Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A1

Common Information

TASK 72-50-10-430-001-A00 LPT Case And Rotor Assembly - Assemble The LPT Stage 3 Stator Vanes And Diffuser Outer Segments, Assembly-001

General

Fig/item numbers in parentheses in the procedure agree with those used in the IPC. Only the primary Fig/item numbers are used. For the service bulletin alpha variants refer to the IPC.

For all parts identified in a different Chapter/Section/Subject, the applicable Chapter/Section/Subject comes before the Fig/item number.

For standard torque data and procedures, refer to the SPM TASK 70-41-01-400-501 and SPM TASK 70-41-02-400-501.

Special torque data and assembly tolerances are included in the procedure.

Lubricate all threads and abutment faces of nuts and bolts with CoMat 10-129 ANTI-SEIZE PASTEA anti-seize paste unless other lubricants are referred to in the procedure.

To identify, lubricate and install seal rings, refer to SPM TASK 70-44-01-400-501.

After assembly apply CoMat 07-038 AIR DRYING ENAMEL to any damaged surface protection, joint flanges and attach parts. Use the correct color of the air drying enamel. Refer to SPM TASK 70-63-02-630-501.

The number for each radial location must be identified in a clockwise direction. These start at the engine top position when you look from the rear of the engine, unless stated differently in the procedure.

NOTE

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| IAE 1F10052 Two cables sling | 0AM53 | IAE 1F10052 | 1 | |

| IAE 1M14031 Assembly stand | 0AM53 | IAE 1M14031 | 1 | |

| IAE 1M14032 Mounting plate | 0AM53 | IAE 1M14032 | 1 | |

| IAE 1M14035 Lifting fixture | 0AM53 | IAE 1M14035 | 1 | |

| IAE 1M14036 Assembly fixture | 0AM53 | IAE 1M14036 | 1 | |

| IAE 1M14037 Assembly plate | 0AM53 | IAE 1M14037 | 1 | |

| IAE 1M14038 Retaining block | 0AM53 | IAE 1M14038 | 29 | |

| IAE 1M14039 Lifting bracket | 0AM53 | IAE 1M14039 | 2 | |

| IAE 1M14040 Guide pin | 0AM53 | IAE 1M14040 | 2 |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-119 LOCKWIRE | 0AM53 | CoMat 02-119 | ||

| CoMat 07-038 AIR DRYING ENAMEL | K3504 | CoMat 07-038 | ||

| CoMat 10-062 ASSEMBLY FLUID | 0AM53 | CoMat 10-062 | ||

| CoMat 10-129A ANTI-SEIZE PASTE | 71984 | CoMat 10-129A | ||

| CoMat 10-129 ANTI-SEIZE PASTE | 34568 | CoMat 10-129 |

Spares

NONESafety Requirements

WARNING

Procedure

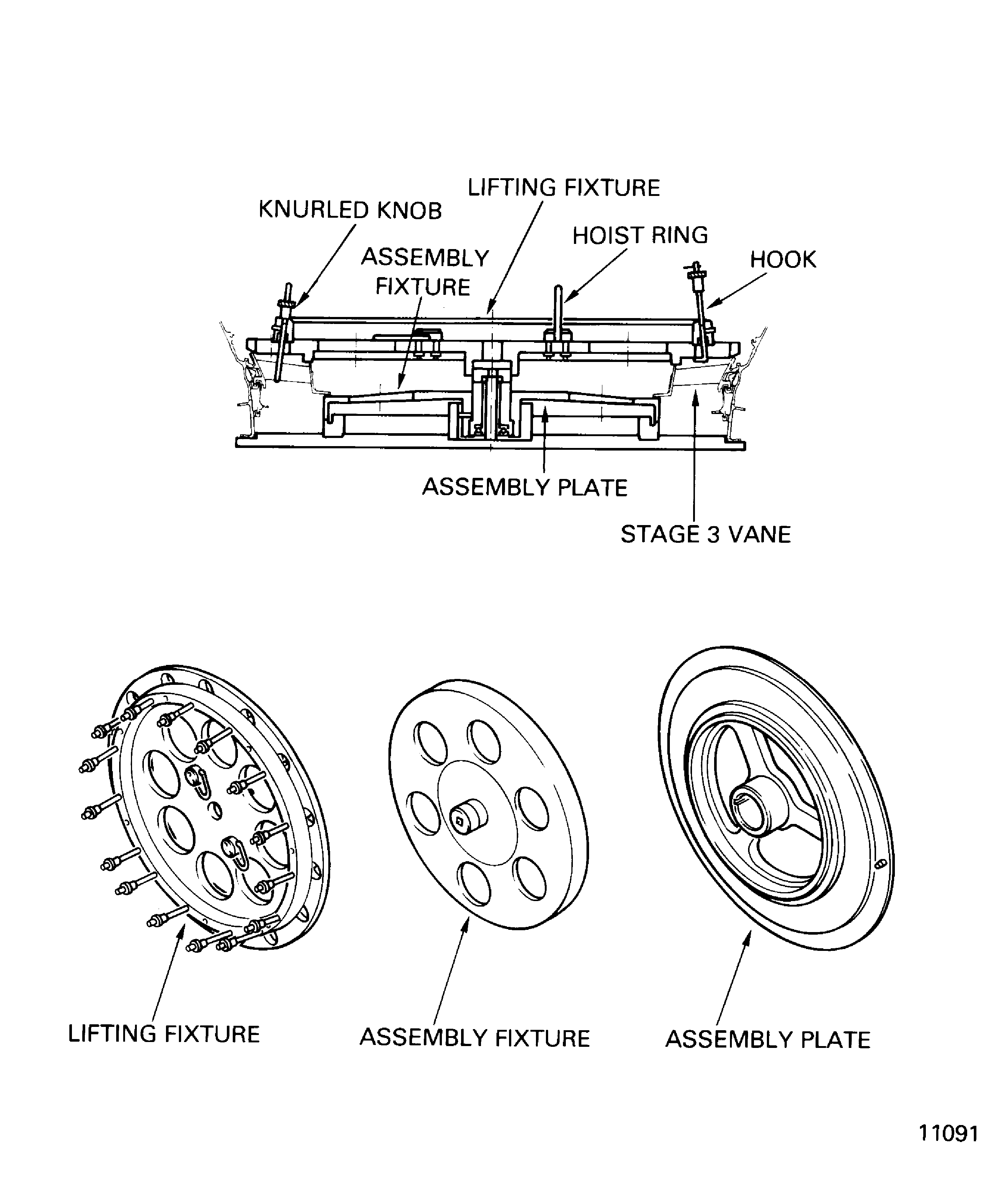

Put the IAE 1M14037 Assembly plate 1 off in the center of the IAE 1M14031 Assembly stand 1 off.

SUBTASK 72-50-10-430-051 Install the Assembly Plate on the Assembly Stand

Refer to Figure.

