Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A1

Common Information

TASK 72-32-82-840-002 LPC Blades - Rework The LPC Stage 1.5, 2, And 2.5 Blades, Rework-002 - SBE 72-0017

General

The practices and processes referred to in the procedure by the TASK number are in the SPM.

Refer to the indicated Service Bulletin for specific application requirements.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-076 METHYL ETHYL KETONE | LOCAL | CoMat 01-076 | ||

| CoMat 02-099 LINT-FREE CLOTH | LOCAL | CoMat 02-099 | ||

| CoMat 05-016 GARNET PAPER, 80-GRIT | LOCAL | CoMat 05-016 | ||

| CoMat 05-017 GARNET PAPER, 60 GRIT | LOCAL | CoMat 05-017 | ||

| CoMat 08-013 COLD CURING SILICONE COMPOUND | LOCAL | CoMat 08-013 | ||

| CoMat 08-014 PRIMER, SILICONE ADHESIVE/SEALANT | 0AM53 | CoMat 08-014 |

Spares

NONESafety Requirements

NONEProcedure

Do Step again to degrease and remove contaminants.

Prepare the bonding surface.

SUBTASK 72-32-82-350-066 Prepare the Bonding Surfaces

Refer to the SPM TASK 70-36-02-360-501.

Use the CoMat 08-014 PRIMER, SILICONE ADHESIVE/SEALANT 151, 152, 153 to mating surface on the blades with the brush.

Dry in air for 30 minutes.

NOTE

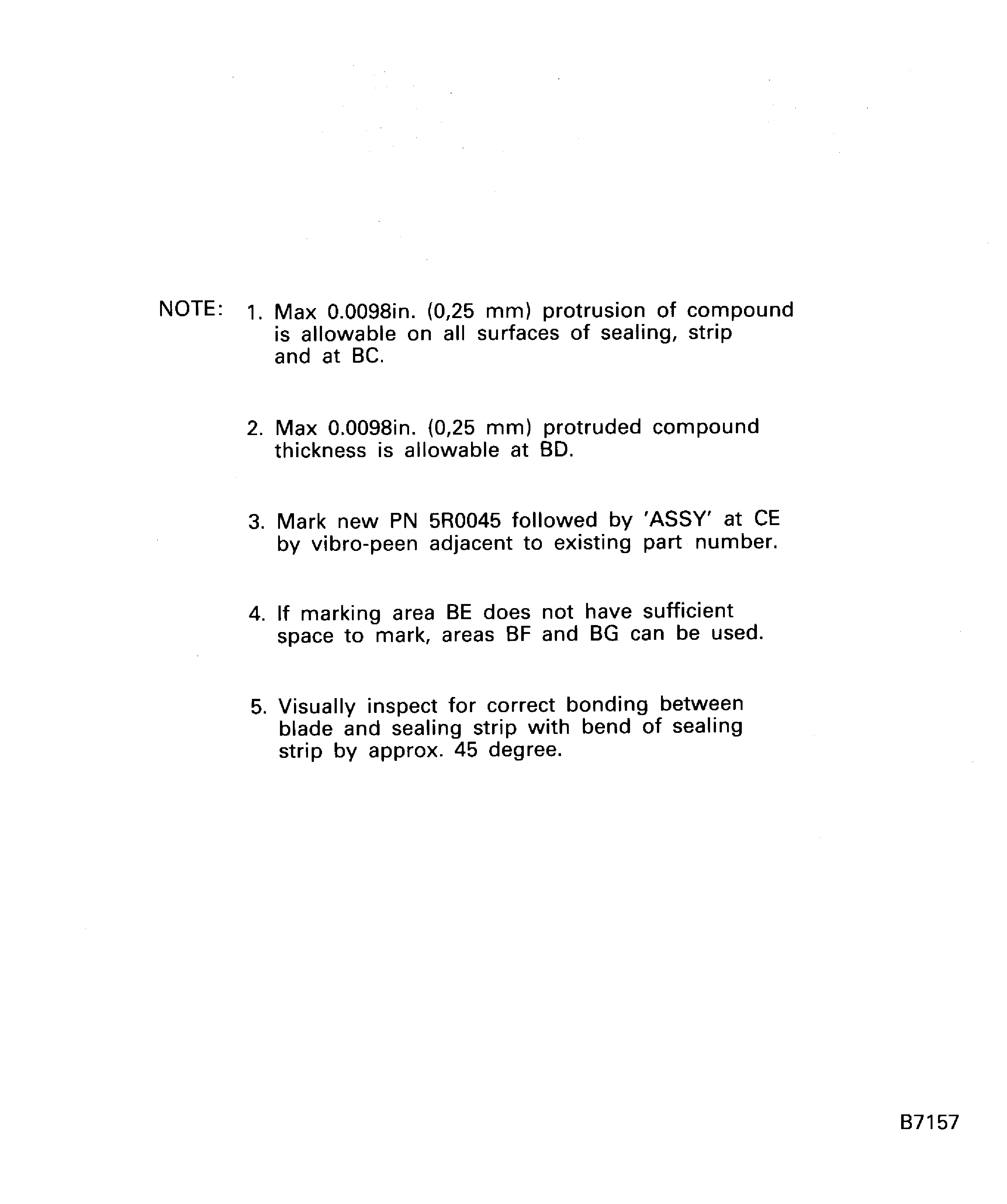

Do not apply the primer on the surface of the sealing strips.NOTE

The primer must be applied immediately, or not longer than 8 hours.Apply the primer to the bonding surface.

