Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A1 AND Pre SBE 72-0103 AND Pre SBE 72-0105

Common Information

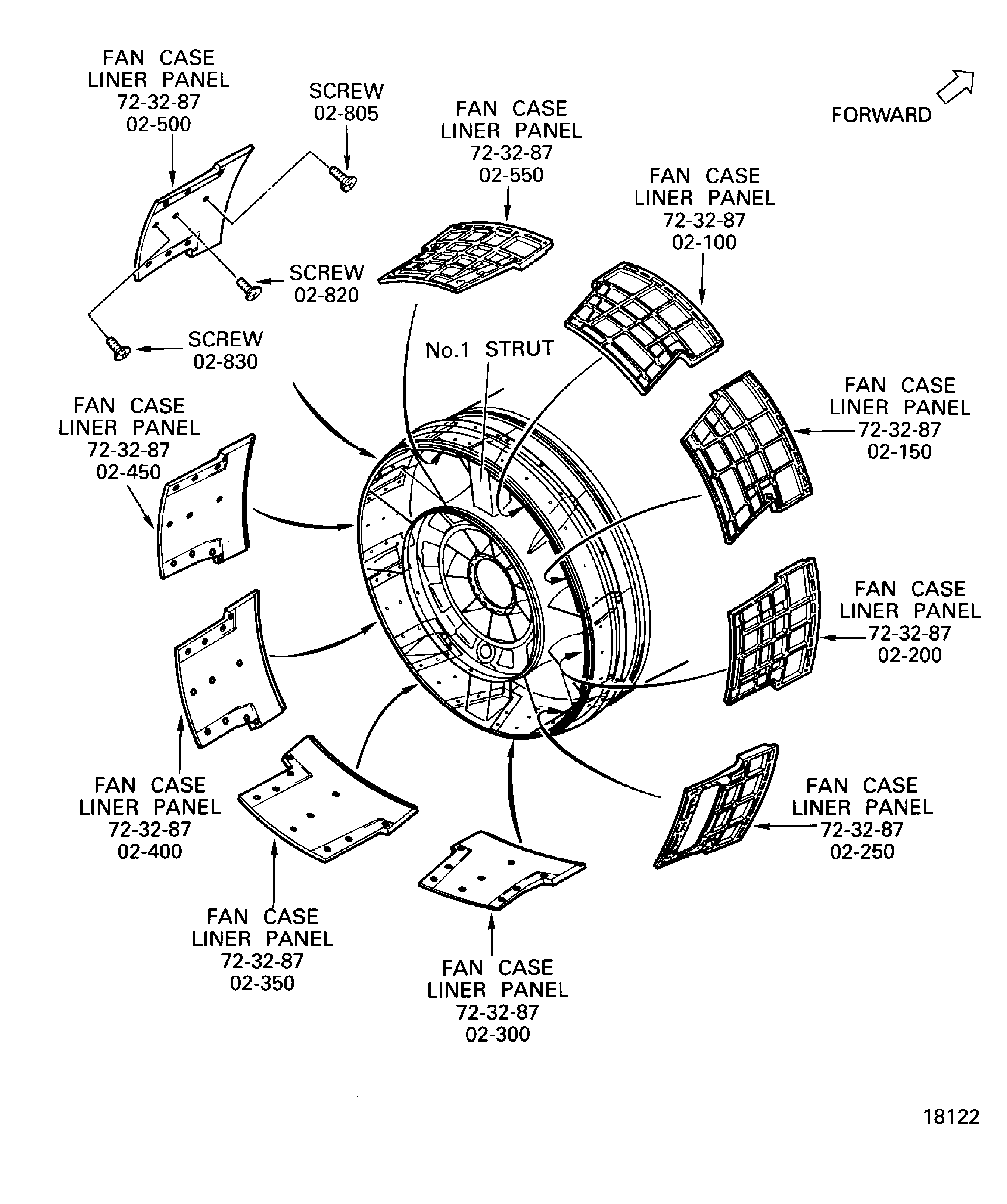

TASK 72-32-00-030-004-A00 LPC/Intermediate Case Module - Remove The Fan Case Liner Panels, Panel Rubber Seals, Fan Exit Guide Vanes, Acoustic Linings, And Rear Fairing, Disassembly-004 - Pre SBE 72-0103, Pre SBE72-0105

General

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary numbers are used. For the service bulletin alpha variants refer to the IPC.

Apply the approved penetrating oil before the removal of threaded parts. Let the parts soak before removal. For the approved oils and procedures, refer to the SPM TASK 70-64-00-640-501.

The number for each radial location must be identified in a clockwise direction. These start at the engine top position when you look from the rear of the engine, unless stated differently in the procedure.

The No. 1 strut, which is the top position strut of the fan frame assembly, is identified by the five pressure tubes on the No. 1 strut leading edge.

This TASK gives the procedure to remove the fan case liner panels, the panel rubber seals, the fan exit guide vanes, the acoustic linings and the rear fairing.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

NONESpares

NONESafety Requirements

NONEProcedure

Make sure that the fan frame and fan case assembly is installed horizontally on the turnover stand. Refer to TASK 72-32-00-030-003-A00 (DISASSEMBLY-003, CONFIG-001).

Make sure that the work mat is in position in the fan case. Refer to TASK 72-32-00-030-003-A00 (DISASSEMBLY-003, CONFIG-001).

SUBTASK 72-32-00-030-089 Remove Silicone Compound from the Fan Exit Guide Vanes (FEGVs) and the Acoustic Linings

Refer to Figure.

SUBTASK 72-32-00-030-090 Remove the Acoustic Linings from the FEGVs

Refer to Figure.

SUBTASK 72-32-00-030-194 Remove the Brackets from the LP Compressor Rear Case

Refer to Figure.

SUBTASK 72-32-00-030-091 Remove the FEGVs from the Fan Case

Refer to Figure.

SUBTASK 72-32-00-030-195 Remove Silicone Compound from the Rear Fairing before Removal of the Bolts and Washers

Refer to Figure.

SUBTASK 72-32-00-030-196 Remove the Rear Fairing from the LP Compressor Bleed Duct

Refer to Figure.

