Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A1

Common Information

TASK 72-32-23-440-001-A00 HPC Front Shaft And Seal Carrier Assembly - Assemble, Assembly-001

General

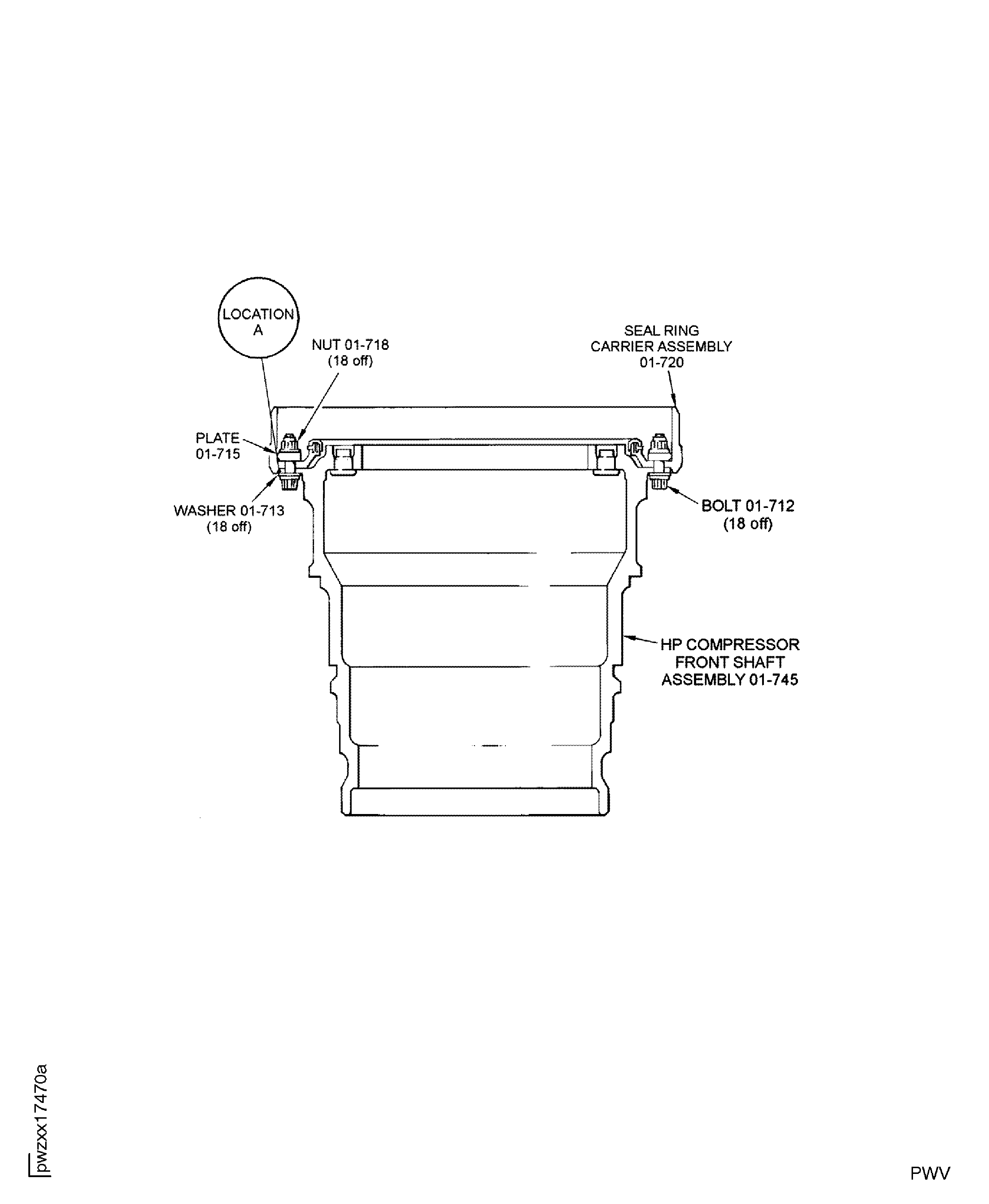

This TASK gives the procedure to assemble the seal ring carrier assembly to the HP Compressor Front Shaft Assembly.

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the EIPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

Overhaul processes referred to in the procedure by the TASK number are in SPM.

For standard torque data and procedures refer to SPM TASK 70-41-00-400-501, SPM TASK 70-41-01-400-501 and SPM TASK 70-41-02-410-501.

Lubricate all threads and mating faces of nuts and bolts with CoMat 10-077 APPROVED ENGINE OILS, unless other lubricants are referred to in the procedure.

All the mating faces must be cleaned with CoMat 01-001 SOLVENT, DELETED or CoMat 01-002 SOLVENT, DELETED. before assembly. Refer to SPM TASK 70-11-01-300-503. They must also be dry assembled unless told differently in the procedure.

