Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 79-21-41-700-401 Oil Pressure Pump/Filter Housing - Related Parts - Test The Oil Pressure Pump, Testing-001

Effectivity

FIG/ITEM | PART NO. |

01-001 | 4A0852 |

01-001 | 4A7076 |

01-001 | 4A7077 |

01-001 | 4A7110 |

01-001 | 4A7110B |

01-001 | 4A7115 |

01-001 | 4A7115A |

General

NOTE

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

You can use this test to do a check of the oil pressure pump after repair or overhaul. This test can also be used to check the operation of the relief valve, setting the trim valve and for trouble shooting purposes.

Make sure that the mesh of the test stand filter element is not bigger than 30 microns.

If installed, remove the storage parts from the oil pressure pump.

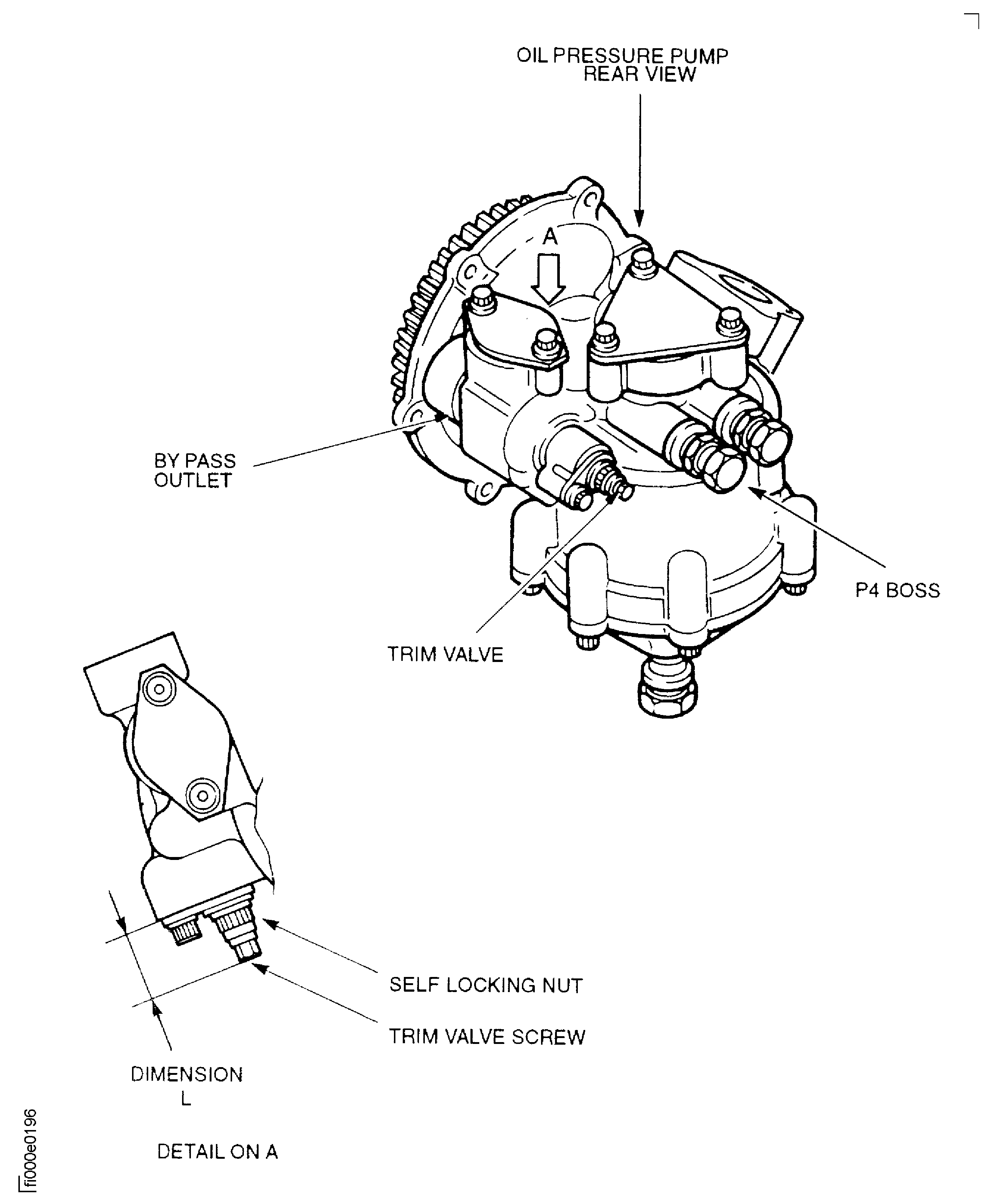

The drive gear of the oil pressure pump turns clockwise in normal operation (looking from rear of pump). Refer to Figure.

Make sure that the drive gear of the oil pump can be freely turned by hand.

For standard torque data and procedure, refer to SPM TASK 70-41-02-400-501 and SPM TASK 70-41-00-400-501.