SUBTASK 72-32-00-030-197 Remove the Remaining Silicone Compound from the Rear Fairing the Bolts and the Washers

CAUTION

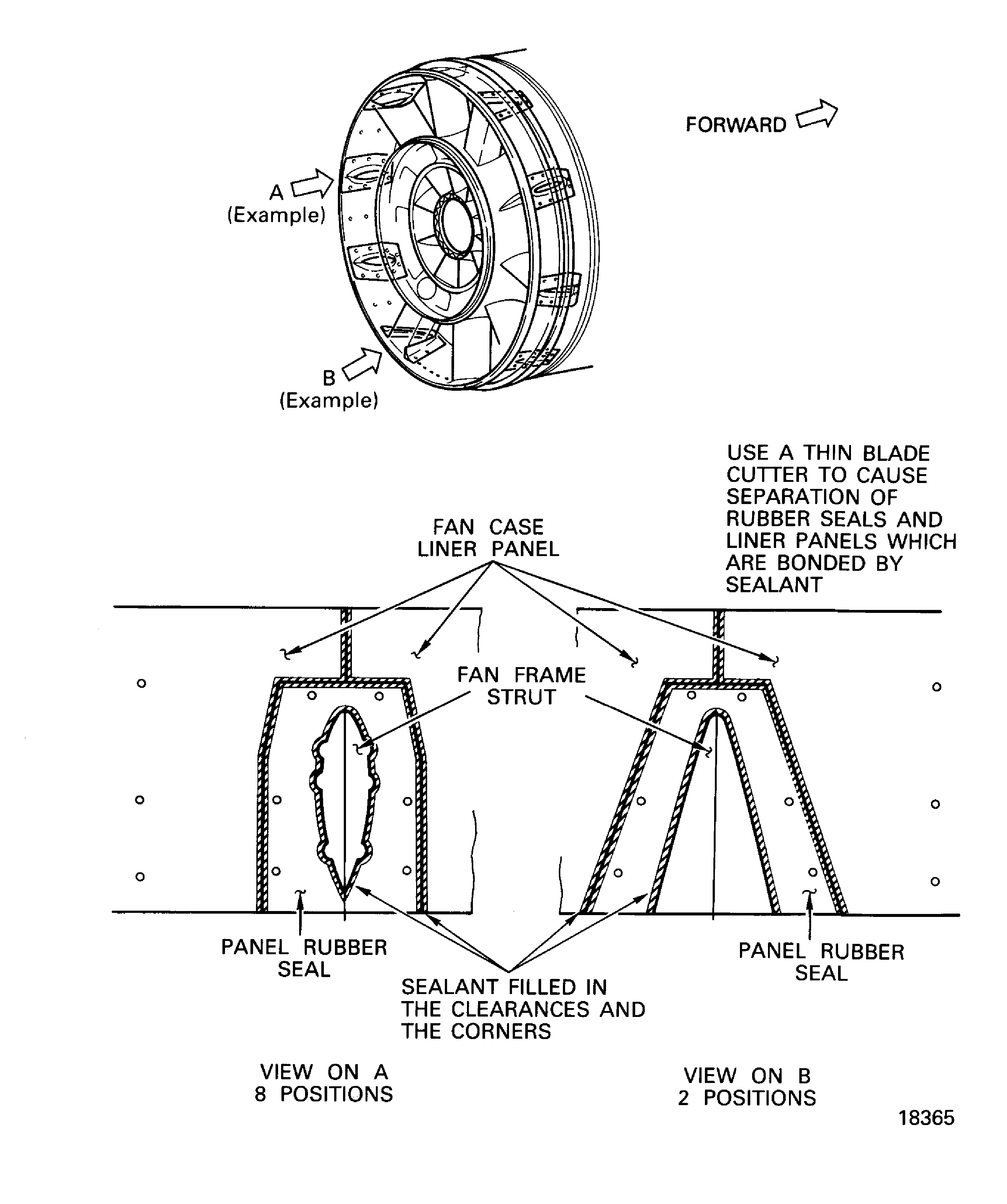

CAREFULLY USE A THIN BLADE CUTTER TO PREVENT DAMAGE TO THE SURFACES OF THE PANEL RUBBER SEALS. THE FAN CASE LINER PANELS AND THE STRUTS.Carefully use a thin blade cutter to break sealant filled in the clearances between the panel rubber seals and the fan case liner panels and the corners around the struts.

SUBTASK 72-32-00-030-093 Remove the Fan Case Liners and the Panel Rubber Seals from the Fan Case

Refer to Figure.

SUBTASK 72-32-00-030-094 Remove the Remaining Sealant from the Panel Rubber Seals and the Fan Case Liner Panels

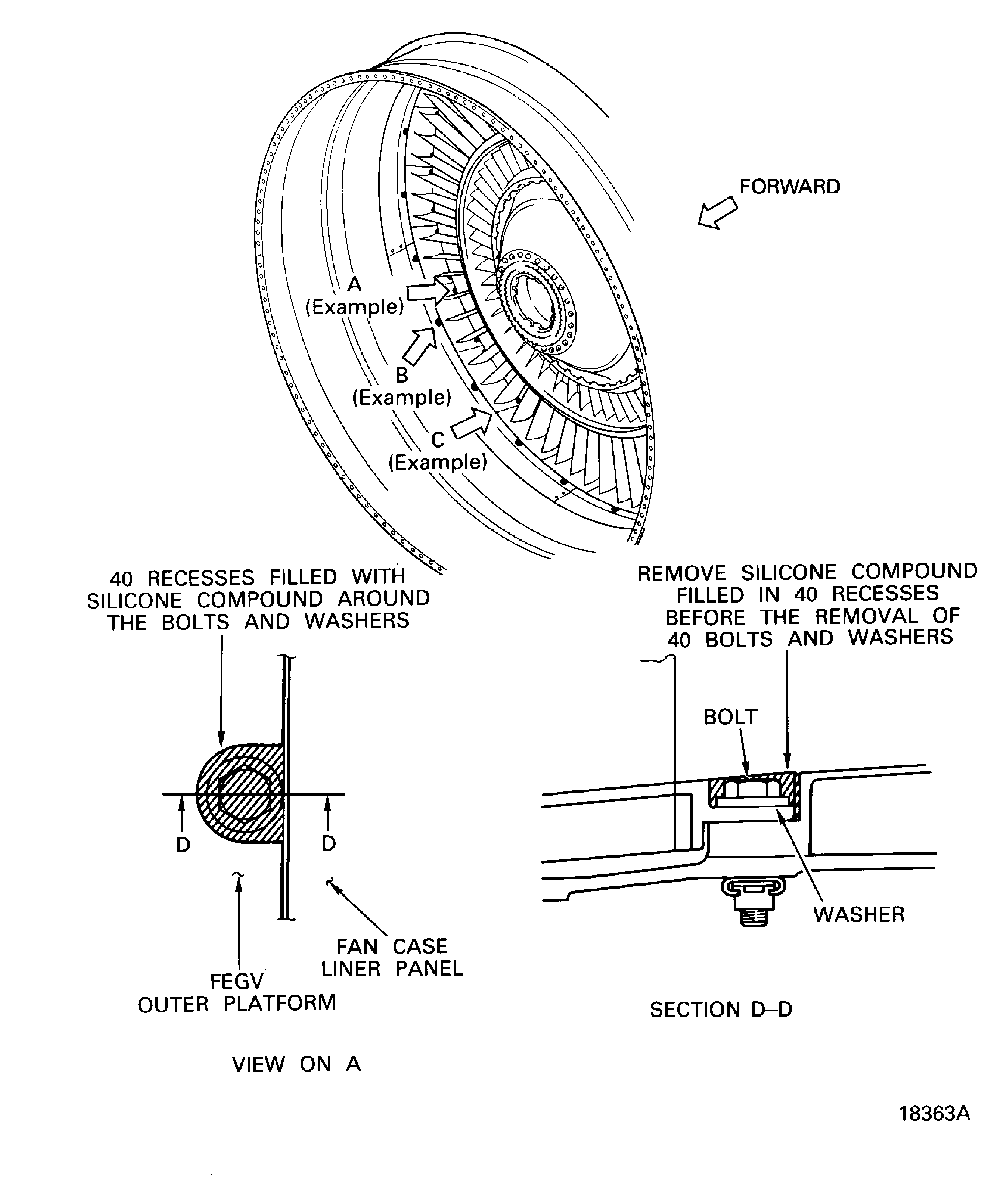

Figure: Remove silicone compound from the FEGV outer platforms and the acoustic linings

