Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 72-50-23-300-064S Low Pressure (LP) Turbine Outer Static Seals - Replace The Honeycomb Seal Segments, Repair-064 (VRS4566)

Material of Component

PART IDENT | IAE SYMBOL | MATERIAL |

|---|---|---|

Stage 3 shroud seal segment | - | Inconel 625 |

Honeycomb seal segment | - | Hastelloy X |

General

Price and availability - none

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Belt grinder | LOCAL | Belt grinder | ||

| Grinding Machine | 0AM53 | Grinding Machine | ||

| IAE 3M14212 Grinding/turning fixture | 0AM53 | IAE 3M14212 | 1 off | |

| IAE 3M14220 Cross slide table | 0AM53 | IAE 3M14220 | 1 off | |

| IAE 3M14221 Electrode guide | 0AM53 | IAE 3M14221 | 1 off | |

| IAE 3M14222 Electrode holder | 0AM53 | IAE 3M14222 | 1 off | |

| IAE 3M14223 Universal joint electrode | 0AM53 | IAE 3M14223 | 1 off | |

| IAE 3M14444 Spotwelding fixture | 0AM53 | IAE 3M14444 | 1 off | |

| IAE 3M14454 Spotwelding fixture | 0AM53 | IAE 3M14454 | 1 off | |

| Spot welding machine | LOCAL | Spot welding machine | ||

| Turning lathe | LOCAL | Turning lathe |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 02-144 BONDING AGENT | LOCAL | CoMat 02-144 | ||

| CoMat 03-148 BRAZING FILLER POWDER | LOCAL | CoMat 03-148 | ||

| CoMat 03-227 WHITE STOP OFF | D3309 | CoMat 03-227 | ||

| CoMat 03-249 BRAZING FILLER MATERIAL,Ni-BASE | LOCAL | CoMat 03-249 | ||

| CoMat 03-469 HONEYCOMB, NICKEL ANDCOBALT ALLOYS | LOCAL | CoMat 03-469 |

Spares

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| SEAL SEGMENT - HONEYCOMB | 0AM53 | 3A3088 | 1 | FIG/ITEM - 01-371 |

| SEAL SEGMENT - HONEYCOMB | 0AM53 | 3A3089 | 1 | FIG/ITEM - 01-381 |

Safety Requirements

NONEProcedure

Refer to Figure.

Use IAE 3M14212 Grinding/turning fixture 1 off and Turning lathe or Grinding Machine.

Keep material removal to a minimum.

Remove the damaged honeycomb seal segments fully.

Remaining braze thickness not more than 0.005 in. (0.127 mm) is permitted.

Machine off the worn honeycomb seal segments.

Use cold work.

Bend the shroud seal segments back to shape if required.

SUBTASK 72-50-23-320-001 Machine the Damaged Honeycomb Seal Segments

Refer to SPM TASK 70-11-03-300-503.

Aqueous cleaning.

SUBTASK 72-50-23-110-001 Clean the Stage 3 Shroud Seal Segment

Refer to SPM TASK 70-23-02-230-501. Refer to Task TASK 72-50-23-200-004-G00 (Inspection - 004) for acceptable limits.

Do the test for cracks.

SUBTASK 72-50-23-230-001Examine the Stage 3 Shroud Seal Segment for Cracks

Replacement honeycombs are supplied longer than necessary.

Use Belt grinder.

Cut the honeycomb seal segments to length.

SUBTASK 72-50-23-310-001 Prepare the Honeycomb Seal Segments for Brazing

Refer to SPM TASK 70-11-03-300-503.

Use clean gloves when you touch the clean parts.

Aqueous cleaning.