All of the temporary marks made in this procedure must be removed after completion of this task.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Air circulated oven | LOCAL |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-001 SOLVENT, DELETED | X111X | CoMat 01-001 | ||

| CoMat 01-002 SOLVENT, DELETED. | X111X | CoMat 01-002 | ||

| CoMat 02-121 TEMPORARY MARKER PENCIL/CRAYON | IE304 | CoMat 02-121 | ||

| CoMat 02-122 TEMPORARY MARKER PENCIL/CRAYON | K6835 | CoMat 02-122 | ||

| CoMat 10-077 APPROVED ENGINE OILS | X333X | CoMat 10-077 |

Spares

NONESafety Requirements

NONEProcedure

Refer to Figure.

Reference dimensions at location A. If required, use the data written as the note in TASK 72-32-23-200-000 (INSPECTION-000).

Table 1. Fits and Clearances (all dimensions are in inches) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION A

HP Compressor Front Shaft Assembly ENGINE-NO.3 BEARING ROTOR CENTRE (72-32-23, 01-745)

And

Seal Ring Carrier Assembly ENGINE-NO.3 BEARING ROTOR CENTRE (72-32-23, 01-720)

HP Compressor Front Shaft Assembly Rear Location Outside Diameter

7.5287

Intf

7.5287

Intf

7.5298

0.0073

7.5398

0.0073

Seal Ring Carrier Front Location Bore Diameter

7.5197

0.0101

7.5197

0.0101

7.5214

Intf

7.5214

Intf

Table 2. Fits and Clearances (all dimensions are in millimeters) NEW PART

WORN PART

DIMENSIONS

DIMENSIONS

PART IDENT

Size

Clearance

Non-select

REJECT IF

MORE THAN

LOCATION A

HP Compressor Front Shaft Assembly ENGINE-NO.3 BEARING ROTOR CENTRE (72-32-23, 01-745)

And

Seal Ring Carrier Assembly ENGINE-NO.3 BEARING ROTOR CENTRE (72-32-23, 01-720)

HP Compressor Front Shaft Assembly Rear Location Outside Diameter

191.2280

Intf

191.2280

Intf

191.2570

0.182

191.2570

0.182

Seal Ring Carrier Front Location Bore Diameter

191.000

0.257

191.000

0.257

191.046

Intf

191.046

Intf

SUBTASK 72-32-23-220-120 Reference Fits and Clearances of the HP Compressor Front shaft Assembly and the Seal Ring Carrier Assembly at Location A

Refer to Figure.

Put the HP Compressor Front Shaft Assembly ENGINE-NO.3 BEARING ROTOR CENTRE (72-32-23, 01-745) on to a suitable work surface in a vertical position, with the curvic teeth to the top.

Put the seal ring carrier assembly ENGINE-NO.3 BEARING ROTOR CENTRE (72-32-23, 01-720) into an air circulated oven and increase the temperature of the assembly to 743 to 761 deg F (395 to 405 deg C).

Install the plate ENGINE-NO.3 BEARING ROTOR CENTRE (72-32-23, 01-715) on to the seal ring carrier assembly. Make sure the bolt holes are aligned.

Use CoMat 02-121 TEMPORARY MARKER PENCIL/CRAYON or CoMat 02-122 TEMPORARY MARKER PENCIL/CRAYON to make a mark which identifies the six slave nuts and bolts.

Put 12 bolts ENGINE-NO.3 BEARING ROTOR CENTRE (72-32-23, 01-712) with 12 washers ENGINE-NO.3 BEARING ROTOR CENTRE (72-32-23, 01-713) through the bolt holes from the HP compressor shaft side and hold in position with 12 nuts ENGINE-NO.3 BEARING ROTOR CENTRE (72-32-23, 01-718). Torque the nuts to 45 lbfin (5.00 Nm).

Put six bolts ENGINE-NO.3 BEARING ROTOR CENTRE (72-32-23, 01-712) with six washers ENGINE-NO.3 BEARING ROTOR CENTRE (72-32-23, 01-713) through the bolt holes from the HP compressor shaft side and hold in position with six nuts ENGINE-NO.3 BEARING ROTOR CENTRE (72-32-23, 01-718). Torque the nuts to 45 lbfin (5.00 Nm).

SUBTASK 72-32-23-440-051 Assemble the Seal Ring Carrier Assembly on to the HP Compressor Front Shaft Assembly

Figure: Assemble the Seal Ring Carrier Assembly on to the HP Compressor Front Shaft Assembly

Assemble the Seal Ring Carrier Assembly on to the HP Compressor Front Shaft Assembly