Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 75-24-49-300-055 LPT ACC Support Assemblies - Replace The Rear Flange, Repair-055 (VRS4591)

General

Price and availability - none

The practices and processes referred to in the procedure by the TASK number are in the SPM.

Before repair remove the half loop clamps, the blind rivets or the self locking nuts, refer to Repair, VRS4025 (Repair-016) TASK 75-24-49-300-016.

After repair replace the half loop clamps, the blind rivets or the self locking nuts, refer to Repair, VRS4025 (Repair-016) TASK 75-24-49-300-016.

NOTE

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-184 WELDING FILLER WIRE, NICKEL | LOCAL | CoMat 03-184 | ||

| CoMat 03-387 WELDING FILLER WIRE | LOCAL | CoMat 03-387 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Replacement rear flange | 0AM53 | Replacement rear flange |

Safety Requirements

NONEProcedure

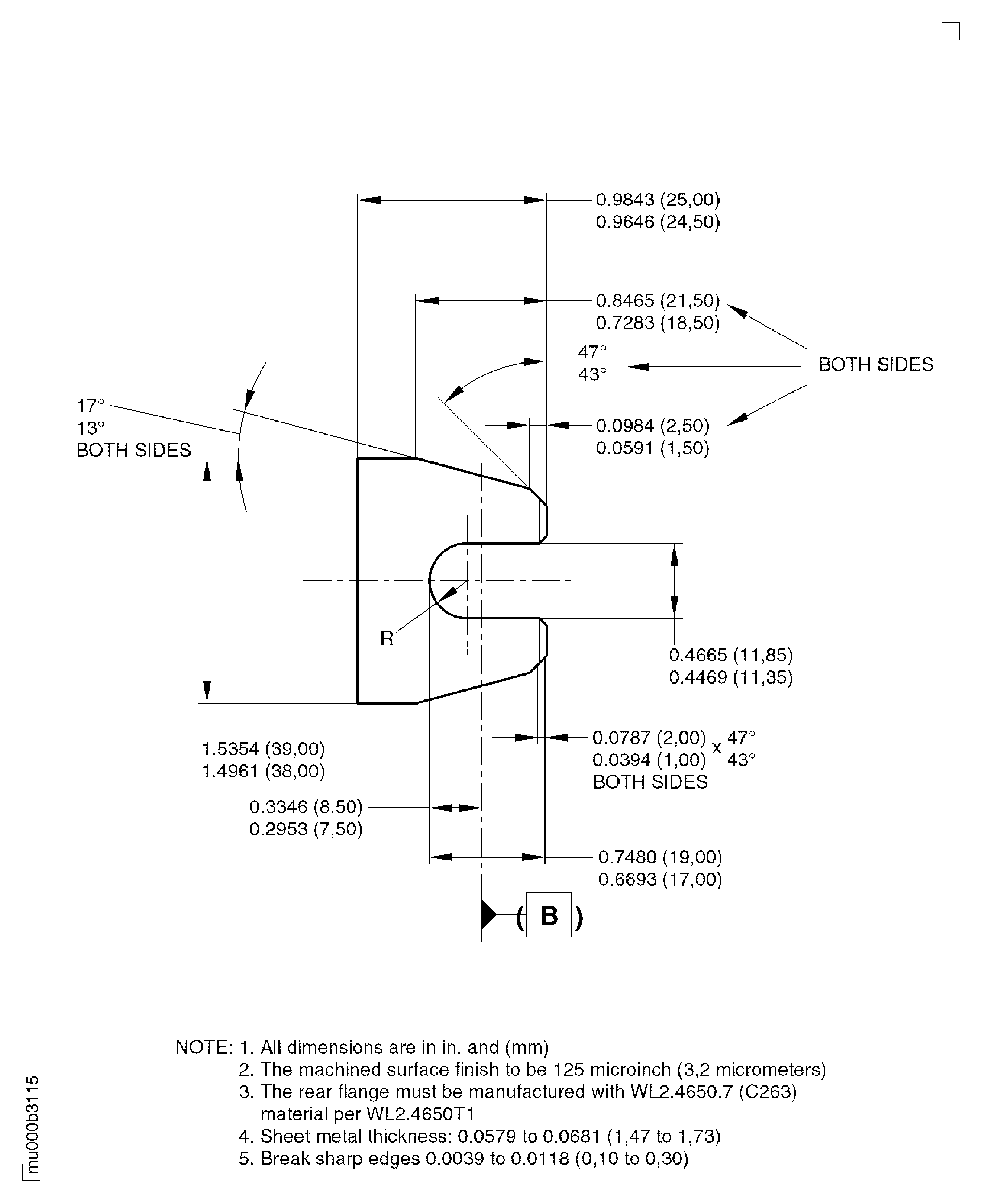

Refer to Figure.

Cut off the damaged rear flange.

SUBTASK 75-24-49-326-009 Cut off the Damaged Rear Flange

Refer to Figure.