SUBTASK 72-50-23-110-002 Clean the New Honeycomb Seal Segments and the Stage 3 Shroud Seal Segment

NOTE

If CoMat 03-249 BRAZING FILLER MATERIAL,Ni-BASE is used, do not perform Step and Step. If CoMat 03-148 BRAZING FILLER POWDER is used, do not perform Step.If you install 3A3089 SEAL SEGMENT - HONEYCOMB (72-50-23, 01-381 or detail N), do not perform Step and if you install 3A3088 SEAL SEGMENT - HONEYCOMB (72-50-23, 01-371 or detail M), do not perform Step.Use IAE 3M14220 Cross slide table 1 off and Spot welding machine.

Install the cross slide table onto the spot welding machine.

Use IAE 3M14222 Electrode holder 1 off.

Install the electrode holder onto the spot welding machine.

Use IAE 3M14223 Universal joint electrode 1 off. Make sure that the electrode insert with the mark "OUTER" (part of the electrode swivel) is installed.

Install the electrode swivel onto the electrode holder.

Use IAE 3M14221 Electrode guide 1 off.

Install the electrode guide onto the cross slide table.

Use IAE 3M14444 Spotwelding fixture 1 off.

Install the spot welding fixture onto the electrode guide.

Use IAE 3M14454 Spotwelding fixture 1 off.

Install the spot welding fixture onto the electrode guide.

Make sure that the shroud seal segment is installed correctly against the stop plates (parts of the spot welding fixture).

Attach the shroud seal segment onto the spot welding fixture.

Align the honeycomb seal segments.

Put the honeycomb seal segments onto the shroud seal segment.

Use a short time and low weld amperage to safety the honeycomb seals without damage. Start to weld in the middle and continue to the outer sides.

Resistance weld the honeycomb seal segments.

Use CoMat 03-148 BRAZING FILLER POWDER. Make sure that the brazing filler powder is applied equally around the honeycomb seal segments.

Apply brazing filler powder to the honeycomb seal segments.

Apply white stop off around the edges of the shroud seal segment.

Refer to SPM TASK 70-31-07-310-501. Use process 2.

Vacuum braze.

SUBTASK 72-50-23-310-002 Braze in the New Honeycomb Seal Segments

Refer to SPM TASK 70-11-03-300-503.

Aqueous cleaning.

SUBTASK 72-50-23-110-003 Clean the Stage 3 Shroud Seal Segment

Refer to SPM TASK 70-31-07-310-501.

Do the gravity leak test.

No unbrazed honeycomb cells around the edges of the honeycomb segments are permitted.

The minimum space between the unbonded areas of more than 0.063 sq. in. (40.65 sq-mm) should be 1.000 in (25.40 mm).

The honeycomb wall thickness must not be increased by more than 0.001 in. (0.025 mm) in the area above the braze fillet.

Refer to SPM TASK 70-31-07-310-501 except the following limits:

Acceptance limits.

SUBTASK 72-50-23-210-001 Examine the Brazed Honeycomb Seal Segments

Use IAE 3M14212 Grinding/turning fixture 1 off and grinding machine.

Grind the honeycomb seal segments.

Refer to SPM TASK 70-31-07-310-501.

Deburr the honeycomb seal segments.

SUBTASK 72-50-23-320-002 Machine the Honeycomb Seal Segments

Refer to SPM TASK 70-11-03-300-503.

Aqueous cleaning.

SUBTASK 72-50-23-110-004 Clean the Stage 3 Shroud Seal Segment

Examine dimensionally.

Refer to SPM TASK 70-31-07-310-501.

Examine visually.

SUBTASK 72-50-23-220-001 Do the Post Repair Inspection

Refer to SPM TASK 70-09-00-400-501.

Electrolytically etch or vibropeen VRS4566 adjacent to the part number.