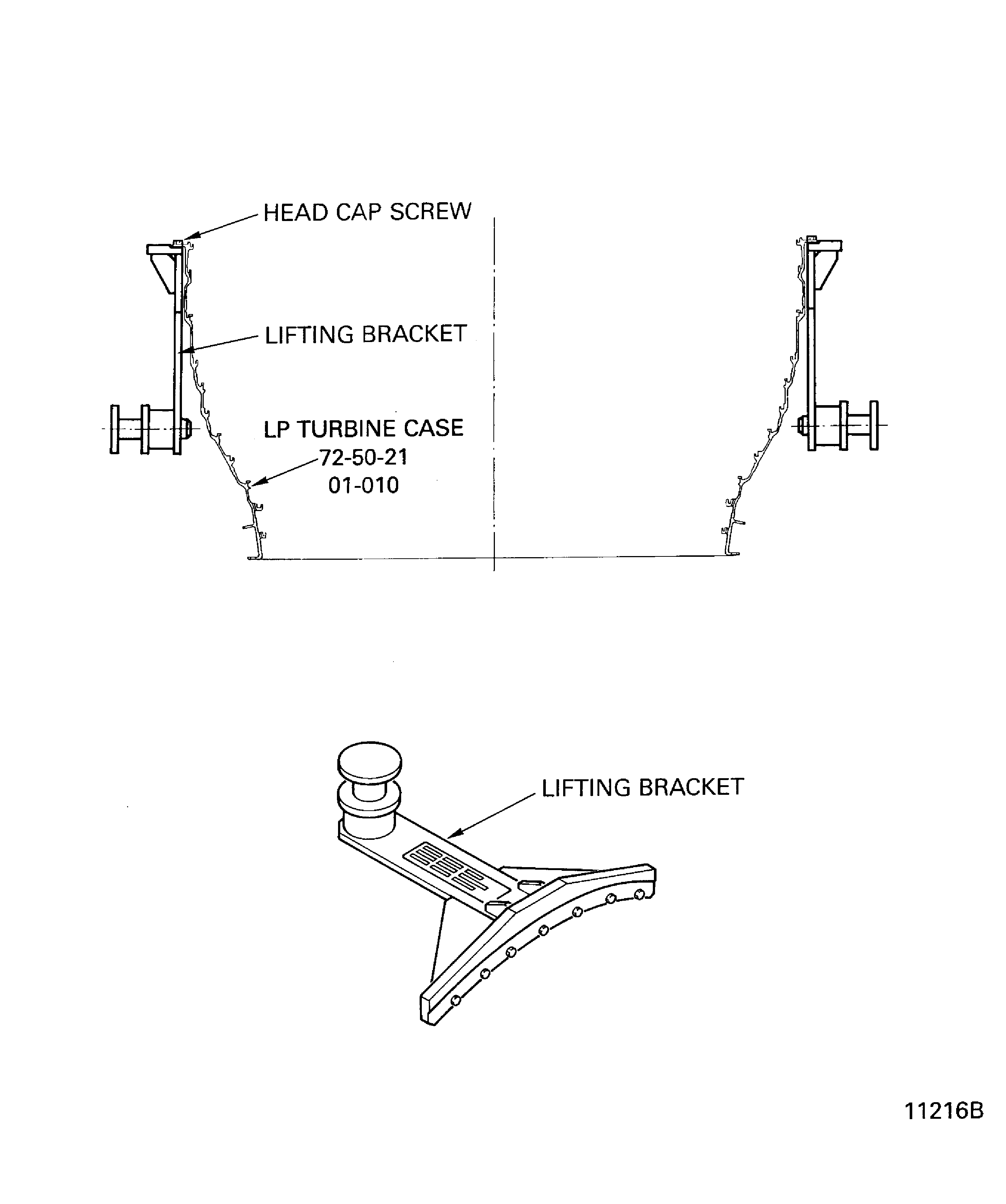

Attach the IAE 1M14039 Lifting bracket 2 off at the rear flange of the LP turbine case with the seven screws.

Use hoist equipment. Install the IAE 1F10052 Two cables sling 1 off to the lifting brackets.

SUBTASK 72-50-10-430-052 Lift the LP Turbine Case on to the Assembly Plate

Refer to Figure.