Do the test in the sequence specified.

WARNING

WARNING

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Motor Drive Unit | LOCAL | Motor Drive Unit | Variable speed, 4000 rpm maximum and 12 kW | |

| Mechanical Adapter | LOCAL | Mechanical Adapter | To install the oil pressure pump on the test stand. | |

| Torquemeter | LOCAL | Torquemeter | (Optional) 0 to 50 Nm | |

| Temperature gauge | LOCAL | Temperature gauge | 4 | 68 to 392 deg F (20 to 160 deg C) |

| Heat exchanger | LOCAL | Heat exchanger | To keep the temperature of the test fluid between 104 to 230 deg F (40 to 110 deg C) | |

| Flowmeter | LOCAL | Flowmeter | at location 1 - 5 to 50 gal/min (19 to 189 l/min) | |

| Flowmeter | LOCAL | Flowmeter | at location 10 - 2.37 to 24.83 gal/min (9 to 94 l/min) | |

| Flowmeter | LOCAL | Flowmeter | at location 11 - 0.1 to 5 gal/min (0.4 to 19 l/min.) | |

| Vacuum gauge | LOCAL | Vacuum gauge | at location 8 - 14.5 to 21.7 psia (100 to 150 kpa) | |

| Pressure gauge | LOCAL | Pressure gauge | at location 13 - 0 to 580 psig (0 to 4000 kpa) | |

| Pressure gauge | LOCAL | Pressure gauge | at location 4 - 0 to 580 psig (0 to 4000 kpa) | |

| Variable restrictor | LOCAL | Variable restrictor | 2 | at locations 2 and 12 - 1 in. (25.4 mm) |

| Variable restrictor | LOCAL | Variable restrictor | 1 | at location 2 - 1 1/2 in. (38.1 mm) |

| Cut-off cock | LOCAL | Cut-off cock | 3 | Inlet and supply ducts |

| Oil reservoir | LOCAL | Oil reservoir | 47.5 gal (180 l) filled for 3/4 and pressurized to 21 psia (145 kpa) | |

| Filter | LOCAL | Filter | 2 | 25 micron |

| Filter | LOCAL | Filter | 2 | 12 micron |

| Supply oil ducts | LOCAL | Supply oil ducts | Inner diameter 0.787 in. (20 mm) | |

| Inlet oil ducts | LOCAL | Inlet oil ducts | Inner diameter 1.299 in. (33 mm) | |

| Leakage capacity indicator | LOCAL | Leakage capacity indicator | 0 to 305 cu in/min (0 to 5000 cc/min) |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 10-077 APPROVED ENGINE OILS | LOCAL | CoMat 10-077 |

Spares

NONESafety Requirements

NONEProcedure

Testing of the oil pressure pump is subject to source demonstration requirements. This means than any facility which has not previously been authorized to do the test must utilize the testing facility of the OEM (Original Equipment Manufacturer) of the pump, or any authorized testing vendors listed here below.

The source demonstration program for a new facility is required in order to correlate the oil pressure pump parameters of the new facility to those of the OEM. This is in order to determine acceptable parameters at which an oil pressure pump can be released as serviceable. The OEM is the sole source for correlation data in support of Source Demonstration Programs.

Any facility not authorized to carry out testing may contact IAE Technical Services to determine if a qualification program can be initiated at their facility.

International Aero Engines, AG

400 Main Street

M/S 121-10

East Hartford, CT 06108

USA

Attn: Manager Technical Services

The Original Equipment Manufacturer for the oil pressure pump is:

AVIO - Divisone AvioService

EF5Y829M

Viale Impero angolo Viale Alfa

80038 Pomigliano d'Arco (NA) - ITALY

The Authorized Vendor for the oil pressure testing are listed below:

GENERAL ELECTRIC ENGINE SERVICE-DALLAS, LP

Accessory Services Engineering

9311 Reeves ST. MD LF26

Dallas, TX 75235-2095

USA

ISHIKAWAJIMA-HARIMA HEAVY INDUSTRIES (IHI) Co. LTD

229 Tonogaya

Mizuho-machi

Nishitama-gun

Tokyo 190-12

JAPAN

The designation by IAE of an authorized testing vendor indicates that the vendor has demonstrated the necessary capability to enable it to carry out the testing. However, IAE makes no warranties or representations concerning the qualifications or quality standards of the Vendor to carry out the testing and accepts no responsibility what so ever for any work that may be carried out by a Vendor, other than when IAE is listed as the vendor. Authorized vendors do not act as agents or representatives of IAE.

Remove the filter element from the oil pressure pump, if installed. Refer to Disassembly-000 TASK 79-21-41-060-401.

Reinstall the filter cover on the oil pressure pump. Refer to Assembly-001 TASK 79-21-41-460-401.

Lubricate the 2 packings (79-21-41,01-952) and install on the strainer (79-21-41,01-954).

