, 02-860 | Tube A/O | 1 off |

75-24-49, 02-870 | Tube A/O | 1 off |

75-24-49, 03-870 | Tube A/O | 1 off |

75-24-49, 03-940 | Tube A/O | 1 off |

75-24-49, 03-880 | Tube A/O | 1 off |

75-24-49, 03-890 | Tube A/O | 1 off |

75-24-49, 03-900 | Tube A/O | 1 off |

75-24-49, 03-910 | Tube A/O | 1 off |

75-24-49, 03-920 | Tube A/O | 1 off |

75-24-49, 03-930 | Tube A/O | 1 off |

75-24-49, 03-800 | Tube A/O | 1 off |

75-24-49, 03-950 | Tube A/O | 1 off |

75-24-49, 03-810 | Tube A/O | 1 off |

75-24-49, 03-820 | Tube A/O | 1 off |

75-24-49, 03-830 | Tube A/O | 1 off |

75-24-49, 03-840 | Tube A/O | 1 off |

75-24-49, 03-850 | Tube A/O | 1 off |

75-24-49, 03-860 | Tube A/O | 1 off |

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-246 WELDING MATERIAL | LOCAL | CoMat 03-246 | ||

| CoMat 03-204 WELDING FILLER WIRE | LOCAL | CoMat 03-204 |

Spares

NONESafety Requirements

NONEProcedure

Rework of cooling ducts (01-010 and 03-010).

SUBTASK 75-24-49-840-001 Rework of ACC Lower and Upper Air Cooling Duct (3A0678 and 3A0698)

Refer to Inspection-000 TASK 75-24-49-200-100.

Do not rework parts that do not satisfy serviceability requirements except damaged tubes.

Make an inspection of air cooling duct.

SUBTASK 75-24-49-220-159 Examine the Lower and Upper Air Cooling Duct

SUBTASK 75-24-49-320-061 Cut Off Damaged Tubes

Use a 10x magnifying glass. No cracks are permitted.

No cracks are permitted.

Visually examine machined tube for cracks.

SUBTASK 75-24-49-220-160 Examine the Machined Tubes

Refer to Cleaning-000 TASK 75-24-49-100-100.

Clean surface to be welded.

SUBTASK 75-24-49-120-001 Clean the Parts

Refer to SPM TASK 70-31-13-310-501, tungsten inert gas method.

For purity of welds, Refer to SPM TASK 70-31-13-310-501.

Protective atmosphere required.

Use applicable fixture to get correct weld repair.

Weld replacement tube into position.

SUBTASK 75-24-49-310-070 Weld the Tube

Refer to SPM TASK 70-31-13-310-501.

Examine weld quality.

SUBTASK 75-24-49-220-161 Examine the Welded Parts

Refer to SPM TASK 70-23-05-230-501.

Use medium sensitivity method.

No cracks are permitted.

Do test for cracks.

SUBTASK 75-24-49-230-124 Examine the Welded Parts for Cracks

One blocked hole maximum for each tube is permitted.

Examine air holes for blockage.

SUBTASK 75-24-49-210-053 Examine the Air Holes of ACC Assembly

Manual vibro-peen adjacent to existing part number as specified below.

Refer to SPM TASK 70-09-00-400-501.

NUMBER BEFORE - 3A0678

NEW NUMBER - 3A2656

NUMBER BEFORE - 3A0698

NEW NUMBER - 3A2657

Identify ACC assembly with new part number.

SUBTASK 75-24-49-850-001 Identify the ACC Assembly with the New Part Number

Rework of cooling ducts (02-010 and 03-010).

SUBTASK 75-24-49-840-002 Rework of ACC Lower and Upper Air Cooling Duct (3A1662 and 3A1666)

Refer to Inspection-000 TASK 75-24-49-200-100.

Do not rework parts that do not satisfy serviceability requirements except damaged tubes.

Make an inspection of air cooling duct.

SUBTASK 75-24-49-220-163 Examine the Lower and Upper Air Cooling Duct

Use a 10x magnifying glass.

No cracks are permitted.

Visually examine machined tube for cracks.

SUBTASK 75-24-49-220-164 Examine the Machined Tubes

Refer to Cleaning-000 TASK 75-24-49-100-100.

Clean surface to be welded.

SUBTASK 75-24-49-120-002 Clean the Parts

Refer to SPM TASK 70-31-13-310-501, tungsten inert gas method.

Use CoMat 03-204 WELDING FILLER WIRE. For purity of welds, refer to SPM TASK 70-31-13-310-501.

Protective atmosphere required.

Use applicable fixture to get correct weld repair.

Weld replacement tube into position.

SUBTASK 75-24-49-310-071 Weld the Tube

Refer to SPM TASK 70-31-13-310-501.

Examine weld quality.

SUBTASK 75-24-49-220-165 Examine the Welded Parts

Refer to SPM TASK 70-23-05-230-501.

Use medium sensitivity method.

No cracks are permitted.

Do test for cracks.

SUBTASK 75-24-49-230-126 Examine the Welded Parts for Cracks

One blocked hole maximum for each tube is permitted.

Examine air holes for blockage.

SUBTASK 75-24-49-210-054 Examine the Air Holes of ACC Assembly

Manual vibro-peen adjacent to existing part number as specified below.

Refer to SPM TASK 70-09-00-400-501.

NUMBER BEFORE - 3A1662.

NEW NUMBER - 3A2658

NUMBER BEFORE - 3A1666

NEW NUMBER - 3A2659

Identify ACC assembly with new part number.

