Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 75-24-48-840-002 HPT ACC Air Manifold and Tube Assembly - Rework for Improved Maintenance Features, Rework-002 - SBE 75-0013

Effectivity

FIG/ITEM | PART NO. |

02-100 | 2A1571 |

02-200 | 2A0220 |

02-210 | 2A0225 |

02-220 | 2A0229 |

02-230 | 2A0233 |

02-300 | 2A1572 |

02-400 | 2A0223 |

02-410 | 2A0227 |

02-420 | 2A0231 |

02-430 | 2A0235 |

02-500 | 2A0202 |

02-500 | 2A3665 |

General

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Grinder, Hand held pneumatic | LOCAL | Grinder, Hand held pneumatic | ||

| Marking pencil, vibrating | LOCAL | Marking pencil, vibrating | ||

| Tungsten Inert Gas (TIG) system | LOCAL | Tungsten Inert Gas (TIG) system | ||

| Magnifying glass | LOCAL | Magnifying glass | 8X |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-031 ACETONE (CH3)2CO | LOCAL | CoMat 01-031 | ||

| CoMat 02-099 LINT-FREE CLOTH | LOCAL | CoMat 02-099 | ||

| CoMat 03-204 WELDING FILLER WIRE | LOCAL | CoMat 03-204 |

Spares

NONESafety Requirements

NONEProcedure

Refer to Figure.

Case 1. NUMBER BEFORE - 2A0202 NEW NUMBER - 2A1540

Case 2. NUMBER BEFORE - 2A3665 NEW NUMBER - 2A1569.

Refer to SPM TASK 70-09-00-400-501.

Identify the turbine cooling manifold assembly with the new part number adjacent to the part number that was there before.

SUBTASK 75-24-48-850-052 Identify the Turbine Cooling Manifold Assembly with the New Part Number

Refer to Figure.