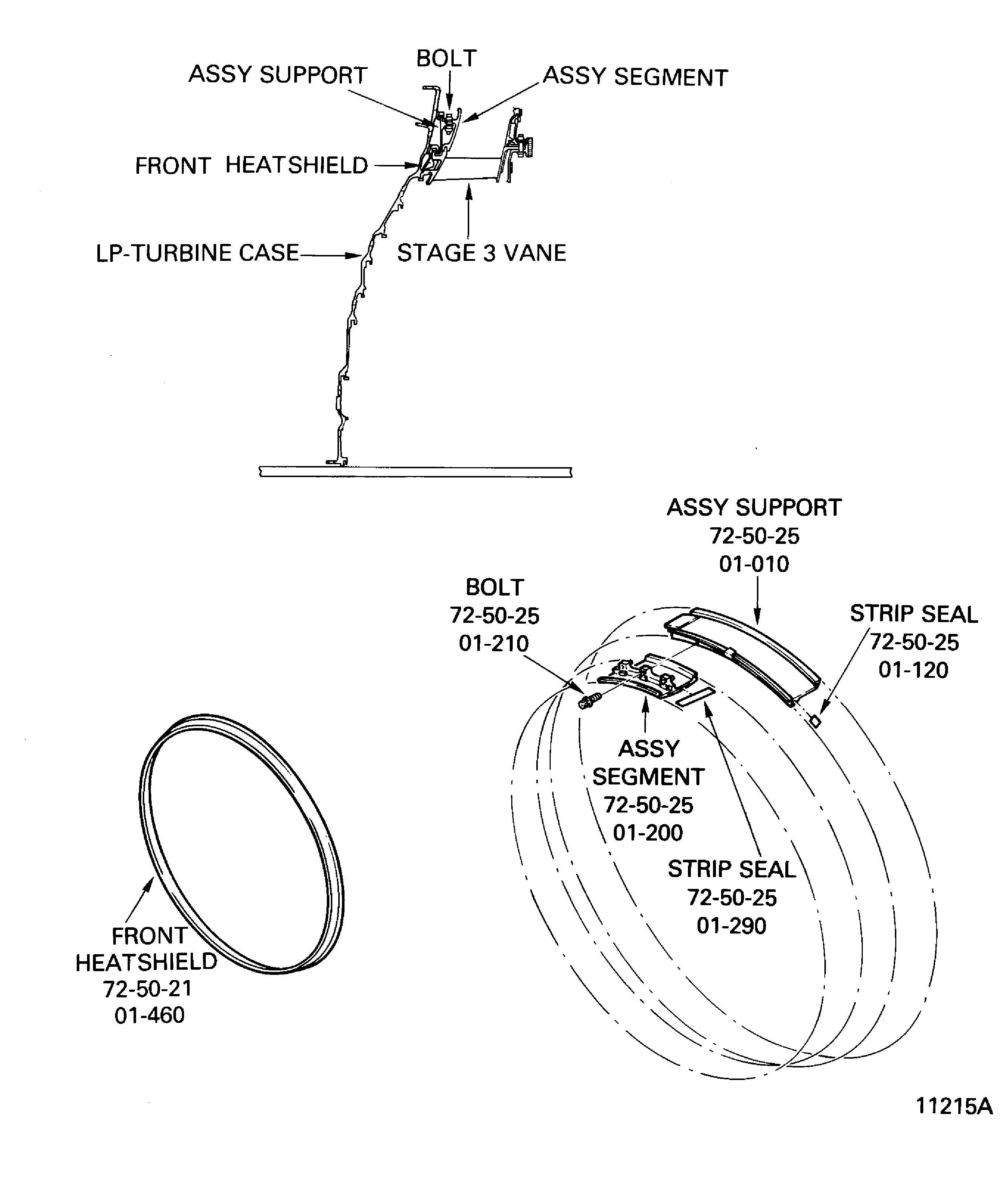

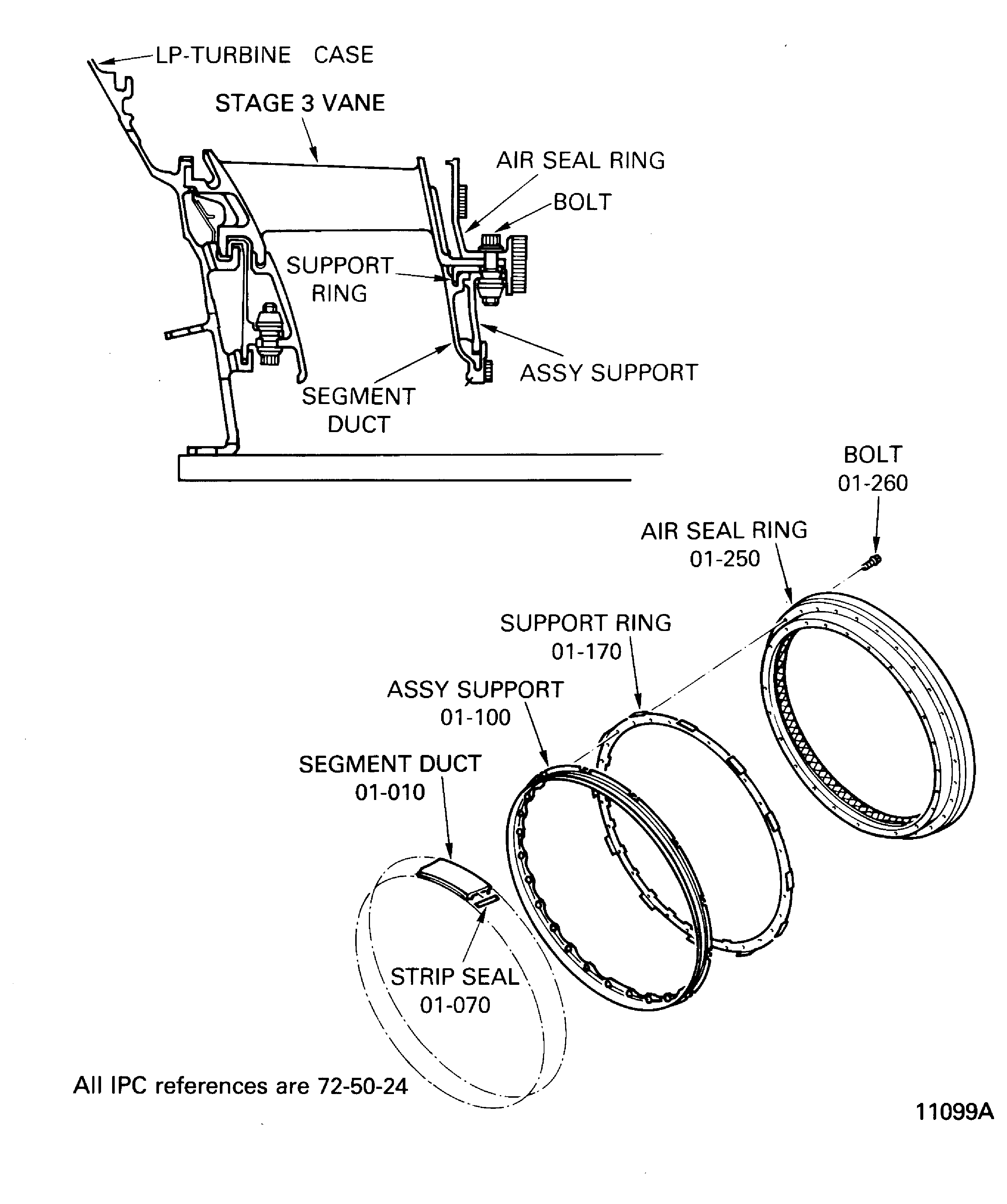

Install the eight strip seals to the eight diffuser outer duct assembly supports. Use the CoMat 10-062 ASSEMBLY FLUID.

SUBTASK 72-50-10-430-053 Install the Diffuser Outer Duct Assembly Support

Refer to Figure.

SUBTASK 72-50-10-430-054 Install the Stage 3 Front Heatshield

Refer to Figure.

Check each stage 3 vane segment for total number of "+" markings on the part.

NOTE

The total number of vane segments which show each two "+" markings is limited to five parts per LPT module assembly. Make sure that not more than five vane segments each marked with two "+" symbols are installed per LPT module assembly.NOTE

Make sure that all the strip seals are correctly installed in the grooves of the stage 3 vane segments.Install the five strip seals in the right grooves of the inner and outer platform of all the vane segments. Use CoMat 10-062 ASSEMBLY FLUID.