SUBTASK 75-24-49-850-002 Identify the ACC Assembly with the New Part Number

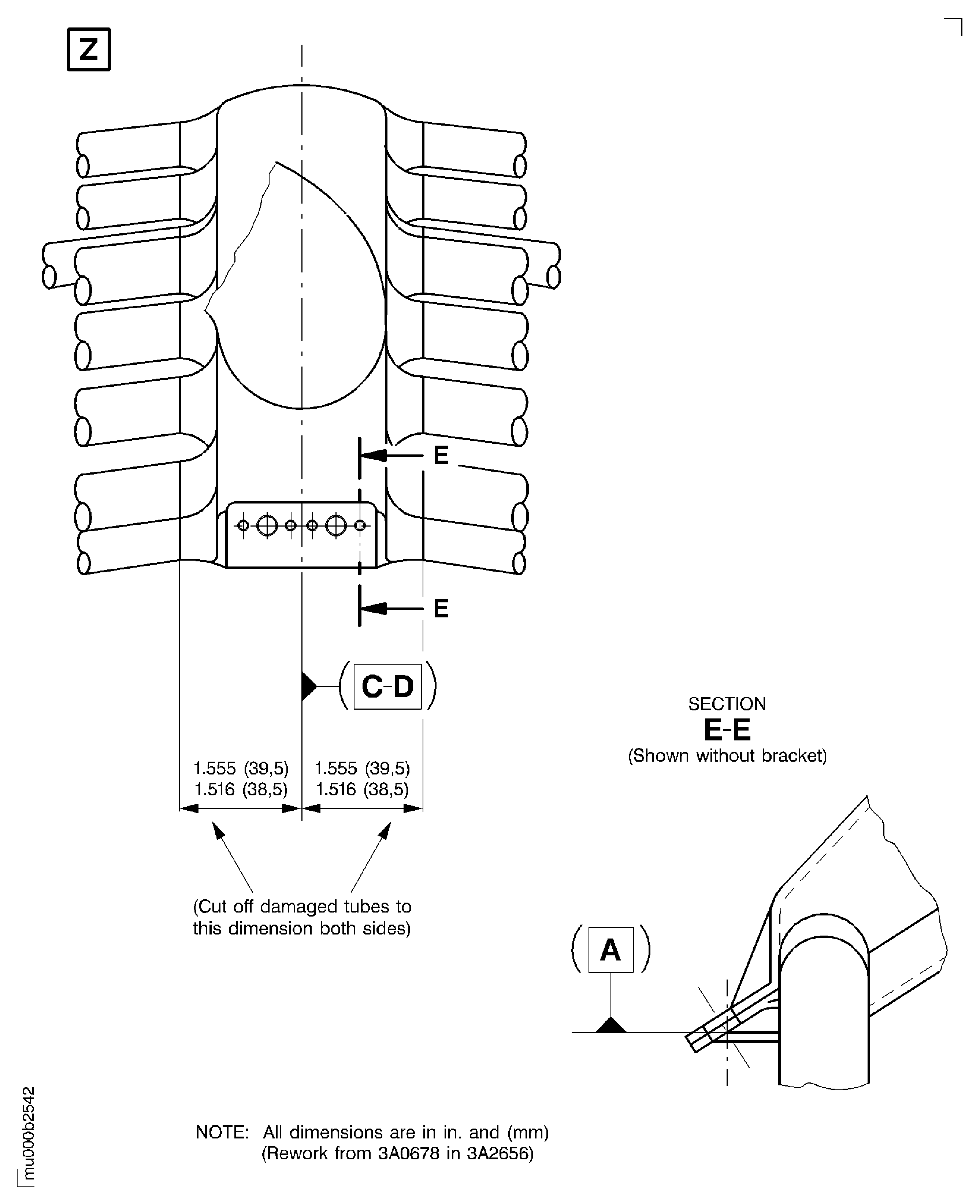

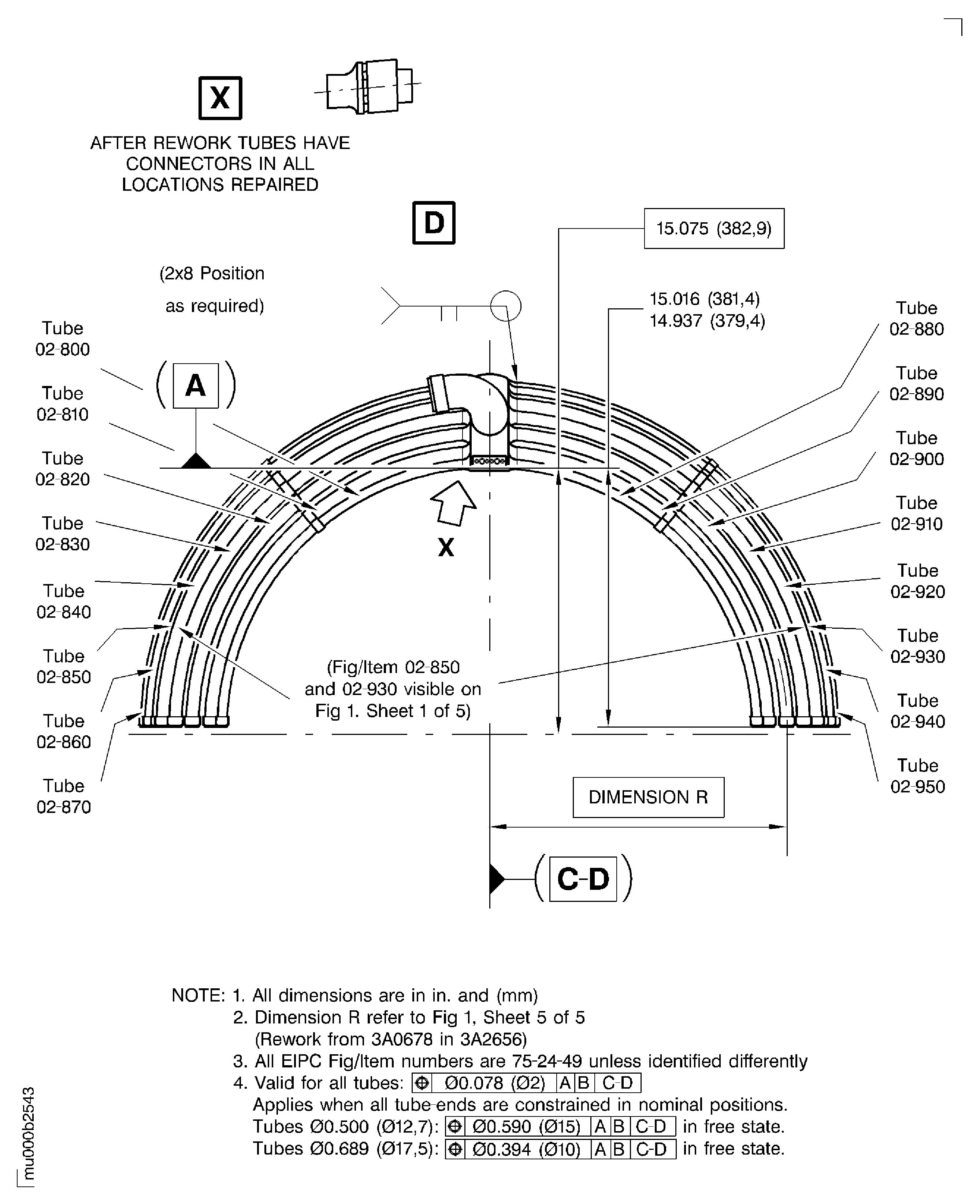

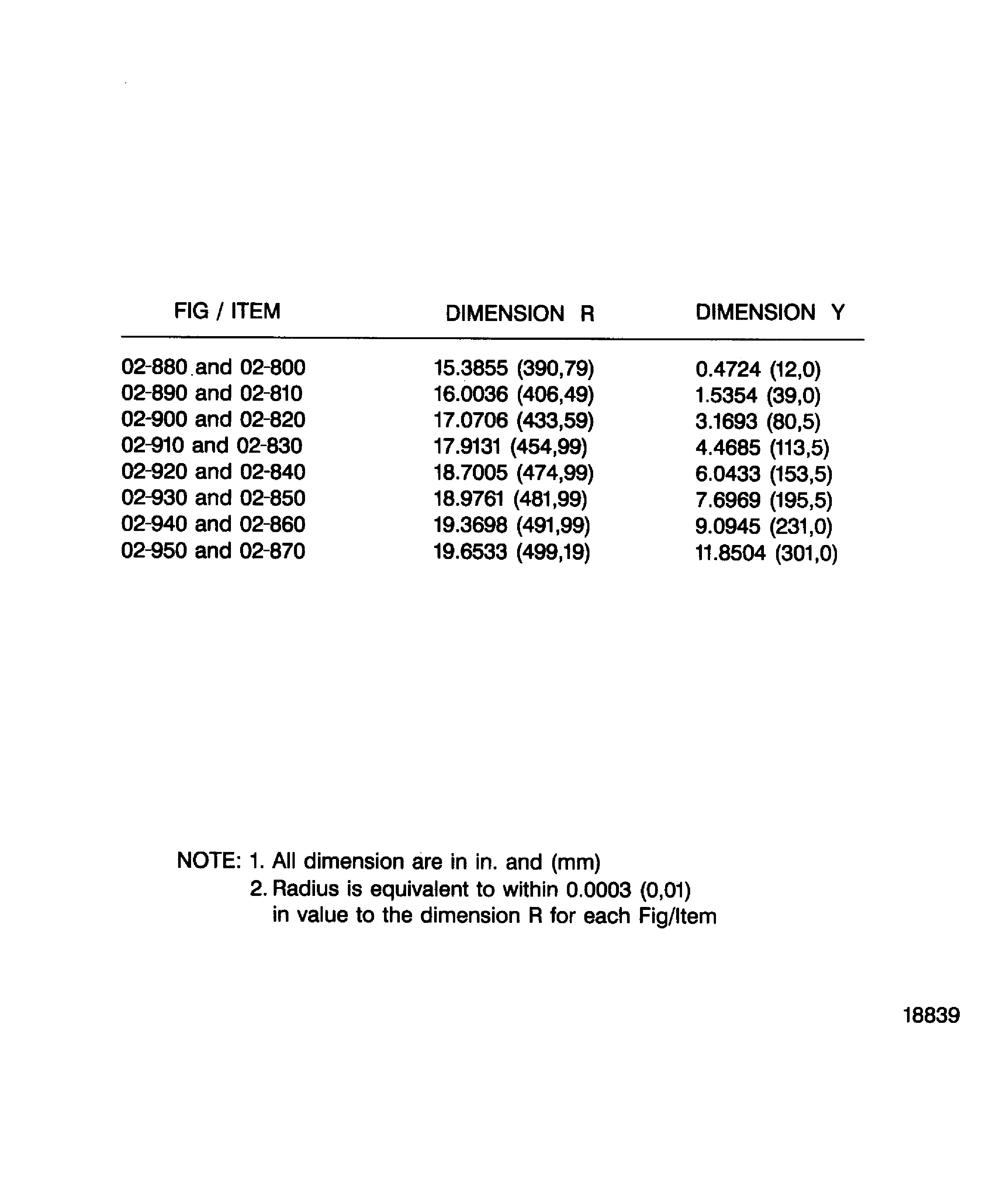

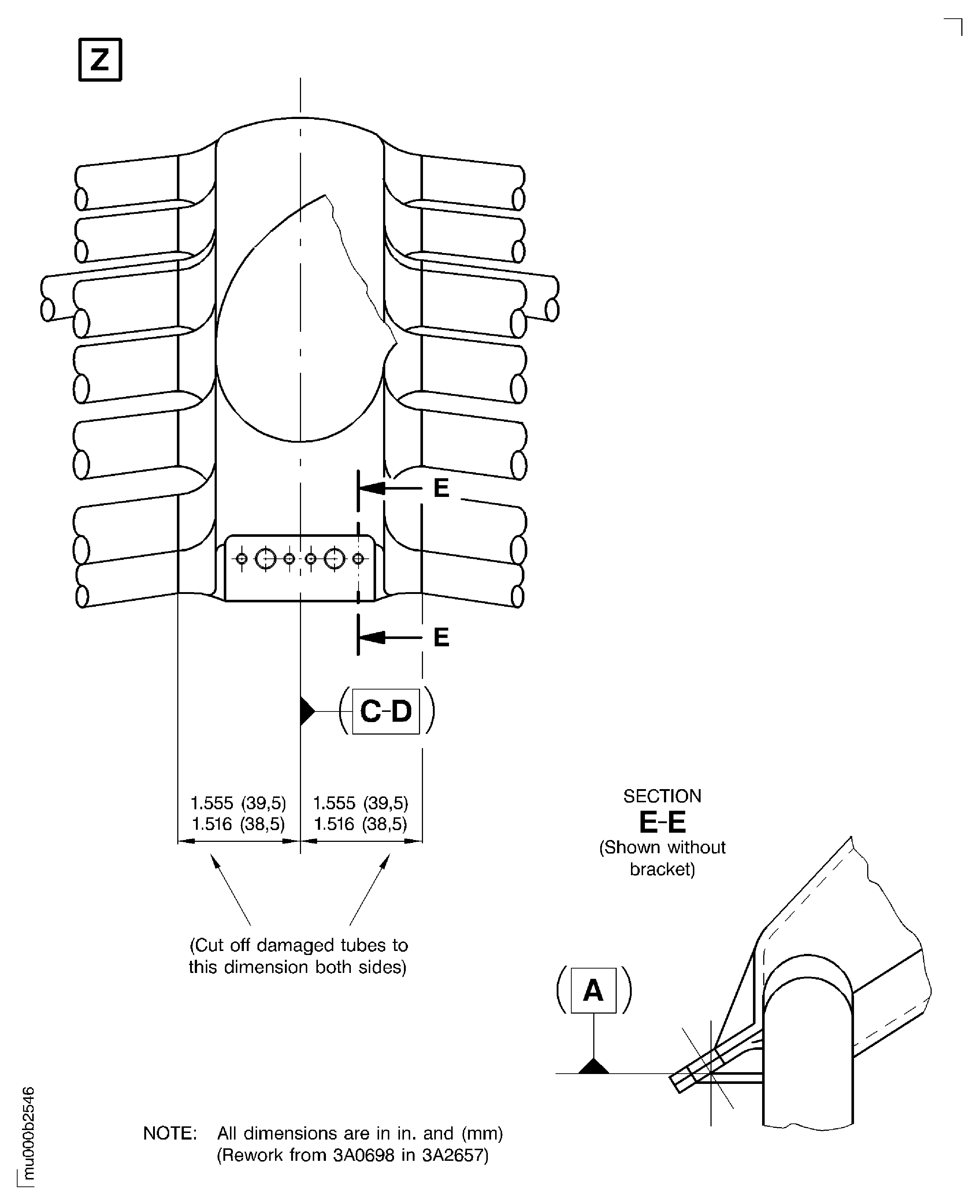