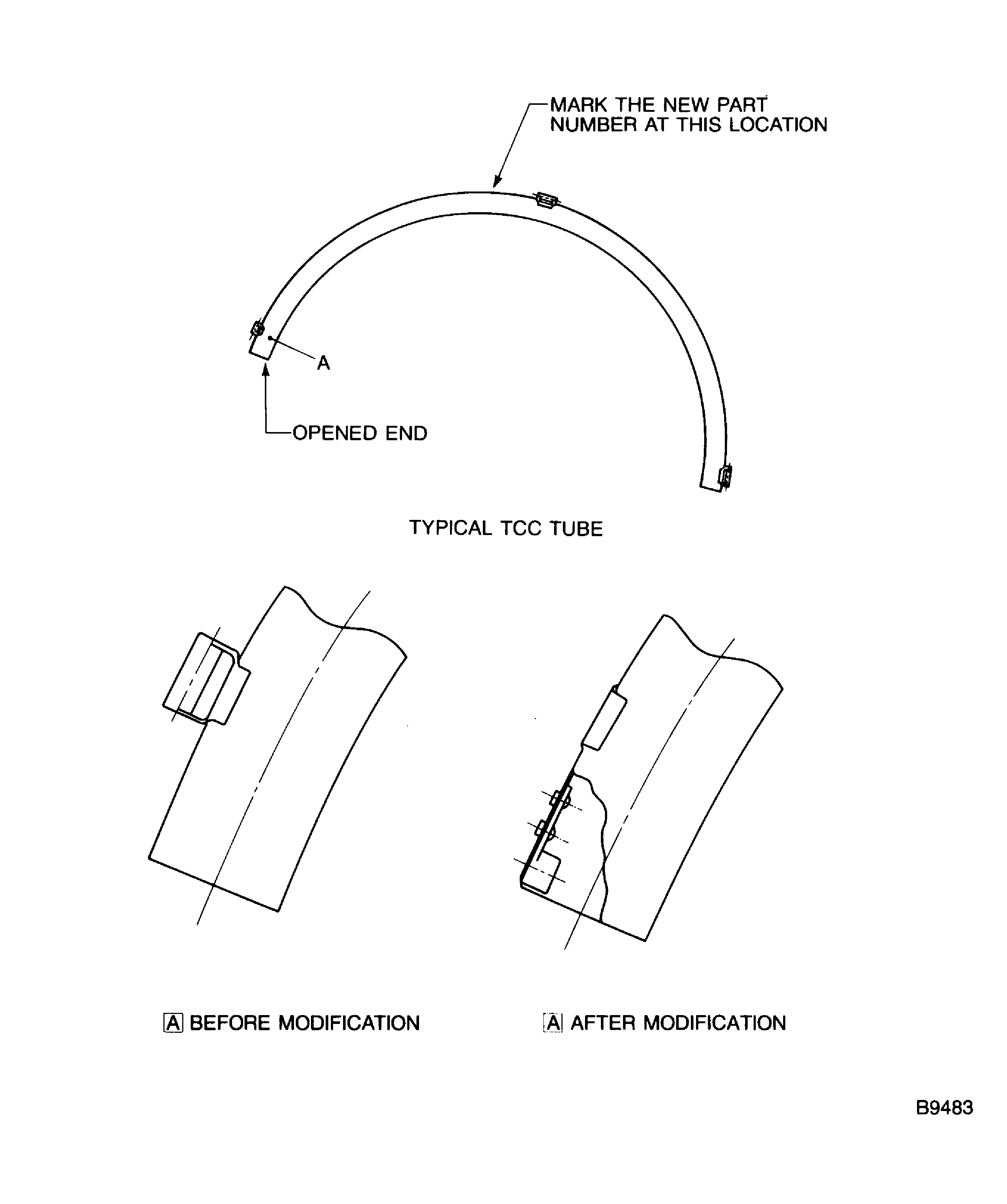

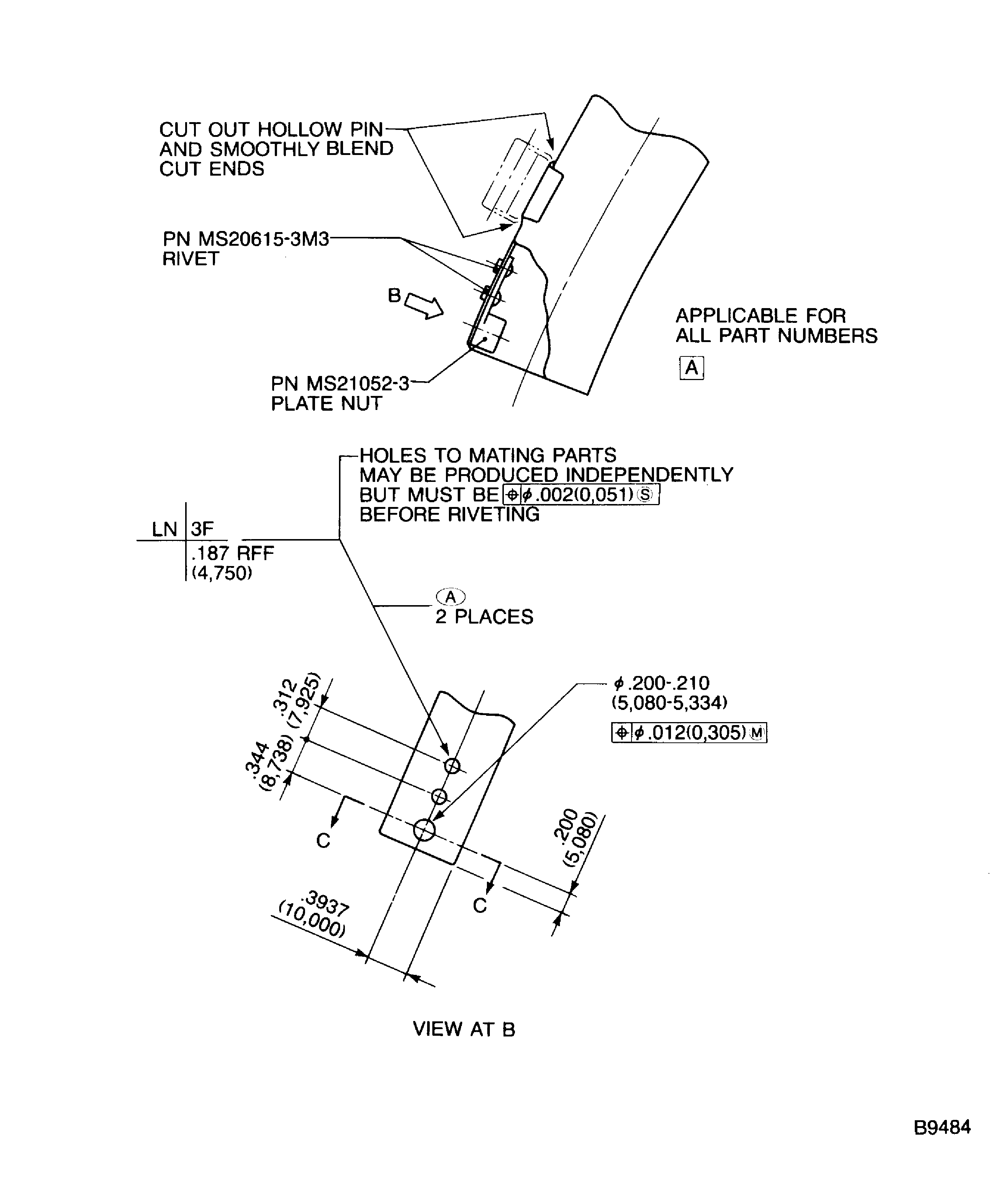

Cut off the hollow pin which positions the open-ended side of the TCC tube assembly.

