Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A1

Common Information

TASK 72-00-40-020-007-A00 HP System Module - Remove The HP System Module (Vertical), Removal-009

General

This TASK gives the procedure to remove the HP system module in the vertical position. Other related TASKS are:

TASK 72-00-40-560-005 Turn the LP compressor/intermediate case module and the HP system module from the horizontal to the vertical.

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

Apply the approved CoMat 10-058 PENETRATING OIL before the removal of threaded parts or parts with an interference fit. Let the parts soak before removal.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 1F10052 Two cables sling | 0AM53 | IAE 1F10052 | 1 | |

| IAE 1P16046 Removal/Installation fixture | 0AM53 | IAE 1P16046 | 1 | |

| IAE 1P16057 Tie-rod adapter | 0AM53 | IAE 1P16057 | 1 | |

| IAE 1P16543 Removal/Installation fixture | 0AM53 | IAE 1P16543 | 1 | |

| IAE 1R18075 Support pedestal | 0AM53 | IAE 1R18075 | 1 | |

| IAE 1R18090 Safety support stand | 0AM53 | IAE 1R18090 | 1 | |

| IAE 1R18214 Build stand | 0AM53 | IAE 1R18214 | 1 | |

| IAE 1R18222 Support rod | 0AM53 | IAE 1R18222 | 2 | |

| IAE 1R18230 Wrench | 0AM53 | IAE 1R18230 | 1 | |

| IAE 1R18234 Support rod | 0AM53 | IAE 1R18234 | 3 | |

| IAE 1R18247 Rigging pin | 0AM53 | IAE 1R18247 | 1 | |

| IAE 1R18673 Dummy stub shaft | 0AM53 | IAE 1R18673 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-002 SOLVENT, DELETED. | LOCAL | CoMat 01-002 | ||

| CoMat 04-005 JOINTING COMPOUND, MEDIUM GRADE | LOCAL | CoMat 04-005 | ||

| CoMat 10-058 PENETRATING OIL | LOCAL | CoMat 10-058 |

Spares

NONESafety Requirements

NONEProcedure

Refer to Figure.