SUBTASK 72-32-82-360-053 Apply the Primer to the Bonding Surface

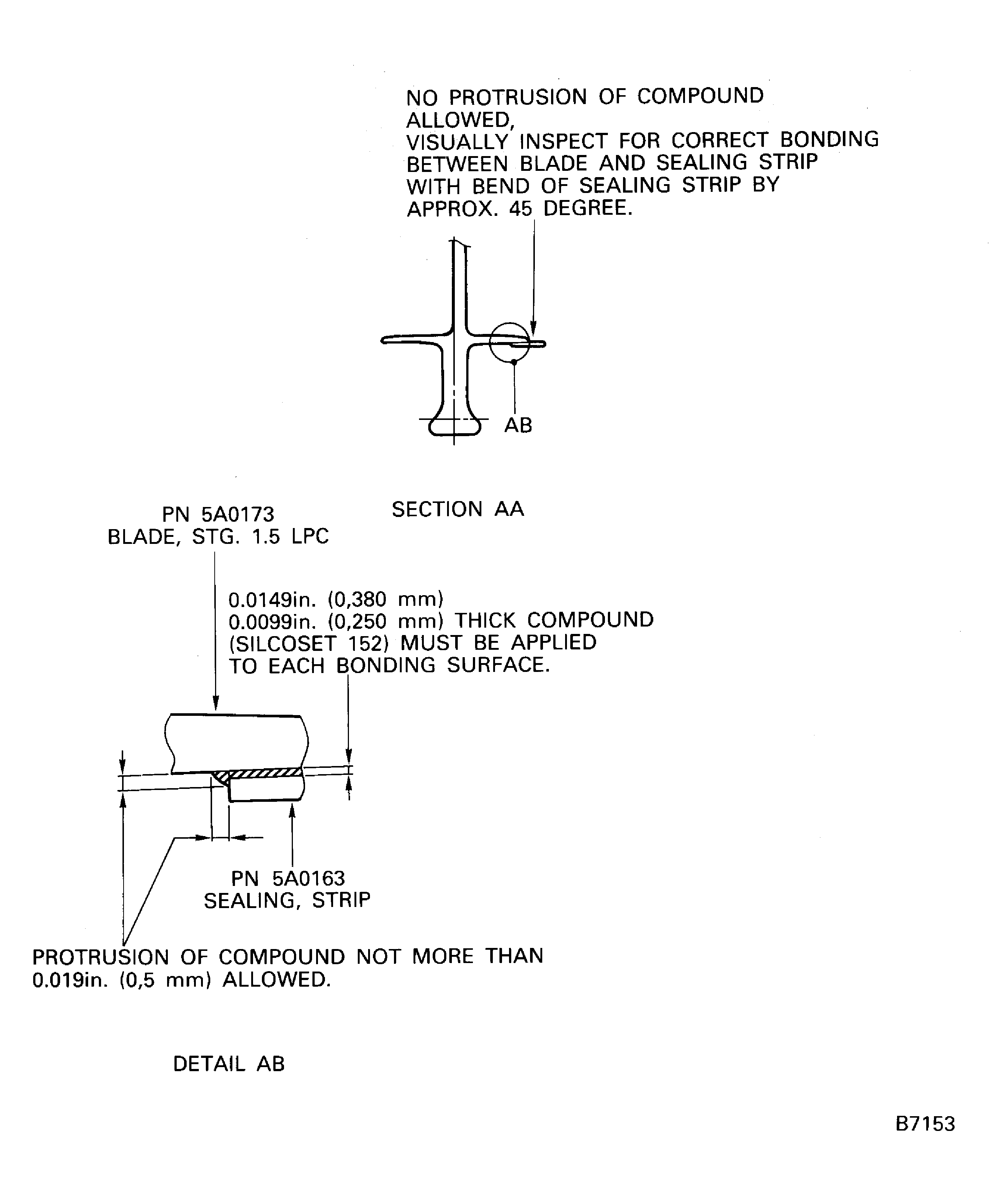

Refer to the SPM TASK 70-36-02-360-501. Use CoMat 08-013 COLD CURING SILICONE COMPOUND.

NOTE

If necessary, clamp the assembly together.The inclusion of air in the bonding surface shall be prevented and the excess compound shall be removed.The parts can be touched after 2 hours.Bond the sealing strips.

