Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 75-24-49-300-025 LPT ACC Cooling Air Ducts - Weld Repair, Repair-025 (VRS4261)

Material of component

PART IDENT | IAE SYMBOL | MATERIAL |

Upper air cooling duct tubes | TiCu2 | |

Upper air cooling duct housing | 1.4544.9 | |

Lower air cooling duct tubes | TiCu-2 | |

Lower air cooling duct housing | 1.4544.9 |

General

Price and availability - none.

The practices and processes referred to in the procedure by the TASK number are in the SPM.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Crack detection kit (fluorescent) | LOCAL | Crack detection kit (fluorescent) | ||

| Vacuum furnace | LOCAL | Vacuum furnace | 2400 deg F (1315 deg C) - bottom loading | |

| Tungsten inert gas system (TIG) | LOCAL | Tungsten inert gas system (TIG) | ||

| Unltraviolet lamp | LOCAL | Ultraviolet lamp |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-204 WELDING FILLER WIRE | LOCAL | CoMat 03-204 | ||

| CoMat 03-246 WELDING MATERIAL | LOCAL | CoMat 03-246 |

Spares

NONESafety Requirements

NONEProcedure

Refer to SPM TASK 70-31-13-310-501.

Keep accurately to the cleaning policy as described, to avoid damage to the titanium.

Clean the areas around the nicks, cracks or wear on the two sides of the upper and lower air cooling duct assemblies.

SUBTASK 75-24-49-110-075 Clean the Upper and Lower Air Cooling Duct Assemblies

Refer to SPM TASK 70-31-13-310-501.

Use protective gas equipment for purity of welds.

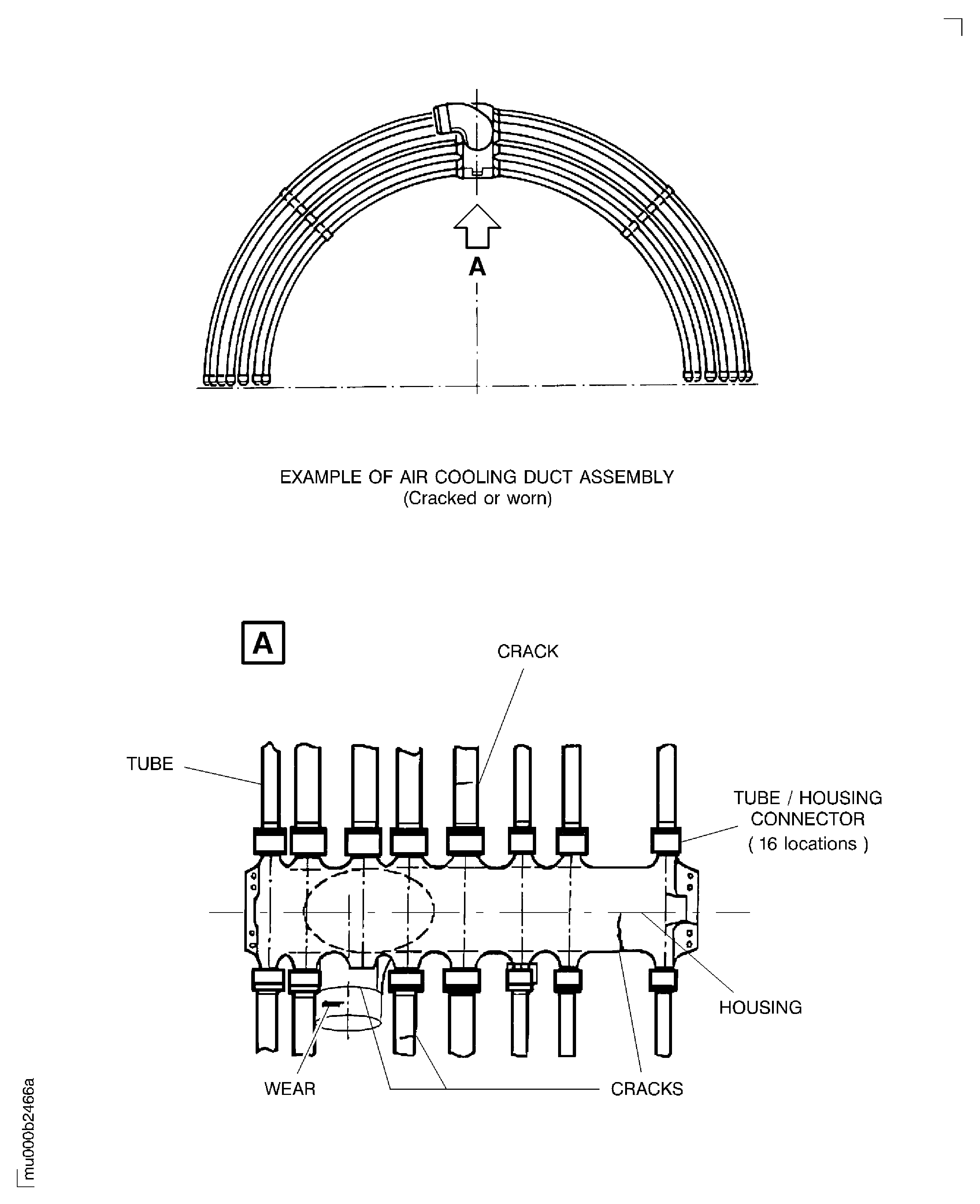

Use CoMat 03-246 WELDING MATERIAL to repair nicks, cracks or wear on tubes.

Use CoMat 03-204 WELDING FILLER WIRE to repair nicks, cracks or wear on housing.