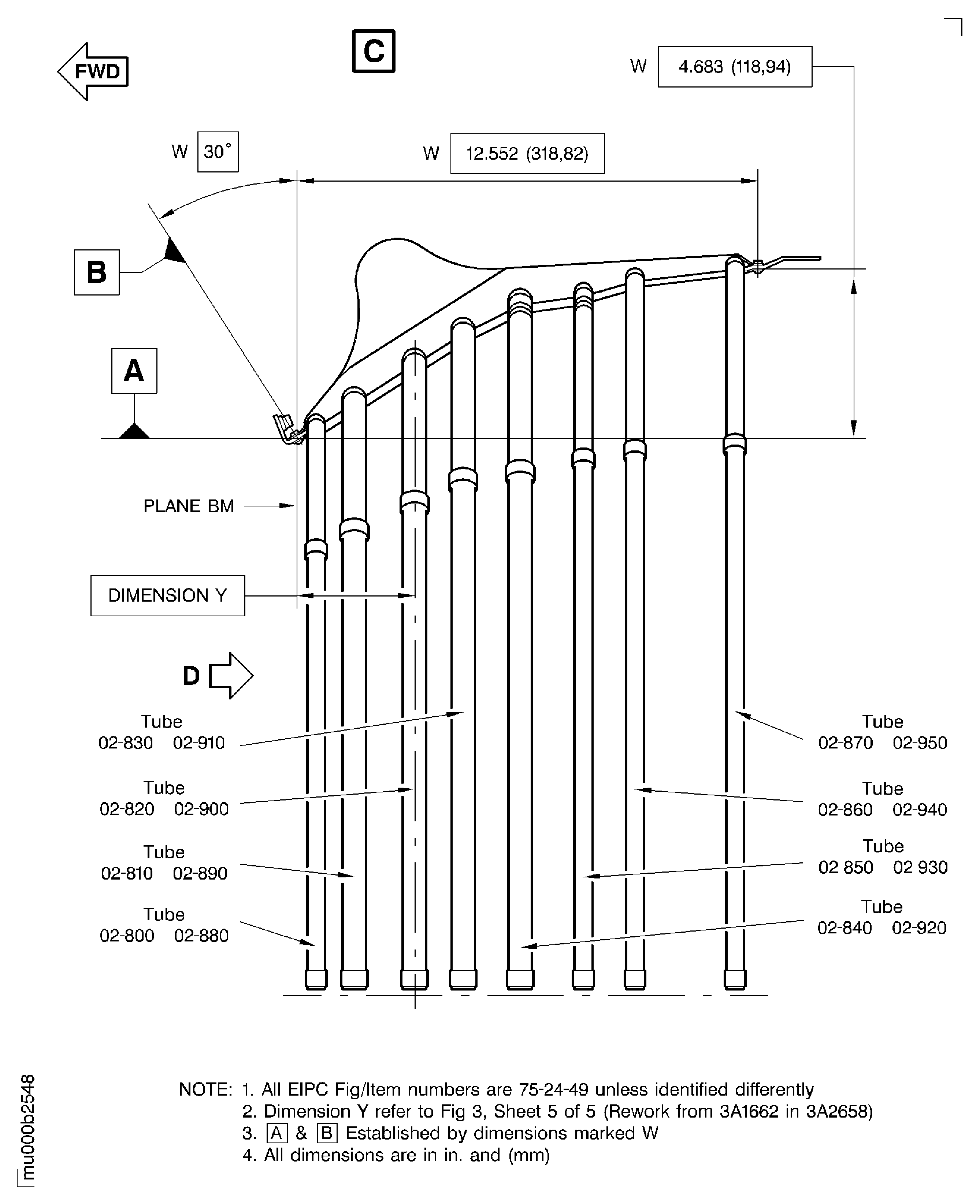

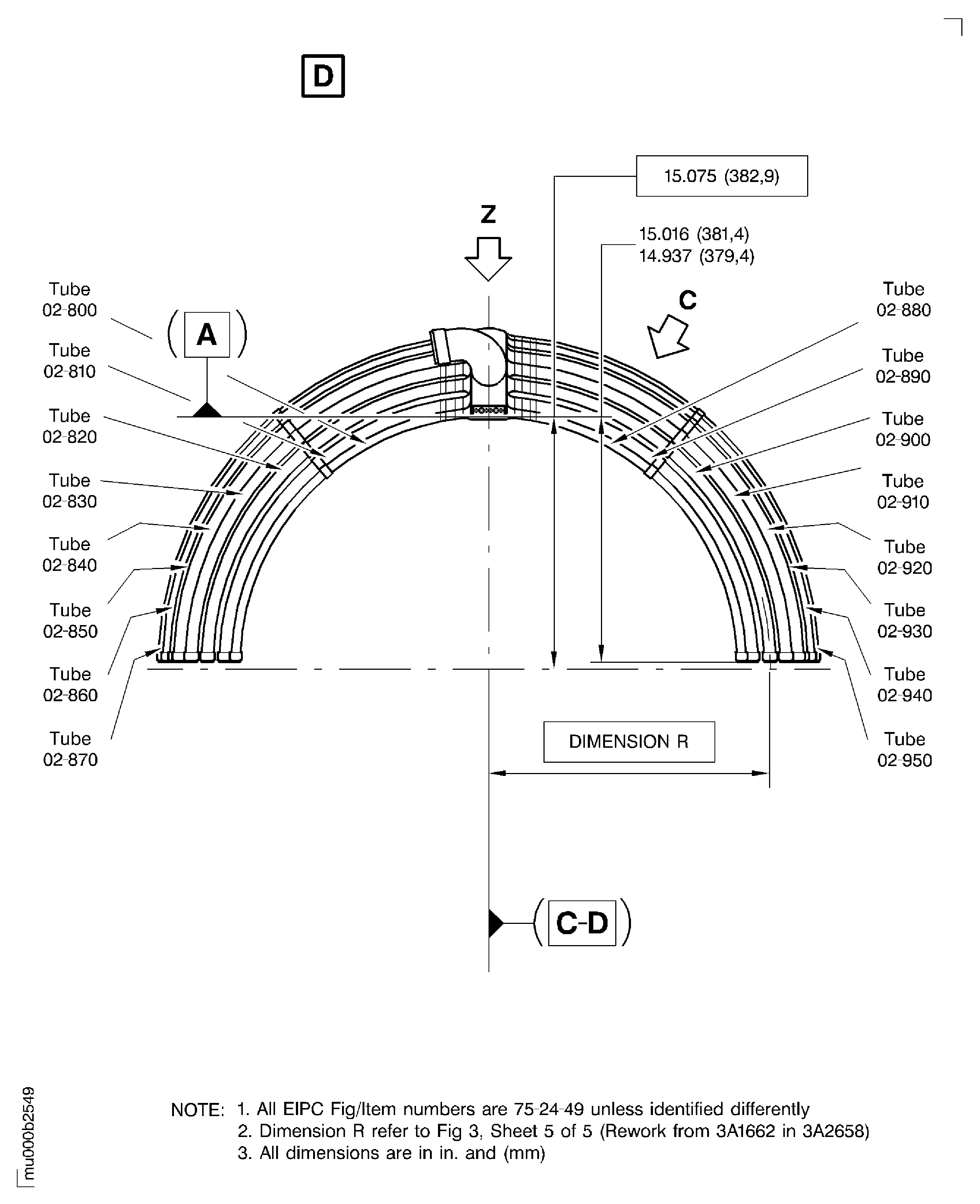

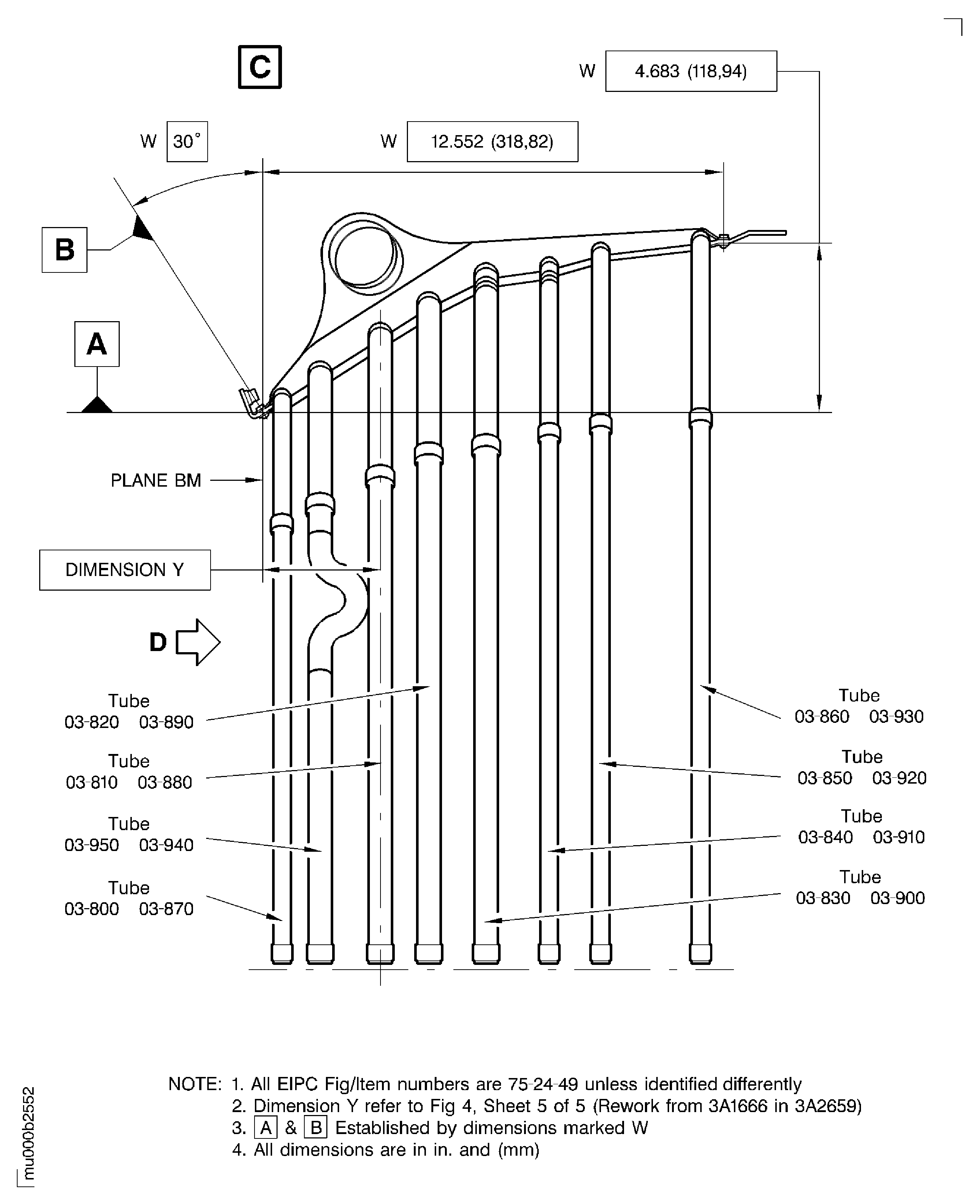

Figure: Rework of Active Clearance Control (ACC) Made from Titanium

Rework of Active Clearance Control (ACC) Made from Titanium