Install the strainer on the oil pressure pump.

Lubricate the 4 packings (79-21-41,01-962) and install them on the sleeve (79-21-41,01-964).

Install the sleeve on the oil pressure pump.

Make sure that the trim valve is fully closed.

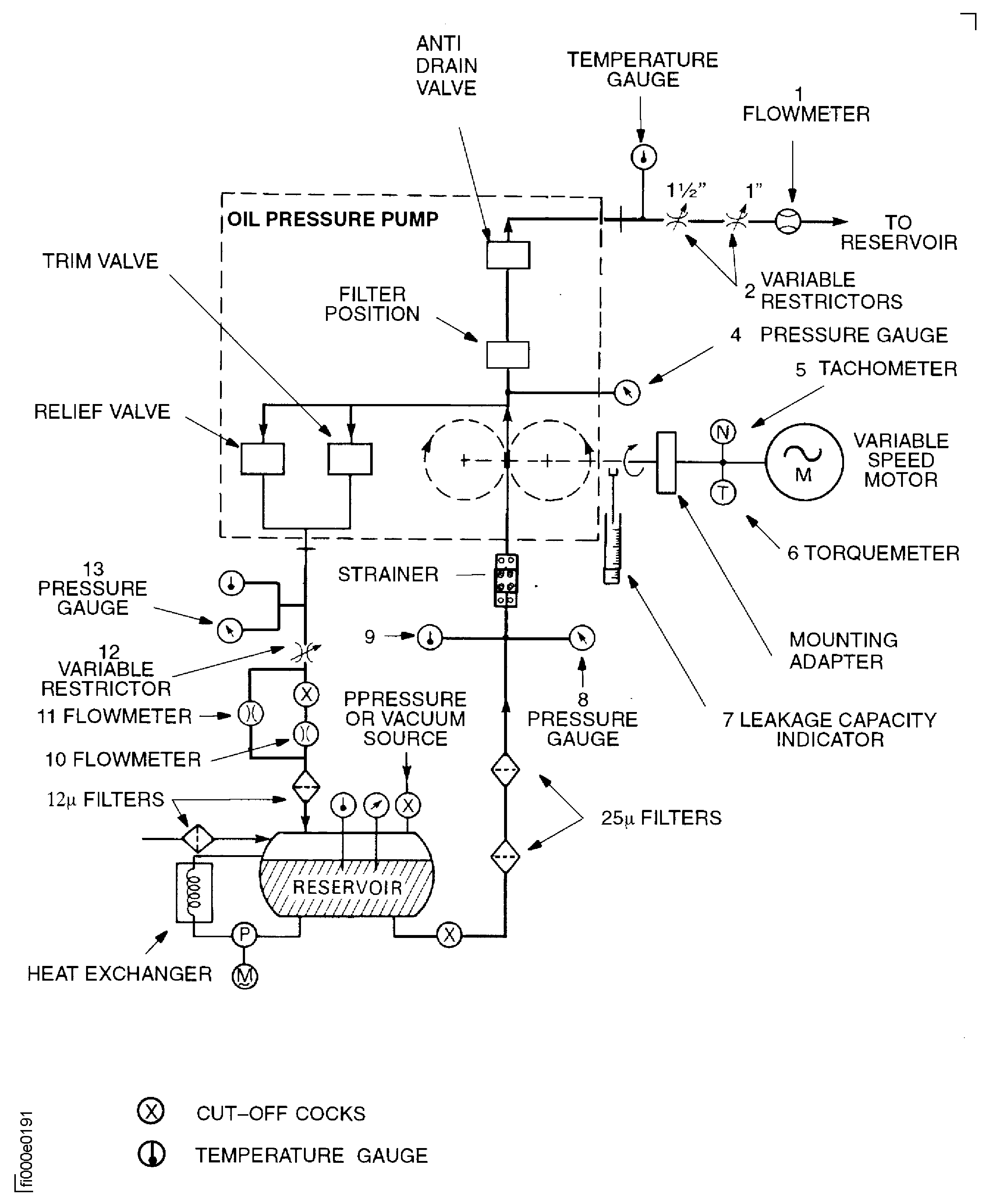

Set up the test stand as shown in Figure.

SUBTASK 79-21-41-780-051 Set-up The Test Stand and the Oil Pressure Pump

Refer to Figure.

