Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A1 and PRE SBE 72-0063

Common Information

TASK 72-50-00-530-001-A00 LP Turbine (LPT) And Turbine Exhaust Case (TEC) Unit - Put The LPT/TEC Unit Into The Shipping Frame, Storage-001 - Pre SBE 72-0063

General

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 1F10036 Removal puller | 0AM53 | IAE 1F10036 | 1 | |

| IAE 1F10052 Two cables sling | 0AM53 | IAE 1F10052 | 1 | |

| IAE 1F10058 Handling fixture | 0AM53 | IAE 1F10058 | 1 | |

| IAE 1F10063 Expanding retainer | 0AM53 | IAE 1F10063 | 1 | |

| IAE 1F10080 Horizontal stand | 0AM53 | IAE 1F10080 | 1 | |

| IAE 1F10084 Support fixture | 0AM53 | IAE 1F10084 | 1 | |

| IAE 1F10107 Protective cover | 0AM53 | IAE 1F10107 | ||

| IAE 5F10125 Shipping equipment | 0AM53 | IAE 5F10125 | ||

| IAE 5F10149 Shipping frame | 0AM53 | IAE 5F10149 | 1 | |

| IAE 1J12221 Impact hammer | 0AM53 | IAE 1J12221 | 1 | |

| IAE 1M14127 Support plate | 0AM53 | IAE 1M14127 | 2 | |

| IAE 1P17038 Slide puller | 0AM53 | IAE 1P17038 | 1 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 12-004 P.V.C. SHEET | LOCAL | CoMat 12-004 | ||

| CoMat 12-022 DESICCANT SELF INDICATING | LOCAL | CoMat 12-022 |

Spares

NONESafety Requirements

NONEProcedure

Refer to Figure.

Loosen and remove the safety parts of the IAE 5F10125 Shipping equipment 1 off.

Install hoist equipment to the upper half of the IAE 5F10125 Shipping equipment.

NOTE

If the handling fixture is installed at the LP turbine module continue with SUBTASK 72-50-00-530-055.

If the No. 5 bearing compartment cover and the turbine blind cap are not installed continue with SUBTASK 72-50-00-530-054.

Lift the upper half of the IAE 5F10125 Shipping equipment and remove it.