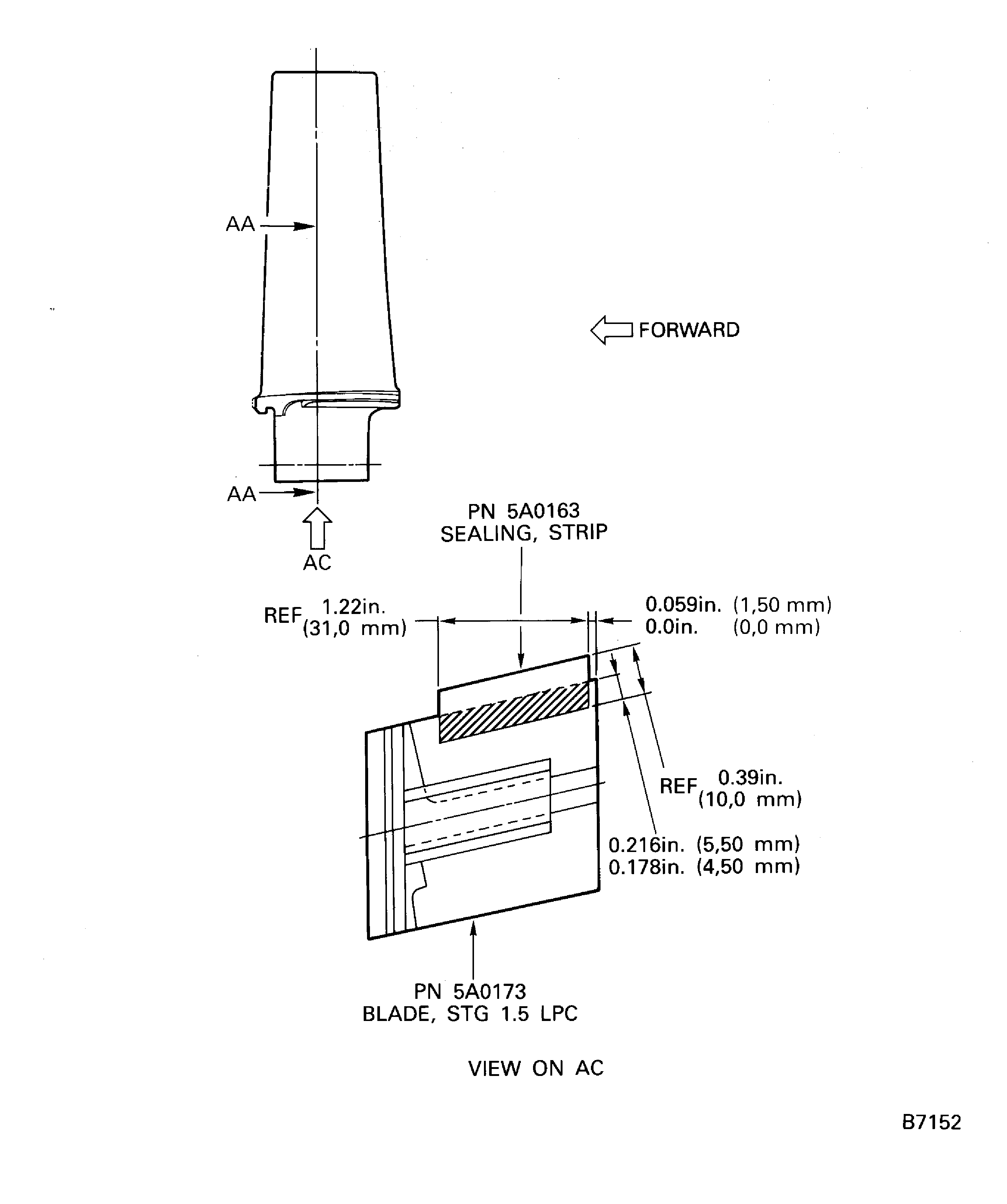

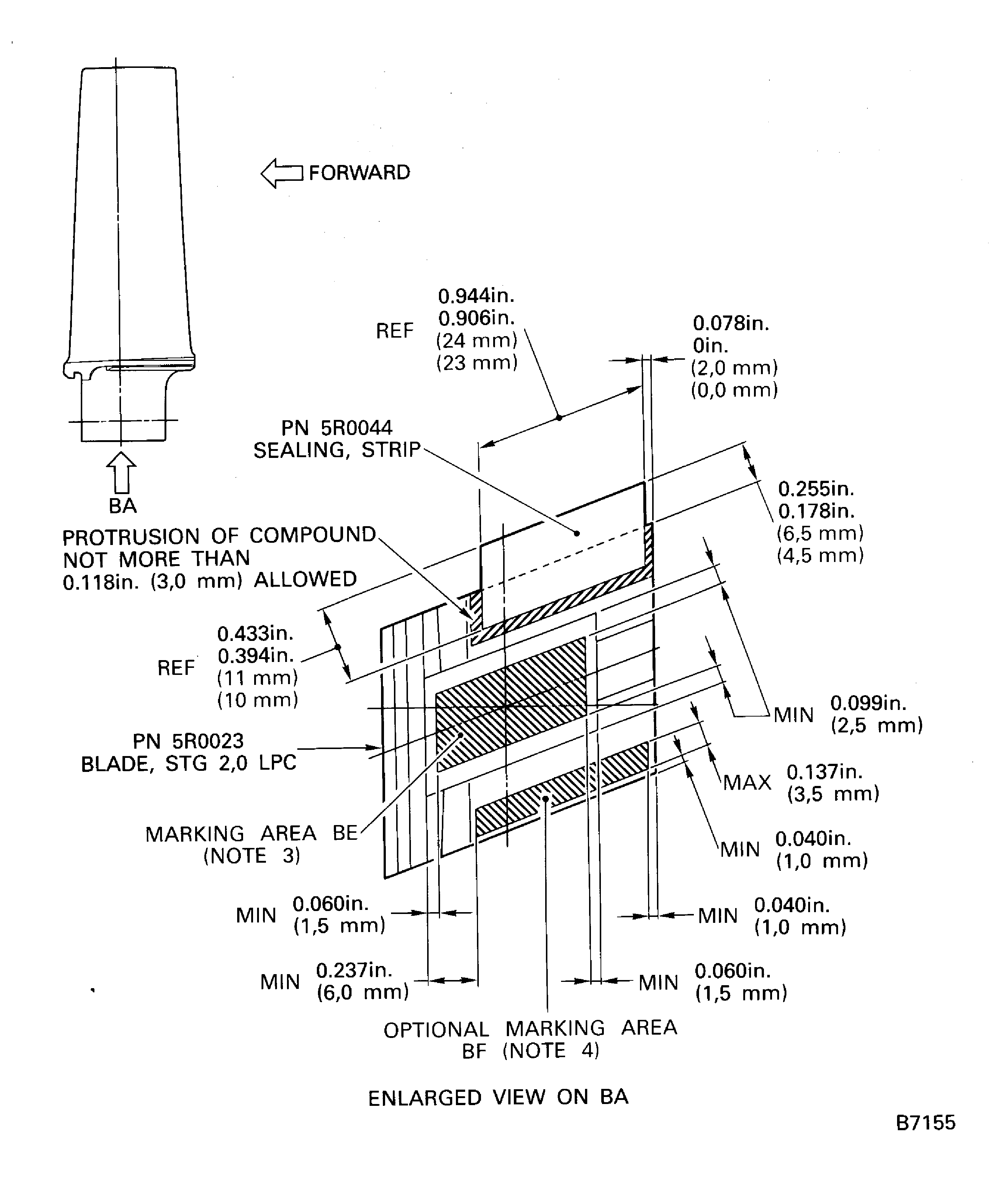