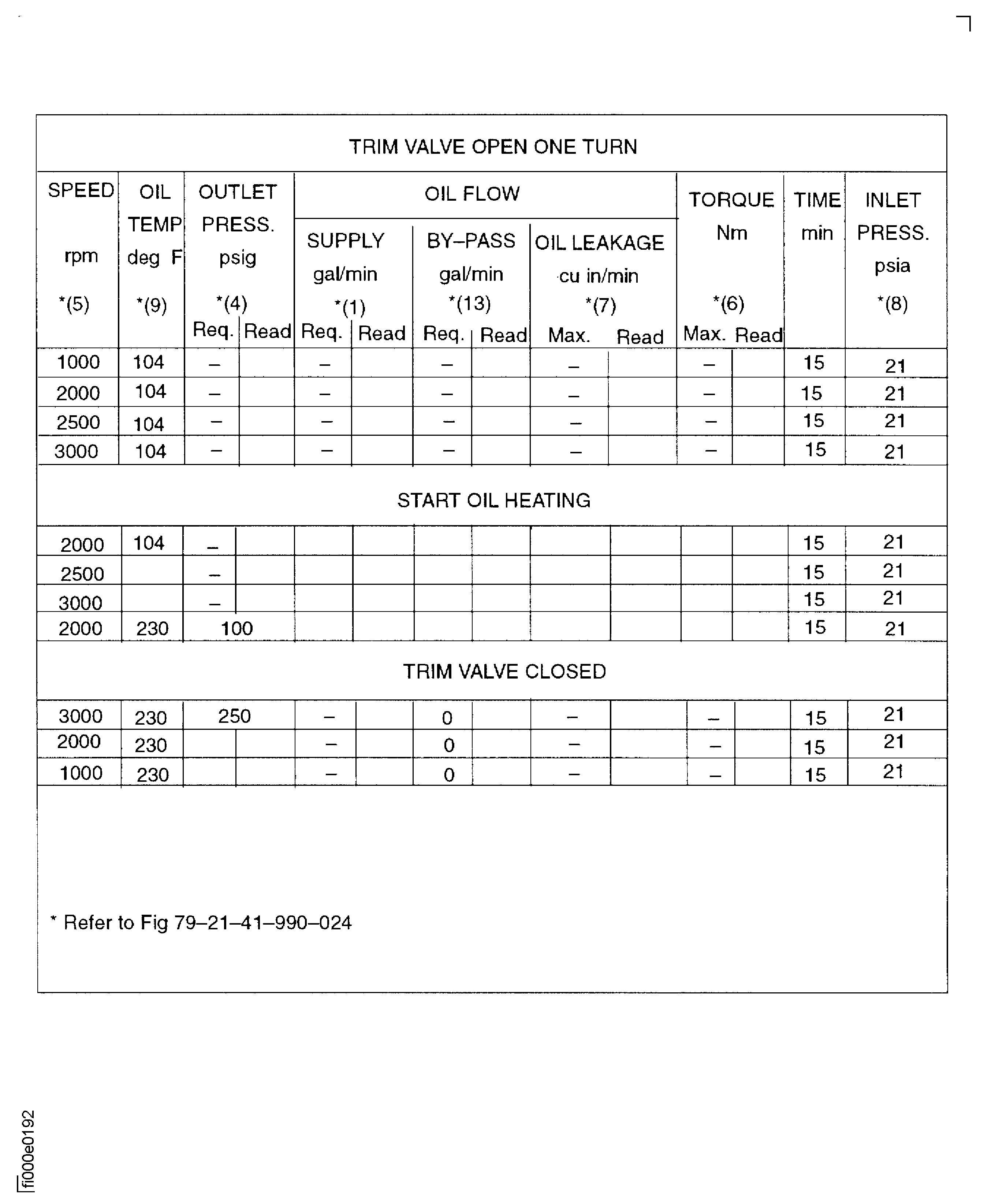

Increase the oil temperature to 104 deg F (40 deg C).

Adjust the Cut-off cock on the reservoir to get a pump inlet pressure of 21 psia (145 KPa) on the Vacuum gauge.

Open the trim valve by one turn counter-clockwise.

Open fully the Variable restrictor .

Start the variable speed motor and adjust pump speed to 1000 rpm.