SUBTASK 72-50-00-530-051 Open the Shipping Equipment

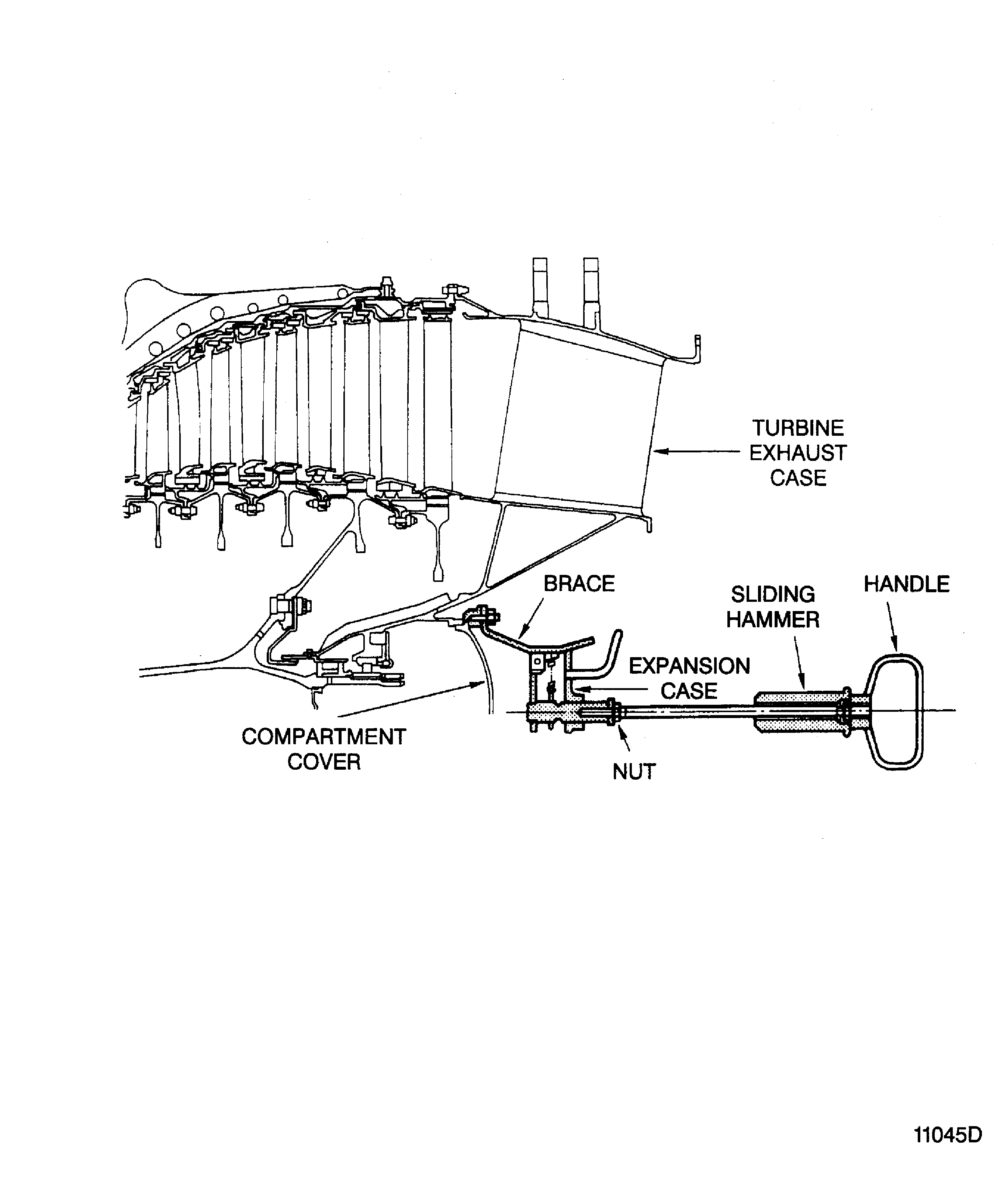

Refer to Figure.

Make sure that the expansion case of the IAE 1F10036 Removal puller 1 off is in the rear position.

Engage the IAE 1F10036 Removal puller onto the compartment cover. Make sure that the three clamps are correctly engaged behind the flange at the compartment cover (see detail A).

Repeat Step until the compartment cover is free from the exhaust case.

SUBTASK 72-50-00-530-052-A00 Remove the No. 5 Bearing Compartment Cover (Pre SBE 72-0173)