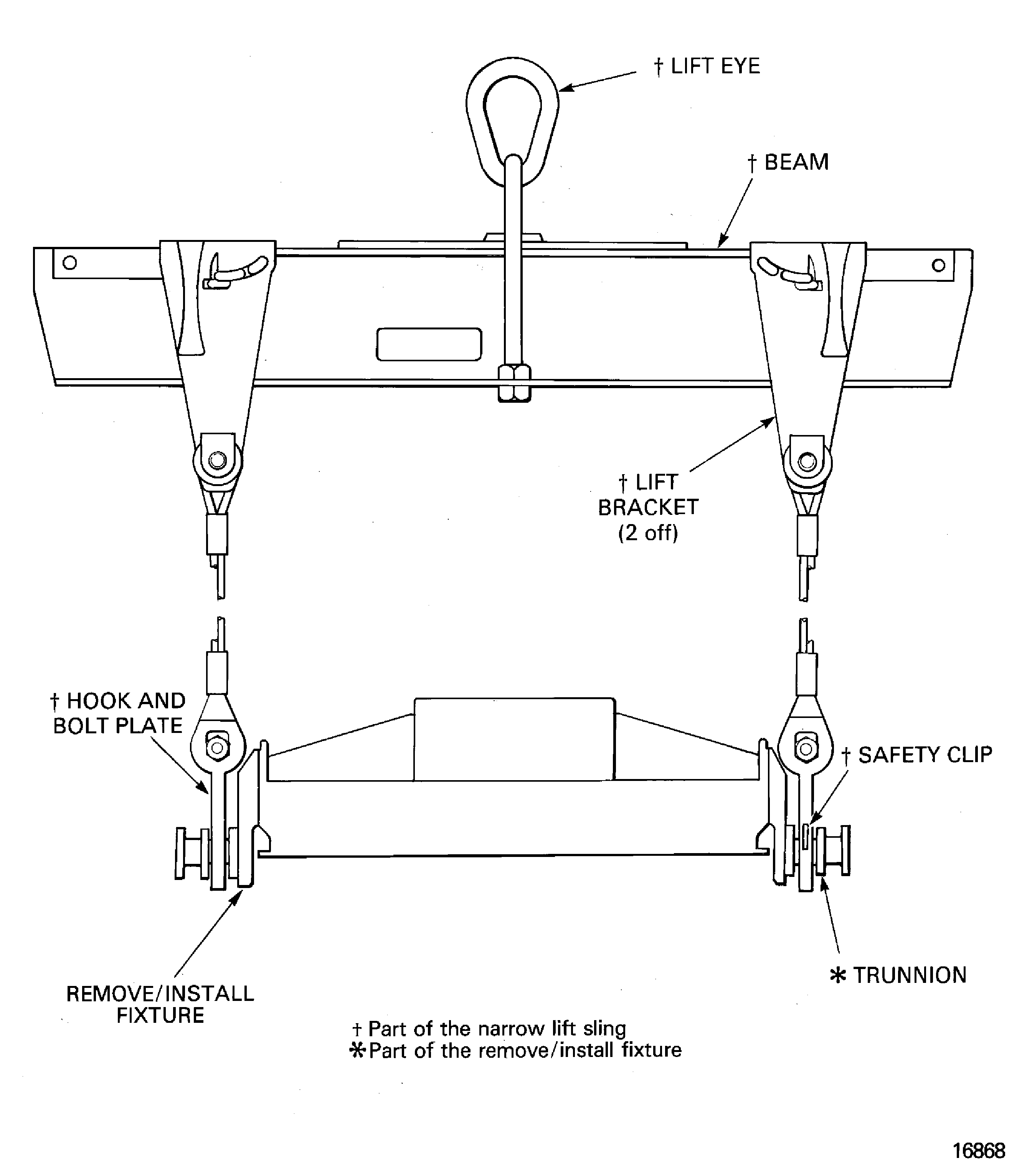

Attach a hoist to the IAE 1F10052 Two cables sling 1 off and attach the lift sling to the remove/install fixture lift eye.