NOTE

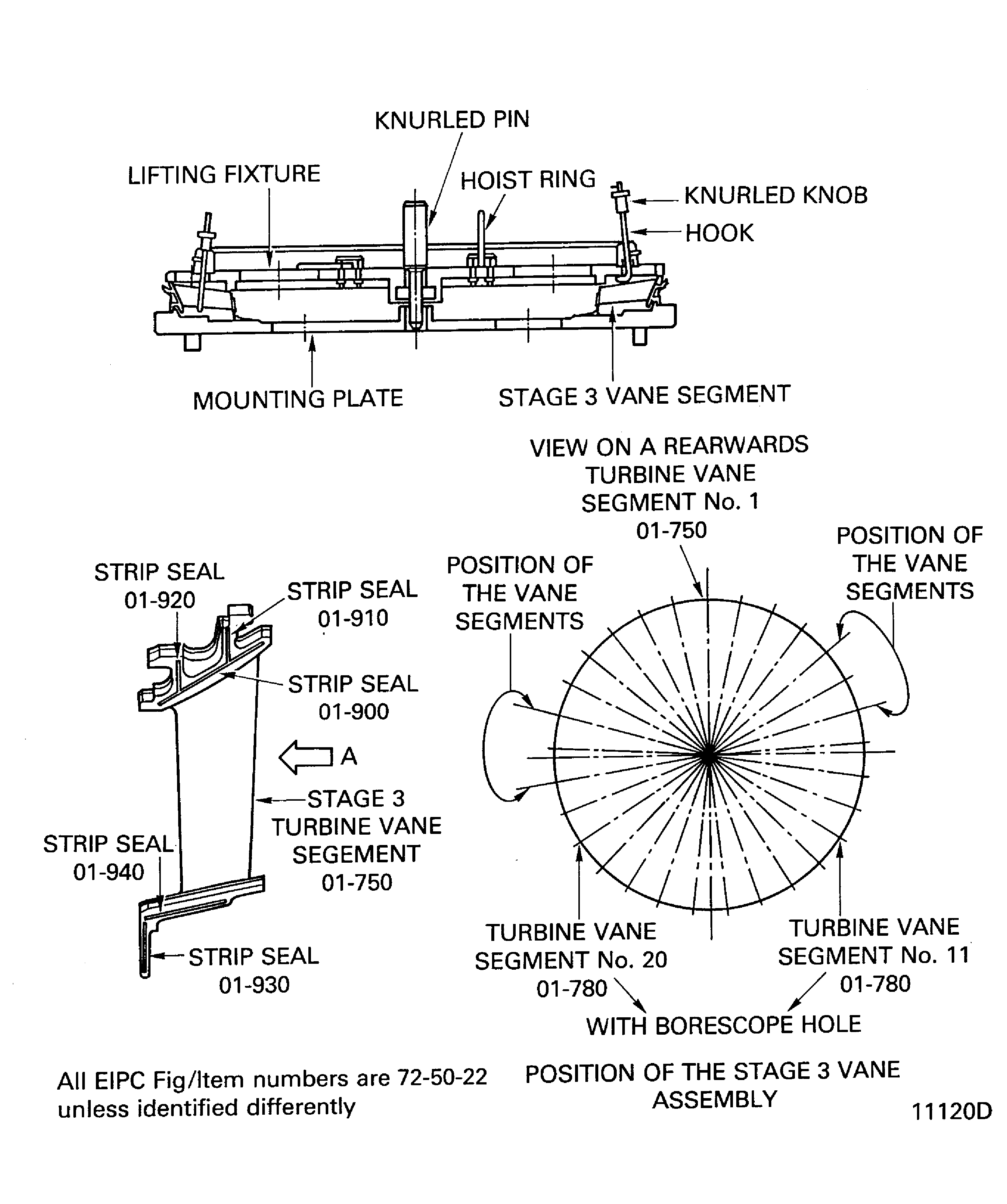

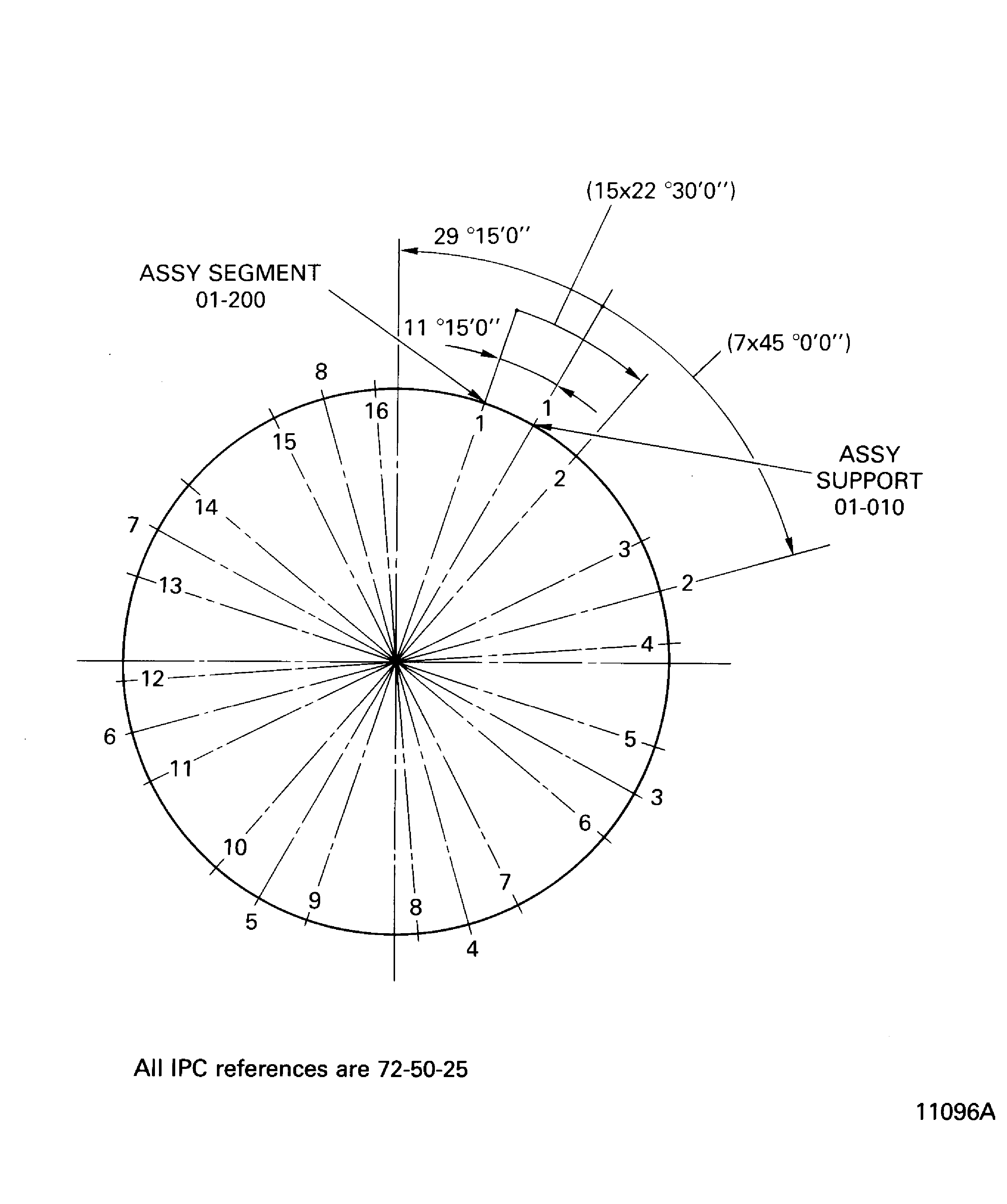

Put the vane segments on to the mounting plate in the accurate sequence. Make sure that the vane segments with the borescope hole are in the position shown on the mounting plate.Put the vane segments on to the IAE 1M14032 Mounting plate 1 off. Engage the outer front groove of the vane segments with the annular flange of the mounting plate.