NOTE

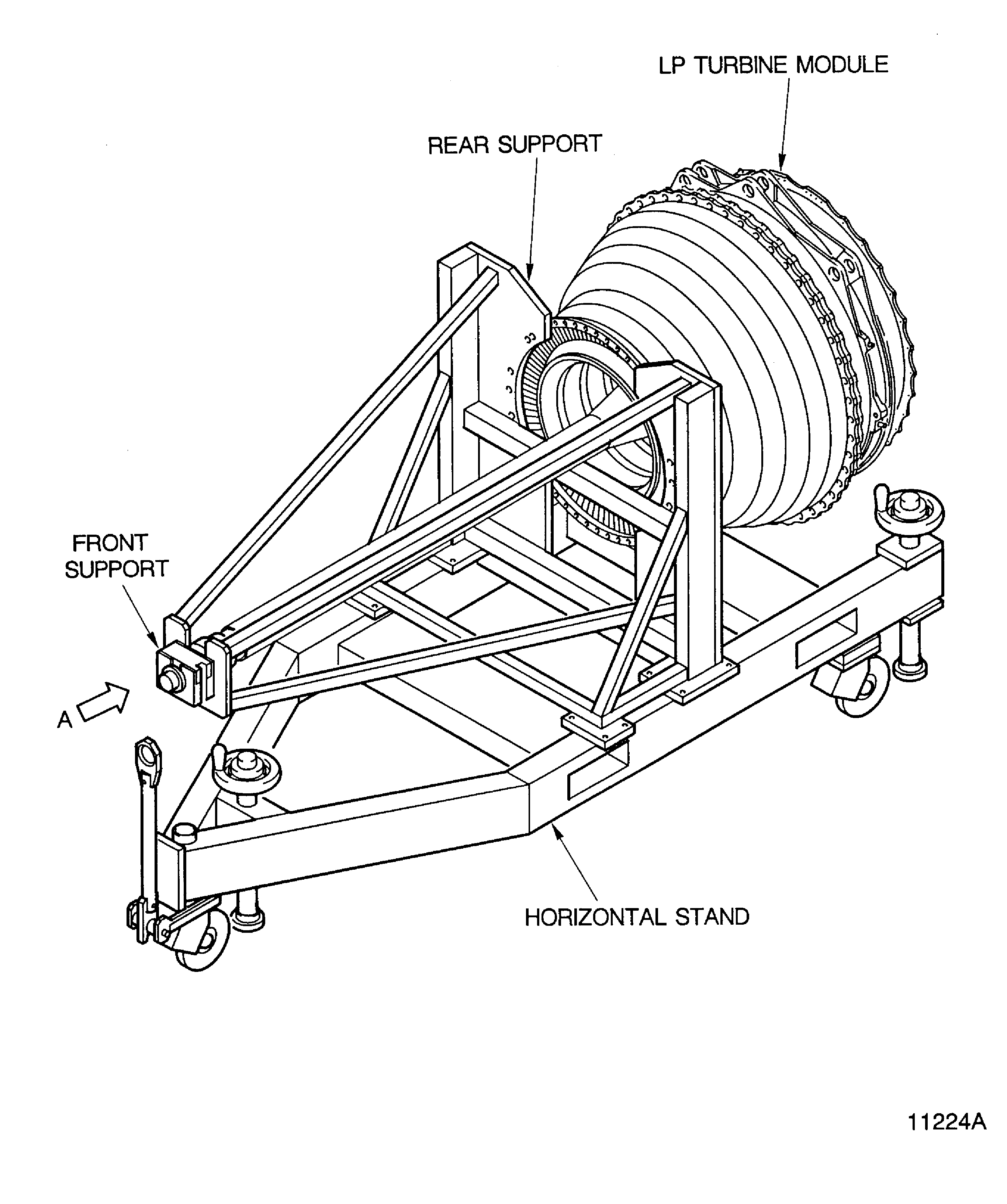

Safety the IAE 1F10080 Horizontal stand 1 off with the three arms. Refer to Figure.Refer to Figure.

SBE 72-0173: Replace the No. 5 bearing rear cover packing with a new improved seal.