Prepare the replacement rear flange.

SUBTASK 75-24-49-310-093 Prepare the Replacement Rear Flange

Aqueous cleaning.

Refer to SPM TASK 70-11-03-300-503

SUBTASK 75-24-49-110-142 Clean the Surfaces to be Welded

Refer to Figure.

Refer to SPM TASK 70-31-13-310-501.

Gas tungsten arc weld the replacement flange to the support assemblies.

SUBTASK 75-24-49-310-094-001 Weld in the Replacement Rear Flange

Refer to Figure.

Refer to SPM TASK 70-31-13-310-501.

Plasma arc weld the replacement flange to the support assemblies.

SUBTASK 75-24-49-310-094-002Weld in the Replacement Rear Flange

CAUTION

DO NOT OVERHEAT THE AREAS TO BE DRESSED.Refer to Figure.

Welded areas must be equal to the original contours and must be flush with the adjacent surfaces.

Dress the welds.

SUBTASK 75-24-49-320-073 Dress the Welded Areas

Refer to SPM TASK 70-37-00-370-501.

Put the part in an oven for two hours +/- 15 minutes at 1450 to 1500 deg F (788 to 816 deg C).

Use argon or vacuum.

Cooling rate equivalent to air cooling.

Heat treat the support assembly.

SUBTASK 75-24-49-370-076 Heat Treatment after Weld Repair

Refer to SPM TASK 70-23-05-230-501.

Use medium sensitivity level. No cracks are permitted.

Do the test for cracks.

SUBTASK 75-24-49-230-173 Examine the Welded Areas for Cracks

Refer to Figure.

Examine dimensionally.