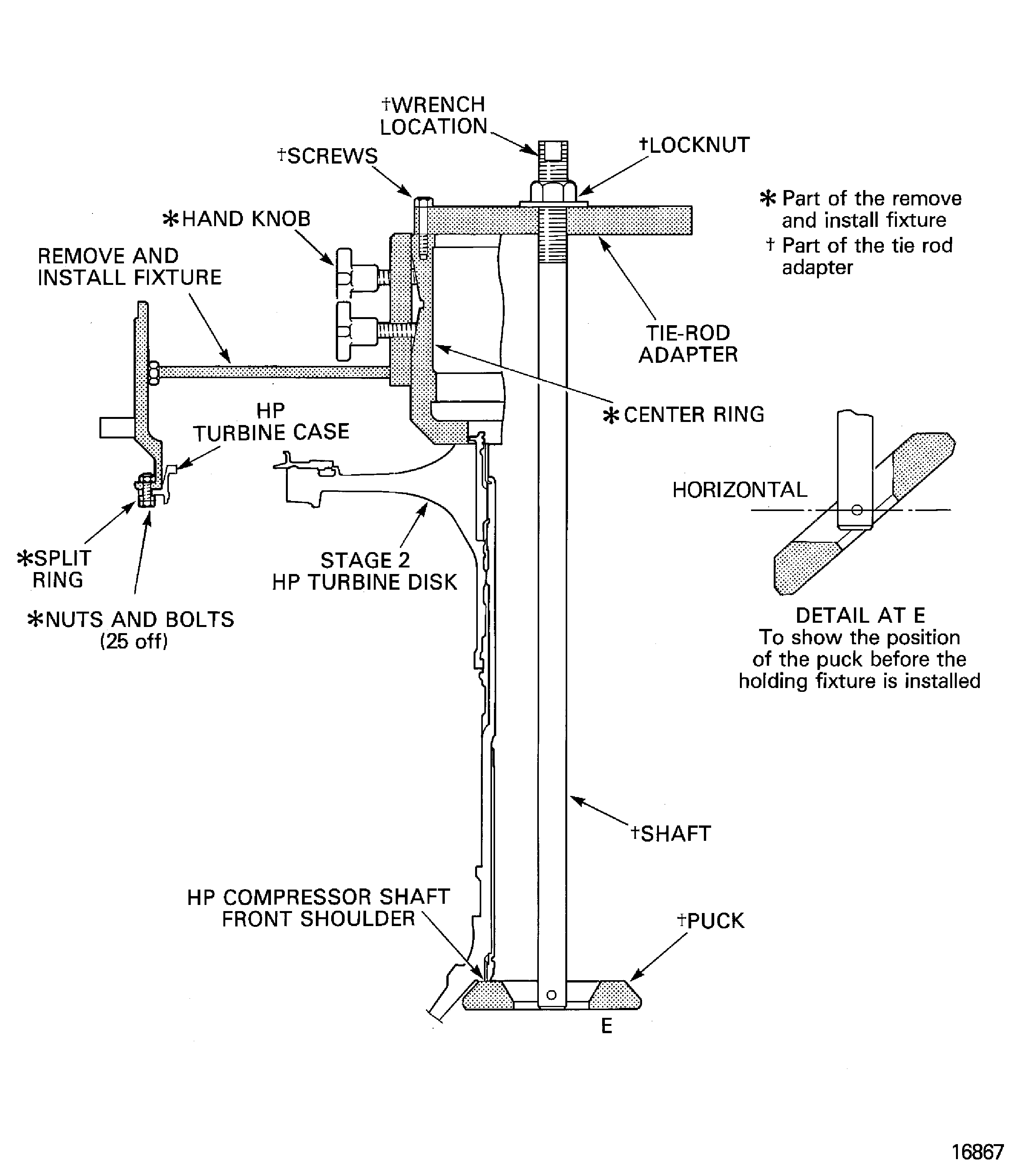

Attach IAE 1P16057 Tie-rod adapter 1 off on to the center ring (part of IAE 1P16046 Removal/Installation fixture or IAE 1P16543 Removal/Installation fixture 1 off).

SUBTASK 72-00-40-020-116 Install the Remove/Install Fixture and the Tie-Rod Adapter to the HP System Module Rear Flange

Refer to Figure.

Install IAE 1R18247 Rigging pin 1 off through the bracket and in to the HP compressor cases to lock the variable stator vanes.

Install IAE 1R18234 Support rod 3 off.

SUBTASK 72-00-40-020-117 Install the HP Compressor Support Rods

Refer to Figure.