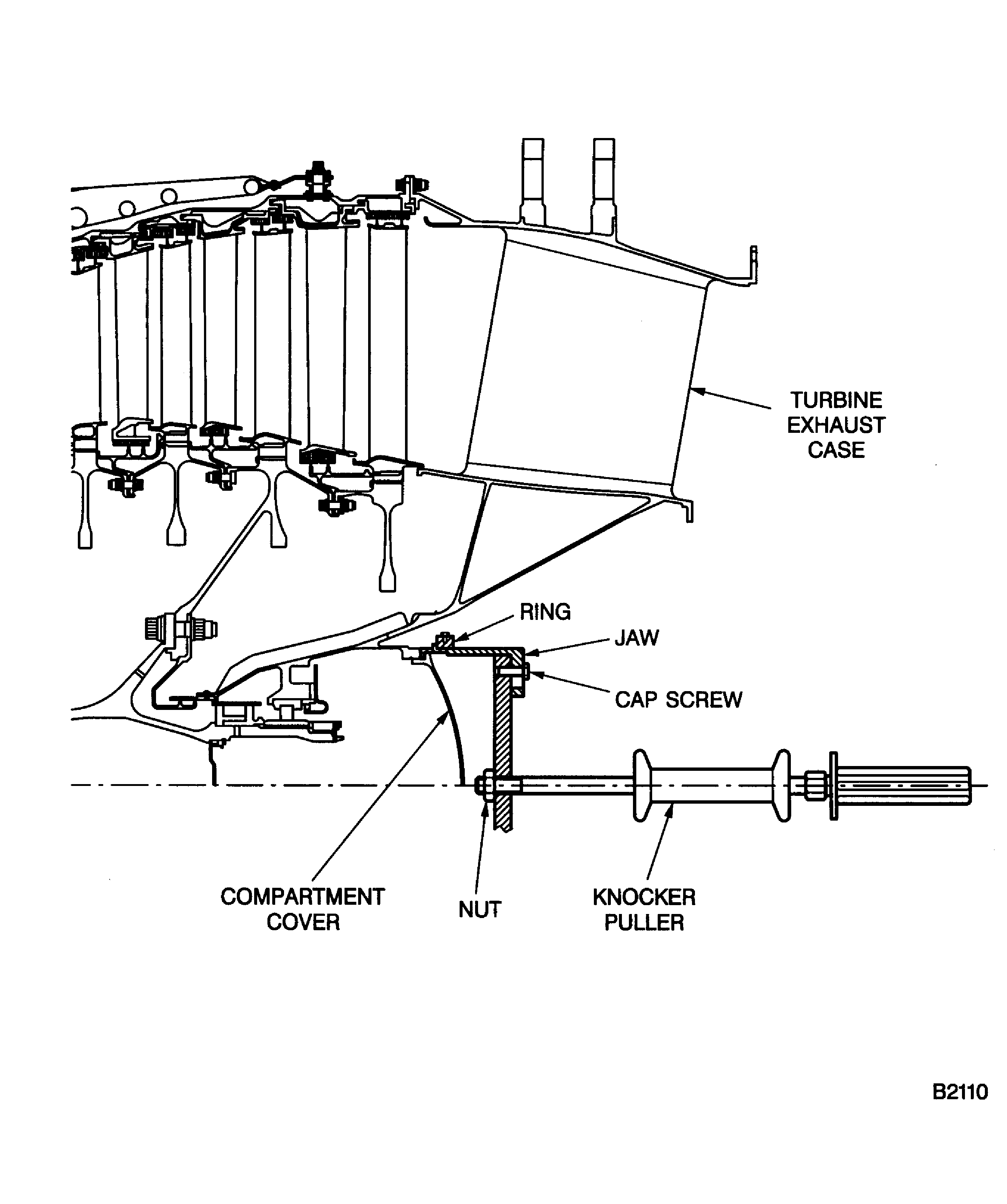

Remove the rear thermal blanket. Make sure that the three jaws of the IAE 1P17038 Slide puller 1 off are in the outward position.

Engage the IAE 1P17038 Slide puller onto the compartment cover. Make sure that the three jaws are correctly engaged behind the flange at the compartment cover.

Slide the ring over the jaws to hold the IAE 1P17038 Slide puller jaws in place.

Repeat Step until the compartment cover is free from the exhaust case.

Remove the ring from the jaws. Move the jaws outwards until the compartment cover is free from the IAE 1P17038 Slide puller.

SUBTASK 72-50-00-530-052-B00 Remove the No. 5 Bearing Compartment Cover (SBE 72-0173)

NOTE

Safety the IAE 1F10080 Horizontal stand 1 off with the three arms. Refer to Figure.Refer to Figure.