SUBTASK 75-24-49-220-252 Examine the Welded Areas

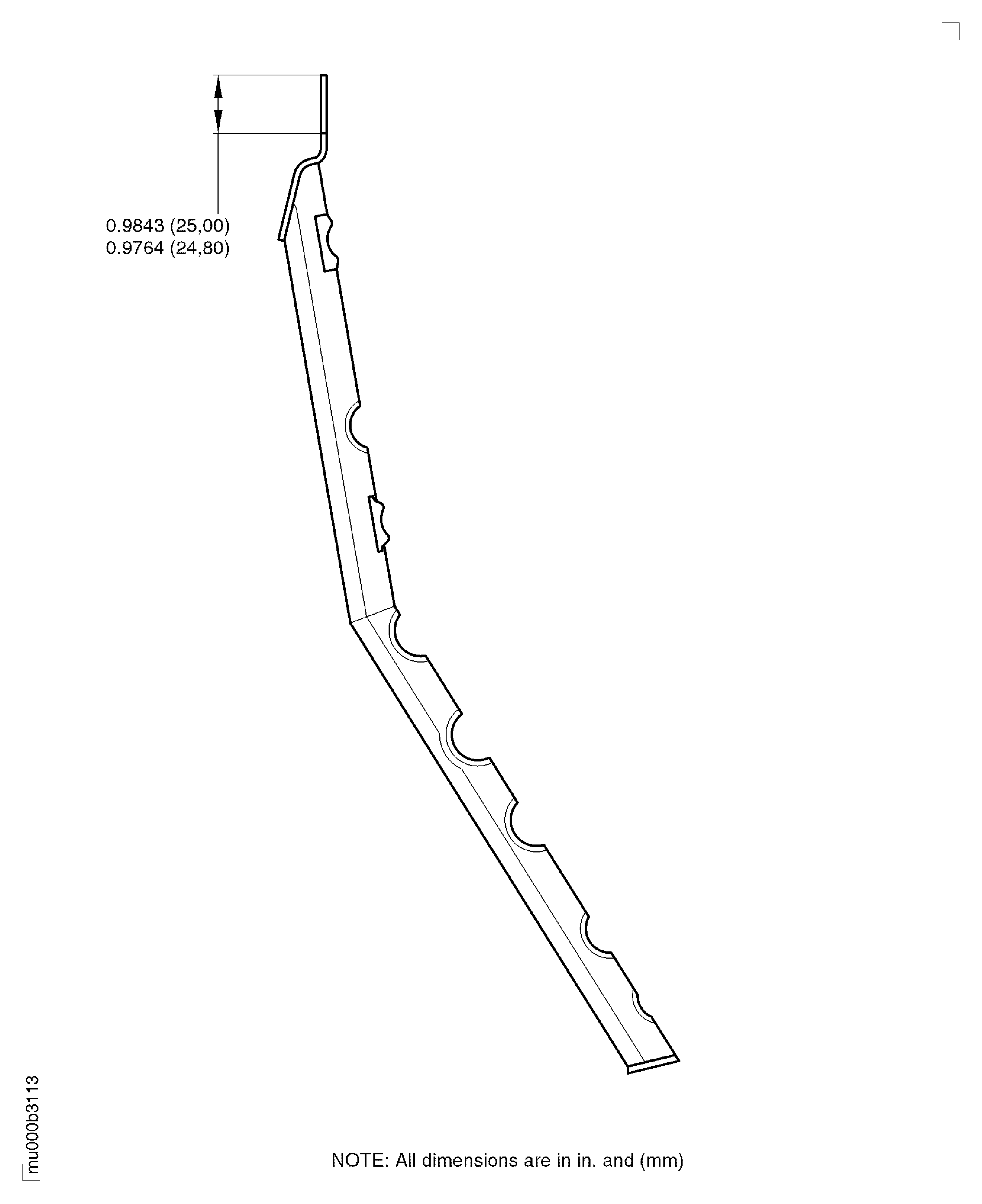

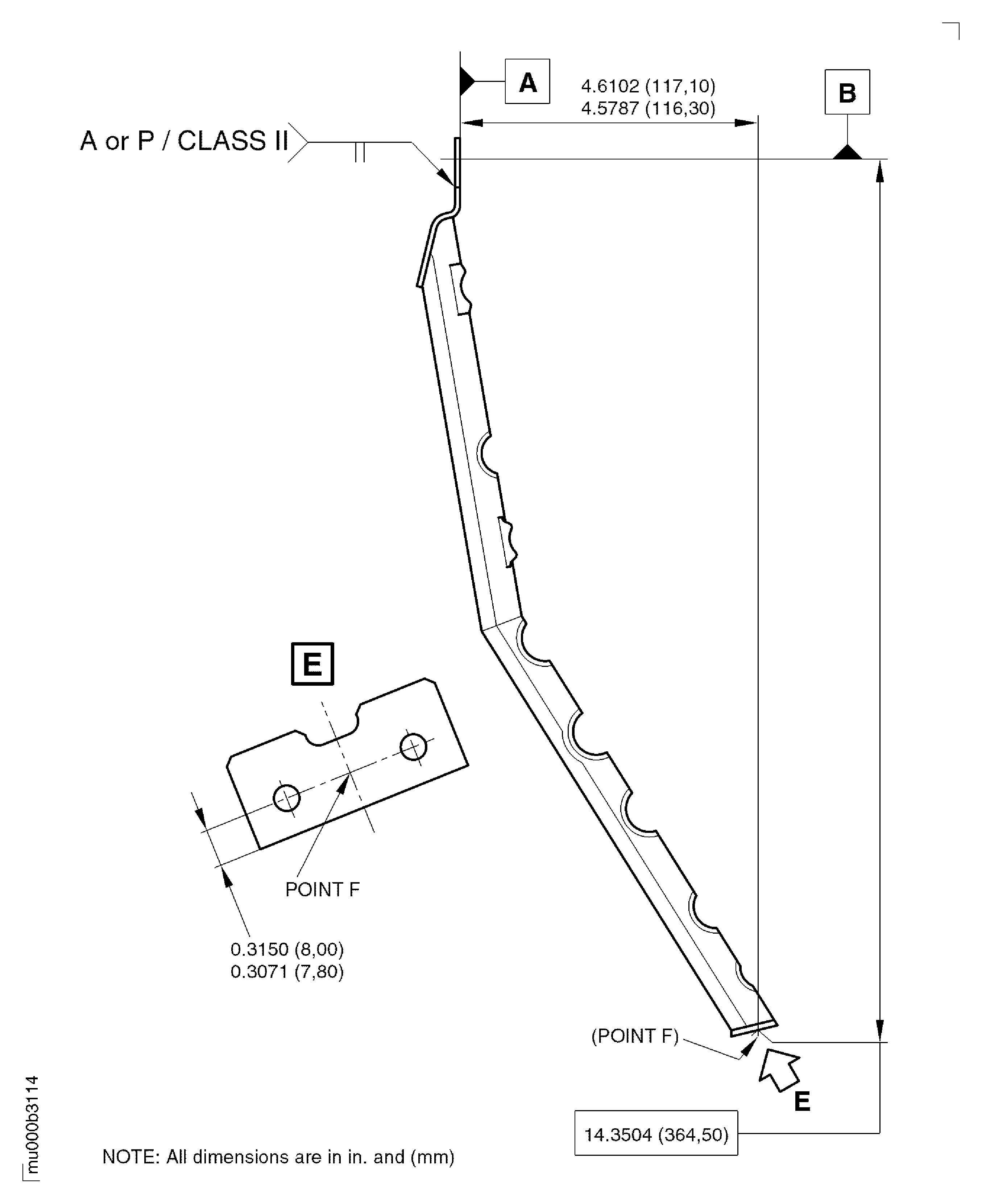

Figure: Repair Details And Dimensions

Repair Details And Dimensions

Figure: Repair Details And Dimensions

Repair Details And Dimensions

Figure: Repair Details And Dimensions

Repair Details And Dimensions