SUBTASK 72-50-10-430-055 Prepare the Stage 3 Vanes for Assembly

Refer to Figure.

Install the IAE 1M14036 Assembly fixture 1 off on to the assembly plate. Make sure that the dowel pin is in the guide slot in the center hole of the assembly plate. Turn the assembly fixture counterclockwise until the outer front flange touches the assembly plate.

SUBTASK 72-50-10-430-056 Install the Assembly Fixture on to the Assembly Plate

Lift the IAE 1M14035 Lifting fixture 1 off above the stage 3 vane assembly.

CAUTION

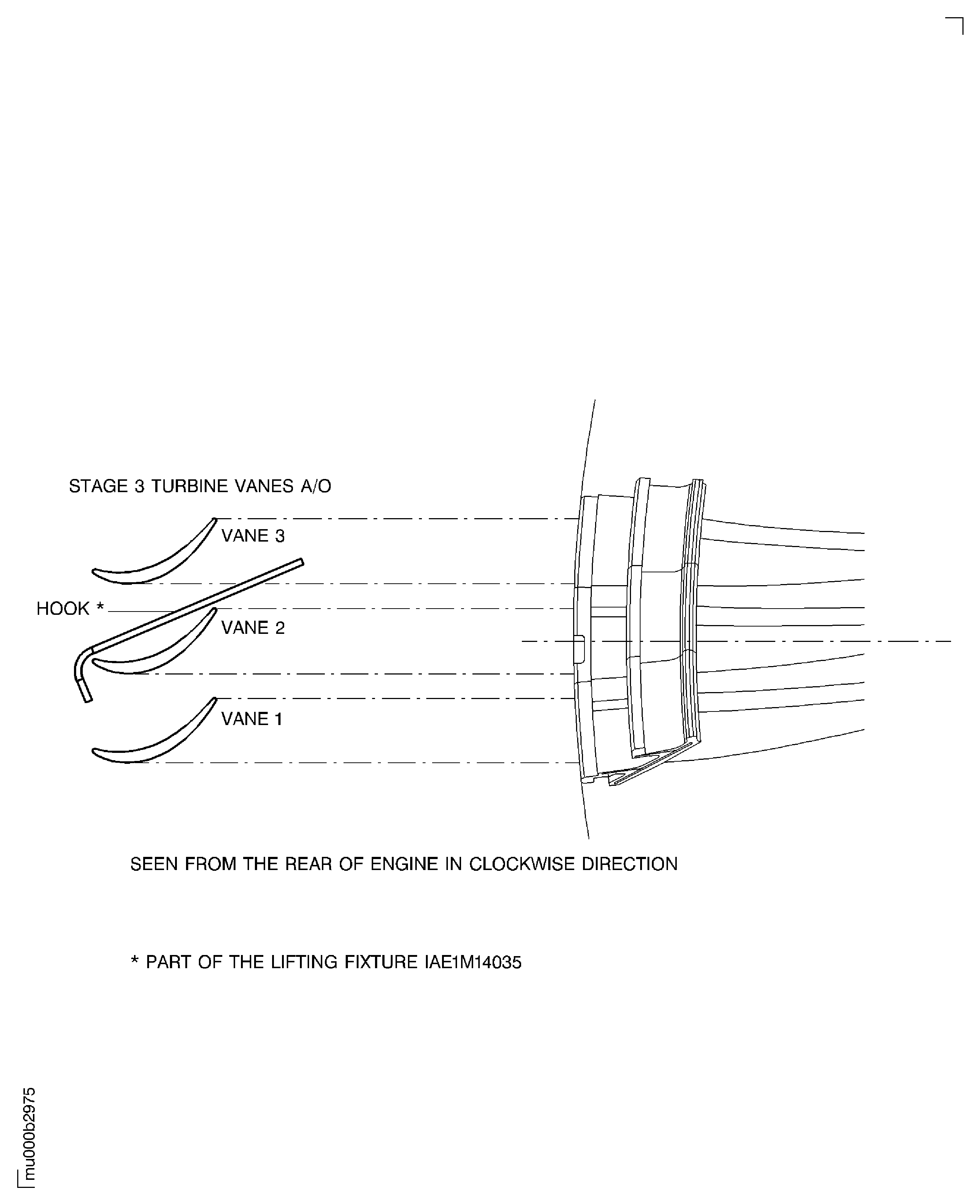

MAKE SURE THAT EACH TAIL OF THE HOOKS IS ATTACHED CORRECTLY TO THE STAGE 3 VANES. IF NOT THE PARTS CAN BE DAMAGED. THE HOOKS CAN BE SEEN THROUGH THE APERTURE OF THE LIFTING FIXTURE.Push the 15 hooks down. Turn the hooks by 90 degrees so that they engage the front edges of the second vane airfoils.

SUBTASK 72-50-10-430-057 Install the Lifting Fixture

Refer to Figure.

NOTE

Make sure that not more than five vane segments each marked with two "+" symbols are installed per LPT module assembly.Turn the lifting shaft, part of the assembly fixture, clockwise to lift the assembly fixture. Make sure that the rear outer locating dogs of the stage 3 vanes fully engage with the mating annular slot of the LP turbine case. Make sure that the stage 3 vanes are correctly installed in the LP turbine case slots.

SUBTASK 72-50-10-430-058 Install the Stage 3 Vane Assembly in to the LP Turbine Case

Install the IAE 1M14038 Retaining block 29 off to each joint of the stage 3 vane segments.

SUBTASK 72-50-10-430-059 Install the Retaining Blocks

Refer to Figure.

Use hoist equipment. Lift the LP turbine case with the IAE 1F10052 Two cables sling 1 off.

Install the 12 strip seals to the 12 inner duct segments. Use CoMat 10-062 ASSEMBLY FLUID.

Install the IAE 1M14040 Guide pin 2 off in the two clinching nuts of the diffuser inner duct assembly. Install the guide pins at 180 degrees apart from each other.

SUBTASK 72-50-10-430-060 Prepare the Inner Duct of the Diffuser

Refer to Figure.