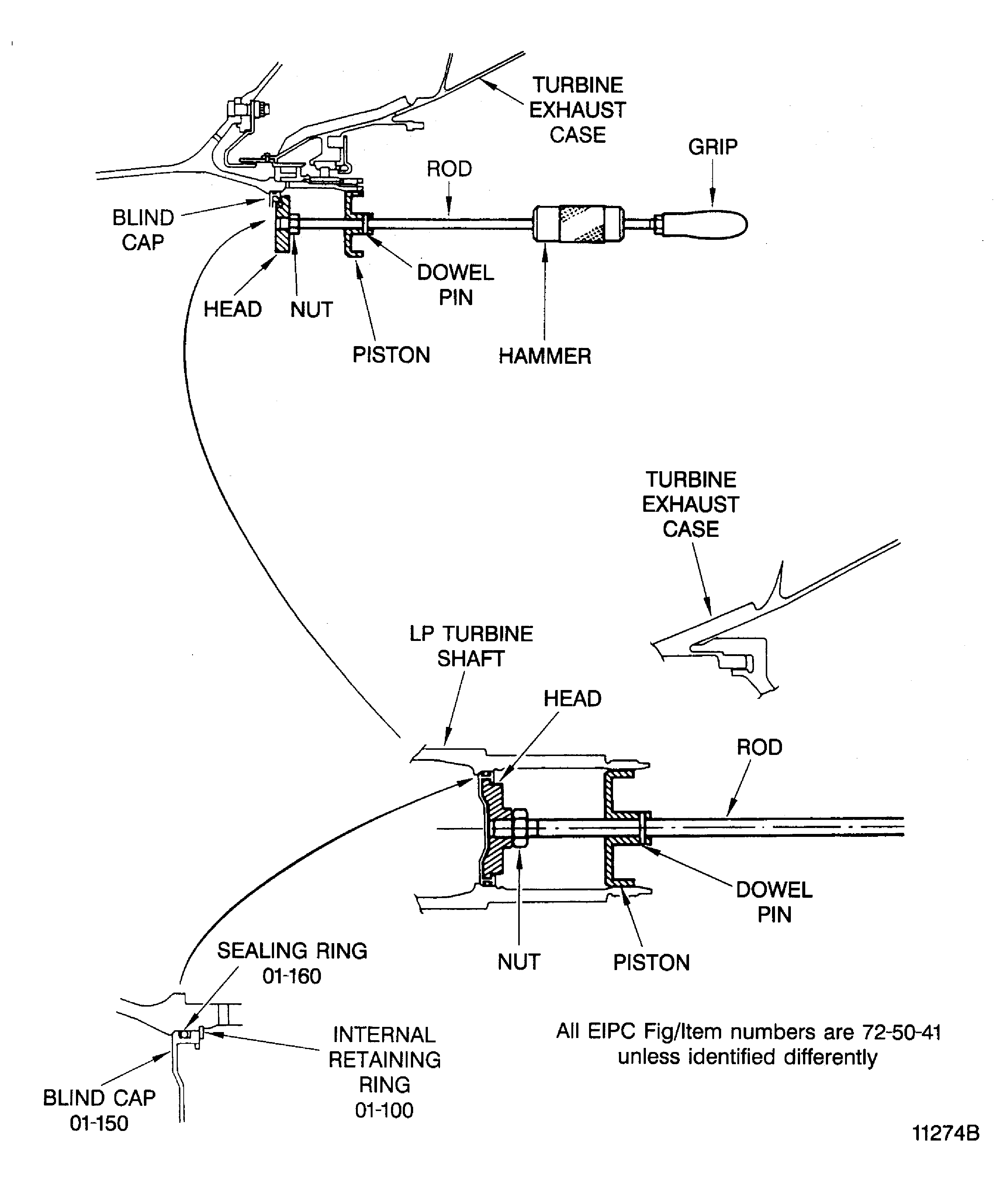

Install IAE 1J12221 Impact hammer 1 off into the LP turbine shaft. Make sure that the piston of the IAE 1J12221 Impact hammer is correctly aligned with the LP turbine shaft.

Move the hammer forward until the head touches the blind cap. Push against the body of the IAE 1J12221 Impact hammer until the jaws engage into the groove of the blind cap.

Repeat Step until the blind cap is free from the LP turbine shaft.

Remove the IAE 1J12221 Impact hammer and the blind cap from the LP turbine shaft.

Release the head of the IAE 1J12221 Impact hammer and remove the blind cap.

SUBTASK 72-50-00-530-053 Remove the Turbine Blind Cap of the LP Turbine Shaft

Refer to Figure.