Tungsten inert gas weld the nicks, cracks or wear on the upper and lower air cooling duct assemblies.

SUBTASK 75-24-49-350-099 Weld Repair the Upper and Lower Air Cooling Duct Assemblies

NOTE

Weld repair at the tube/housing connectors is not permitted.Refer to SPM TASK 70-23-05-230-501, medium sensitivity.

No cracks are permitted.

Do the test for cracks.

SUBTASK 75-24-49-230-090 Examine the Welded Areas for Cracks

Use files or hand held stones.

Maximum step of 0.003 in. (0.076 mm) to parent material is permitted.

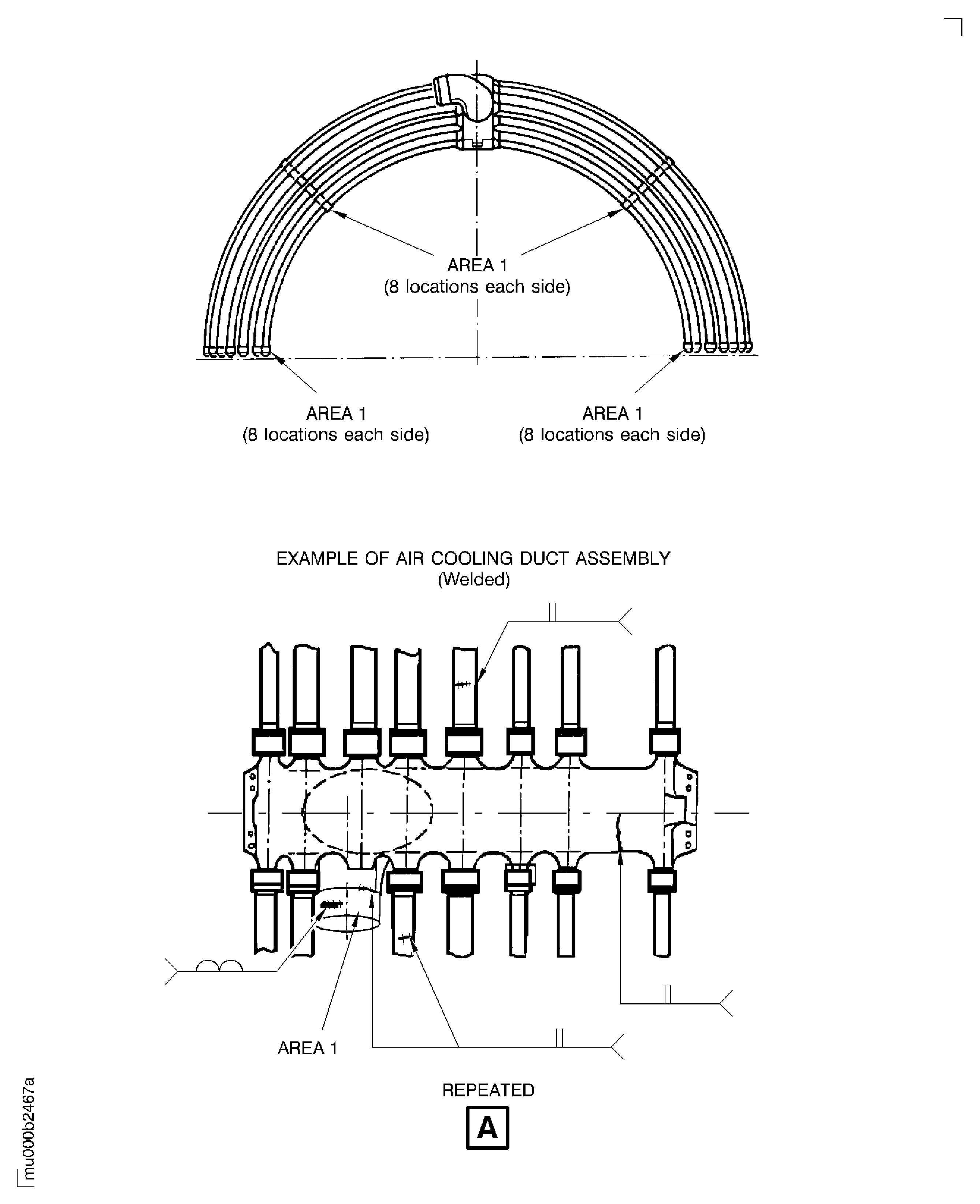

No raised material is permitted in area A1.

Dress welds smooth on repaired surfaces.

Refer to Repair, VRS4048 (Repair-004) TASK 75-24-49-300-004.

Polish welds in area 1.

SUBTASK 75-24-49-350-100 Dress the Welded Areas

Use Vacuum furnace bottom loading for 2 hours at 887 deg F (475 deg C).

Argon or vacuum atmosphere is acceptable.

Heat treat the upper and lower air cooling duct assemblies.

SUBTASK 75-24-49-350-101 Heat Treat the Upper and Lower Air Cooling Duct Assemblies after Weld Repair of the Tubes

NOTE

If only the upper and lower air cooling duct assemblies housing has been welded, no heat treat is required.Refer to SPM TASK 70-23-02-230-501.

No cracks are permitted.

Do the test for cracks.

SUBTASK 75-24-49-230-091 Do the Post Repair Inspection

Figure: Weld Repair of the Upper and Lower Air Cooling Duct Assemblies

Weld Repair of the Upper and Lower Air Cooling Duct Assemblies

Weld Repair of the Upper and Lower Air Cooling Duct Assemblies