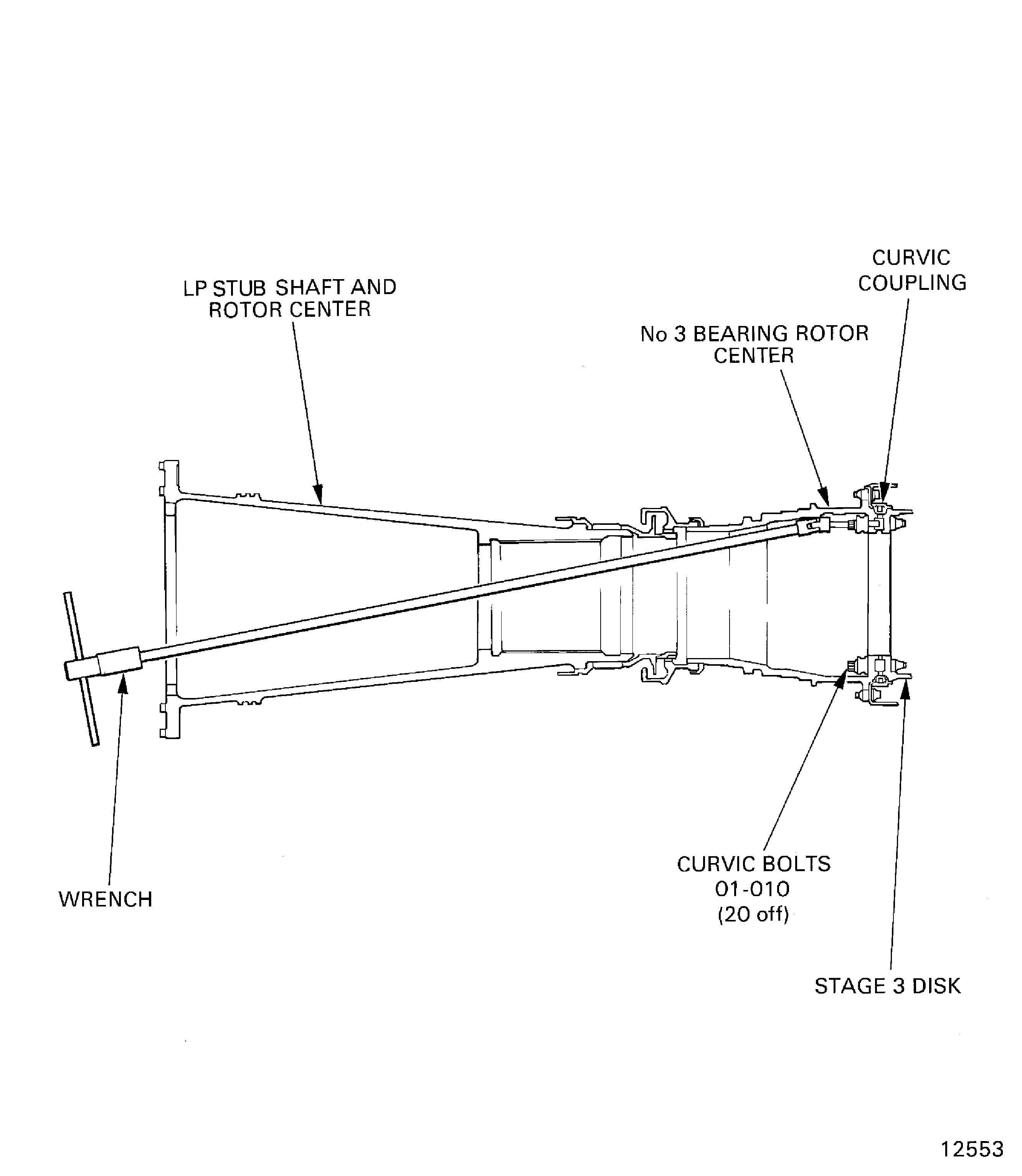

Use IAE 1R18230 Wrench 1 off to release and remove the curvic bolts from the No. 3 bearing rotor center.

SUBTASK 72-00-40-020-118 Remove the Bolts from the HP Compressor Stage 3 Disk Curvic Coupling

Refer to Figure.