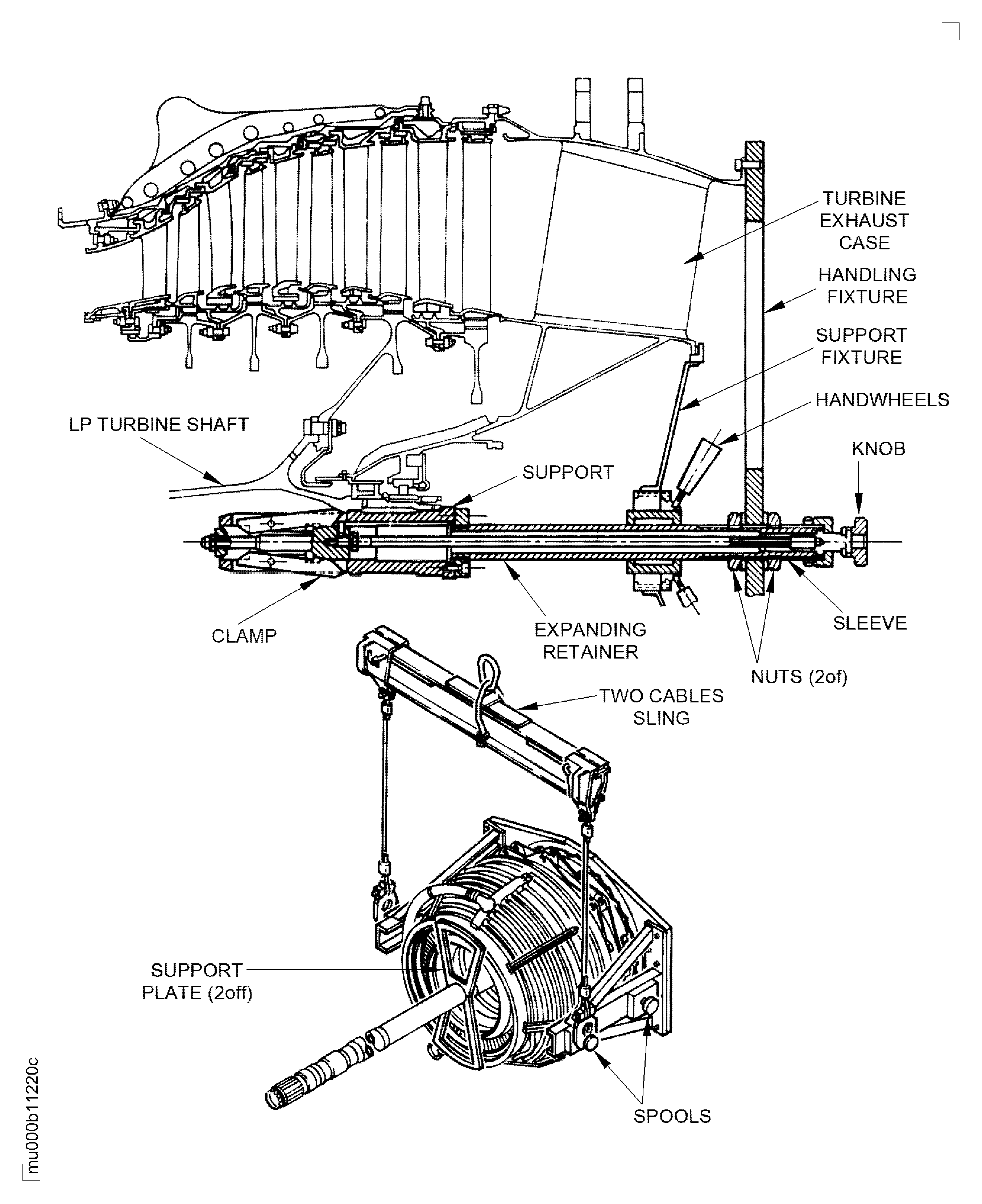

Install the IAE 1F10052 Two cables sling 1 off to the rear spools of the IAE 1F10058 Handling fixture 1 off.

Install the IAE 1F10084 Support fixture 1 off to the IAE 1F10063 Expanding retainer 1 off.

Install the IAE 1F10063 Expanding retainer to the inner diameter of the LP turbine shaft. Attach the IAE 1F10084 Support fixture to the rear inner flange of the turbine exhaust case.

Lift the IAE 1F10058 Handling fixture and install it to the IAE 1F10063 Expanding retainer. Align the IAE 1F10058 Handling fixture with the rear flange of the turbine exhaust case.

Attach the IAE 1F10058 Handling fixture to the rear flange of the turbine exhaust case with 13 screws. Tighten the screws.

Safety the IAE 1F10063 Expanding retainer to the IAE 1F10058 Handling fixture with the two nuts. Tighten the nuts.

CAUTION

MAKE SURE THAT THE NUTS ARE TIGHTENED. IF THE FIXTURES ARE NOT CORRECTLY SECURED THE LP TURBINE CASE AND ROTOR PARTS CAN BE DAMAGED DURING HANDLING OF THE LP TURBINE MODULE.Install the IAE 1F10052 Two cables sling to the front spools of the IAE 1F10058 Handling fixture.

SUBTASK 72-50-00-530-054 Attach the Handling Fixture to the LP Turbine Module

Refer to Figure.

Loosen and remove the seven bolts from each of the IAE 1M14127 Support plate 2 off. Remove the IAE 1M14127 Support plate from the front flange of the LP turbine case and from the LP turbine shaft, refer to Figure.

Install the transportation blanks (part of IAE 5F10125 Shipping equipment) to the LP turbine module.

SUBTASK 72-50-00-530-055 Install the Transportation Blanks to the LP Turbine Module

Refer to Figure.

Attach the IAE 1F10052 Two cables sling 1 off to the front spool of the IAE 1F10058 Handling fixture which is installed at the LP turbine module.

Loosen the nut of the eye bolt (part of the IAE 1F10080 Horizontal stand 1 off).

Loosen and remove the 12 head capscrews which attach the LP turbine module to the rear support of the IAE 1F10080 Horizontal stand.

Move the LP turbine module carefully rearwards, to get it free from the IAE 1F10080 Horizontal stand. Lift the LP turbine module from the IAE 1F10080 Horizontal stand.