Rework of Active Clearance Control (ACC) Made from Titanium

Rework of Active Clearance Control (ACC) Made from Titanium

Rework of Active Clearance Control (ACC) Made from Titanium

Rework of Active Clearance Control (ACC) Made from Titanium

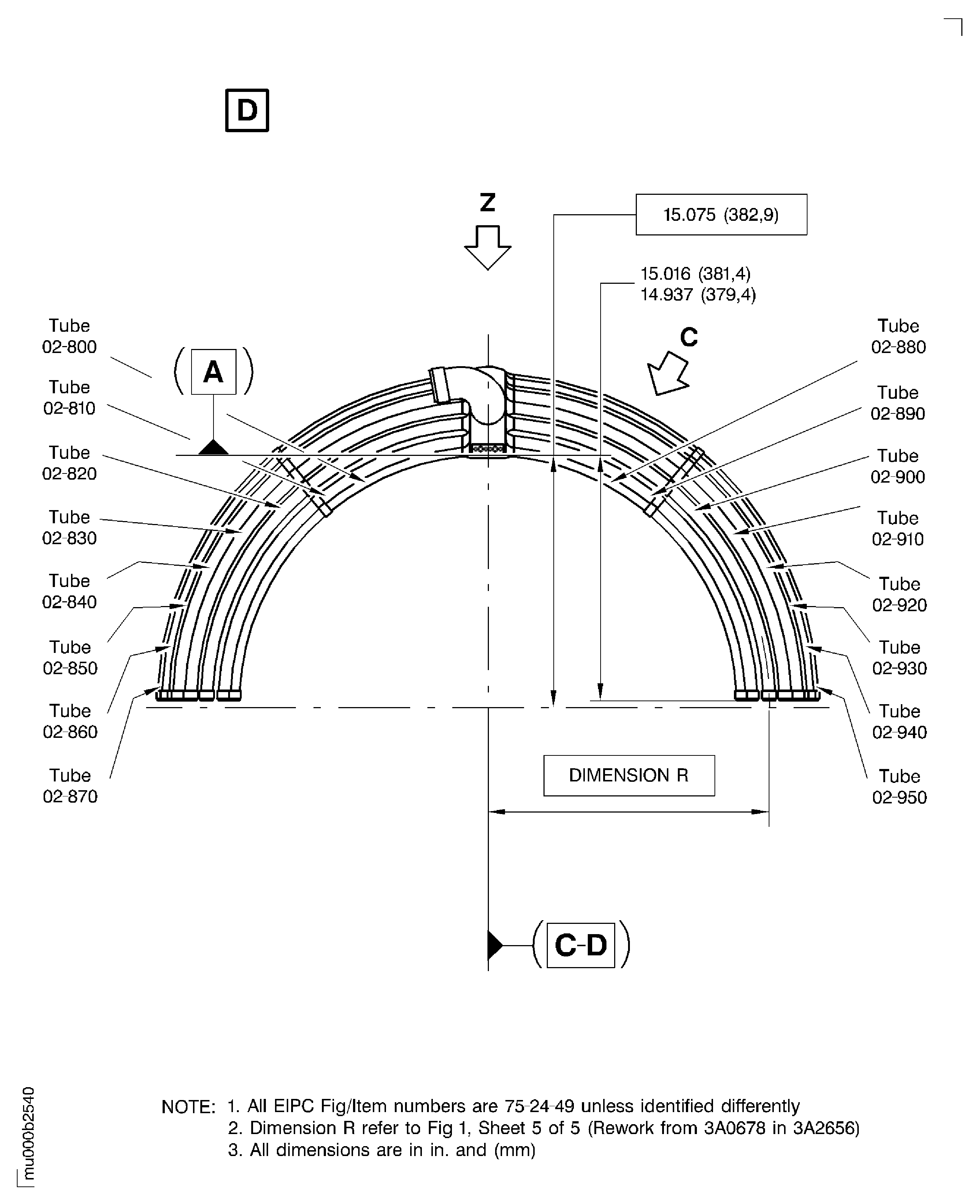