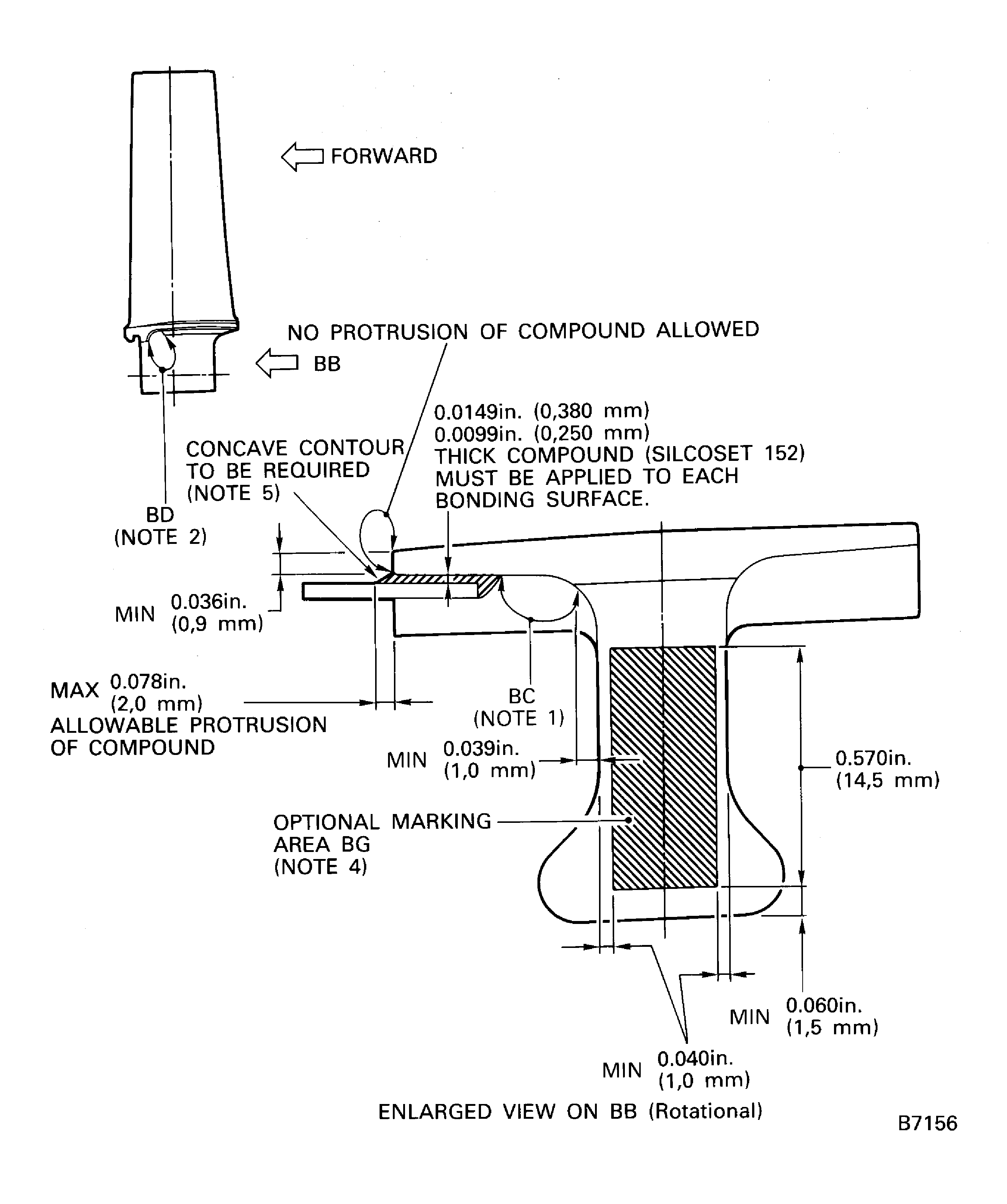

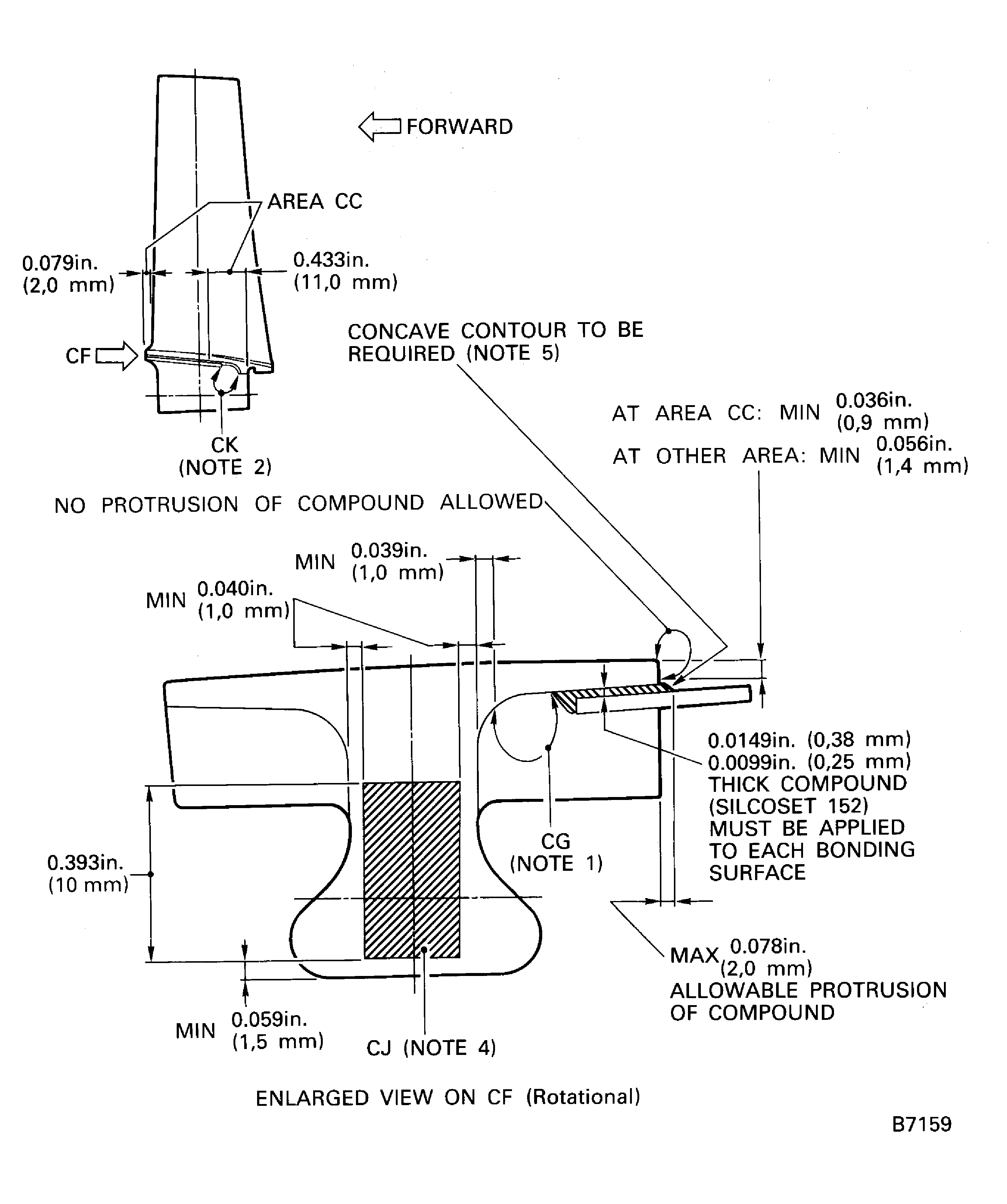