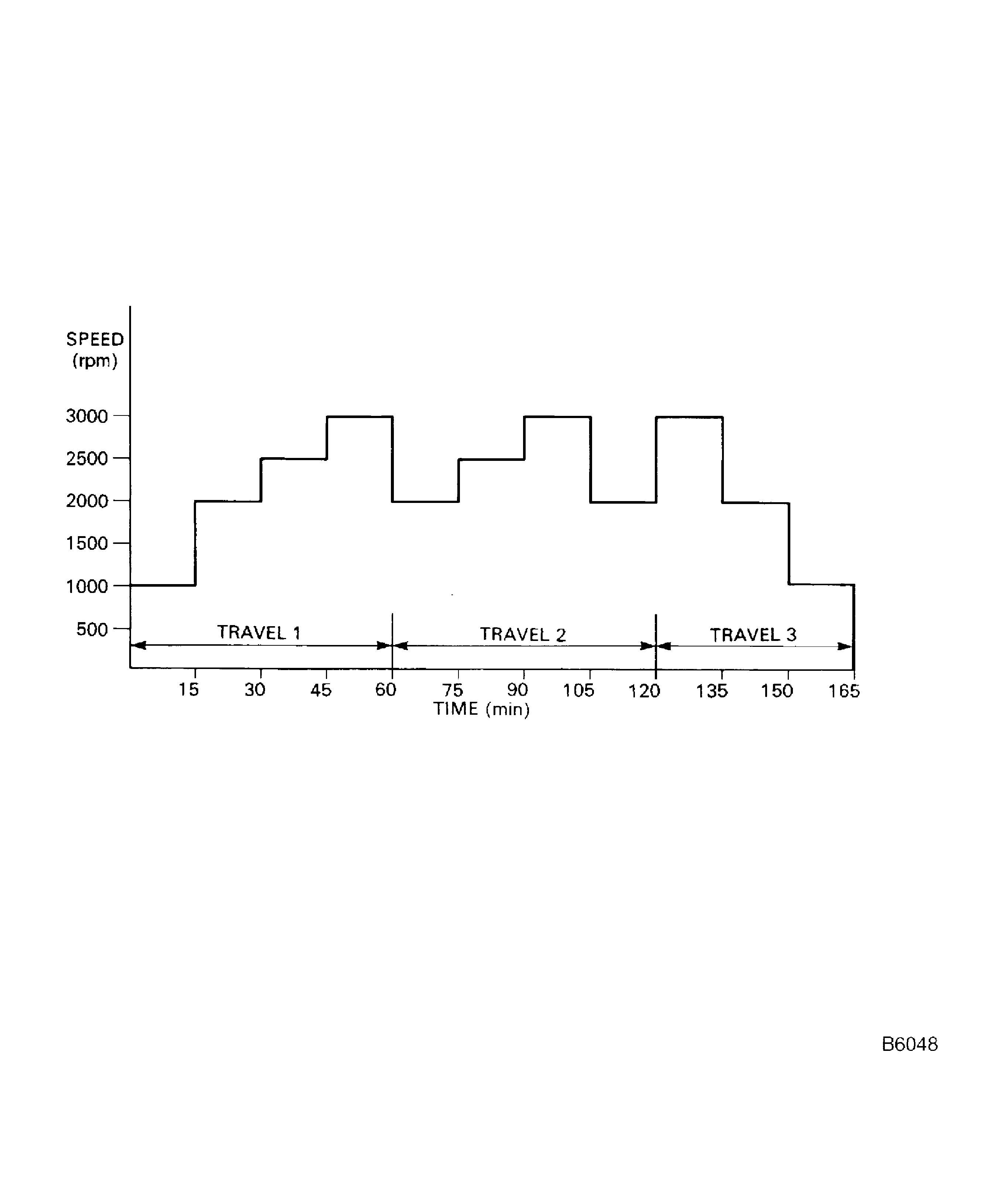

Running-in travel 1 (60 minutes).

Adjust the heater to increase the oil temperature to 230 deg F (110 deg C).

Adjust the Variable restrictor on the oil pressure pump outlet at the 105th minute to get 100 psig.

Make sure that the oil temperature is 230 deg F (110 deg C) at the 120th minute of running-in. If it is not, wait until the temperature increases to the required value.

Running-in travel 2 (between 60 and 120 minutes).

Close the trim valve.

Keep the oil temperature at 230 deg F (110 deg C).

Adjust the oil pressure pump speed to 3000 rpm.

Adjust the Variable restrictor to get a pump outlet pressure of 250 psig.

Running-in travel 3 (between 120 and 165 minutes).

SUBTASK 79-21-41-780-052 Do the Running-In of the Oil Pressure Pump

NOTE

It is not necessary to do the run-in on pumps which have service running time.Do this test after:

- Upgrade of the pump from P/N 4A7076 to P/N 4A0852

- Replacement of the pump gears

- Replacement of the bushes by VRS5310

Refer to Figure.

Close the trim valve.

Make sure that the oil temperature is 230 deg F (110 deg C).

Adjust the oil pressure pump speed to 2000 rpm.

Make sure that the pump inlet pressure is 21 psia (145 kPa).

