Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

V2500-A1

Common Information

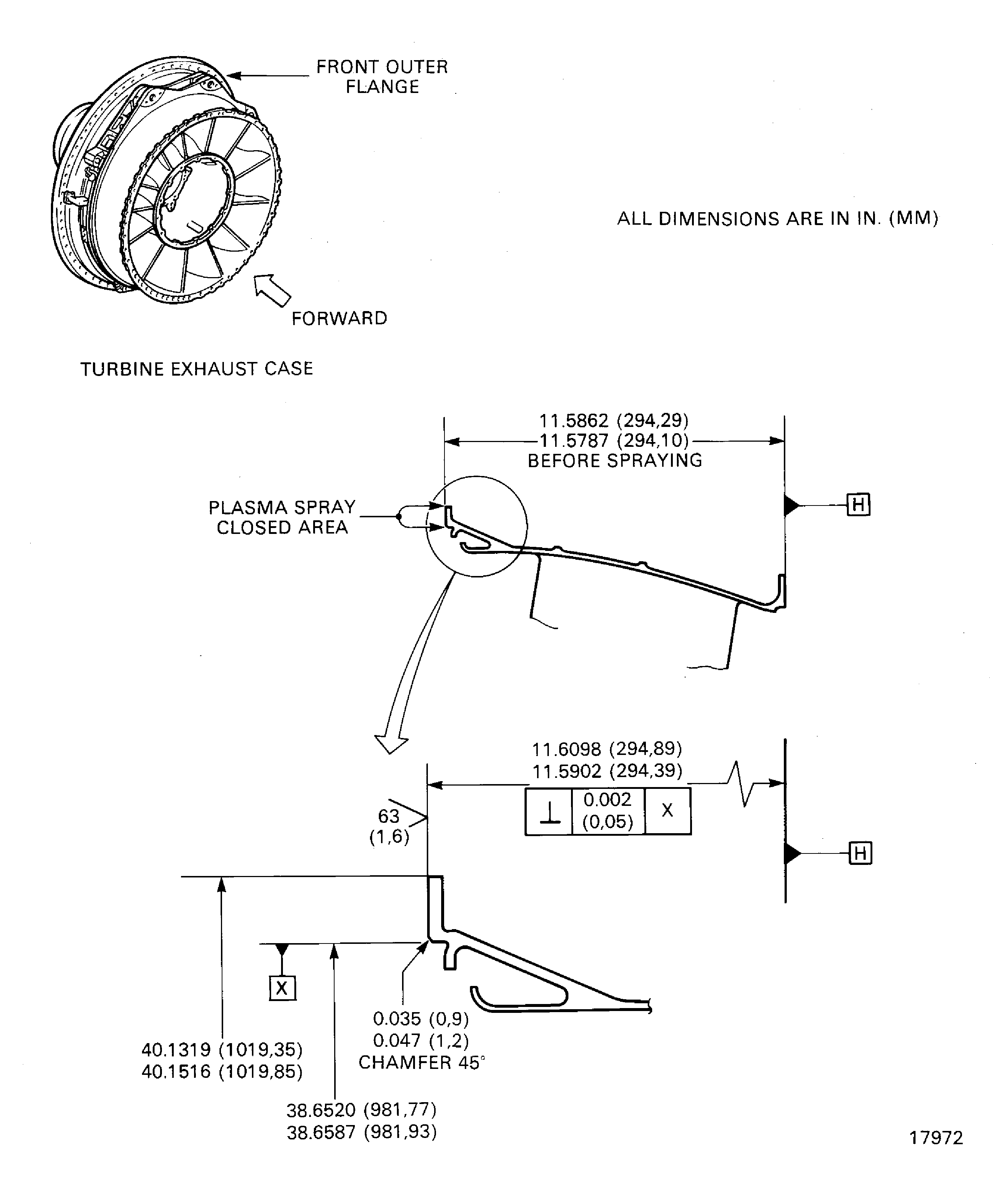

TASK 72-50-53-300-013 Turbine Exhaust Case (TEC) - Plasma Coat The Front Face Of The Front Flange, Repair-013 (VRS5397)

Material of component

DESCRIPTION | SYMBOL | MATERIAL |

|---|---|---|

Turbine exhaust case | Corrosion and heat resistant | |

iron base alloy |

General

Price and availability - none

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

NOTE

To identify the consumable materials refer to the PCI.

Consumable materials are given in the SPM.

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

NONEConsumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 03-096 PLASMA SPRAY POWDER | LOCAL | CoMat 03-096 |

Spares

NONESafety Requirements

NONEProcedure

Refer to: Figure

SUBTASK 72-50-53-320-055 Machine the Front Face of the Front Flange

Refer to the SPM TASK 70-23-02-230-501.

No cracks are permitted.

NOTE

This step is required if the method of machining in Step (4) was grinding. For all other methods, this step is optional.

Do the fluorescent penetrant inspection for cracks.

SUBTASK 72-50-53-230-056 Examine the Front Face

Refer to the SPM TASK 70-11-03-300-503.

Degrease by aqueous cleaning.

SUBTASK 72-50-53-110-055 Clean the Turbine Exhaust Case

Refer to Figure.

Refer to the SPM TASK 70-34-18-380-501.

Prepare the surface of part for plasma and other thermal spray coating.

SUBTASK 72-50-53-120-062 Prepare the Front Face of the Front Flange

Refer to Figure.

Refer to the SPM TASK 70-34-03-340-501.

Spraying distance

5.315 in. (135 mm)

Spraying angle

90 degrees

Component rotation speed

50 rpm

Gun traverse speed

9.84 in/min (250 mm/min)

Maximum working temperature

392 deg F (200 deg C)

Metal plasma spray the front face of the front flange.

SUBTASK 72-50-53-370-053 Metal Plasma Spray the Front Face of the Front Flange

Refer to: Figure

SUBTASK 72-50-53-320-056 Machine the Front Face of the Front Flange

Refer to Figure.

SUBTASK 72-50-53-220-086 Examine the Coated Area

Refer to the SPM TASK 70-09-00-400-501. Use vibration peen method with 0.006 in. (0.15 mm) maximum depth.

Vibration peen VRS5397 adjacent to the part number.

SUBTASK 72-50-53-350-056 Record the Repair

Figure: Repair Details and Dimensions

Repair Details and Dimensions