SUBTASK 72-32-82-360-054 Bond the Sealing Strip

Refer to: Figure

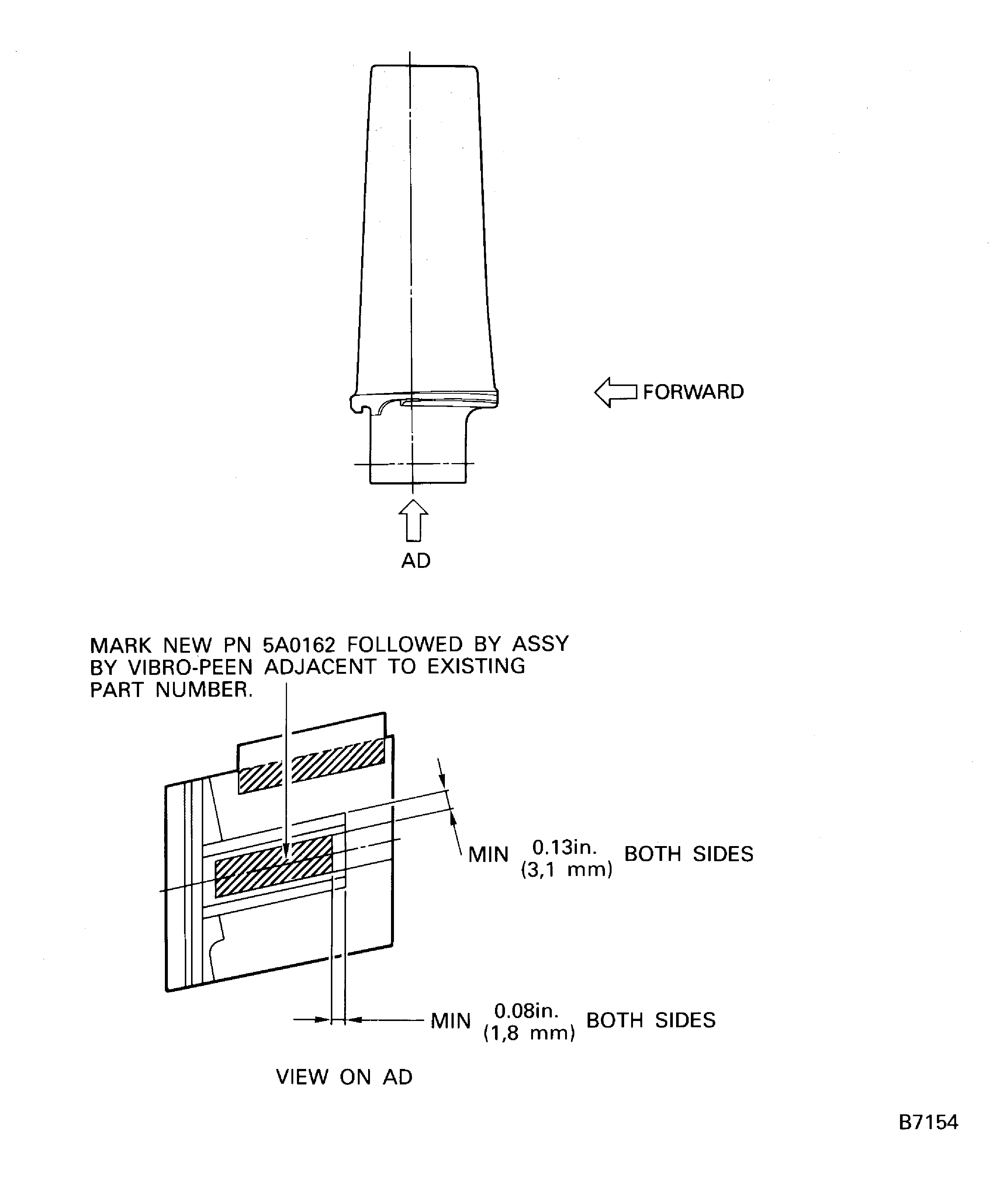

Renumber - Assy 5A0162

Refer to the SPM TASK 70-09-00-400-501.