SUBTASK 72-50-23-350-001 Make a Mark to Identify the Repair

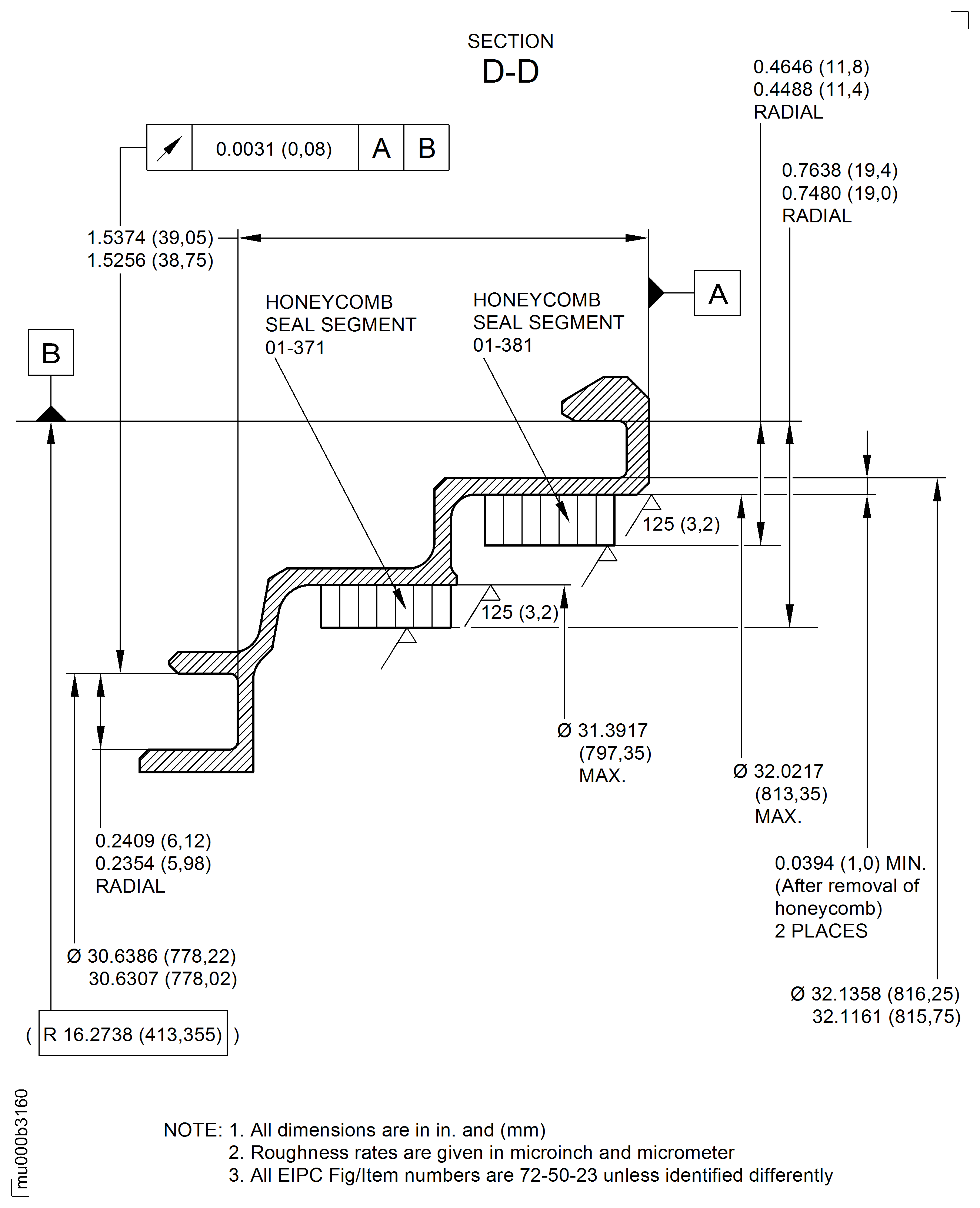

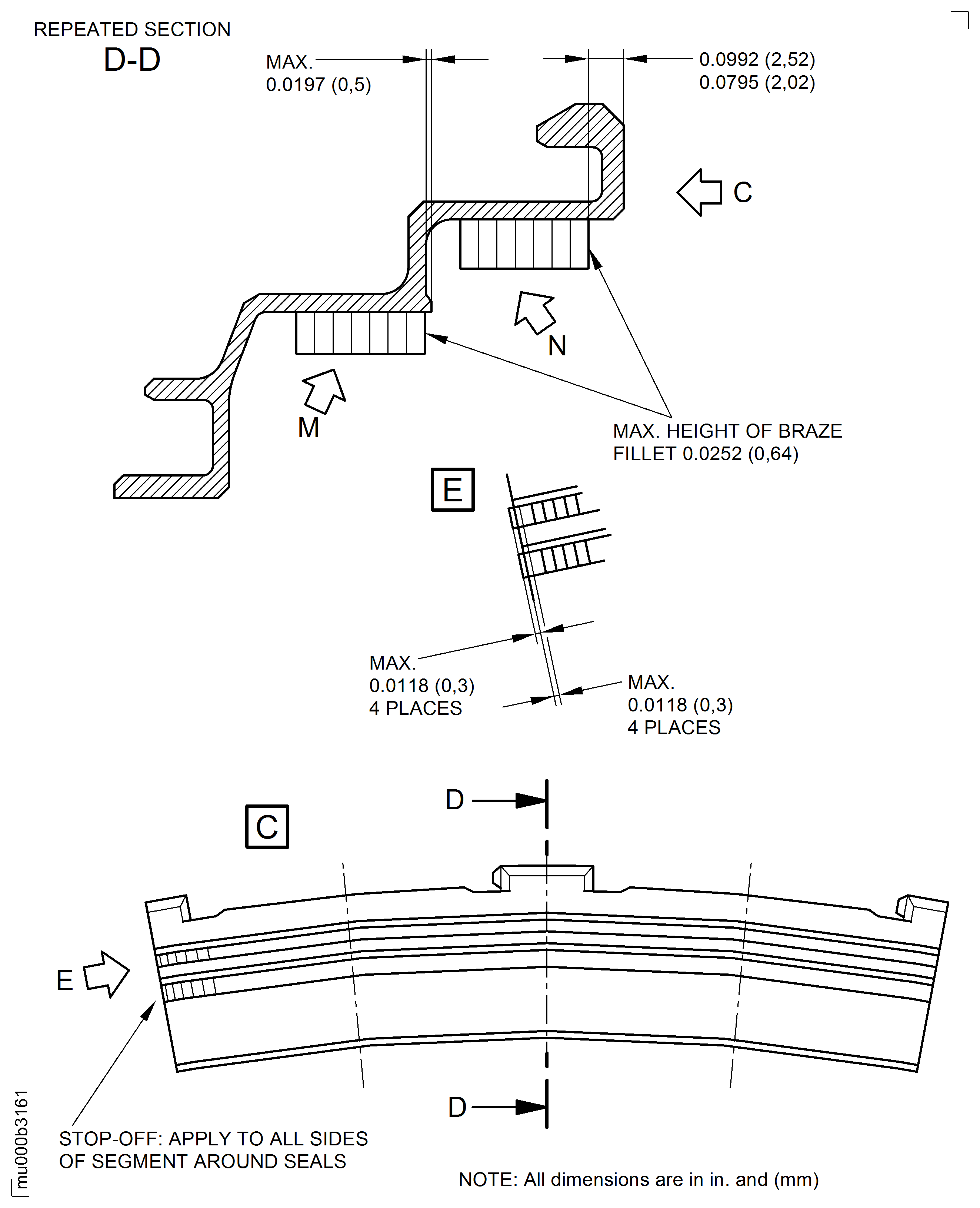