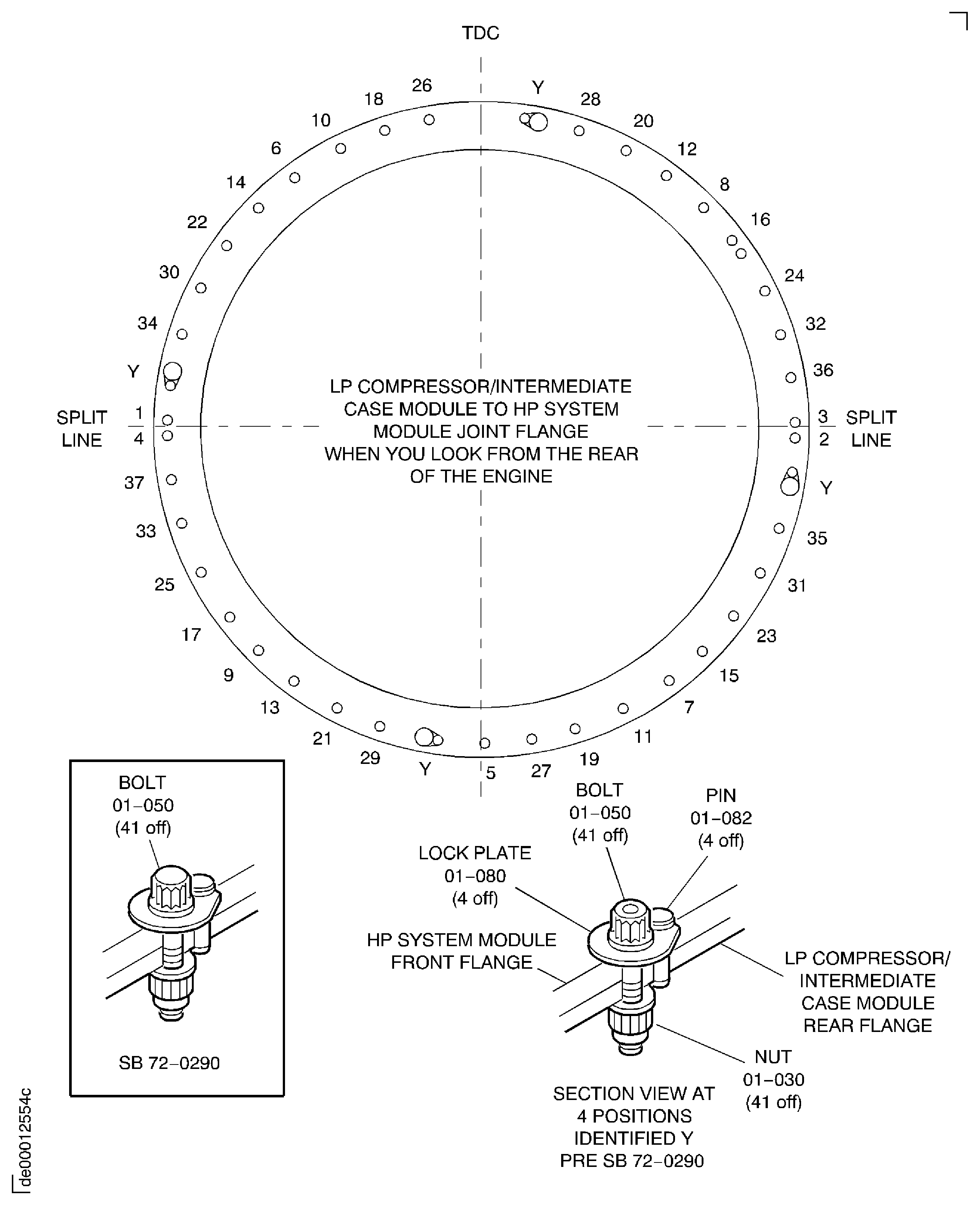

SUBTASK 72-00-40-020-214 Remove the Parts that Attach the LP Compressor/Intermediate Case Module and the HP System Module Joint Flanges (SBE 72-0290)

Refer to Figure.

SUBTASK 72-00-40-020-119 Remove the Parts that Attach the LP Compressor/Intermediate Case Module and the HP System Module Joint Flanges (Pre SBE 72-0290)

Refer to Figure.

SUBTASK 72-00-40-020-120 Remove the HP System Module from the LP Compressor/Intermediate Case Module

Refer to Figure.