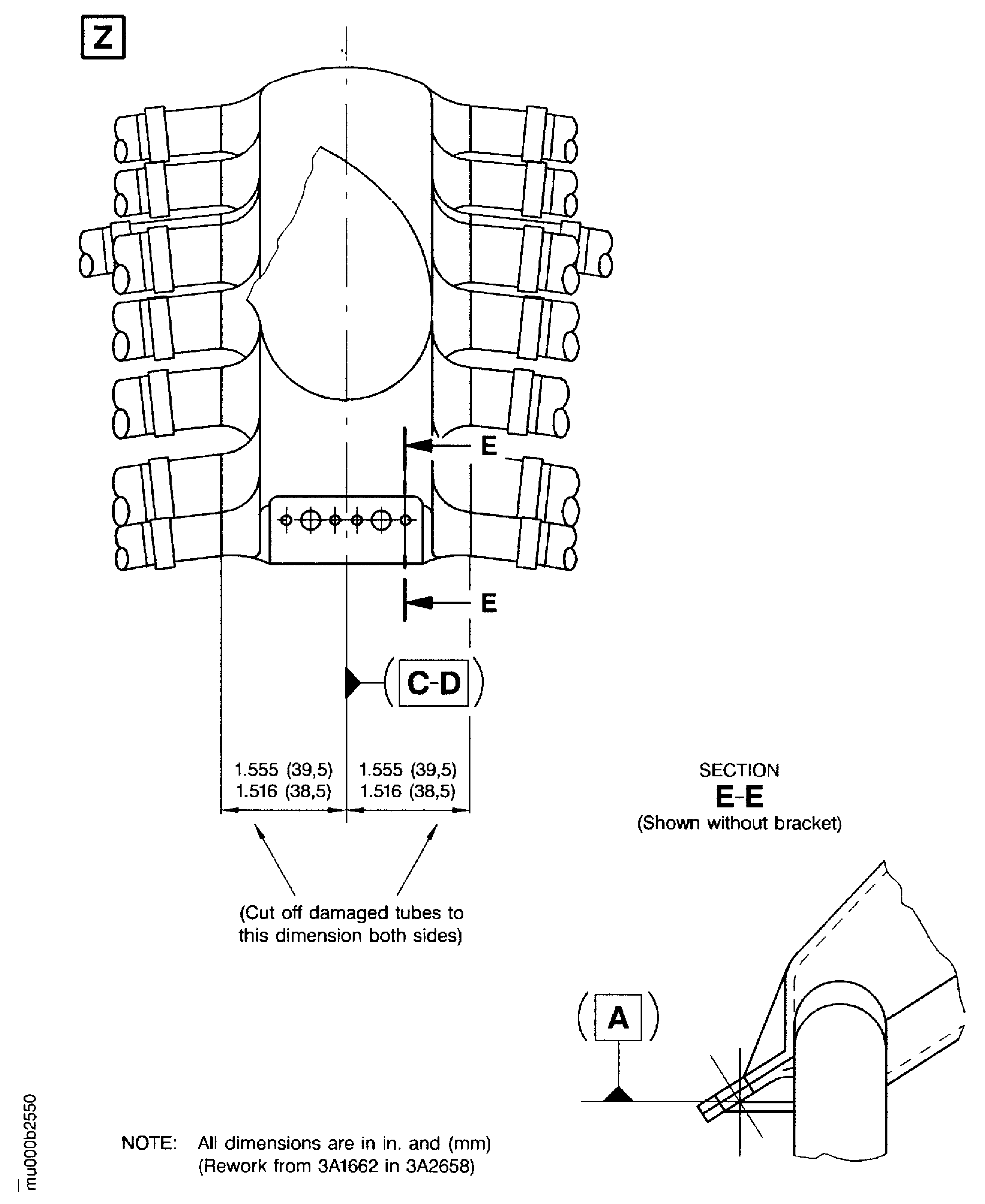

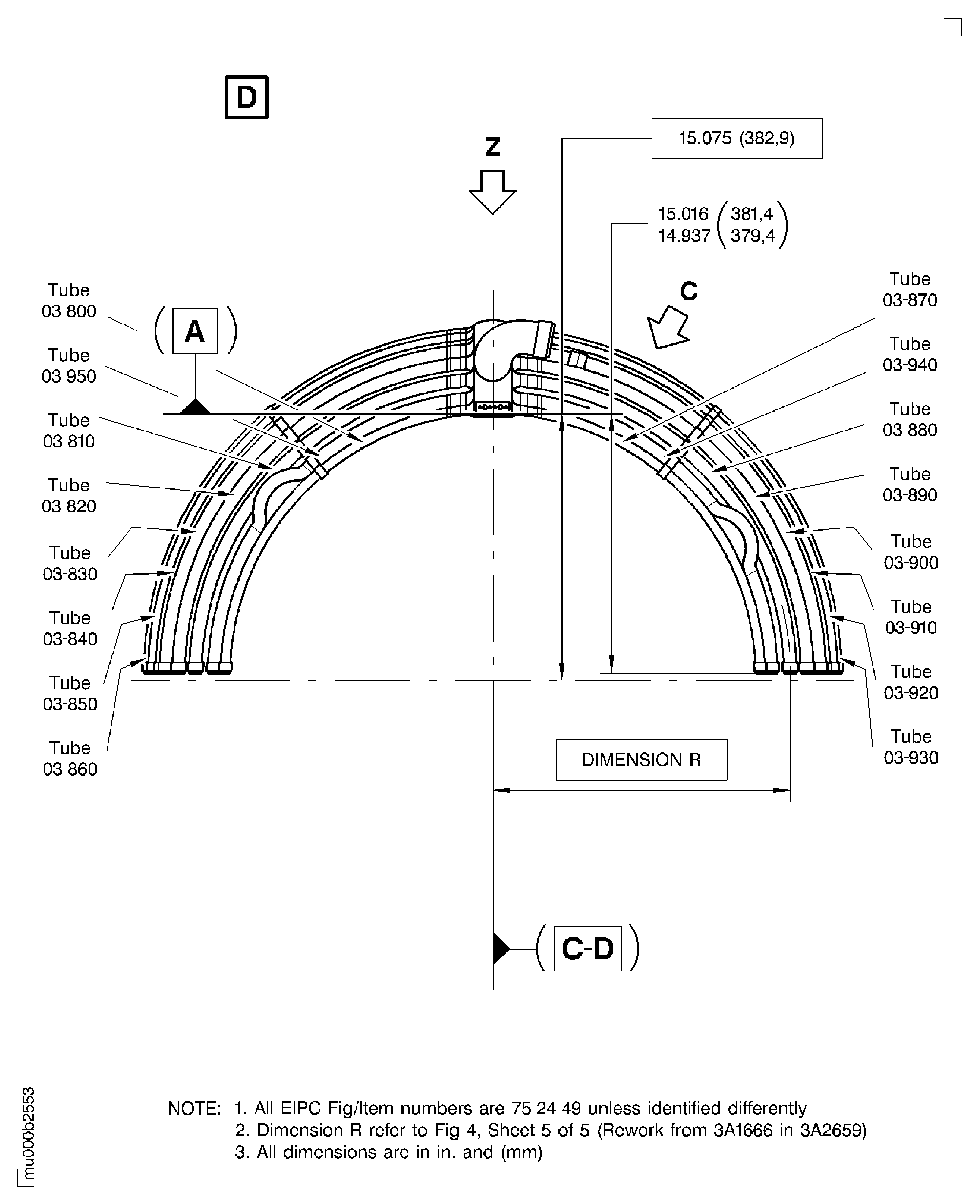

Figure: Rework of Active Clearance Control (ACC) Made from Titanium

Rework of Active Clearance Control (ACC) Made from Titanium

Rework of Active Clearance Control (ACC) Made from Titanium