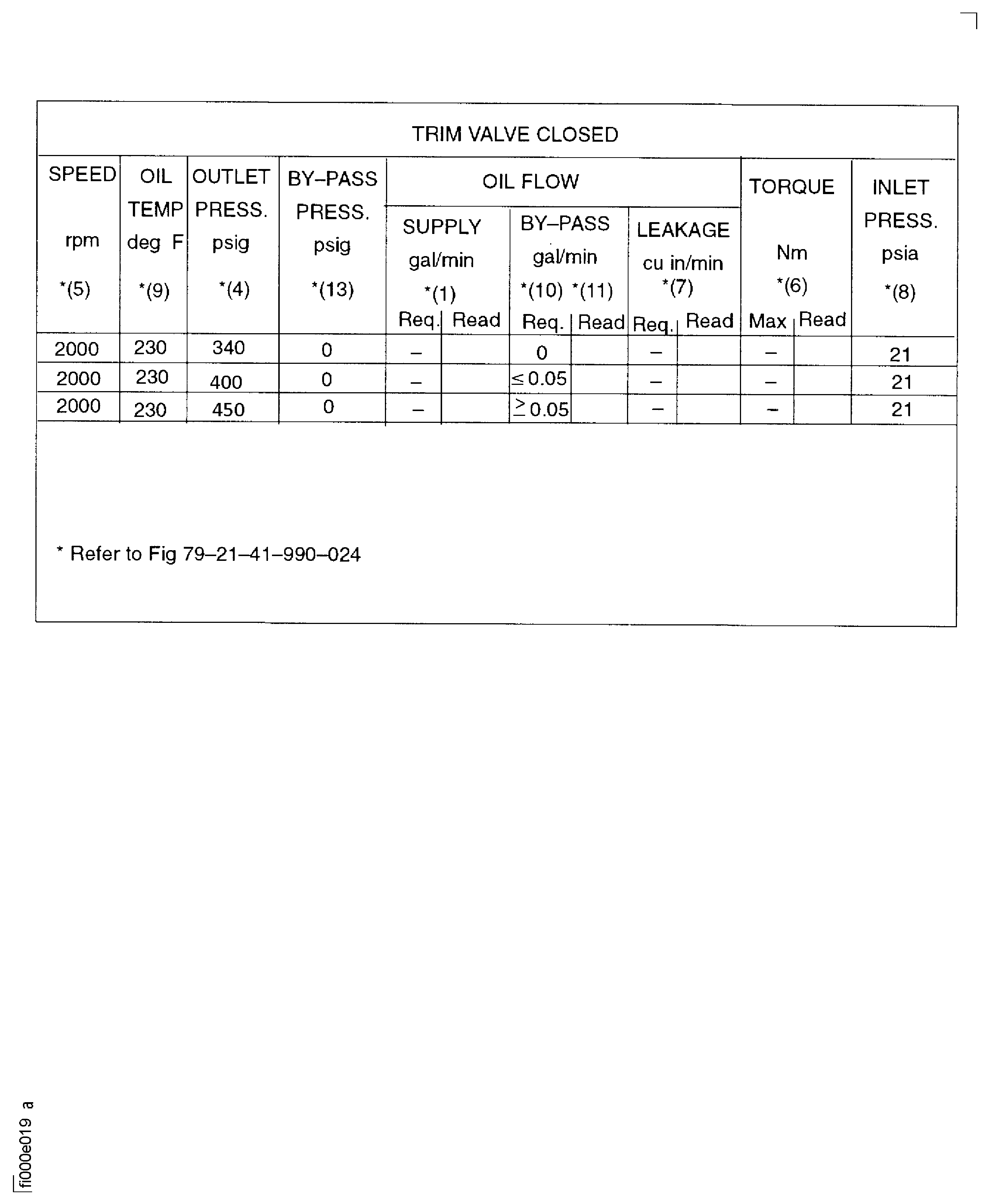

Adjust slowly and continuously the Variable restrictor to get 340, 400 and 450 psig and record the results on the test data sheet. Refer to Figure.