Renumber with vibro-peen adjacent to each existing part number of the blades, stage 1.5 LPC.

SUBTASK 72-32-82-350-067 Reidentify the 5A0173 Stage 1.5 LPC Blades

Refer to Figure.

Renumber - Assy 5R0043

Refer to the SPM TASK 70-09-00-400-501.

Renumber with vibro-peen adjacent to each existing part number of the blades, Stage 2.0 LPC.

SUBTASK 72-32-82-350-068 Reidentify the 5R0023 Stage 2.0 LPC Blades

Refer to Figure.

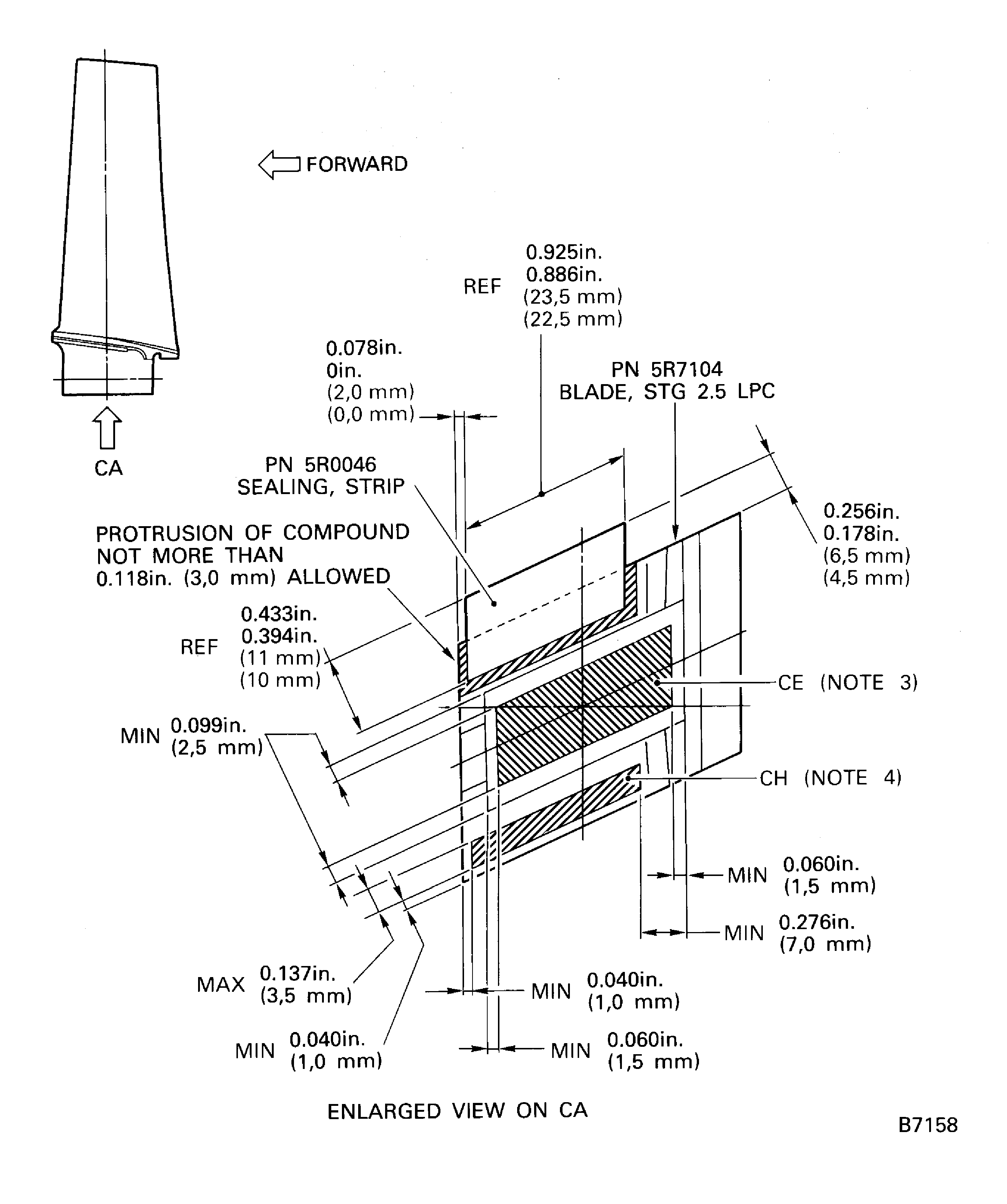

Renumber - Assy 5R0045

Refer to the SPM TASK 70-09-00-400-501.

Renumber with vibro-peen adjacent to each existing part number of the blades, Stage 2.5 LPC.