Remove silicone compound from the FEGV outer platforms and the acoustic linings

Figure: Remove silicone compound from the FEGV outer platforms and the acoustic linings

Remove silicone compound from the FEGV outer platforms and the acoustic linings

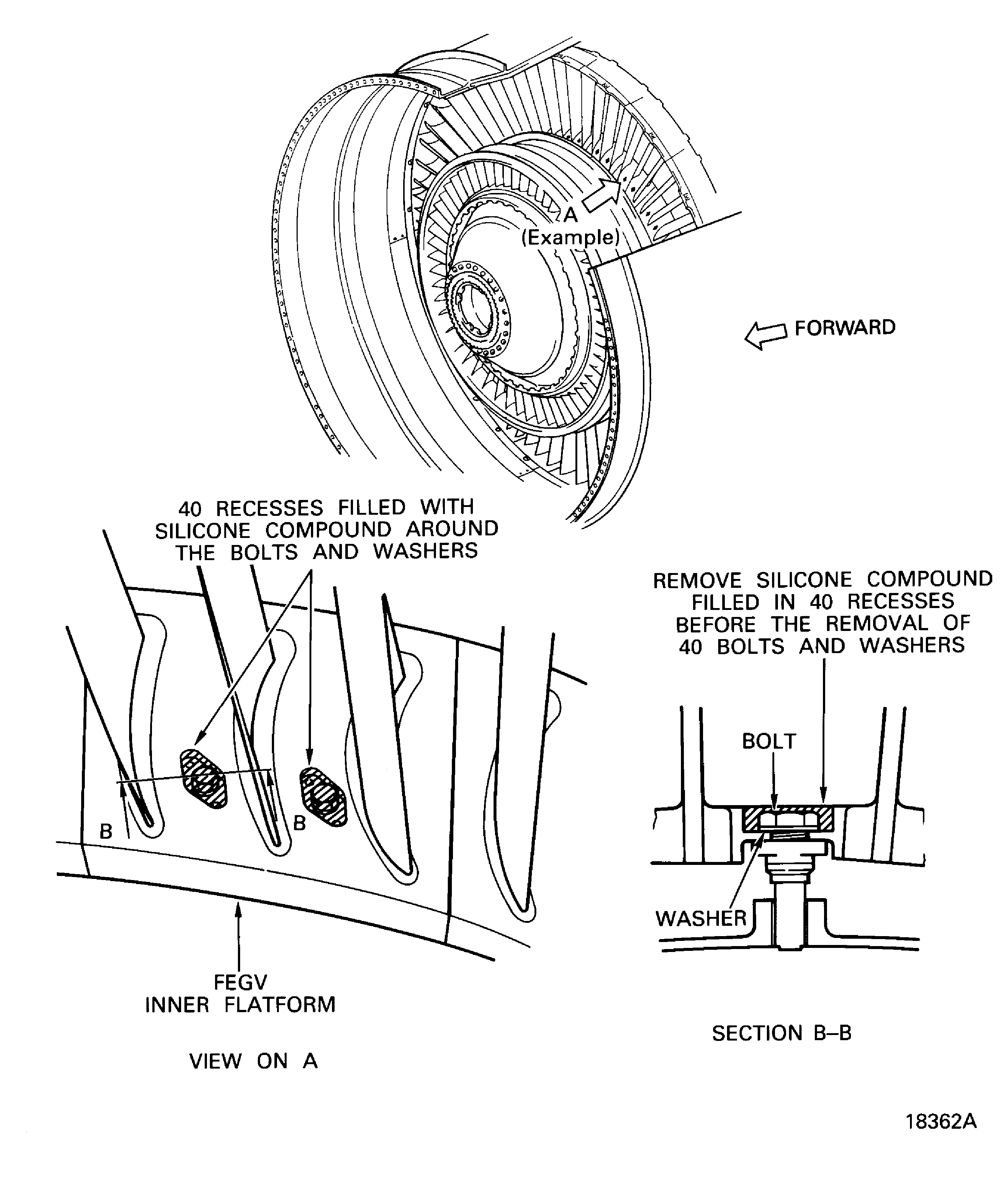

Figure: Remove silicone compound from the FEGV inner platforms

