Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 78-32-47-300-004 Left C-Duct Electrical Harness - Replace The Wire, Repair-004 (VRS2133)

General

Price and availability - refer to Rohr Inc.

Repair may be done by removing the contacts from the damaged wire(s) and installing new wire(s) along the outside of the wire bundle. Insulation tape is wrapped around the damaged area of the wire bundle.

Equivalent material or equipment may be used.

To identify the consumable materials refer to the PCI.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Contact crimping tool | LOCAL | Contact crimping tool | ||

| Contact removal/insertion tool | LOCAL | Contact removal/insertion tool |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-002 ADHESIVE TAPE GENERALPURPOSE PAPER | LOCAL | CoMat 02-002 | ||

| CoMat 02-159 LACING TAPE | LOCAL | CoMat 02-159 | ||

| CoMat 02-176 LOCKWIRE | LOCAL | CoMat 02-176 | ||

| CoMat 02-177 MASKING TAPE (GLASS CLOTH) | LOCAL | CoMat 02-177 | ||

| CoMat 02-186 ELECTRICAL INSULATINGTAPE | LOCAL | CoMat 02-186 | Alternate to 02-187 | |

| CoMat 02-187 ELECTRICAL INSULATINGTAPE | LOCAL | CoMat 02-187 | ||

| CoMat 06-131 MARKING PEN | 0AM53 | CoMat 06-131 |

Spares

NONESafety Requirements

NONEProcedure

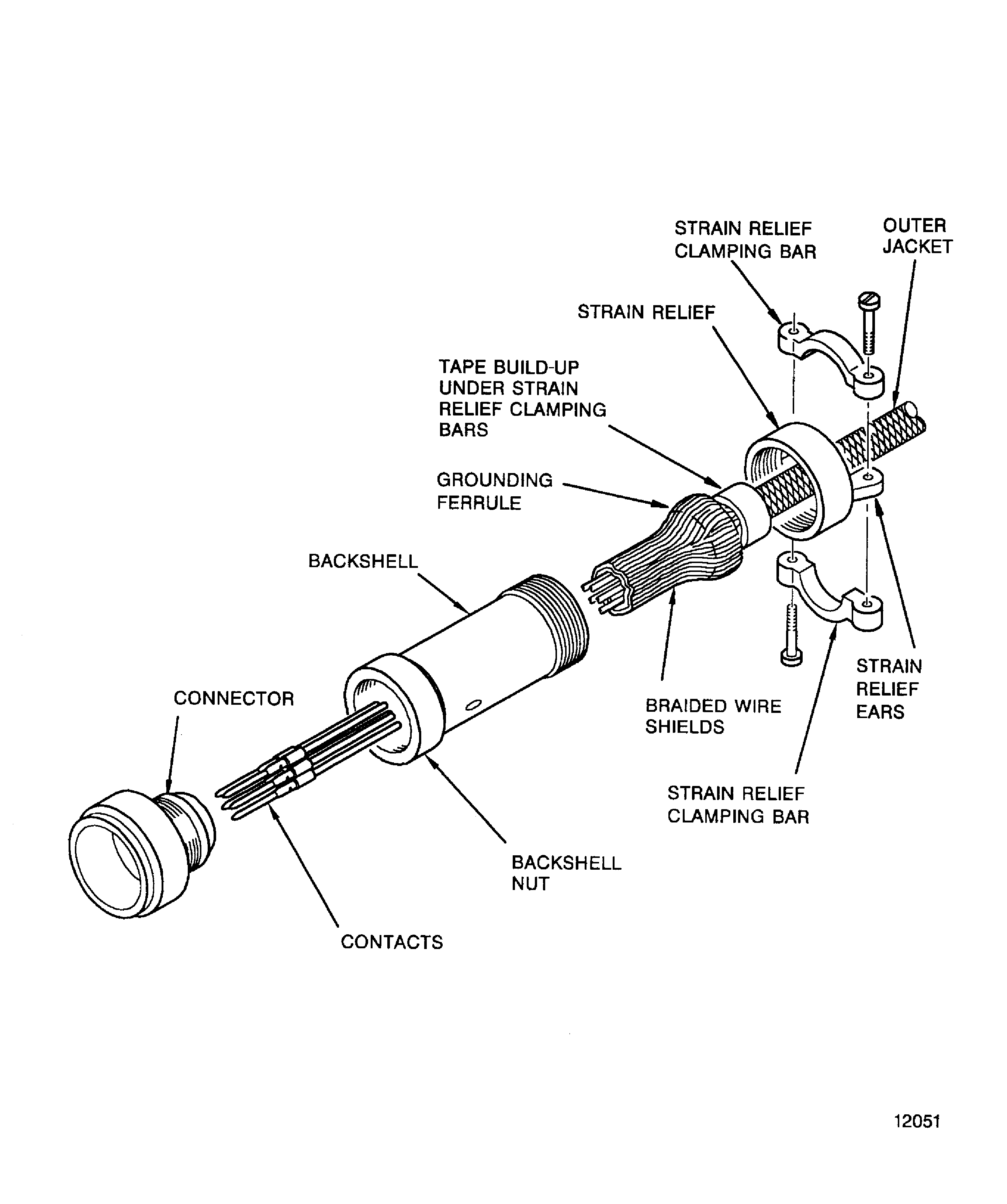

Refer to Figure.