WARNING

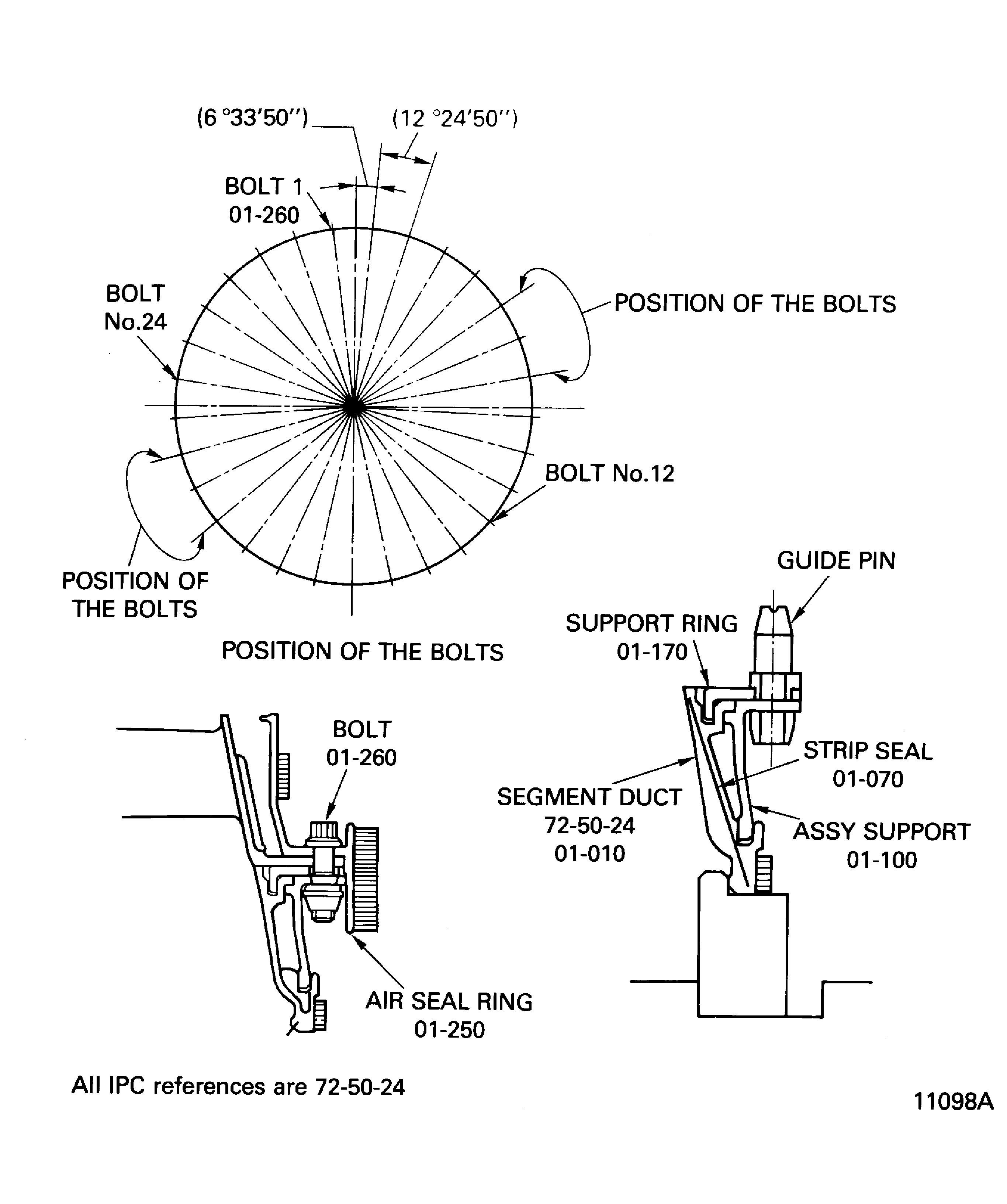

DO NOT GET ANTI-SEIZE PASTE ON YOUR SKIN WHEN YOU LUBRICATE THREADS AND ABUTMENT FACES OF NUTS AND BOLTS. WEAR PROTECTIVE GLOVES.Apply CoMat 10-129 ANTI-SEIZE PASTE to the 29 bolts. Install the bolts which attach the stage 3 vane assembly, the stage 3 air seal ring and the inner duct assembly. Wipe off excess paste.

NOTE

The tightening torque value includes the self locking torque value.

SUBTASK 72-50-10-430-061 Install the Inner Duct of the Diffuser

Refer to Figure.

Lubricate all threads and mating faces with CoMat 10-129 ANTI-SEIZE PASTE.

SUBTASK 72-50-10-430-062-A00 Install the Outer Duct of the Diffuser (Pre SBE 70-0078 and Pre SBE 70-0889)

WARNING

DO NOT GET ANTI-SEIZE PASTE ON YOUR SKIN WHEN YOU LUBRICATE THREADS AND ABUTMENT FACES OF NUTS AND BOLTS. WEAR PROTECTIVE GLOVES.SBE 70-0078: LP turbine - Introduce diffuser outer segment assemblies with reduced gaps

Refer to Figure.