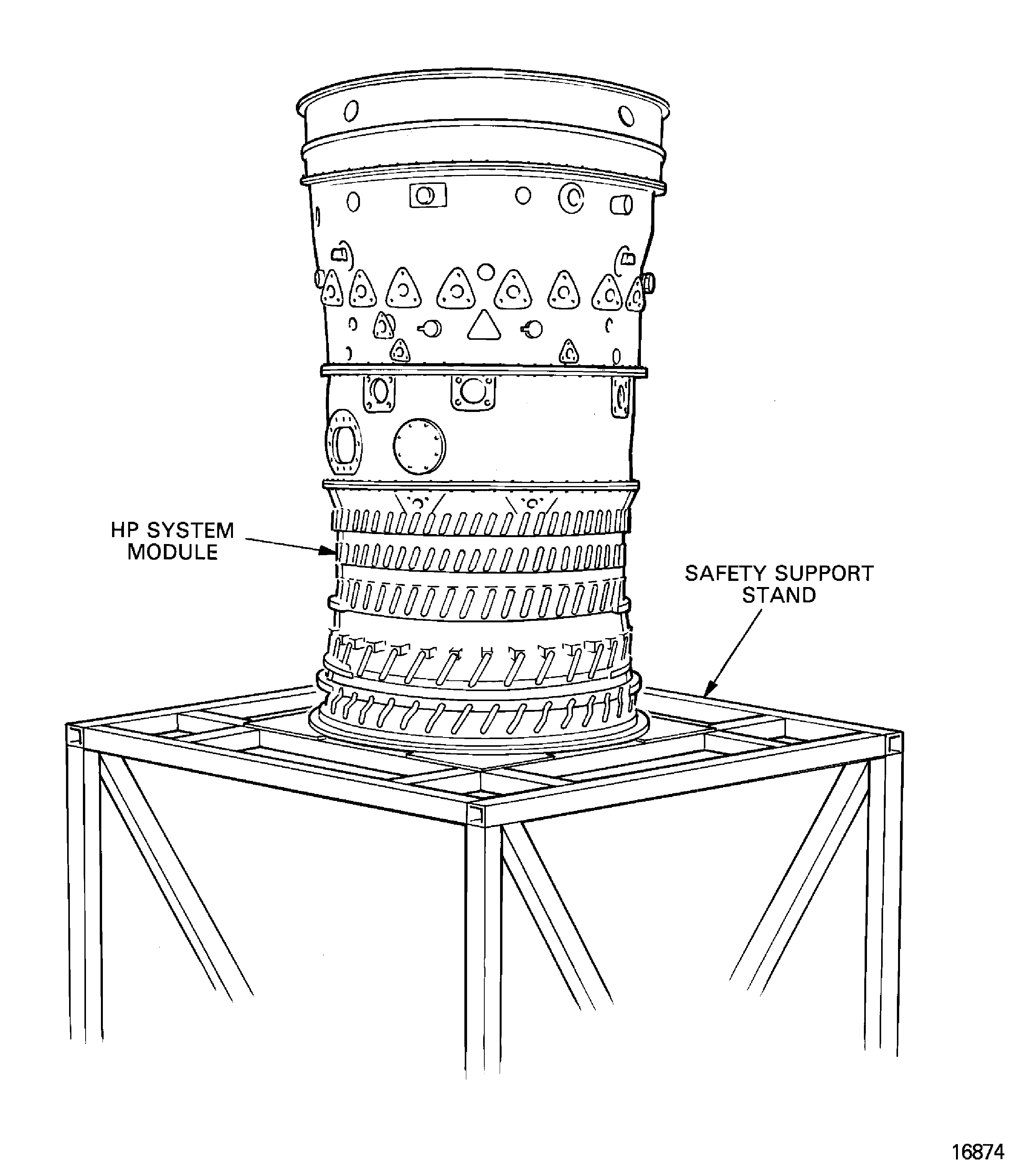

Lower the HP system module on to IAE 1R18090 Safety support stand 1 off. The HP compressor front flange should touch the safety support stand pads. Do not release the lift sling hold.

SUBTASK 72-00-40-020-121 Prepare the HP System Module for Interface Inspection

Visually examine the HP system module and the LP compressor/intermediate case module at interfaces C-32 and C-41. Refer to TASK 72-00-00-200-002.