Rework of Active Clearance Control (ACC) Made from Titanium

Rework of Active Clearance Control (ACC) Made from Titanium

Rework of Active Clearance Control (ACC) Made from Titanium

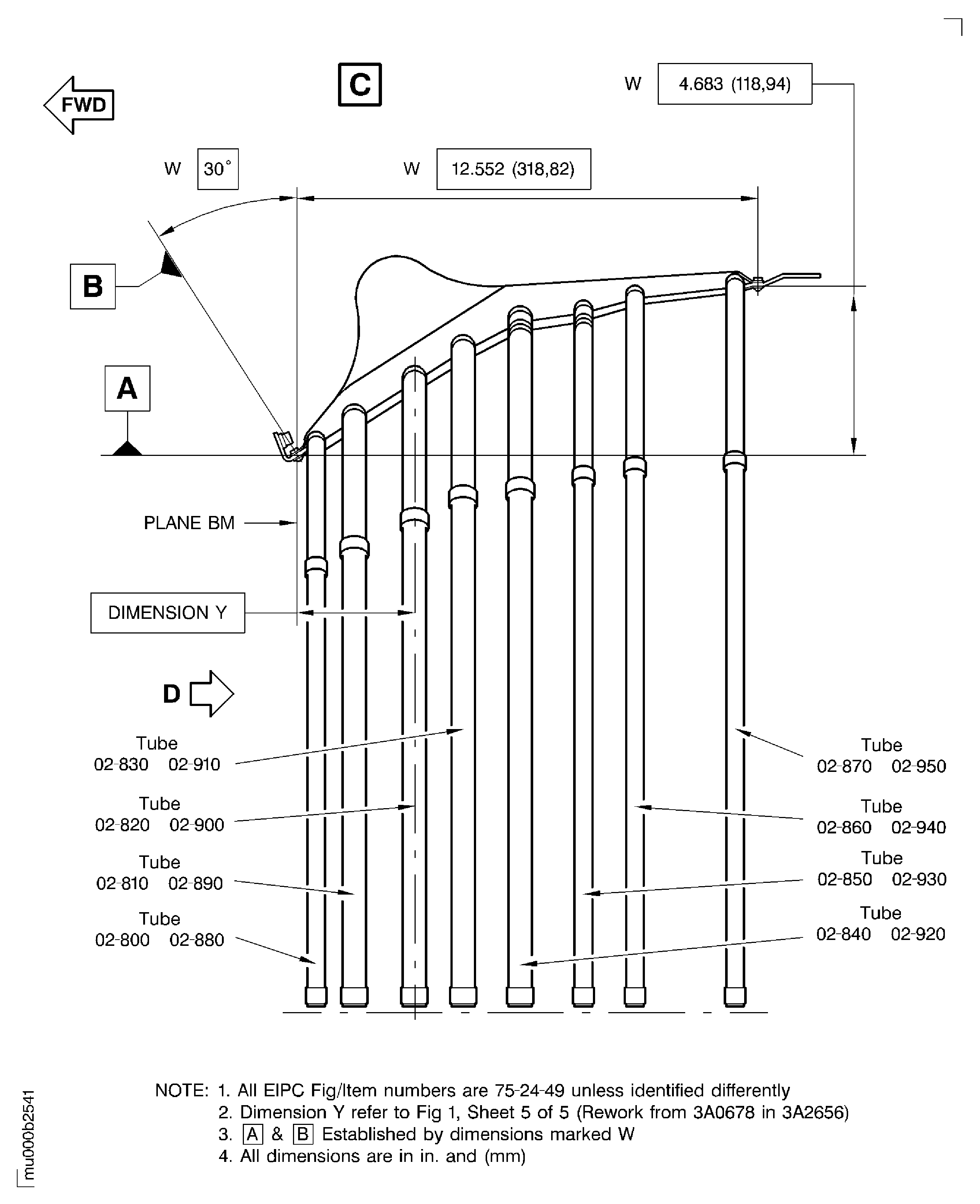

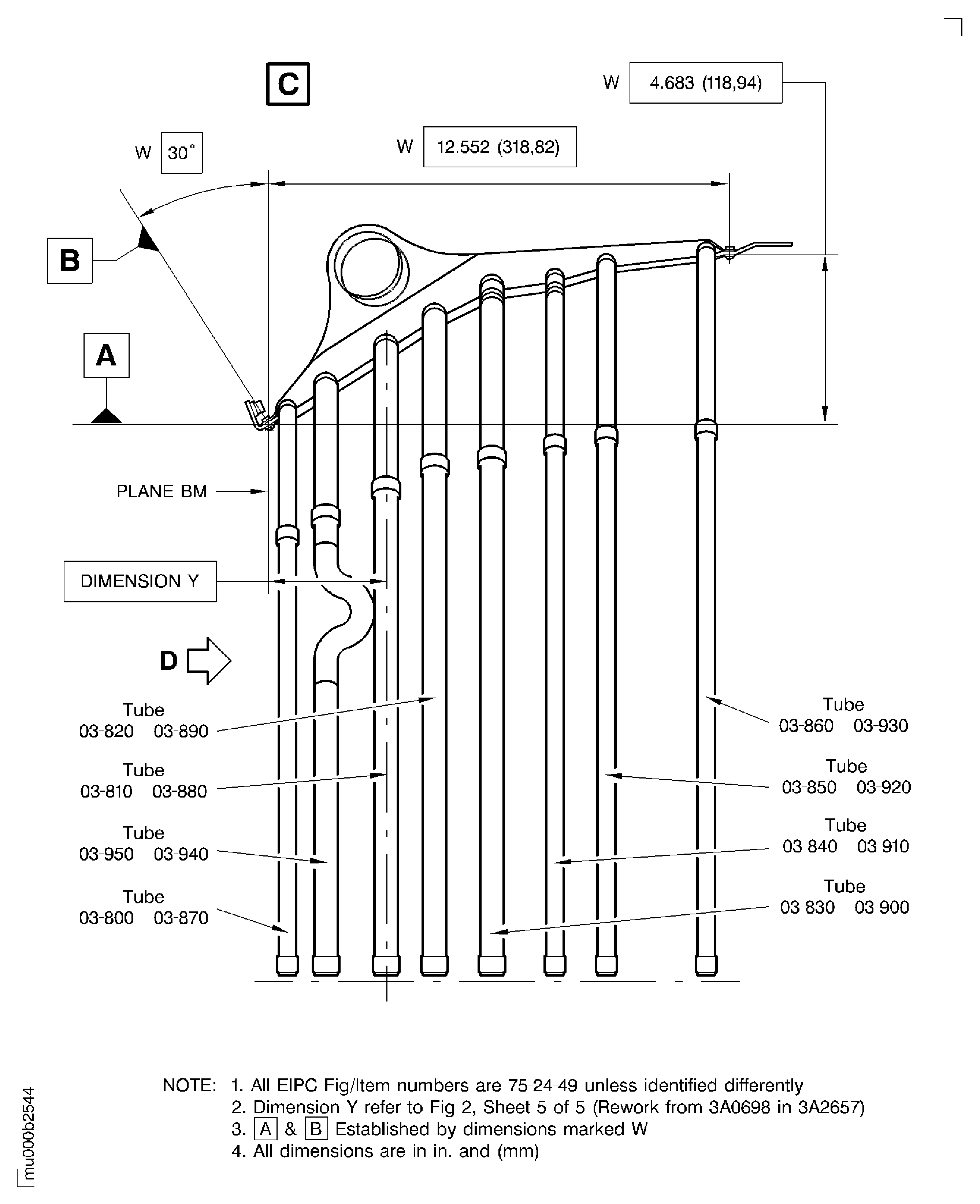