WARNING

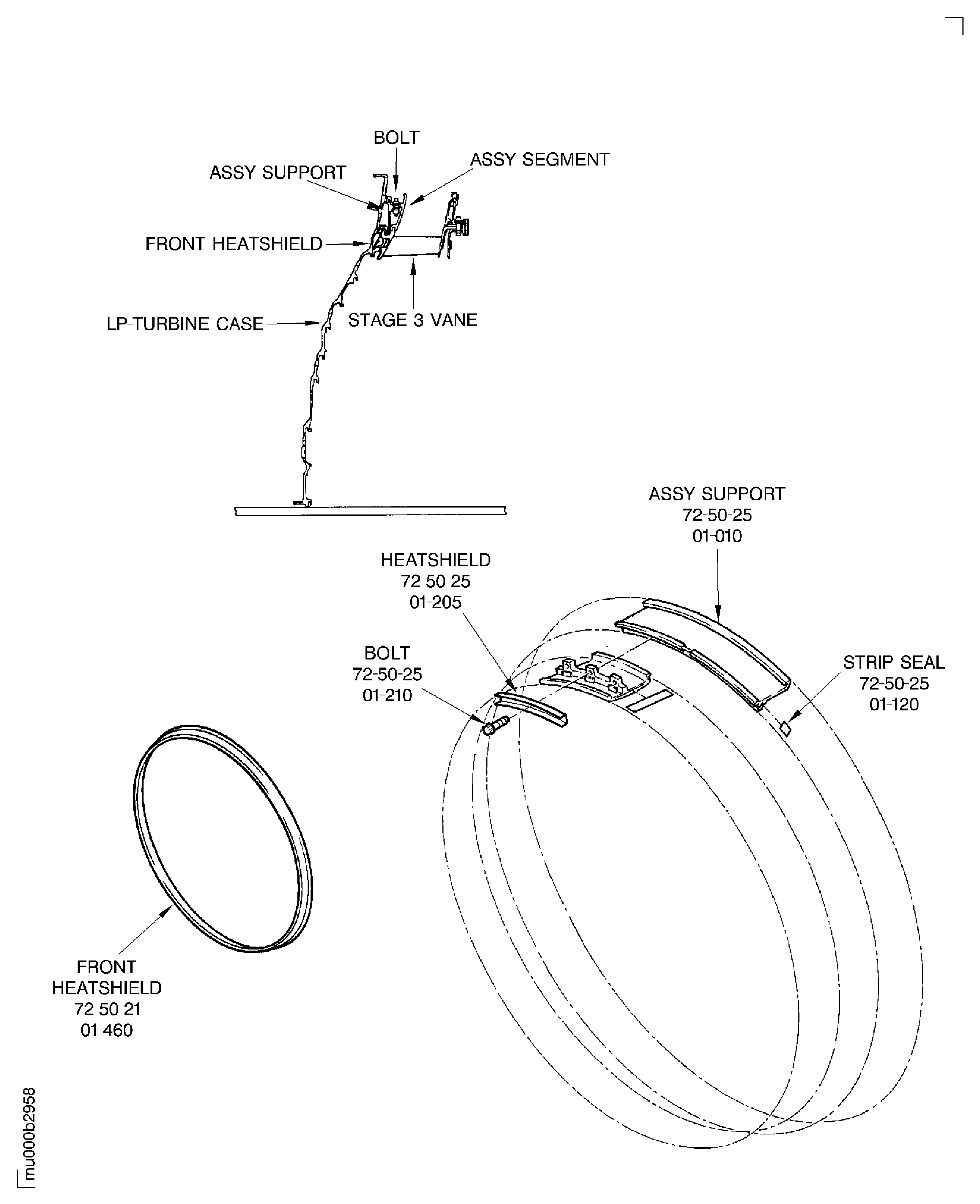

DO NOT GET ANTI-SEIZE PASTE ON YOUR SKIN WHEN YOU LUBRICATE THREADS AND ABUTMENT FACES OF NUTS AND BOLTS. WEAR PROTECTIVE GLOVES.Lubricate all threads and mating faces with CoMat 10-129 ANTI-SEIZE PASTE. Wipe off excess paste.

SUBTASK 72-50-10-430-062-B00 Install the Outer Duct of the Diffuser (SBE 70-0078 and Pre SBE 70-0889)

Lubricate all threads and mating faces with CoMat 10-129 ANTI-SEIZE PASTE.

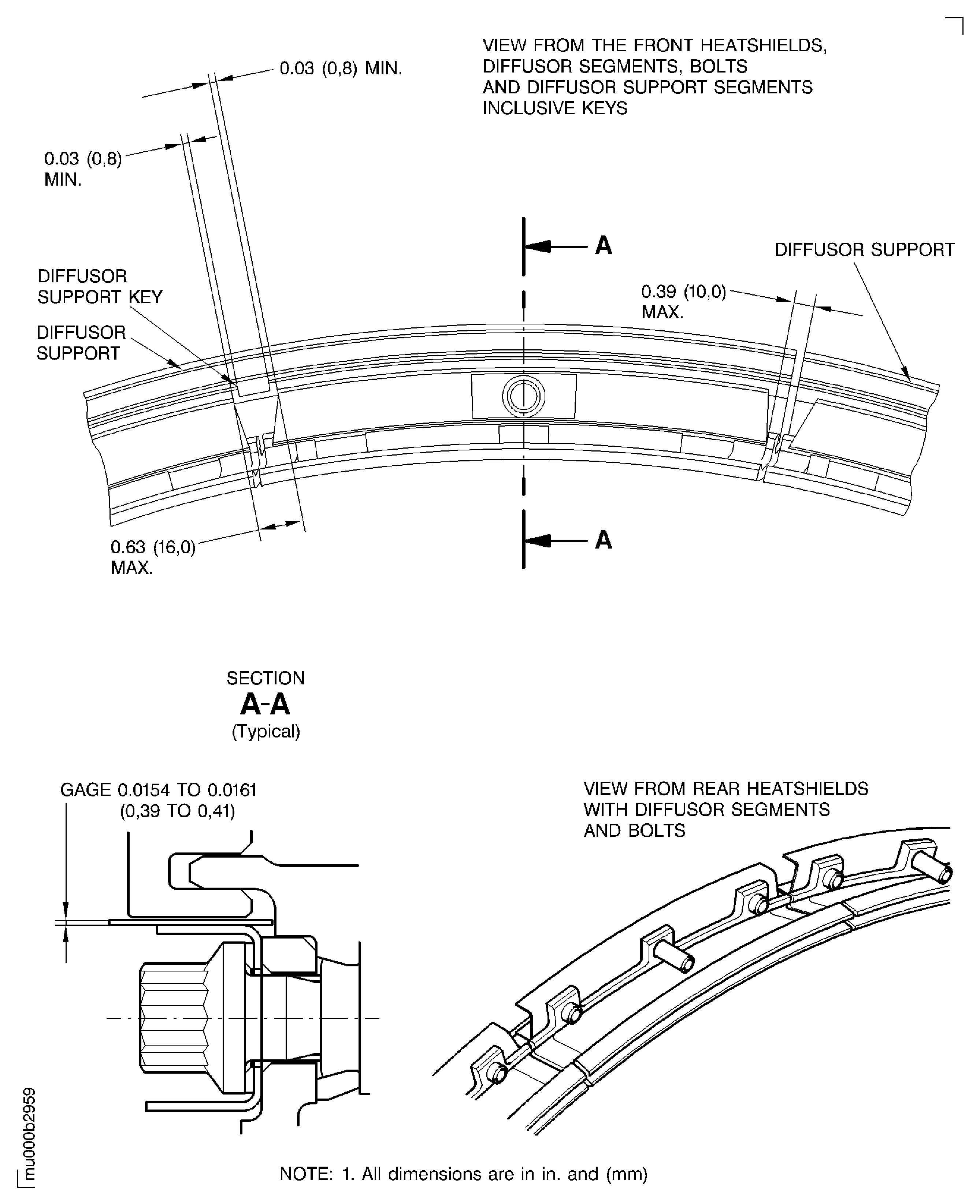

Install all 16 bolts which attach the assembly supports and the assembly segments. Align the heathields in accordance with the limits given in Figure. To obtain a gap of 0.0154 to 0.0161 in. (0.39 to 0.41 mm) use a suitable gage.

NOTE

The tightening torque value includes the self locking torque value.

SUBTASK 72-50-10-430-062-D00 Install the Outer Duct of the Diffuser (Pre SBE 70-0078 and SBE 70-0889)

WARNING

DO NOT GET ANTI-SEIZE PASTE ON YOUR SKIN WHEN YOU LUBRICATE THREADS AND ABUTMENT FACES OF NUTS AND BOLTS. WEAR PROTECTIVE GLOVES.Lubricate all threads and mating faces with CoMat 10-129 ANTI-SEIZE PASTE. Wipe off excess paste.

Install all 16 bolts which attach the assembly supports and the assembly segments. Align the heathields in accordance with the limits given in Figure. To obtain a gap of 0.0154 to 0.0161 in. (0.39 to 0.41 mm) use a suitable gage.