Remove the lockwire from the strain relief screws and the strain relief.

Remove the screws and strain relief clamping bars from the strain relief.

Remove the strain relief from the backshell and move it along the harness away from the backshell.

Remove the tape from under the clamping bar locations.

Remove the strain relief

Remove the grounding ferrule from under the braided wire shields and move it along the harness away from the backshell.

Do not damage the braided wire shields.

Remove the grounding ferrule from the backshell

Remove the lockwire from the backshell nut and the backshell.

Remove the backshell from the connector.

Remove the backshell from the connector

Put a piece of CoMat 02-002 ADHESIVE TAPE GENERALPURPOSE PAPER on the wire to which contacts are connected.

Make a mark on the tape to identify the connector holes in which the contacts are installed.

Identify the contacts

Use theContact removal/insertion tool to remove the contacts from the connector.

Remove the contacts from the connector

Remove the contact from the wire.

Cut the wire as close as possible to the contact.

Cut the end(s) of the wire back in to the wire bundle. Do not remove the wire.

Remove the contact from the wire

SUBTASK 78-32-47-350-058 Remove the Contacts from the Damaged Wire(s)

Refer to Figure.

Put three layers minimum CoMat 02-187 ELECTRICAL INSULATINGTAPE around the wire bundle at the damaged area

Apply tape to the damaged area of the wire bundle

Cut the new wire slightly longer than needed.

Cut the new wire

At both ends of the harness, push the end of the wire through the ferrule, the strain relief, the backshell, and through a hole in the shielding.

Pull enough wire through for connection to the connector.

Put the new wire in to position

Trim both ends of the wire to the length needed to attach it to the contacts.

Fold the shielding back along the wire to match the shielding on the wire bundle.

Weave the shielding from the new wire into the existing wire bundle shield.

Install the new wire

Attach the new wire to the wire bundle with CoMat 02-159 LACING TAPE.

See Repair, VRS2125 (Repair-001) TASK 78-32-47-300-001.

Attach the new wire to the wire bundle

SUBTASK 78-32-47-350-059 Install the New Wire(s)

Refer to Figure.

Remove the insulation from the end of the wire so that the remaining insulation is against the aft edge of the pin.

Make sure that you can see the bare wire through the inspection hole in the contact.

Do not cut or nick the wire

Prepare the wire

Put the contact in the Contact crimping tool.

Put the bare wire in to the contact.

Make sure that you can see the bare wire through the hole in the contact and that the insulation is against the aft edge of the contact

Install the contact on the wire

Install the contacts in the connector with the Contact removal/insertion tool.

Push on the contacts from the front of the connector to make sure that they are fully installed.

They are fully installed if they do not move rearward when you push them from the front of the connector.

Remove the tape markers from the wires.

Install the contacts in the connector

Install the backshell on the connector.

Tighten the backshell nut by hand plus one eighth turn with the connector pliers.

Safety the backshell nut with CoMat 02-176 LOCKWIRE.

Install the backshell on the connector

Move the grounding ferrule toward the backshell and under the braided wire shields.

Put the braided wire shields evenly over the grounding ferrule.

Push the grounding ferrule in to the backshell.

Shape the braided wire shields over the top of the grounding ferrule and along the outer jacket of the harness. The braided wire shields must end at the aft end of the strain relief.

Install the grounding ferrule

Put enoughCoMat 02-177 MASKING TAPE (GLASS CLOTH) on the electrical harness and over the ends of the braided wire shields so that the strain relief clamping bars will fit tight on the wire harness.

It is not necessary for the clamping bars to fit tight against the strain relief.

Install the strain relief on the backshell.

Tighten the strain relief until firmly gripped connector pliers slip on the strain relief.

Install the clamping bars on the strain relief ears with the screws.

Torque the screws to between 12 and 15 lbfin (1 and 2 Nm).

Safety the screws with the CoMat 02-176 LOCKWIRE.

Install the strain relief on the backshell

SUBTASK 78-32-47-350-060 Install the Contacts on the New Wire(s)

Examine the completed repair to make sure all the requirements of this repair procedure are done.

Visually examine

SUBTASK 78-32-47-220-055 Examine the Completed Repair

Refer to Testing-001 TASK 78-32-47-700-301.

Test the harness

SUBTASK 78-32-47-750-054 Test the Right C-Duct Electrical Harness

Use CoMat 06-131 MARKING PEN of a color that contrasts.

Make a mark VRS2127 adjacent to the assembly numbers.

SUBTASK 78-32-47-350-061 Identify the Repair

Figure: Left C-Duct Electrical Harness Connector Replacement

Left C-Duct Electrical Harness Connector Replacement