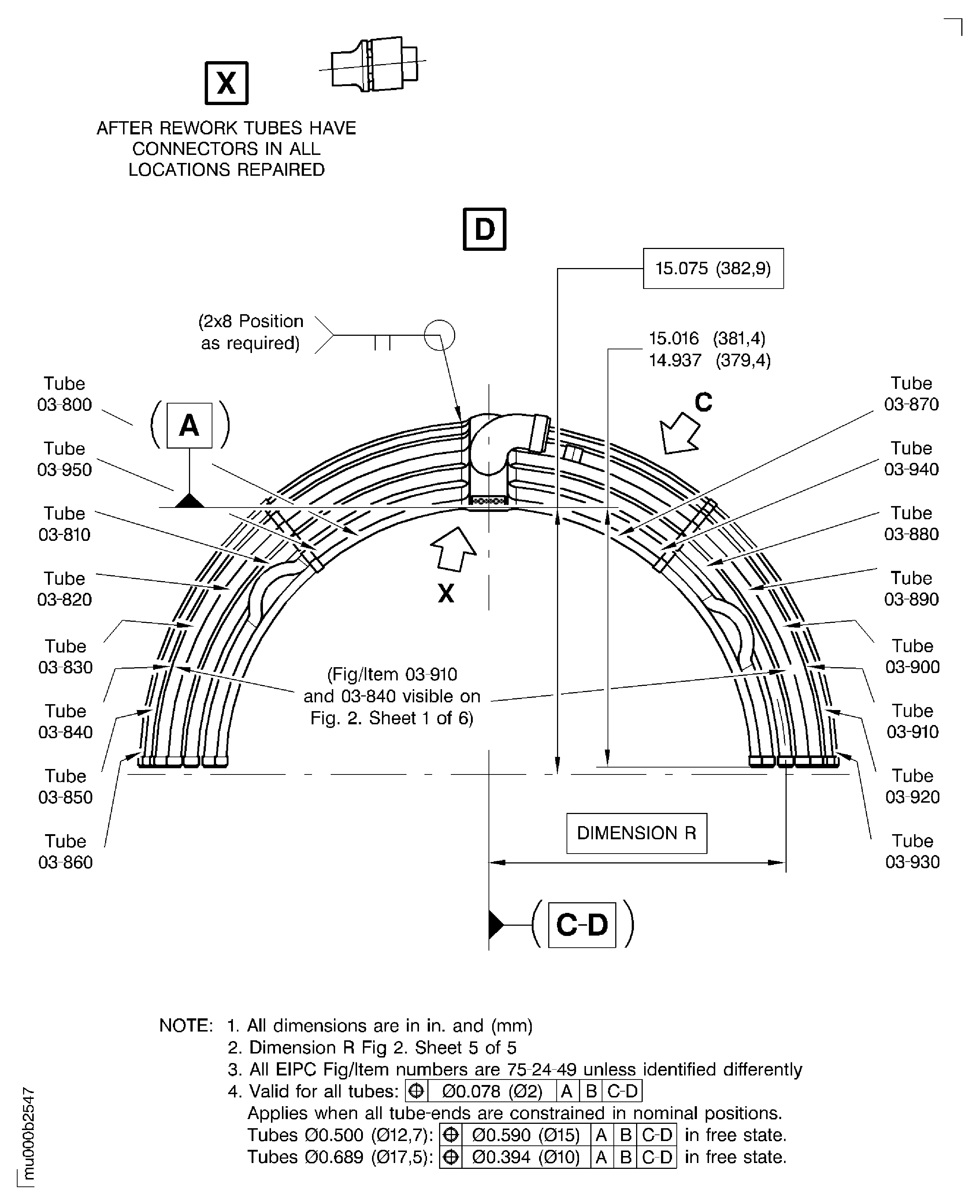

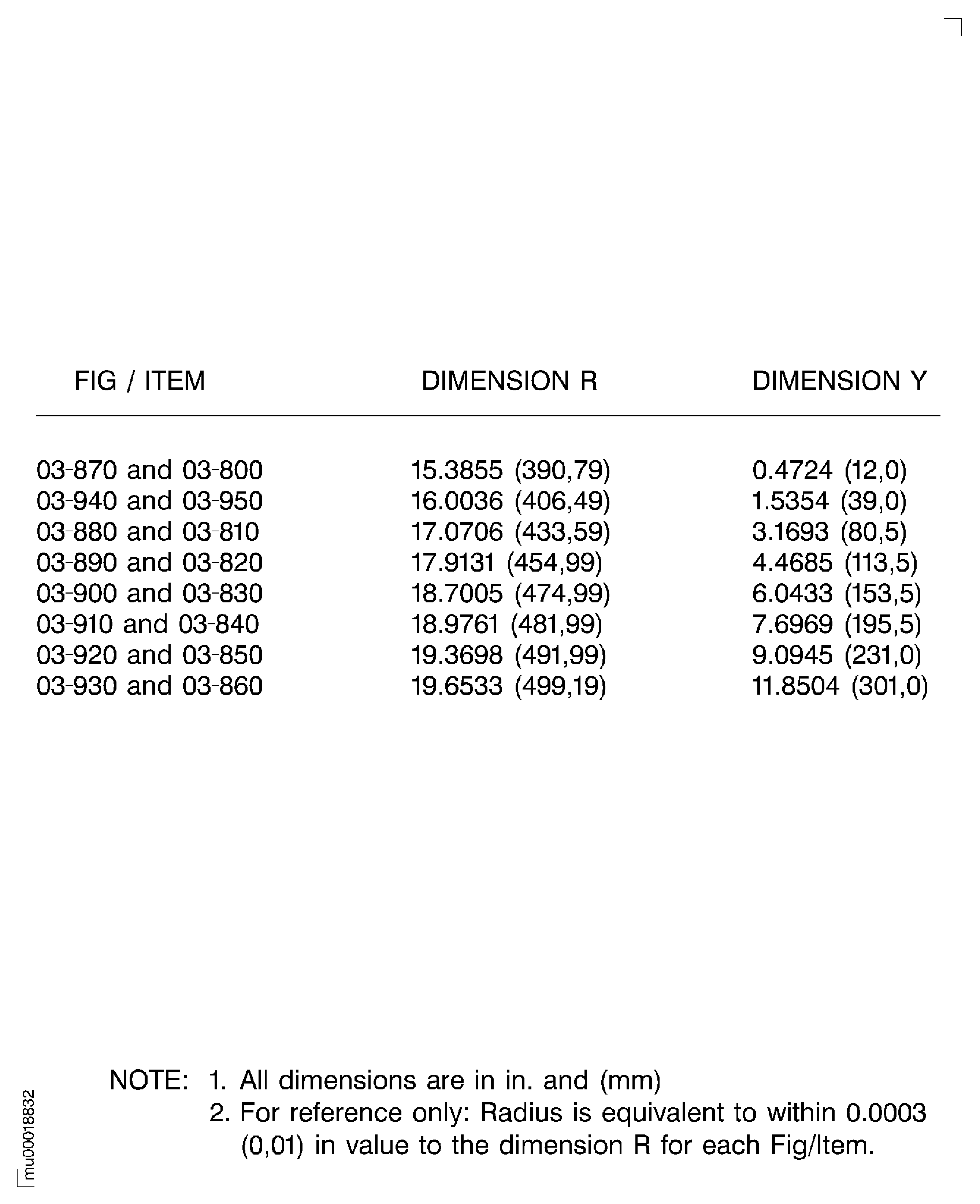

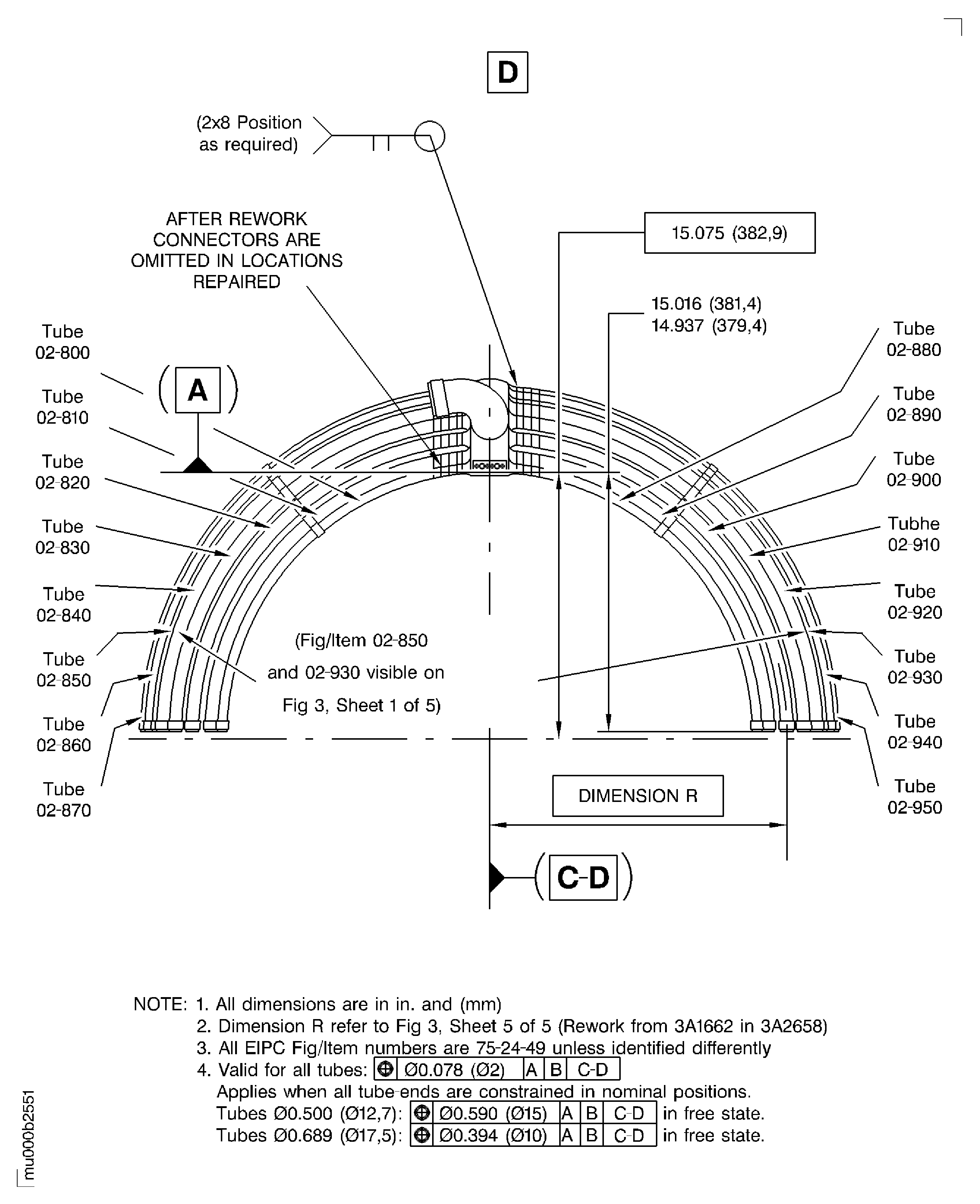

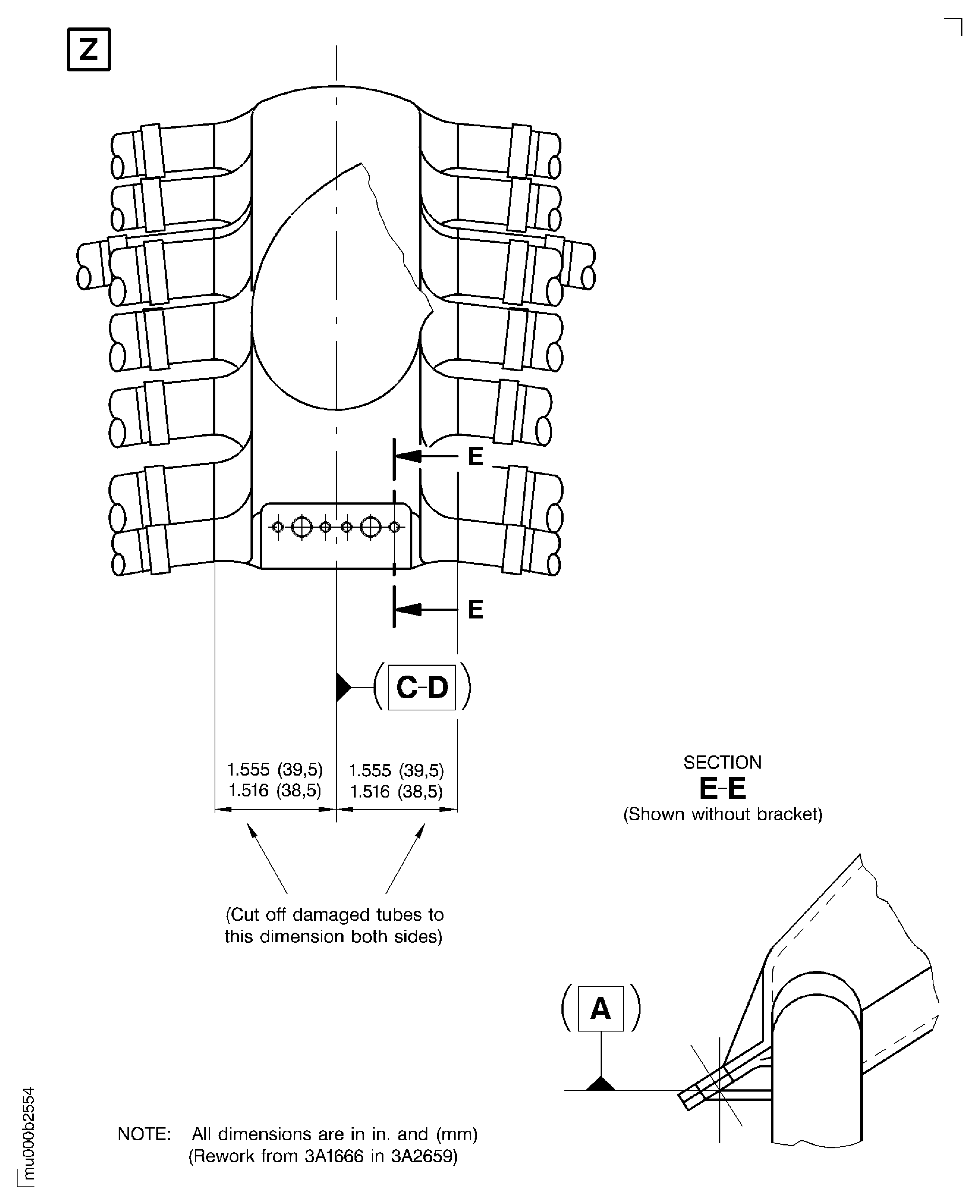

Figure: Rework of Active Clearance Control (ACC) Made from Steel Wit Titanium Tubes