SUBTASK 79-21-41-780-053 Do the Opening Test on the Relief Valve

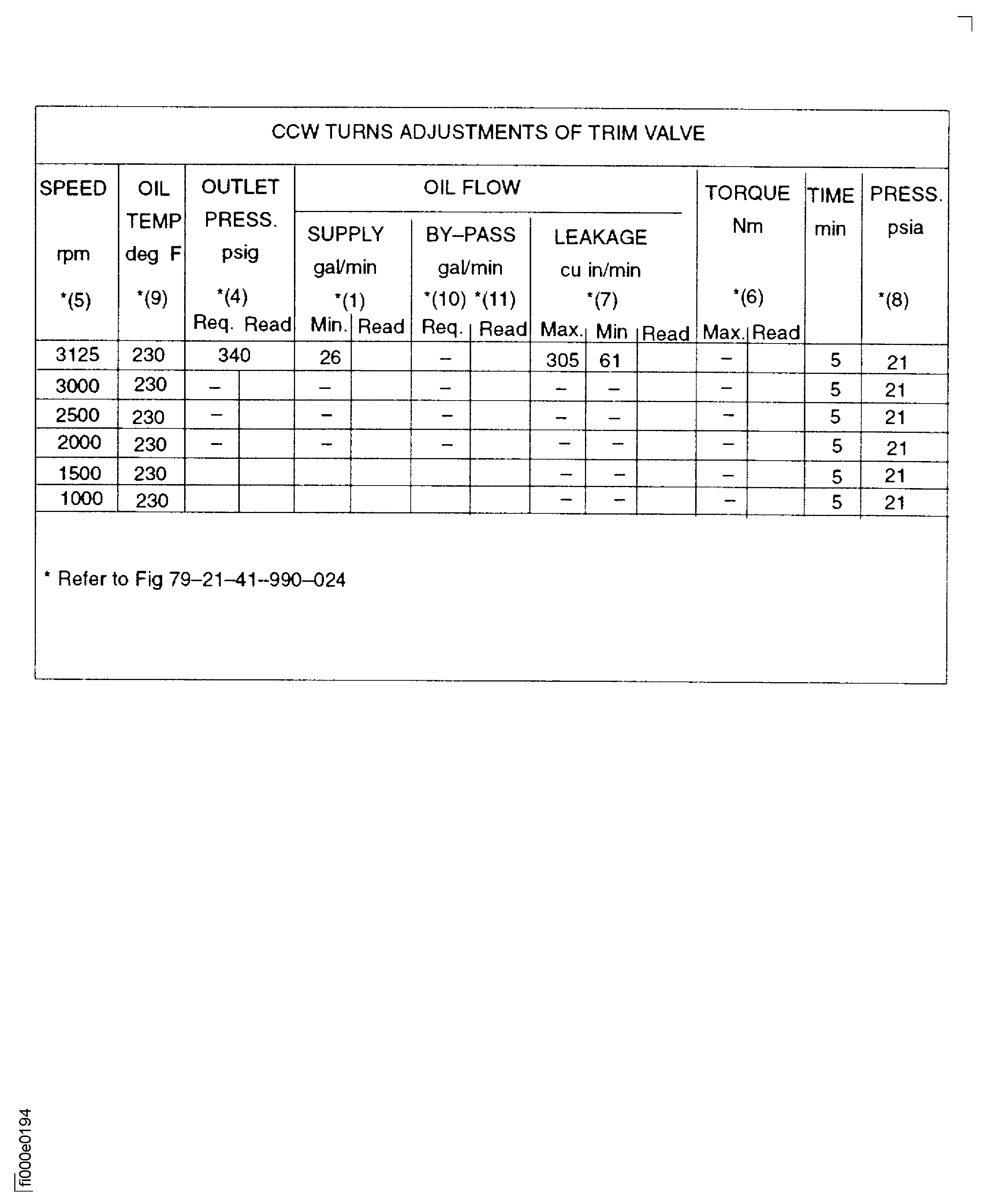

Refer to Figure.

Make sure that the oil temperature is 230 deg F (110 deg C).

Adjust the Variable restrictor, to get a pump outlet pressure P4 of 340 psig (2344 kPa).

Adjust the Variable restrictor, to get a by-pass outlet pressure P13 between 20 and 25 psig (138 to 172 kPa).

Adjust the trim valve to get an oil flow of 26gal/min (98.4 l/min). Lock the trim valve.

If the trim valve is fully closed and oil flow is less than 25.5 gal/min (96.5 l/min) reject the pump.

Lock the trim valve with the lock nut. Torque to 290 to 370 ibfn (33 to 42 Nm).

Test the pump as specified in Figure.

SUBTASK 79-21-41-780-054-A00 V2500-A1: Do the Setting of the Trim Valve

(Pre SBE 79-0006)

(Pre SBE 79-0071)

Make sure that the oil temperature is 230 deg F (110 deg C).

Adjust the oil pressure pump speed to 3125 rpm.

Adjust the Variable restrictor , to get a pump outlet pressure P4 of 340 psig (2344 kPa).

Adjust the Variable restrictor o get a by-pass outlet pressure P13 between 20 and 25 psig (138 and 172 kPa).

Lock the trim valve with the lock nut. Torque to 290 to 370 lbfin (33 to 42 Nm).

Operate the variable speed motor and adjust the pump speed to the required values. Record the results on the appropriate test data sheet. Refer to Figure.