SUBTASK 72-00-40-220-074 Visually Examine the Interfaces

Refer to Figure.

Install the IAE 1R18673 Dummy stub shaft 1 off in to the IAE 1R18075 Support pedestal 1 off. Make sure the curvic protector is at the rear.

WARNING

WHEN YOU USE COMAT 01-002 INHIBITED AND STABILIZED TRICHLOROETHANE YOU MUST USE THE NECESSARY PROTECTIVE CLOTHING. DO NOT GET THE SOLVENT ON YOUR SKIN OR IN YOUR EYES. YOU MUST NOT SMOKE WHEN YOU USE THE SOLVENT AS THE VAPOR CHANGES AND BECOMES TOXIC.Use a soft brush and apply CoMat 01-002 SOLVENT, DELETED. to the curvic teeth.

Clean the curvic teeth on the dummy stub shaft and the HP compressor stage 3 disk.

SUBTASK 72-00-40-020-122 Install the Dummy Stub Shaft on to the HP System Module

Refer to Figure.

Install IAE 1R18222 Support rod 2 off on to the IAE 1R18214 Build stand 1 off.

SUBTASK 72-00-40-020-123 Install the HP System Module on to the Build Stand

Put a thin layer of CoMat 04-005 JOINTING COMPOUND, MEDIUM GRADE on to the bracket where it touches the blank.

Install one of the blanks ENGINE-HP COMPRESSOR SPLIT CASES (72-41-31, 01-120), the bracket ENGINE-HP COMPRESSOR SPLIT CASES (72-41-31, 01-118) and two of the bolts ENGINE-HP COMPRESSOR SPLIT CASES (72-41-31, 01-122) in to the HP compressor at location C.

Put a thin layer of CoMat 04-005 JOINTING COMPOUND, MEDIUM GRADE on the bracket where it touches the blank.

Install one of the blanks ENGINE-HP COMPRESSOR SPLIT CASES (72-41-31, 01-120), the bracket ENGINE-HP COMPRESSOR SPLIT CASES (72-41-31, 01-115) and two of the bolts ENGINE-HP COMPRESSOR SPLIT CASES (72-41-31, 01-122) in the HP compressor at location A.

Install the other blank ENGINE-HP COMPRESSOR SPLIT CASES (72-41-31, 01-120) and the other bolts ENGINE-HP COMPRESSOR SPLIT CASES (72-41-31, 01-122) in to the HP compressor at location B. Torque the bolts to 85 to 105 lbf.in (10 to 12 Nm).

Remove the rigging pin installed in Step.

Remove the support rods.

SUBTASK 72-00-40-020-124 Remove the Hoist, the Remove/Install Fixture, the Tie-Rod Adapter and the HP Compressor Support Rods and

Figure: Install the remove/install fixture and the tie-rod adapter on to the HP system module

Install the remove/install fixture and the tie-rod adapter on to the HP system module

Figure: Install the remove/install fixture and the tie-rod adapter to the HP system module

Install the remove/install fixture and the tie-rod adapter to the HP system module

Figure: Install the support rods in to the HP compressor

Install the support rods in to the HP compressor

Figure: Install the support rods in to the HP compressor

Install the support rods in to the HP compressor

Figure: Remove the stage 3 HP compressor curvic bolts

Remove the stage 3 HP compressor curvic bolts

Figure: LP compressor/intermediate case module to HP system module joint flange hole positions

LP compressor/intermediate case module to HP system module joint flange hole positions

Figure: Install the HP system module on to the safety support stand

Install the HP system module on to the safety support stand

Figure: Install the dummy stub shaft on to the stage 3 disk curvic coupling

Install the dummy stub shaft on to the stage 3 disk curvic coupling

Figure: Install the HP compressor/diffuser case assembly on to the build stand

Install the HP compressor/diffuser case assembly on to the build stand