Loosen the ringnut C and remove the shaft (part of the IAE 1F10080 Horizontal stand) from the LP turbine shaft.

Install the shaft to the front support of the IAE 1F10080 Horizontal stand. Close the block and safety with the eye bolt and the nut.

Install the shaft which is part of the IAE 5F10149 Shipping frame 1 off to the front end of the LP turbine shaft. Safety the shaft to the LP turbine shaft with the ringnut C.

SUBTASK 72-50-00-530-063 Remove the LP Turbine Module from the Horizontal Stand

Refer to Figure.

Lower the LP turbine module carefully to the front support of the IAE 5F10149 Shipping frame.

Move the LP turbine module slowly down and align the shaft in the front support of the IAE 5F10149 Shipping frame.

Make sure that the LP turbine shaft is correctly aligned to the front support. Align the bolt holes of the LP turbine case front flange with the bolt holes of the IAE 5F10149 Shipping frame.

Attach the LP turbine module with the 28 head capscrews to the IAE 5F10149 Shipping frame. Tighten the capscrews.

Turn the ringnuts A and B to the support to safety the LP turbine module axially to the front support of the IAE 5F10149 Shipping frame. Tighten the ringnuts A and B.

SUBTASK 72-50-00-530-057 Install the LP Turbine Module to the Shipping Equipment

Refer to Figure.

Attach the IAE 1F10052 Two cables sling 1 off to the front spools of the IAE 1F10058 Handling fixture.

Turn the knob (part of IAE 1F10063 Expanding retainer 1 off) clockwise until it is blocked.

Move the IAE 1F10058 Handling fixture carefully 4 in. (101 mm) rearwards until it is free from the turbine exhaust case flange.

Move the hIAE 1F10058 Handling fixture carefully downwards to disengage it from the IAE 1F10063 Expanding retainer.

Lift the IAE 1F10058 Handling fixture carefully away from the LP turbine module and store it.

Remove the IAE 1F10052 Two cables sling from the IAE 1F10058 Handling fixture.

Remove the hoist equipment from the IAE 1F10052 Two cables sling.

Turn the handwheels (part of IAE 1F10084 Support fixture 1 off) clockwise to disengage the support from the rear end of the LP turbine shaft.

Disconnect the bearing protection from the turbine exhaust case rear inner flange. Remove the IAE 1F10084 Support fixture and the retainer.

SUBTASK 72-50-00-530-058 Remove the Handling Fixture from the LP Turbine Module

Put the blind cap and the internal retaining ring of the LP turbine module into a bag of the IAE 5F10125 Shipping equipment.

Put the eight bolts of the compartment cover into a bag of the IAE 5F10125 Shipping equipment.

Install the IAE 1F10107 Protective cover 1 off to the rear flange of the LP turbine module.

SUBTASK 72-50-00-530-059 Install the Compartment Cover Temporarily

CAUTION

MAKE SURE THAT THE DESICCANT BAGS WILL NOT BE DAMAGED OR RUPTURED. IF PARTICLES OF DESICCANT ENTER THE LP TURBINE MODULE, REMOVE THE LP TURBINE MODULE FROM THE SHIPPING FRAME. DISASSEMBLE THE LP TURBINE MODULE AS FAR AS NECESSARY TO REMOVE ALL DESICCANT PARTICLES COMPLETELY (REFER TO TASK 72-50-00-030-001-A00 AND TASK 72-50-10-030-007-A00).Put the necessary quantity of CoMat 12-022 DESICCANT SELF INDICATING into the MVP bag of the IAE 5F10125 Shipping equipment.

SUBTASK 72-50-00-530-060 Put the Desiccant in to the MVP Bag

Put the engine documentation into a CoMat 12-004 P.V.C. SHEET.

Put the CoMat 12-004 P.V.C. SHEET into the MVP bag of the IAE 5F10125 Shipping equipment.

SUBTASK 72-50-00-530-061 Put the Engine Documentation in to the Shipping Equipment

Refer to Figure.

Install hoist equipment to the upper half of the IAE 5F10125 Shipping equipment.

Install the upper half of the IAE 5F10125 Shipping equipment to the lower half.

Safety the two halves of the IAE 5F10125 Shipping equipment with the attaching parts.