SUBTASK 72-32-82-350-069 Reidentify the 5R7104 Stage 2.5 LPC Blades

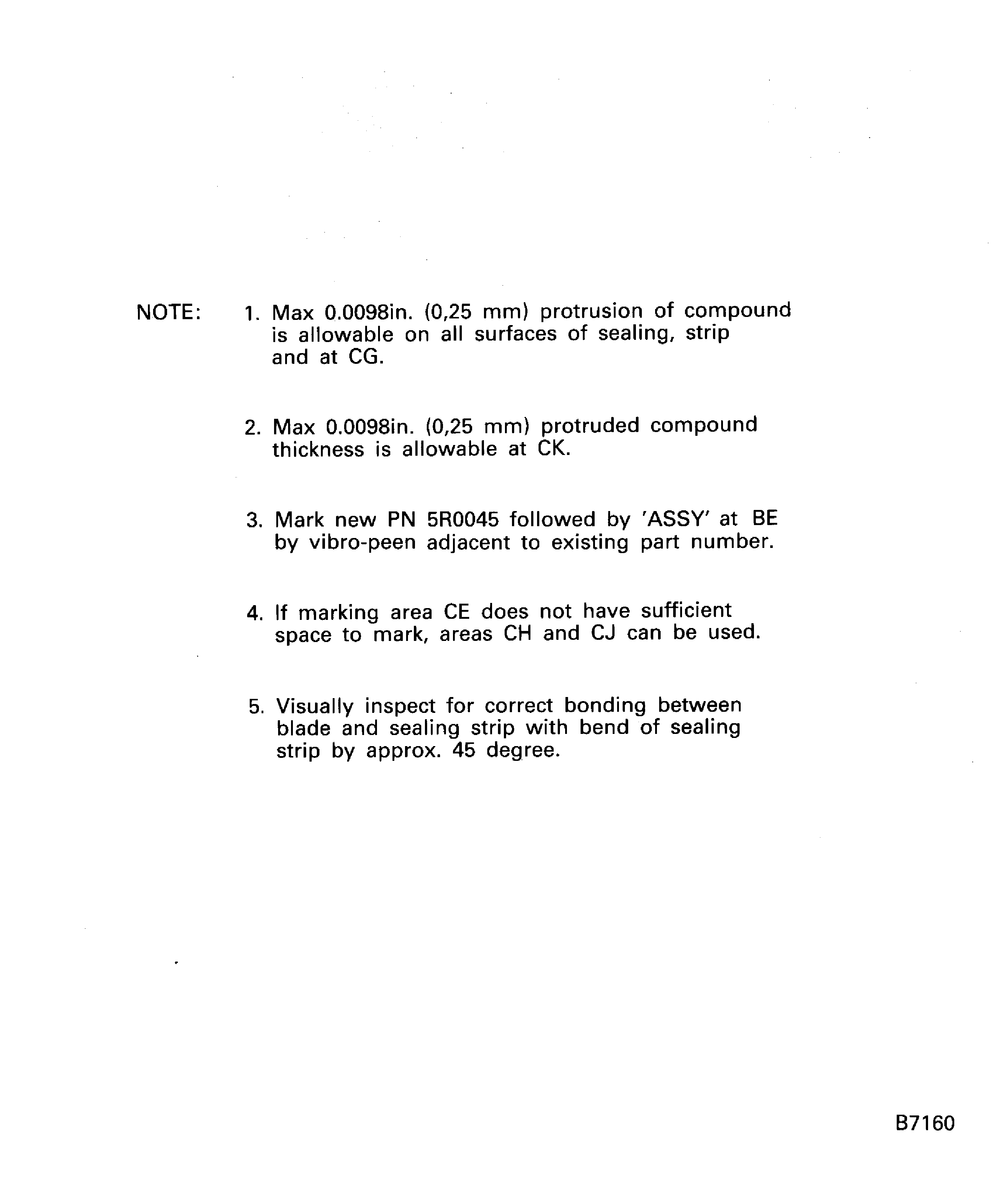

Figure: Rework of the blades, Stage 1.5 LPC

Rework of the blades, Stage 1.5 LPC

Figure: Rework of the blades, Stage 1.5 LPC

Rework of the blades, Stage 1.5 LPC

Figure: Rework of the blades, Stage 1.5 LPC

Rework of the blades, Stage 1.5 LPC

Figure: Rework of the blades, Stage 2.0 LPC

Rework of the blades, Stage 2.0 LPC

Figure: Rework of the blades, Stage 2.0 LPC

Rework of the blades, Stage 2.0 LPC

Figure: Rework of the blades, Stage 2.0 LPC

Rework of the blades, Stage 2.0 LPC

Figure: Rework of the blades, Stage 2.5 LPC

Rework of the blades, Stage 2.5 LPC

Figure: Rework of the blades, Stage 2.5 LPC

Rework of the blades, Stage 2.5 LPC

Figure: Rework of the blades, Stage 2.5 LPC

Rework of the blades, Stage 2.5 LPC