Remove silicone compound from the FEGV inner platforms

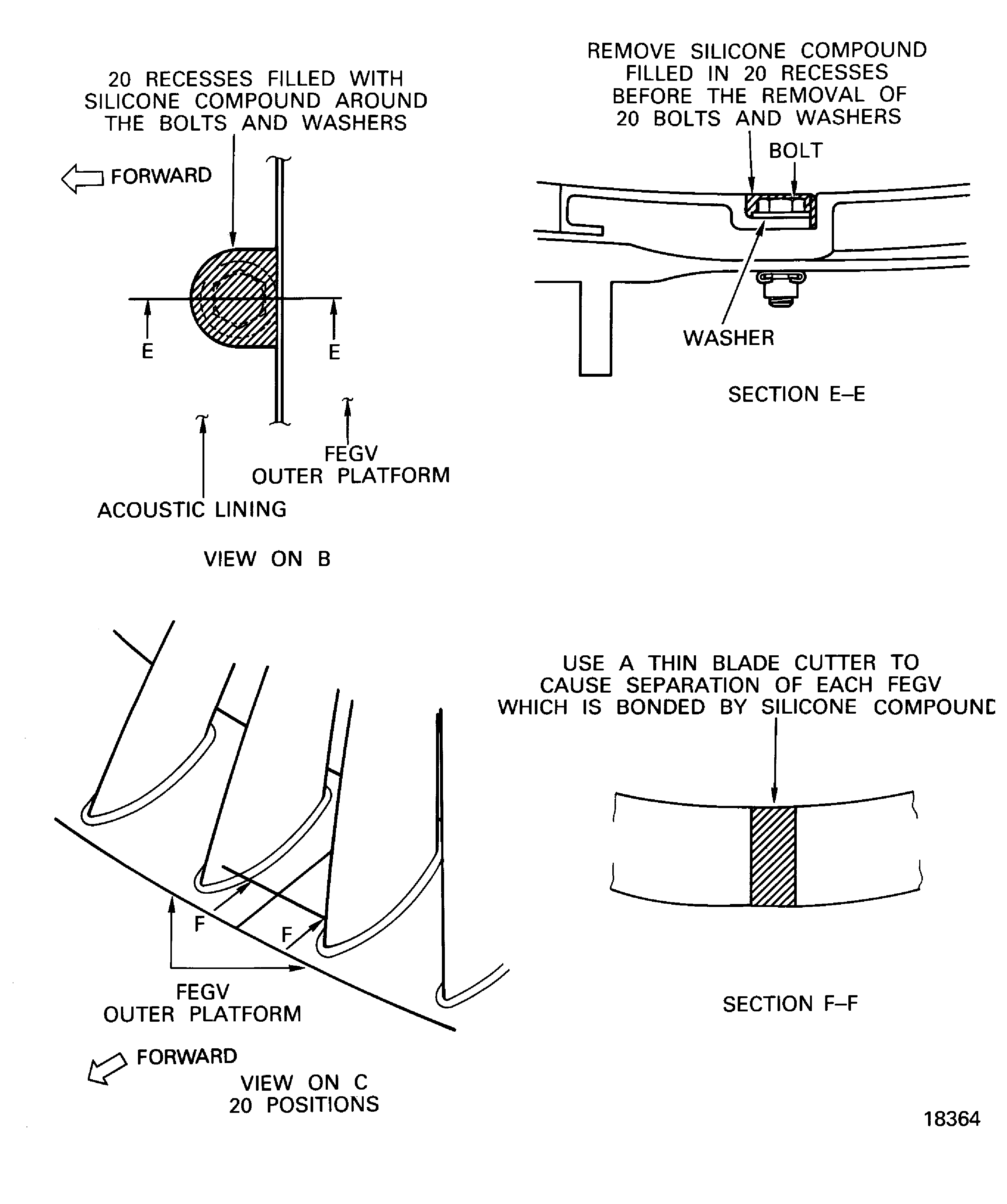

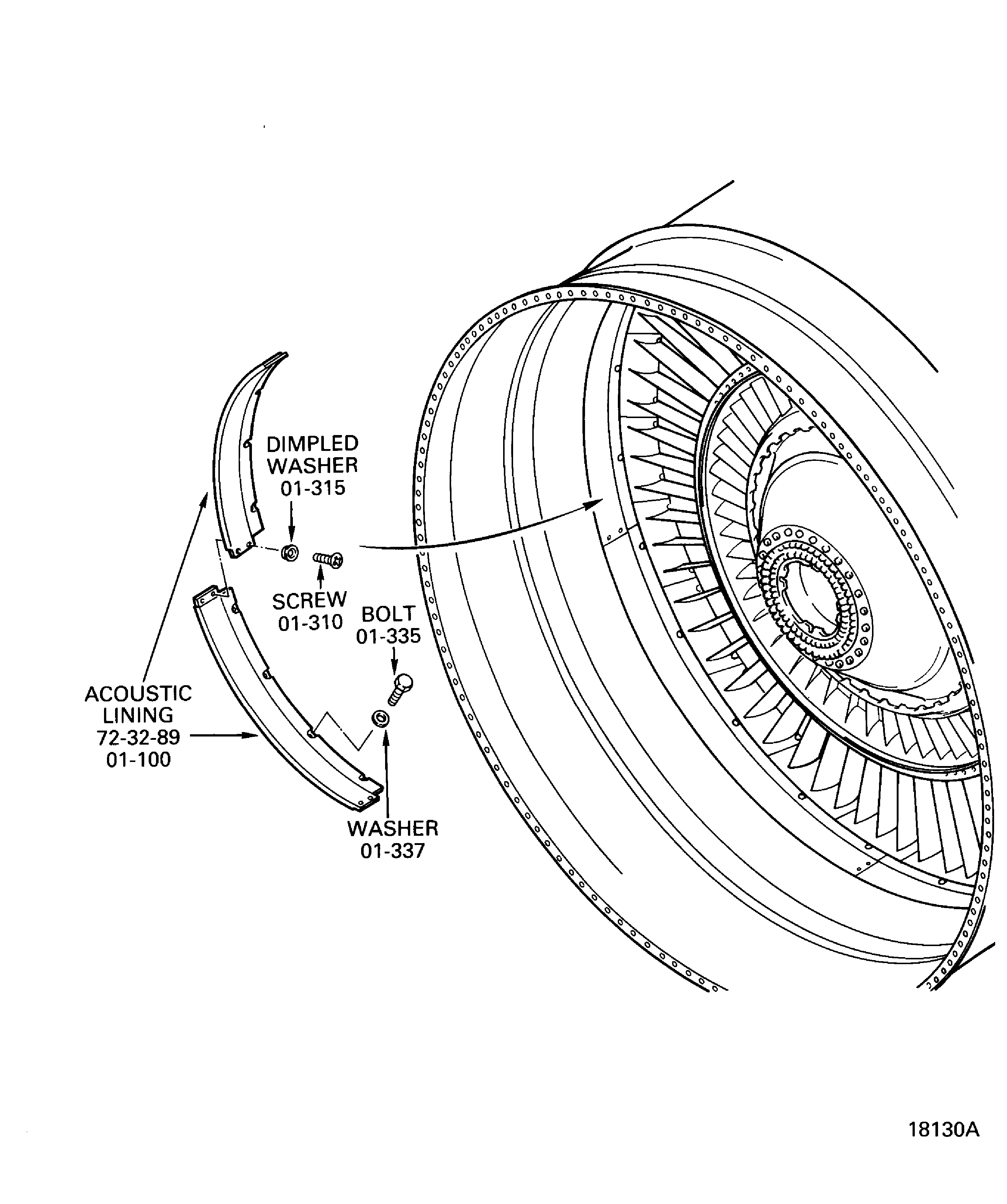

Figure: Remove the acoustic linings from the FEGVs

Remove the acoustic linings from the FEGVs

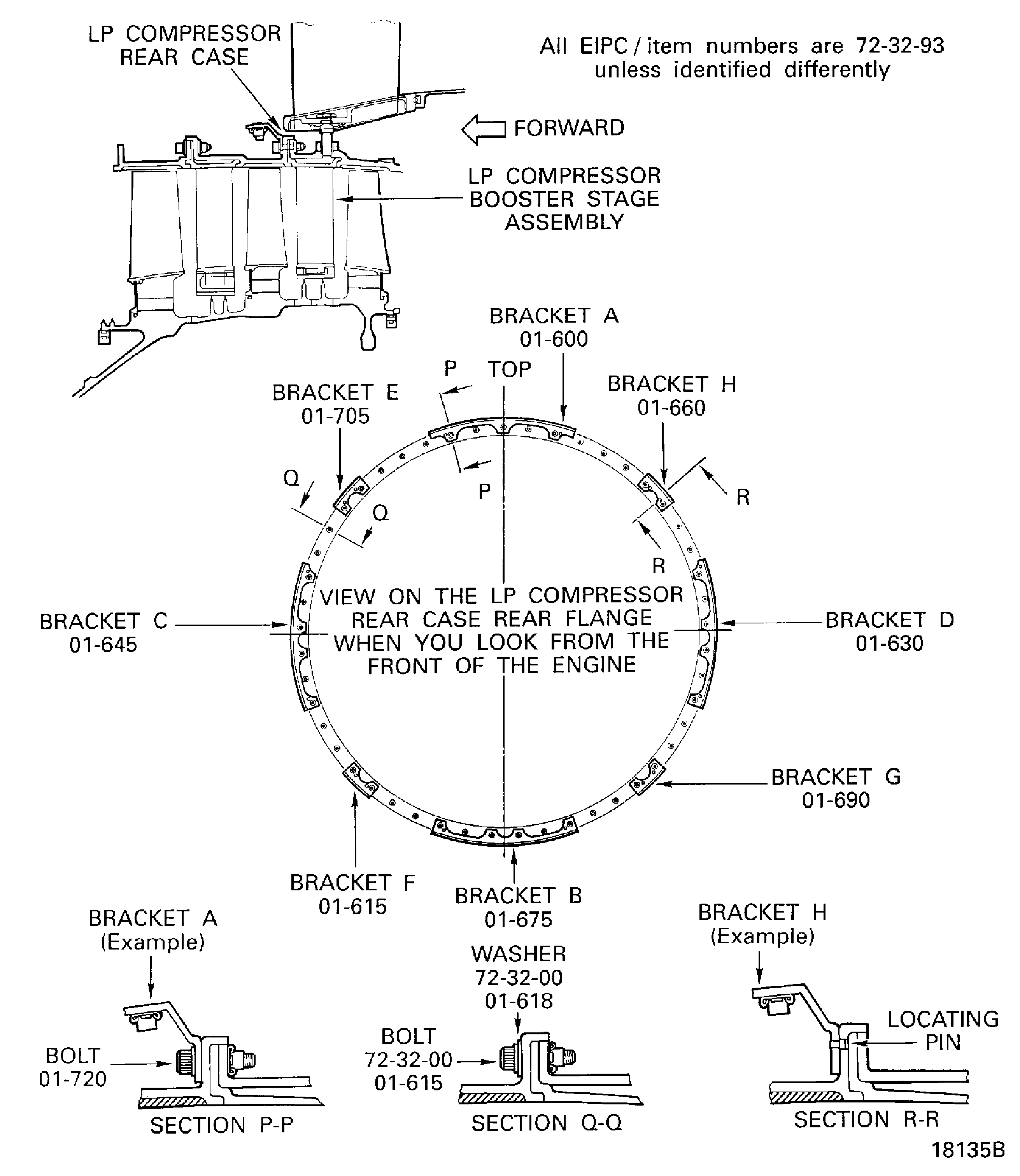

Figure: Remove the brackets from the LP compressor rear case