Figure: Repair Details and Dimensions

Repair Details and Dimensions

Repair Details and Dimensions

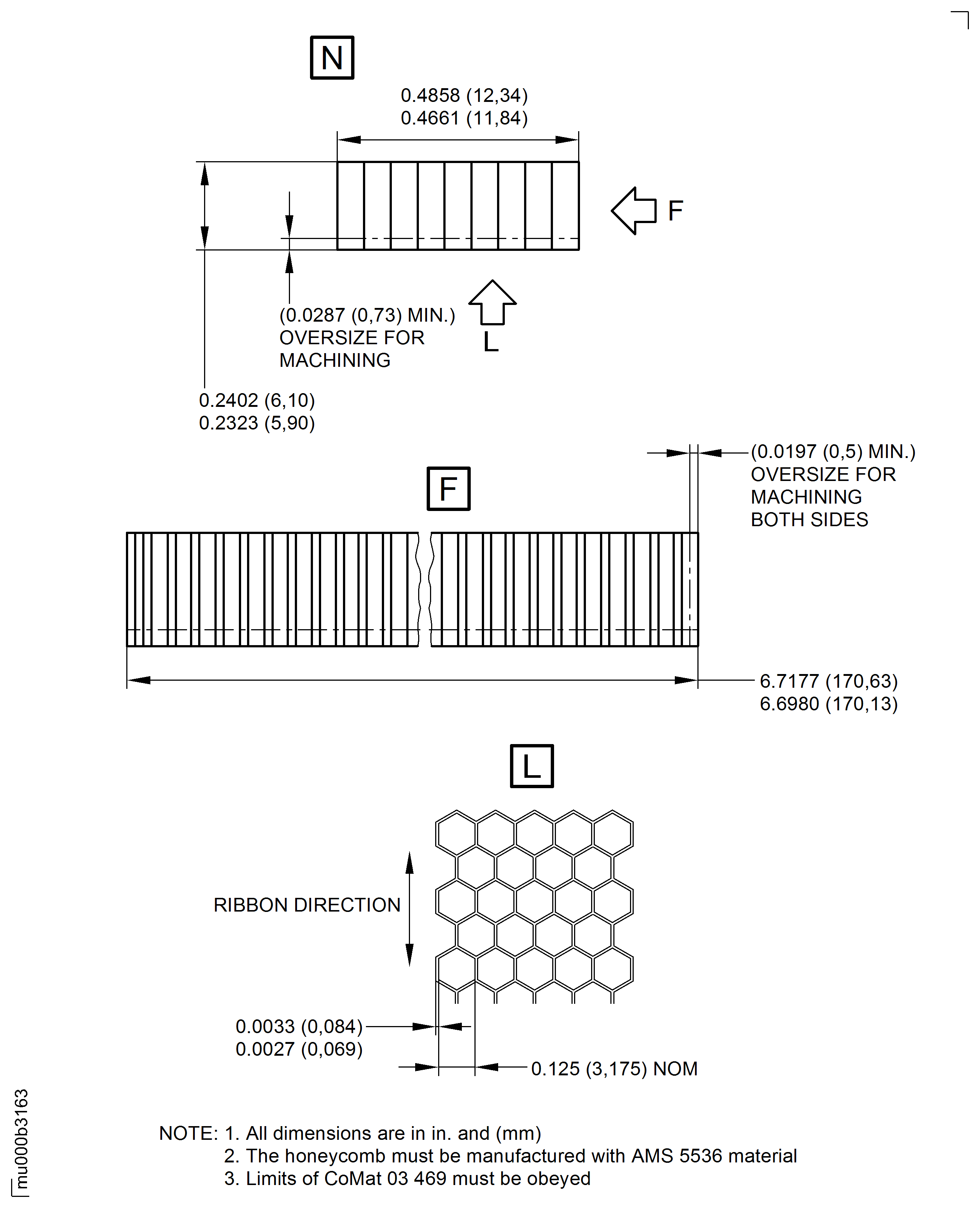

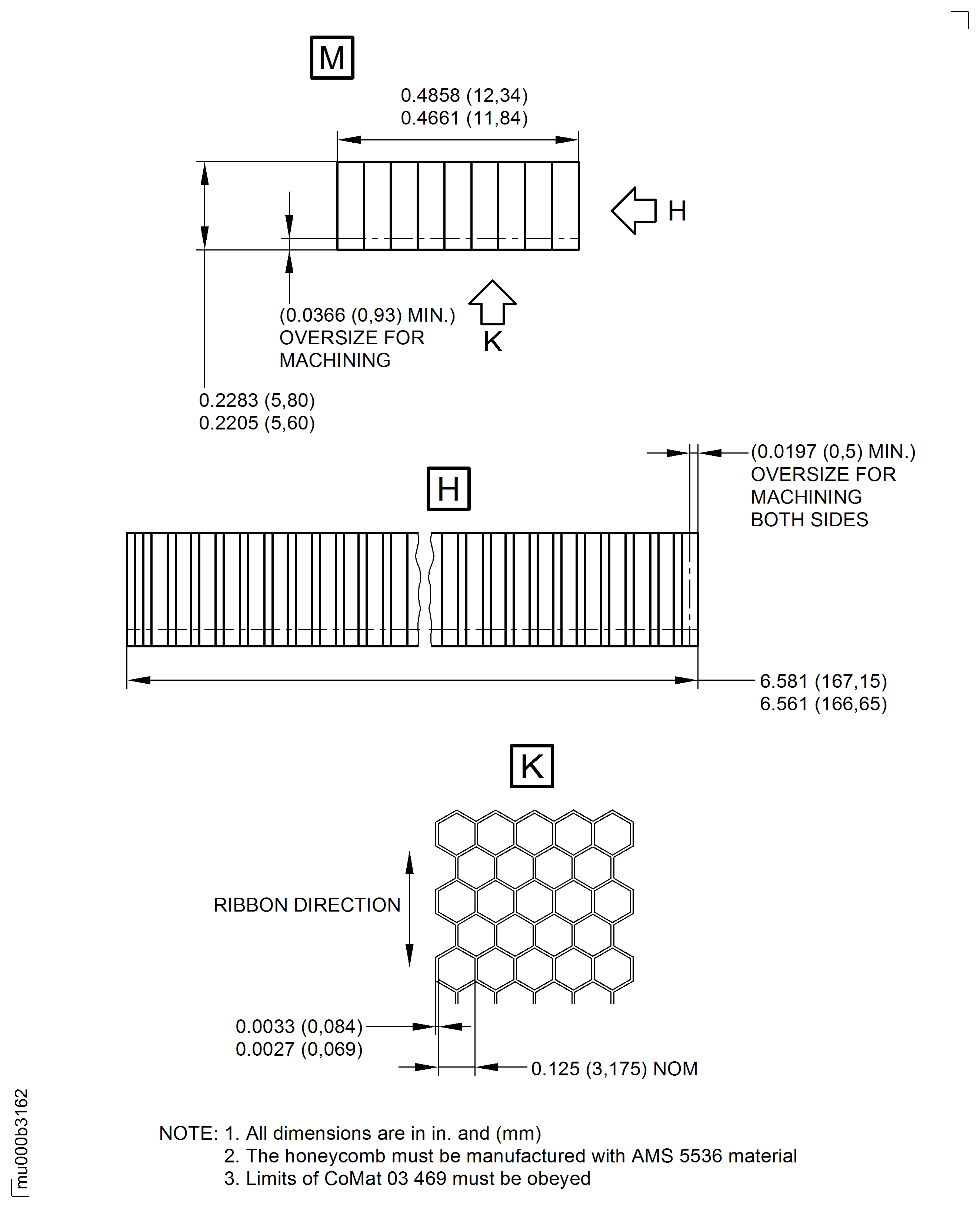

Figure: Local Manufacture Honeycomb Seal Segment of the Shroud Seal Segment

Local Manufacture Honeycomb Seal Segment of the Shroud Seal Segment

Figure: Local Manufacture Honeycomb Seal Segment of the Shroud Seal Segment

Local Manufacture Honeycomb Seal Segment of the Shroud Seal Segment