SUBTASK 72-50-00-530-062 Close the Shipping Equipment

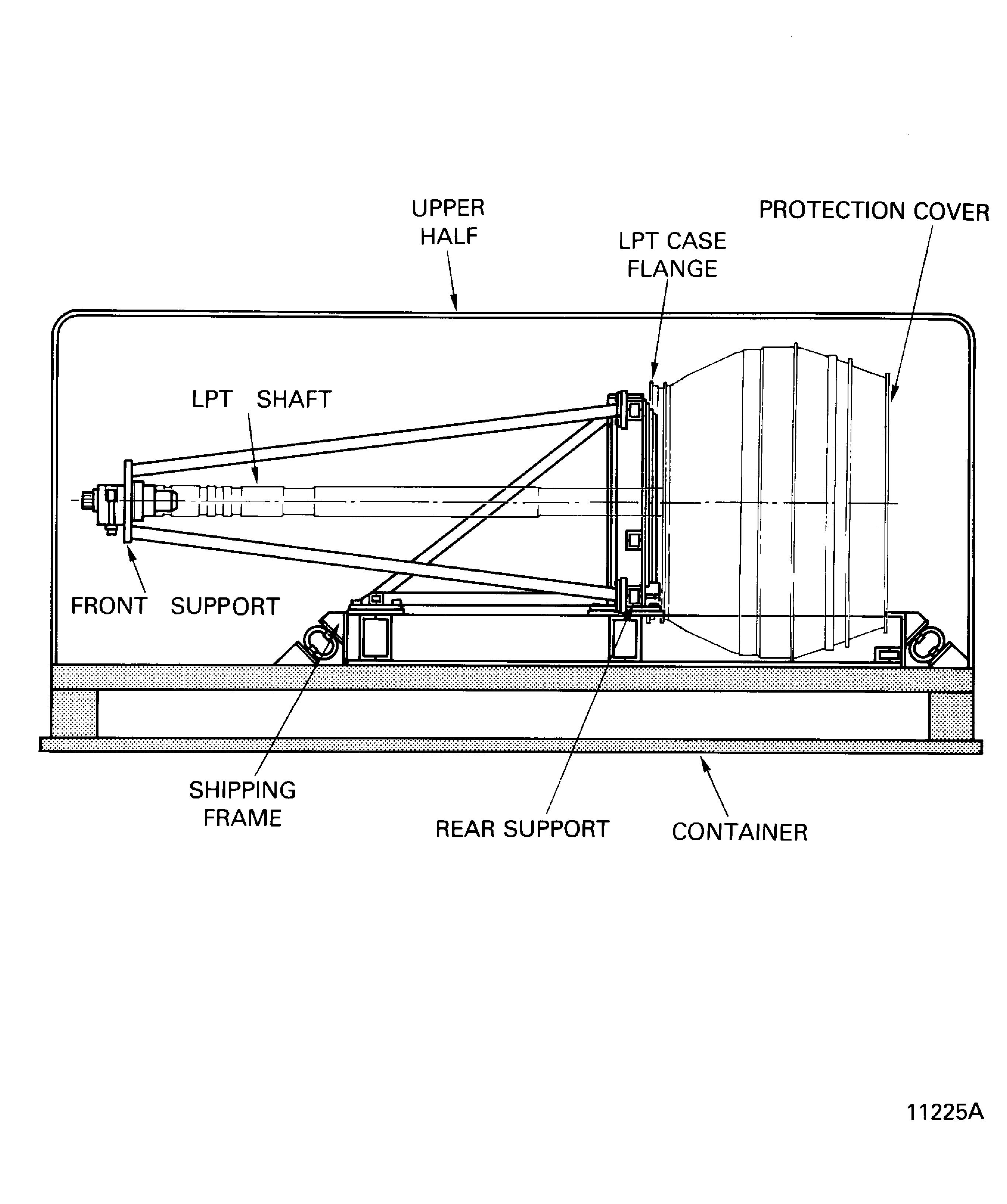

Figure: Open the shipping equipment

Open the shipping equipment

Figure: Pre SBE 72-0173 Remove the No. 5 bearing compartment cover

Sheet 1

Figure: SBE 72-0173 Remove the No. 5 bearing compartment cover

Sheet 2

Figure: Attach the handling fixture and the expanding retainer

Attach the handling fixture and the expanding retainer

Figure: Remove the blind cap of the LP turbine shaft

Remove the blind cap of the LP turbine shaft

Figure: Remove the LP turbine module from the horizontal stand

Remove the LP turbine module from the horizontal stand

Figure: Remove the LP turbine module from the horizontal stand

Remove the LP turbine module from the horizontal stand