Remove the brackets from the LP compressor rear case

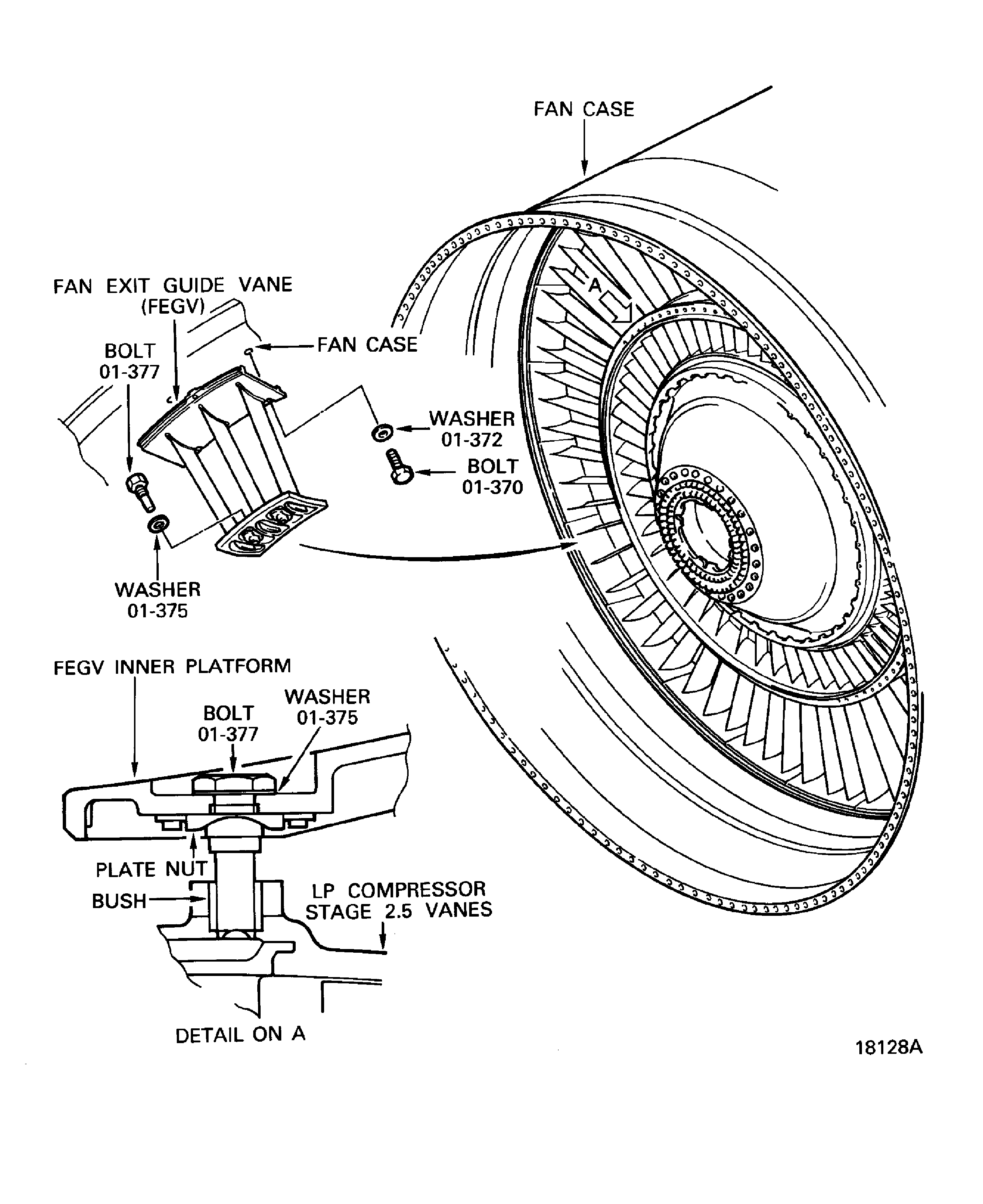

Figure: Remove the FEGVs from the fan case

Remove the FEGVs from the fan case

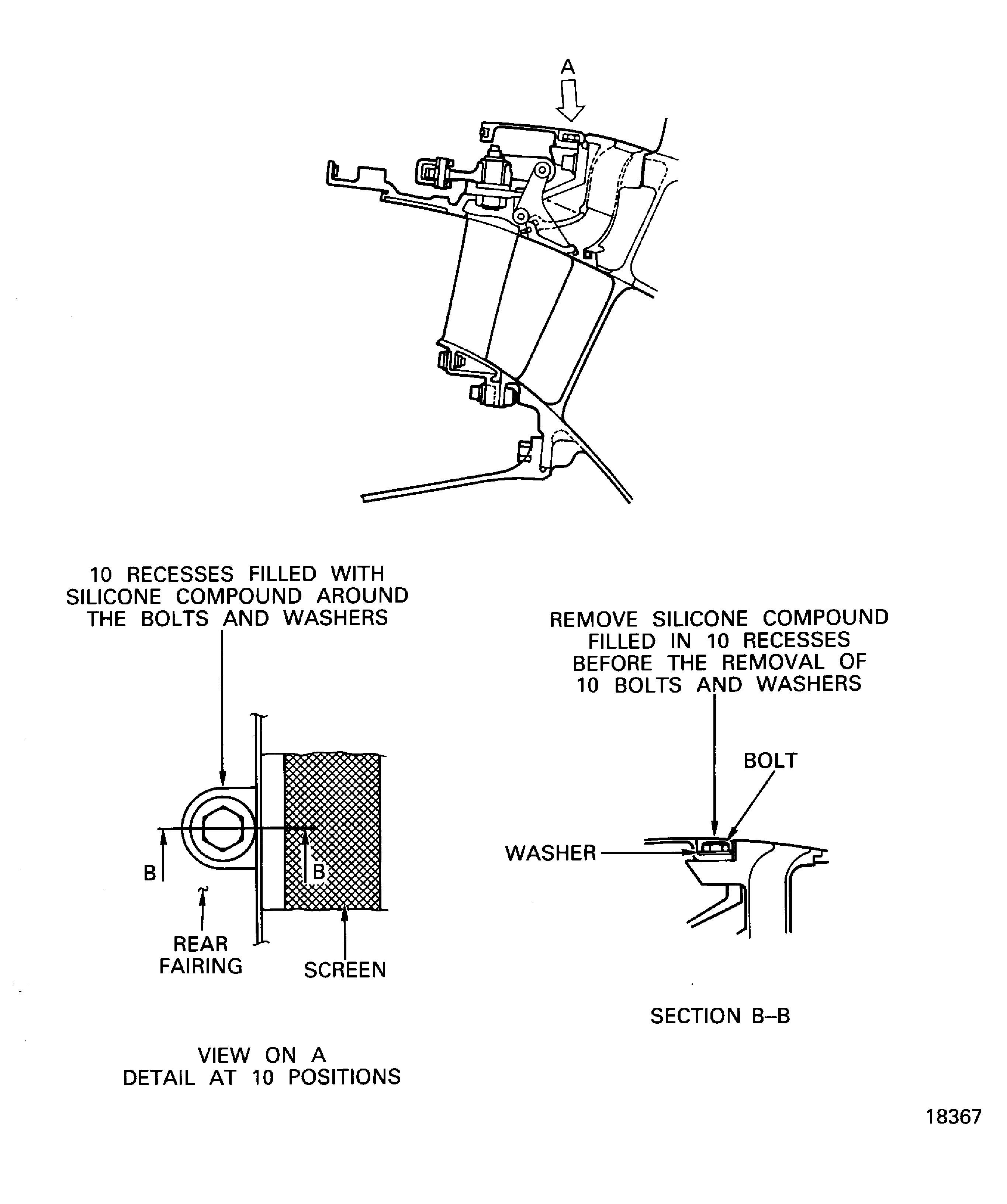

Figure: Remove the silicone compound from the rear fairing

Remove the silicone compound from the rear fairing

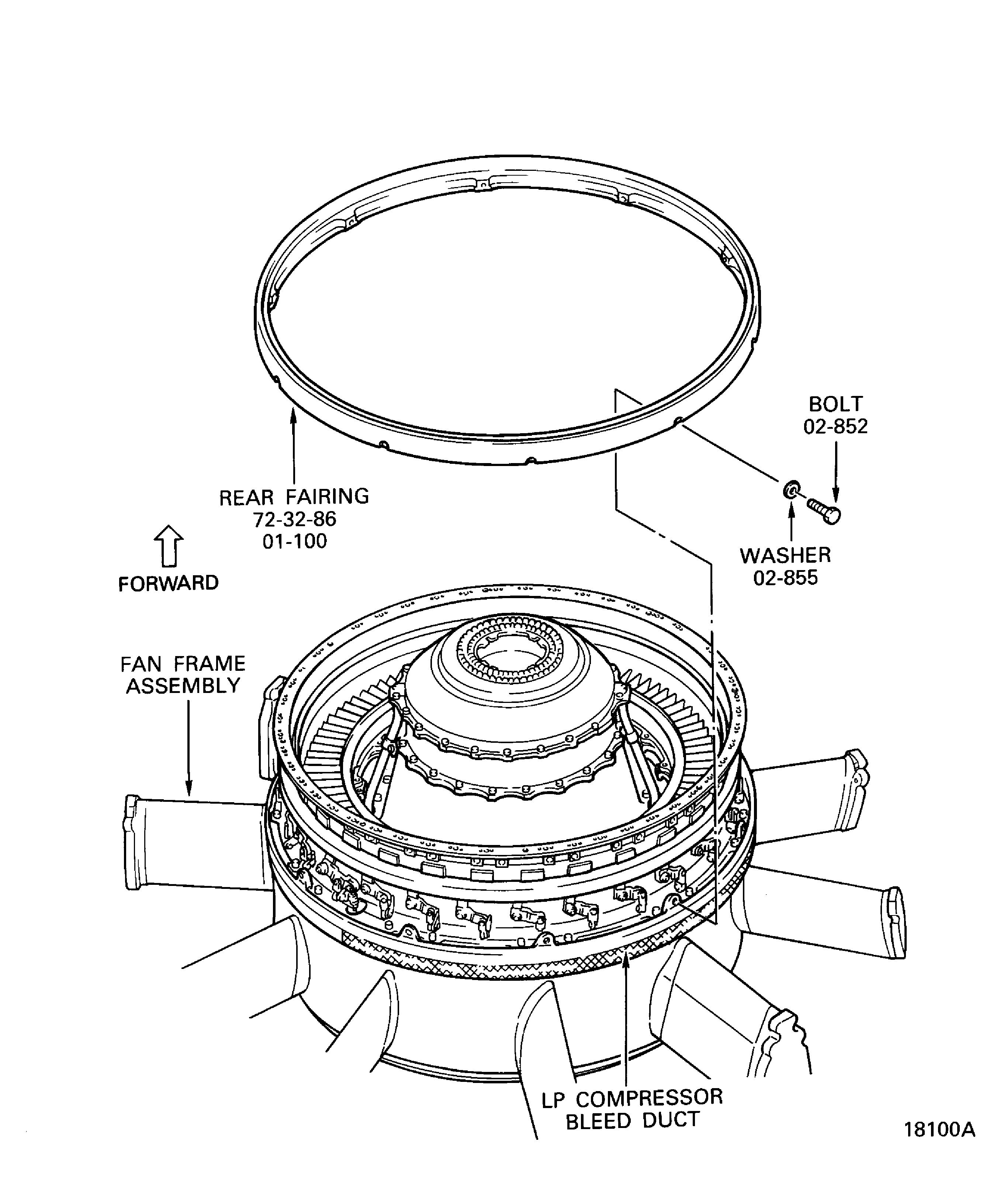

Figure: Remove the rear fairing from the LP compressor bleed duct

Remove the rear fairing from the LP compressor bleed duct

Figure: Use a thin blade cutter to cause separation of the rubber seals and the liner panels which bonded by sealant

Use a thin blade cutter to cause separation of the rubber seals and the liner panels which bonded by sealant