NOTE

The tightening torque value includes the self locking torque value.

SUBTASK 72-50-10-430-062-E00 Install the Outer Duct of the Diffuser (SBE 70-0078 and SBE 70-0889)

WARNING

DO NOT GET ANTI-SEIZE PASTE ON YOUR SKIN WHEN YOU LUBRICATE THREADS AND ABUTMENT FACES OF NUTS AND BOLTS. WEAR PROTECTIVE GLOVES.Refer to Figure.

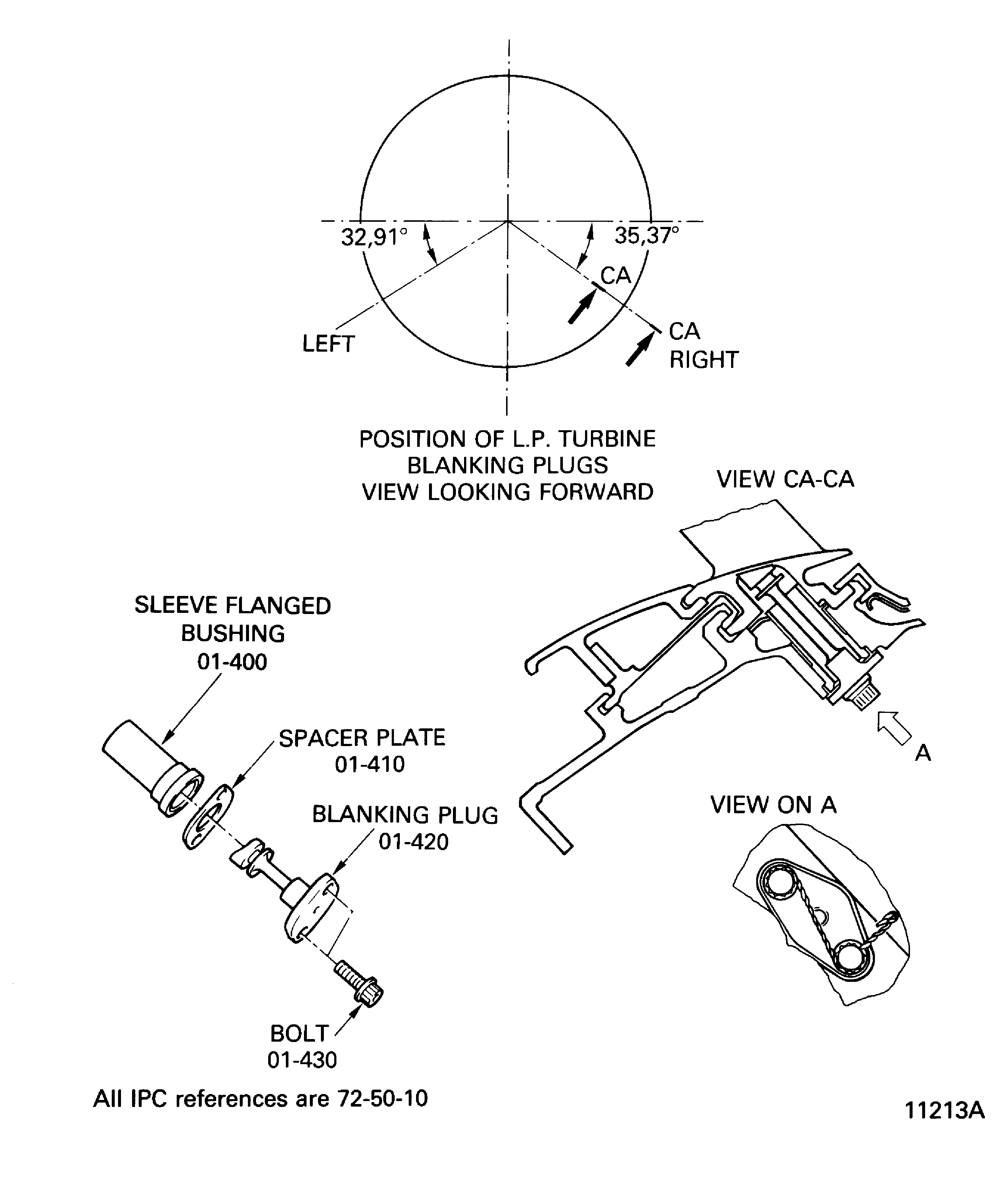

Install the blanking plug.

NOTE

The blanking plug surface must be continuous to the stage 3 vane outer platform surface. A tolerance of maximum minus 0.024 in. (0.6 mm) against the stage 3 vane outer platform surface is permitted. If necessary spacer plate(s) must be used. Usually one spacer plate is necessary.

WARNING

DO NOT GET ANTI-SEIZE PASTE ON YOUR SKIN WHEN YOU LUBRICATE THREADS AND ABUTMENT FACES OF NUTS AND BOLTS. WEAR PROTECTIVE GLOVES.Apply CoMat 10-129 ANTI-SEIZE PASTE to the two bolts.

Safety the bolts with CoMat 02-119 LOCKWIRE.

SUBTASK 72-50-10-430-063 Install the Blanking Plugs to the LP Turbine Borescope Ports

Figure: Lift and Turn the LP Turbine Case

Lift and Turn the LP Turbine Case

Figure: Install the Stage 3 LP Turbine Diffuser Outer Duct (Pre SBE 70-0889)

Install the Stage 3 LP Turbine Diffuser Outer Duct (Pre SBE 70-0889)

Figure: Install the Stage 3 LP Turbine Diffuser Outer Duct (SBE 70-0889)

Install the Stage 3 LP Turbine Diffuser Outer Duct (SBE 70-0889)

Figure: Assembly of the Heatshield (SBE 70-0889)

Assembly of the Heatshield (SBE 70-0889)

Figure: Prepare the Stage 3 Vane Assembly for Assembly

Prepare the Stage 3 Vane Assembly for Assembly

Figure: Position of the Assembly Segments and the Assembly Supports of the Stage 3 Outer Duct

Position of the Assembly Segments and the Assembly Supports of the Stage 3 Outer Duct

Figure: Install the Stage 3 Vane Assembly with the Lifting Fixture

Install the Stage 3 Vane Assembly with the Lifting Fixture

Figure: Prepare the Stage 3 LP Turbine Diffuser Inner Duct for Assembly

Prepare the Stage 3 LP Turbine Diffuser Inner Duct for Assembly

Figure: Stage 3 LP Turbine Diffuser Inner Duct

Stage 3 LP Turbine Diffuser Inner Duct

Figure: Install the Stage 3 LP Turbine Borescope Blanking Plug

Install the Stage 3 LP Turbine Borescope Blanking Plug

Figure: Correct Installation of the Hooks of the Lifting Fixture

Correct Installation of the Hooks of the Lifting Fixture