Rework of Active Clearance Control (ACC) Made from Steel Wit Titanium Tubes

Rework of Active Clearance Control (ACC) Made from Steel Wit Titanium Tubes

Rework of Active Clearance Control (ACC) Made from Steel Wit Titanium Tubes

Rework of Active Clearance Control (ACC) Made from Steel Wit Titanium Tubes

Rework of Active Clearance Control (ACC) Made from Steel Wit Titanium Tubes

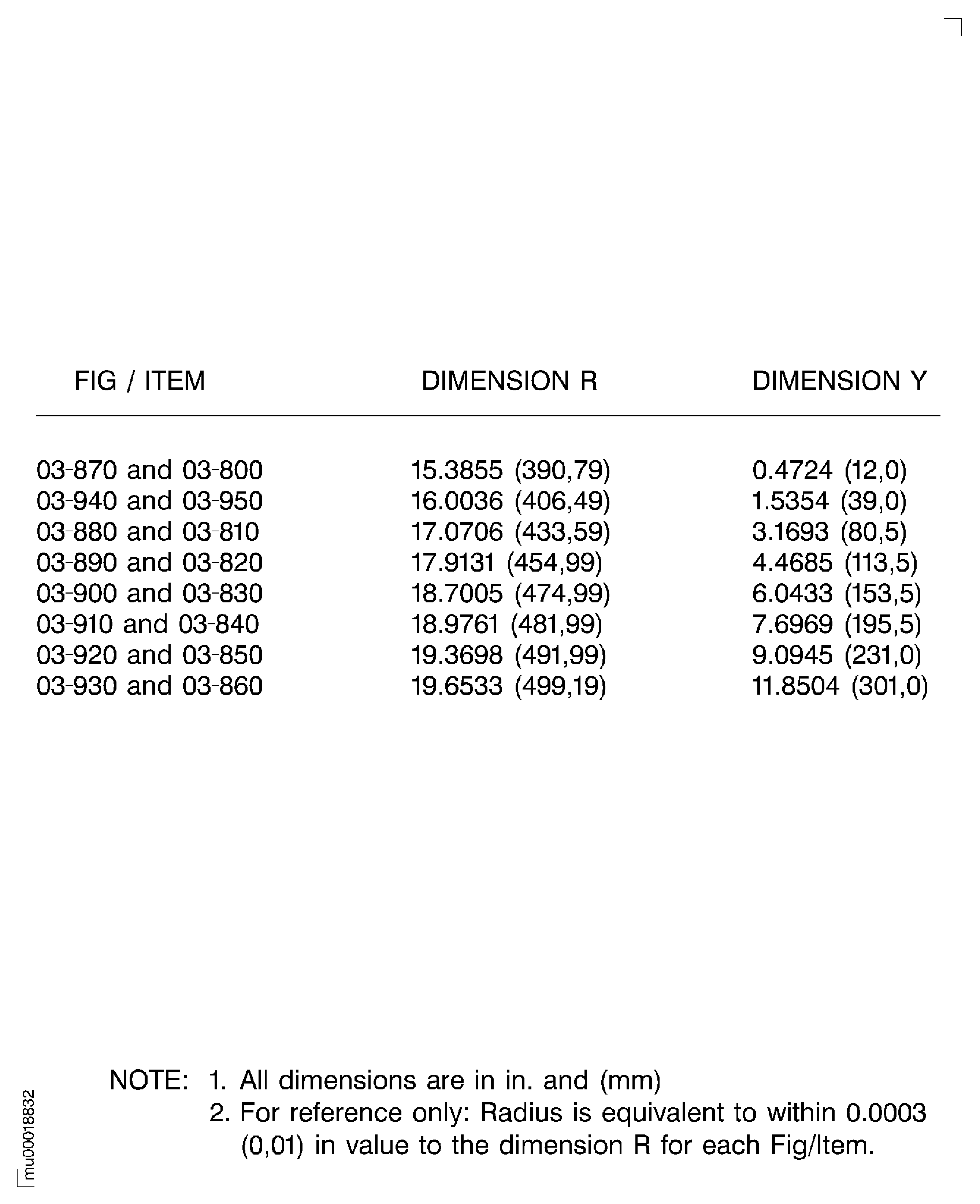

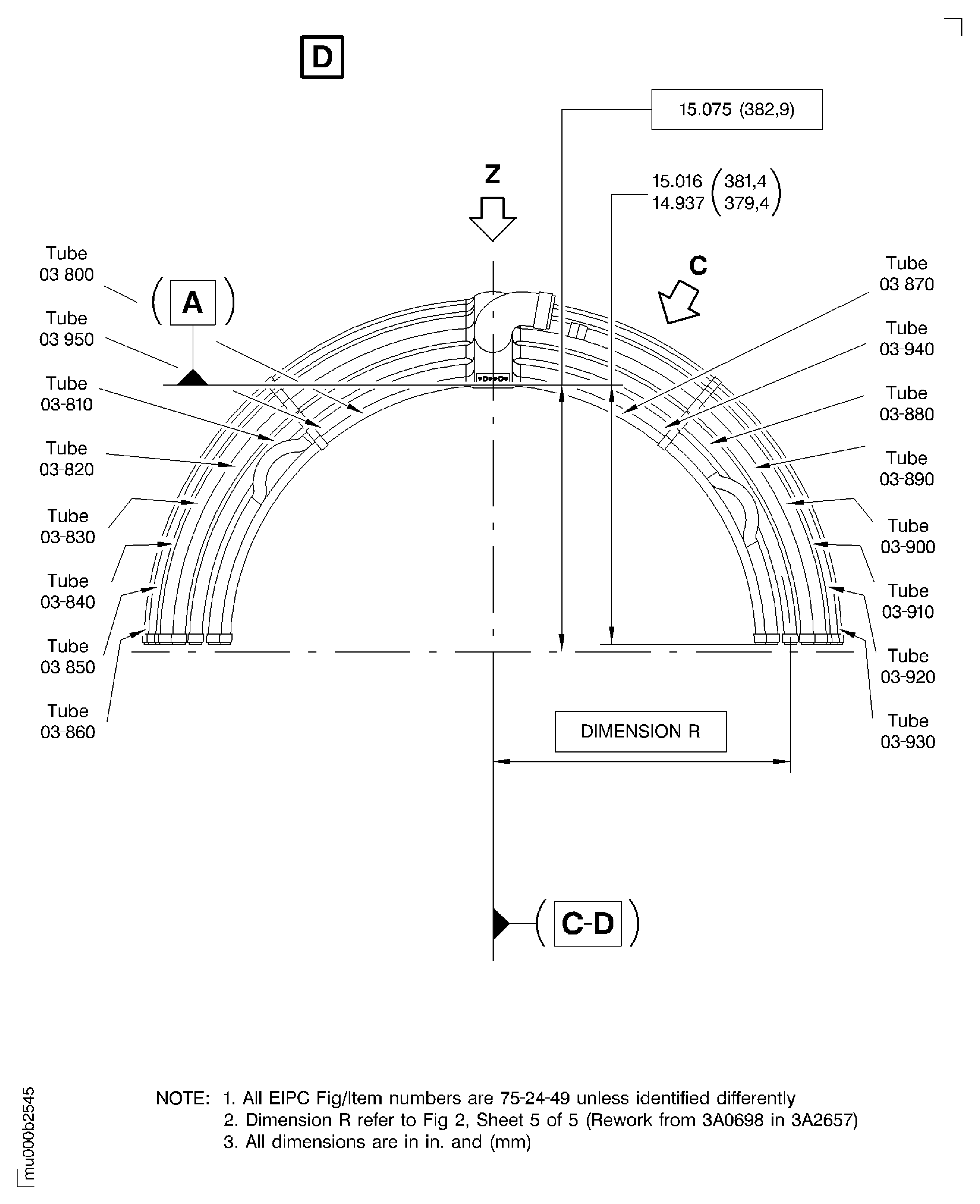

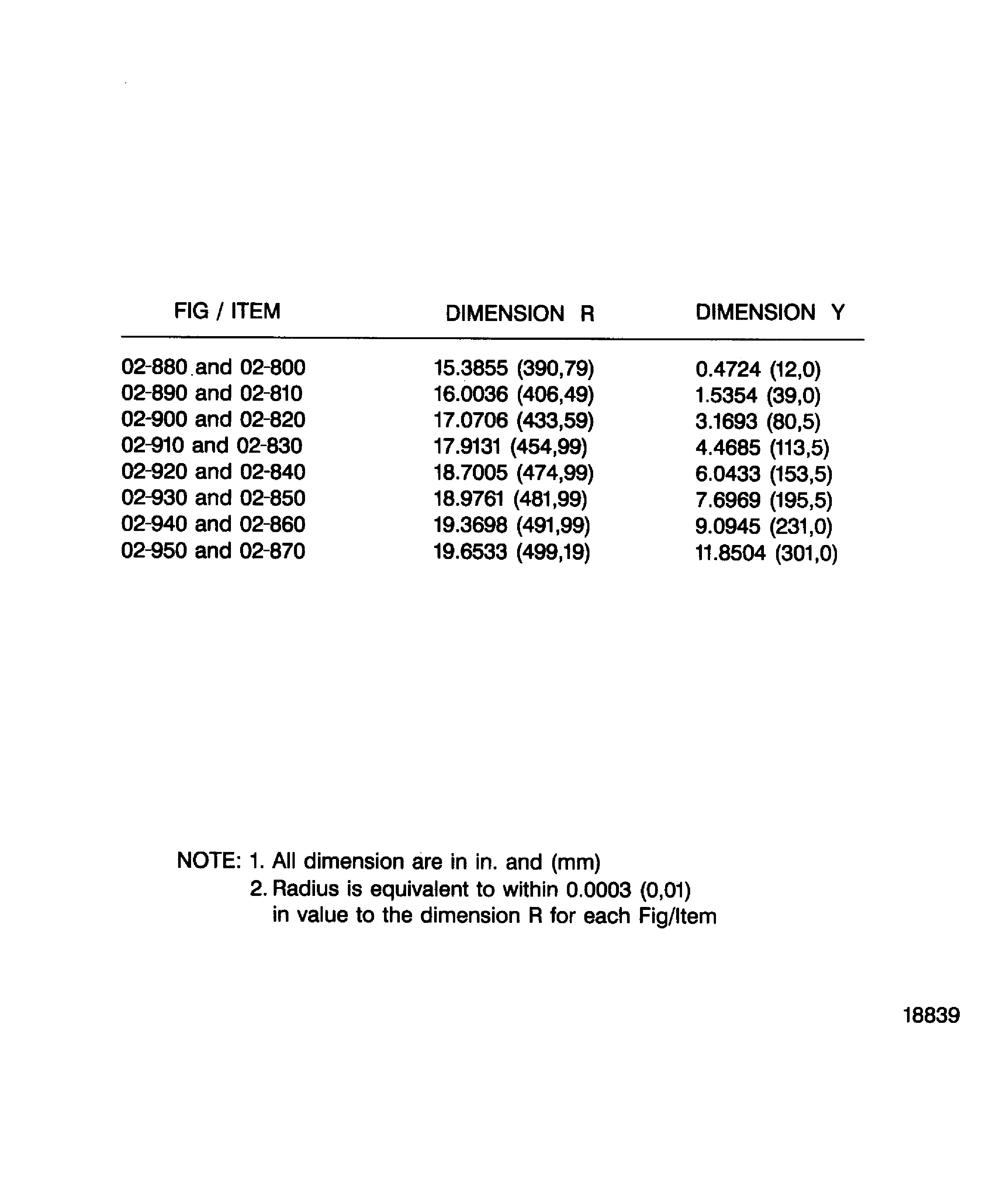

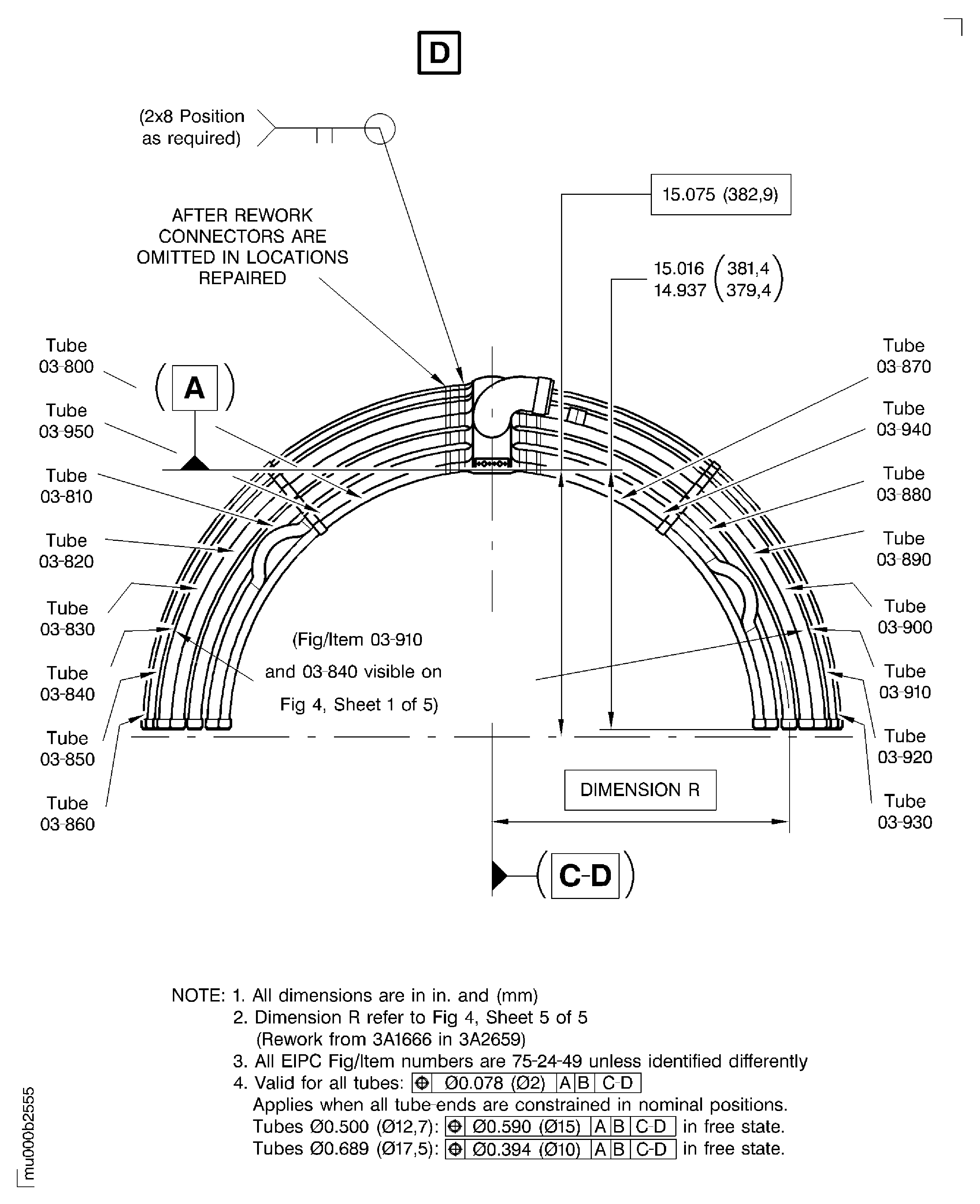

Figure: Rework of Active Clearance Control (ACC) Made from Steel Wit Titanium Tubes

Rework of Active Clearance Control (ACC) Made from Steel Wit Titanium Tubes

Rework of Active Clearance Control (ACC) Made from Steel Wit Titanium Tubes

Rework of Active Clearance Control (ACC) Made from Steel Wit Titanium Tubes

Rework of Active Clearance Control (ACC) Made from Steel Wit Titanium Tubes

Rework of Active Clearance Control (ACC) Made from Steel Wit Titanium Tubes