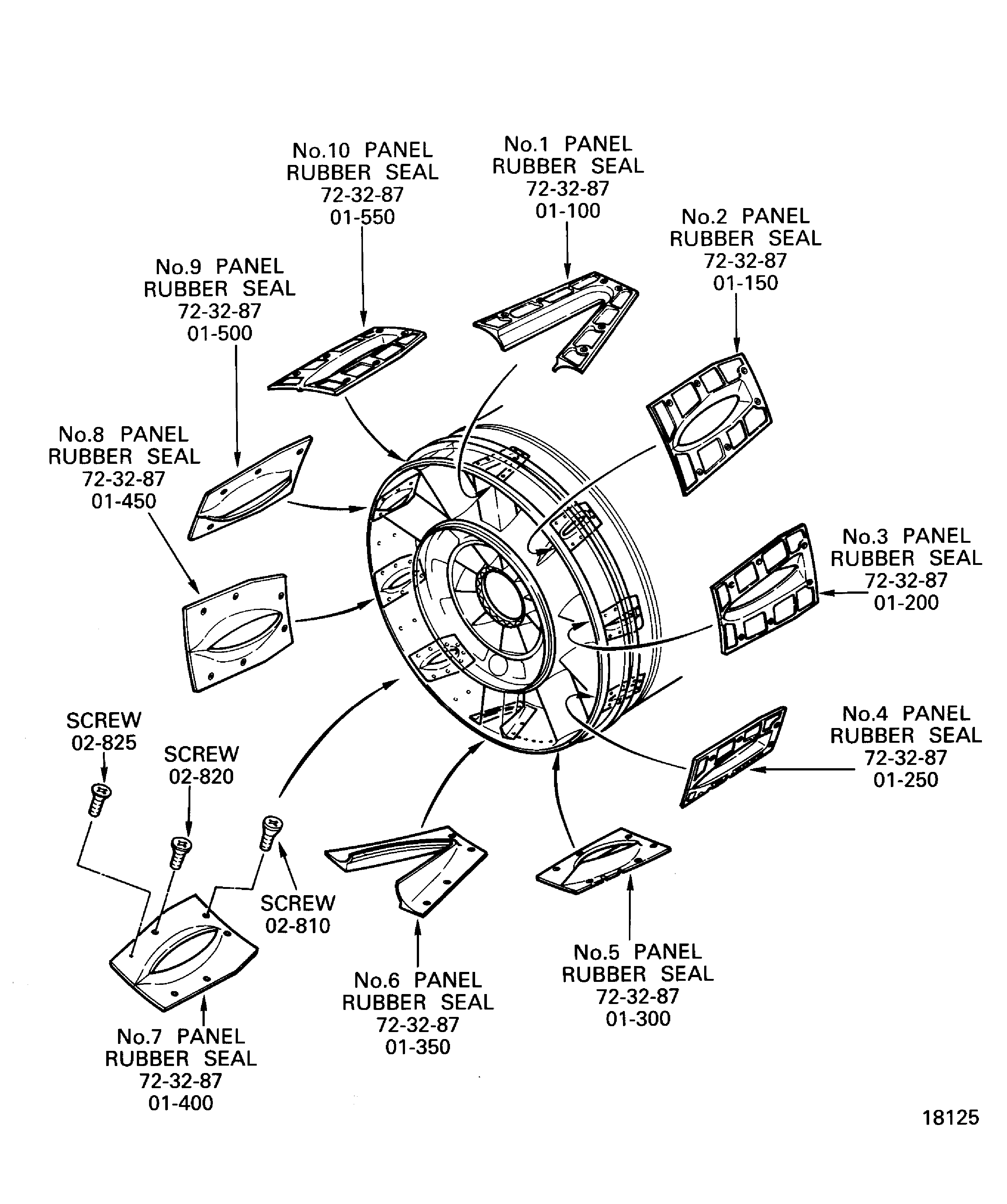

Figure: Remove the panel rubber seals from the fan case liner panels

Remove the panel rubber seals from the fan case liner panels

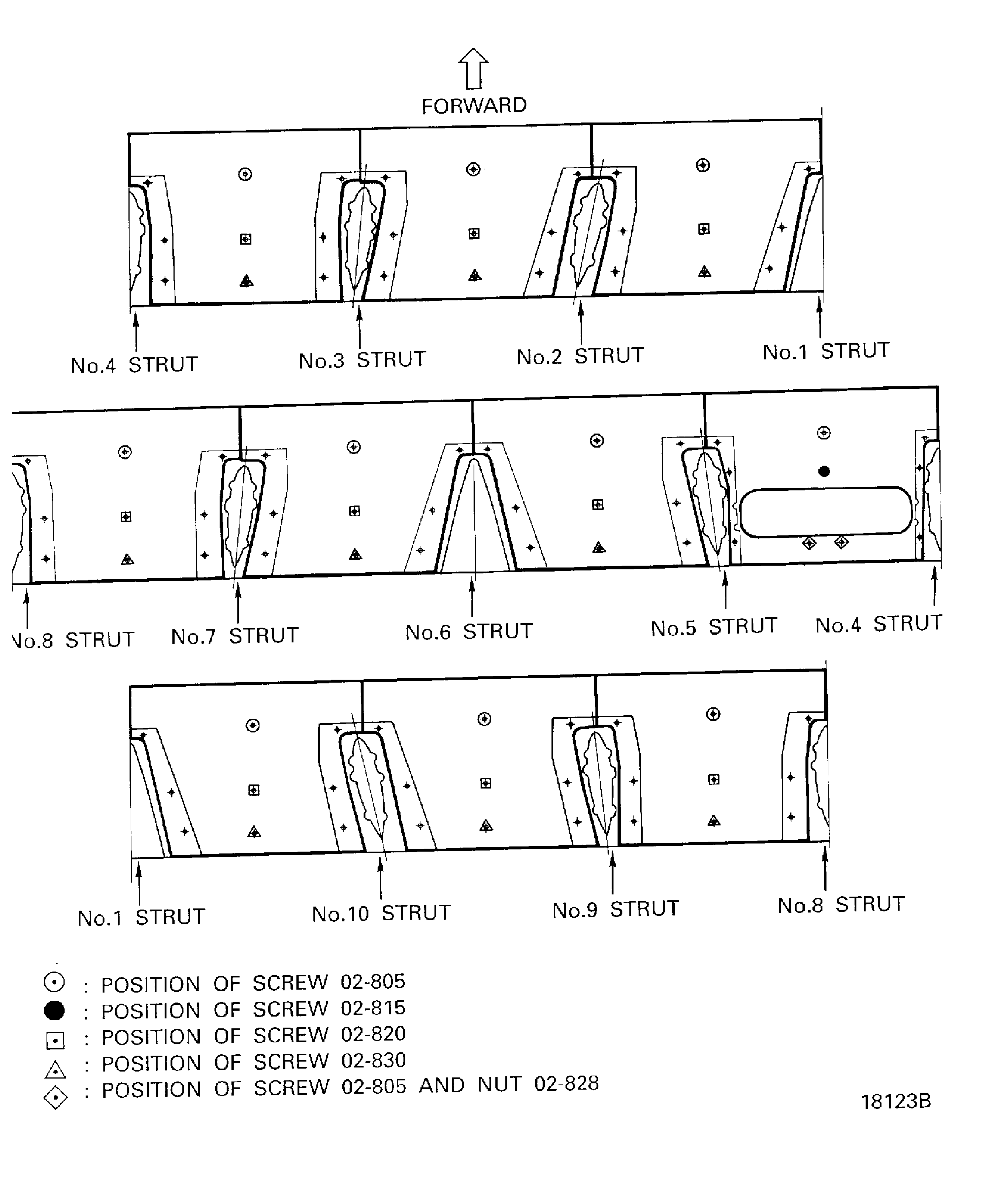

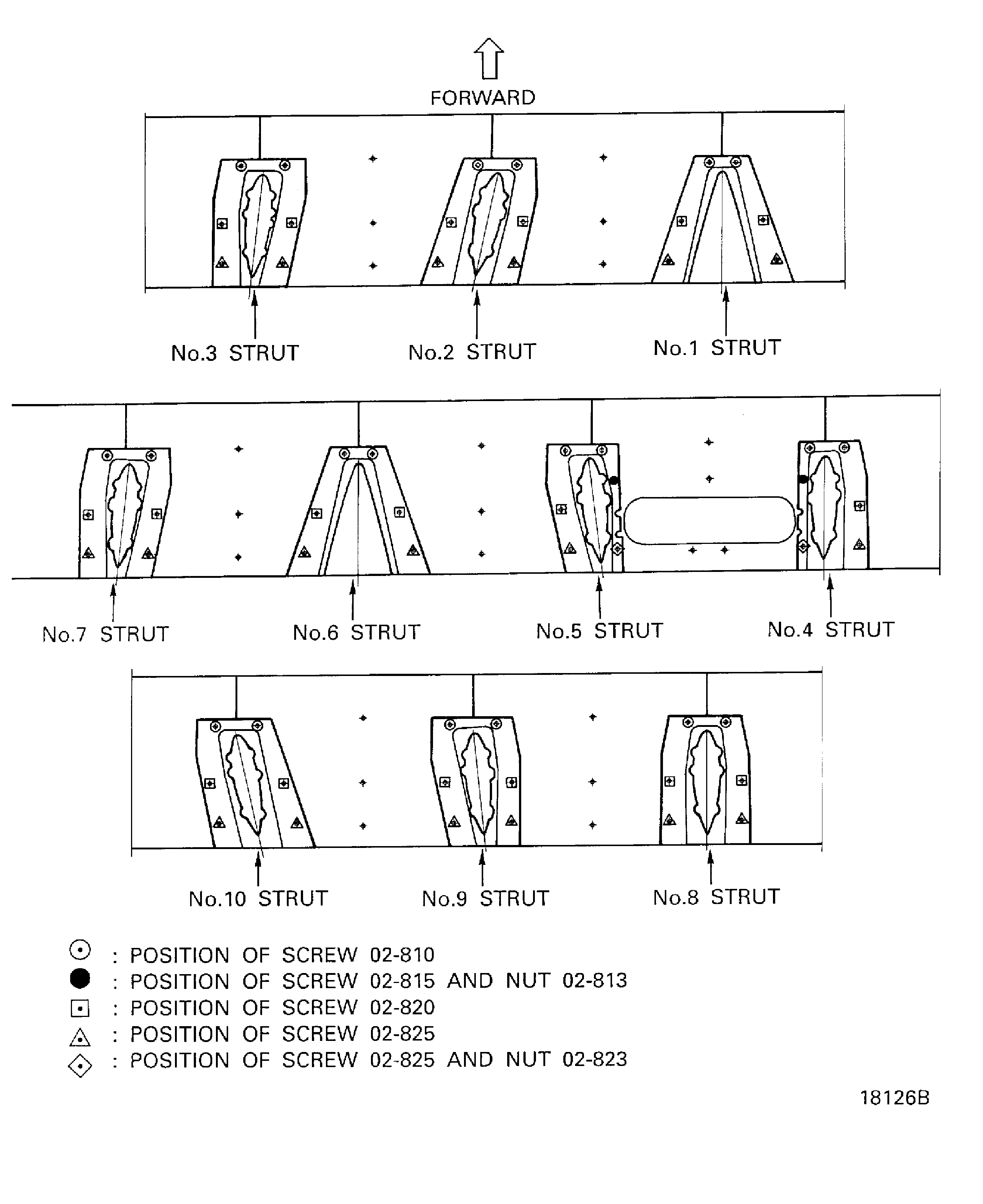

Figure: Remove the screws and the nuts which attach the panel rubber seals to the fan case liner panels

Remove the screws and the nuts which attach the panel rubber seals to the fan case liner panels

Figure: Remove the fan case liner panels from the fan case

Remove the fan case liner panels from the fan case

Figure: Remove the screws and the nuts which attach the fan case liner panels to the fan case

Remove the screws and the nuts which attach the fan case liner panels to the fan case