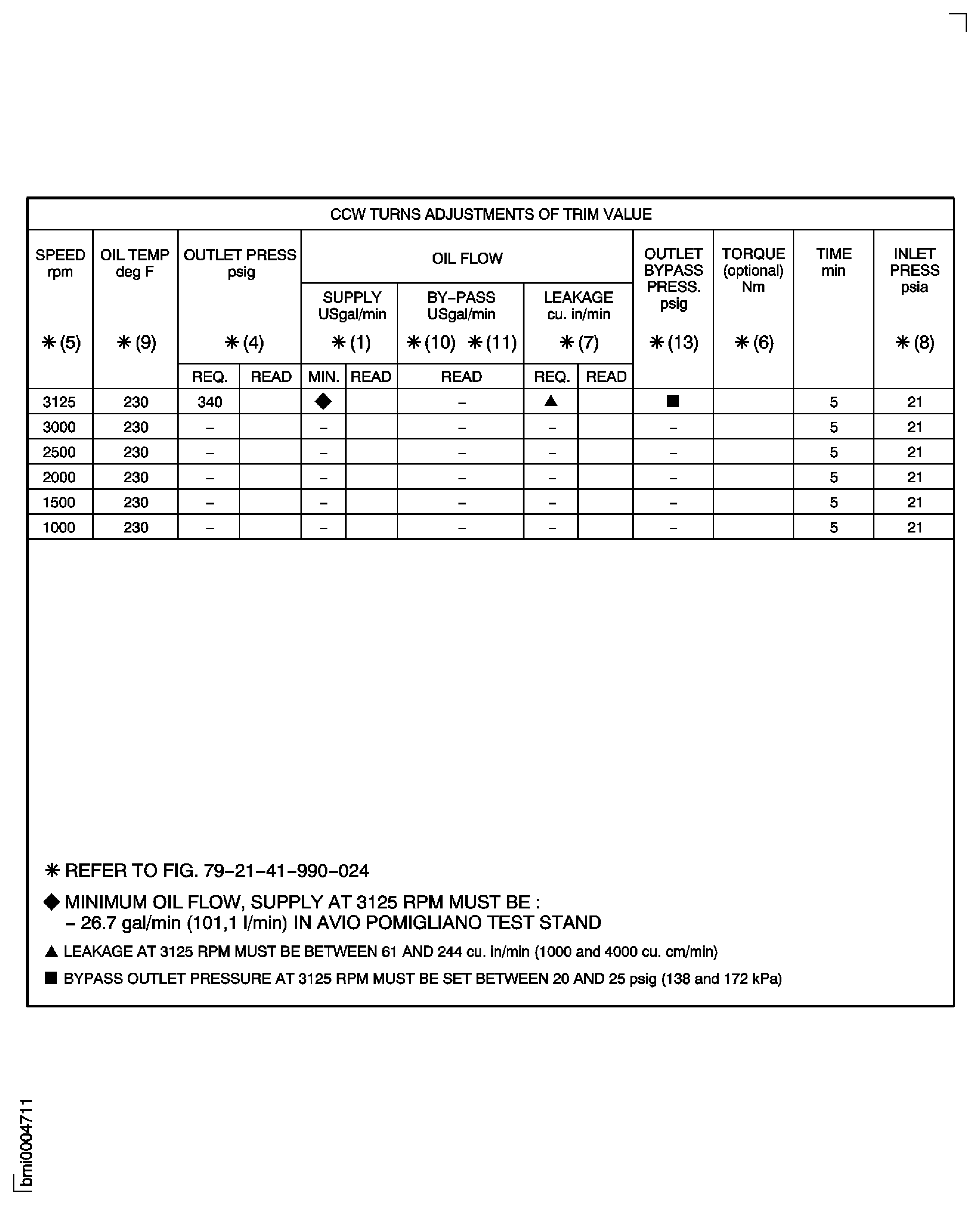

SUBTASK 79-21-41-780-054-B00 V2500-A1: Do the Setting of the Trim Valve

(SBE 79-0006)

(SBE 79-0071)

Make sure that the oil temperature is 230 deg F (110 deg C).

Adjust the oil pressure pump speed to 3125 rpm.

Adjust the Variable restrictor, to get a pump outlet pressure P4 of 340 psig (2344 kPa).

Adjust the Variable restrictor, to get a by-pass outlet pressure P13 between 20 and 25 psig (138 and 172 kPa).

Lock the trim valve with the lock nut. Torque to 290 to 370 lbfin (33 to 42 Nm).

Operate the variable speed motor and adjust the pump speed to the required values. Record the result on the appropriate test data sheet. Refer to Figure.

SUBTASK 79-21-41-780-054-C00 V2500-A5: Do the Setting of the Trim Valve

Refer to Figure.

Turn the heater off.

Operate the variable speed motor until the oil temperature decreases to 104 deg F (40 deg C). Refer to the cycle in Figure.

Stop the variable speed motor.

Allow the oil pressure pump to cool down.

Remove the oil pressure pump from the test bench and drain the excess oil from the unit.

Install the protective covers on the oil pressure pump openings.

SUBTASK 79-21-41-780-055 Complete the Oil Pressure Pump Testing

Figure: Hydraulic Pressure Test Set-Up

Hydraulic Pressure Test Set-Up

Figure: Running-In Cycle

Running-In Cycle

Figure: Oil pressure pump running-in test data sheet

Oil pressure pump running-in test data sheet

Figure: Relief Valve Open Test Data Sheet

Relief Valve Open Test Data Sheet

Figure: V2500-A1 (Pre Sbe 79-006 And Pre SBE 79-0071) Trim valve setting test data sheet

V2500-A1 (Pre Sbe 79-006 And Pre SBE 79-0071) Trim valve setting test data sheet

Figure: V2500-A1 (SBE 79-0006 and SBE 79-0071) and V2500-A5: Trim Valve Setting Test Data Sheet

V2500-A1 (SBE 79-0006 and SBE 79-0071) and V2500-A5: Trim Valve Setting Test Data Sheet

Figure: Measure The Dimension L

Measure The Dimension L