Blend the cut end and remove the sharp edge.

Refer to SPM TASK 70-23-05-230-501.

Examine the blended area for cracks.

SUBTASK 75-24-48-350-088 Cut off the Hollow Pin from each TCC Tube Assembly

Refer to Figure.

Drill three holes.

Remove all burrs and sharp edges.

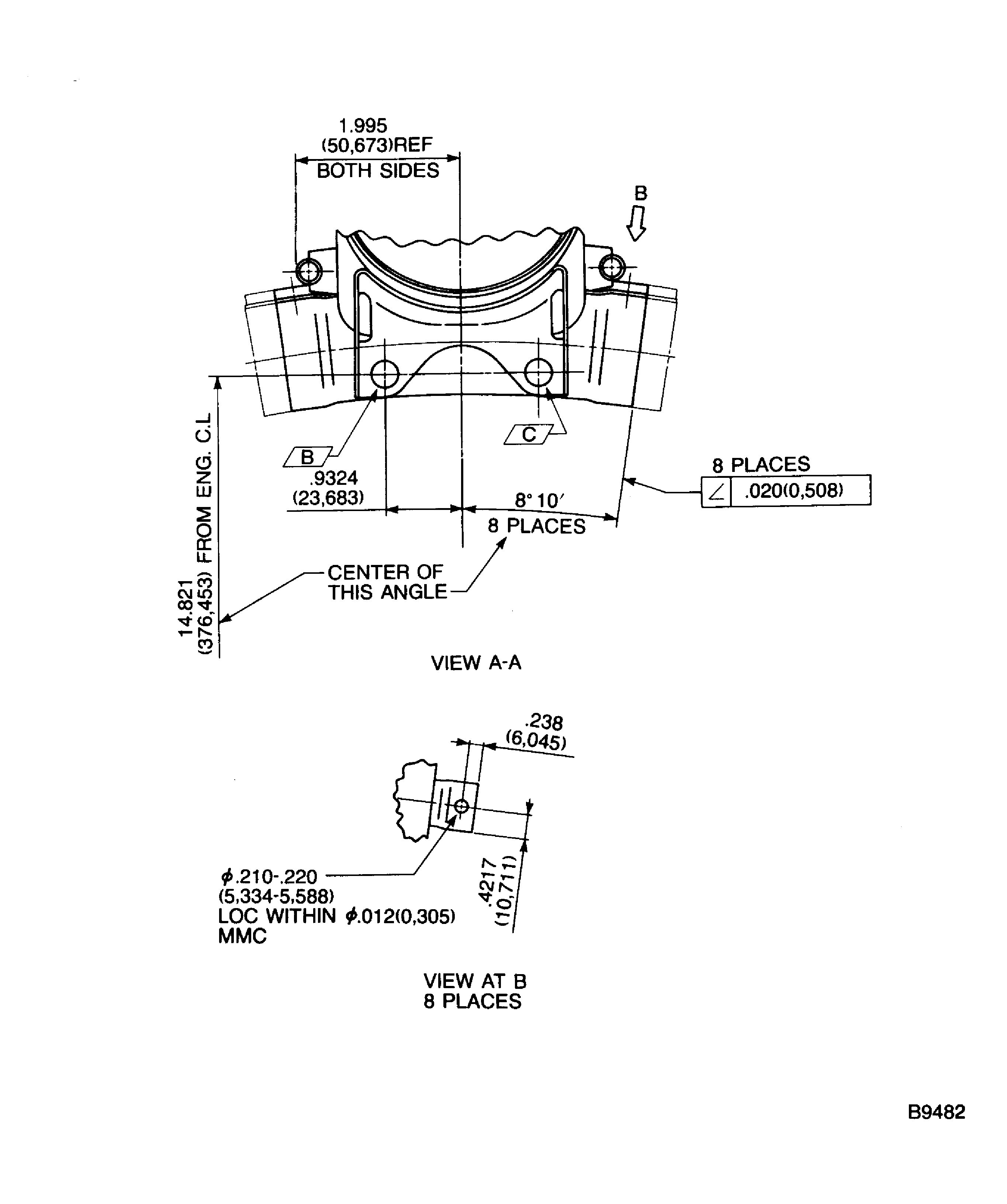

SUBTASK 75-24-48-350-089 Drill Three Holes in each TCC Tube Assembly

Refer to Figure.

Put the plate nut in position.

Refer to Figure.

Refer to SPM TASK 70-39-03-390-501.

Insert and upset two rivets.

SUBTASK 75-24-48-350-090 Install the Plate Nut

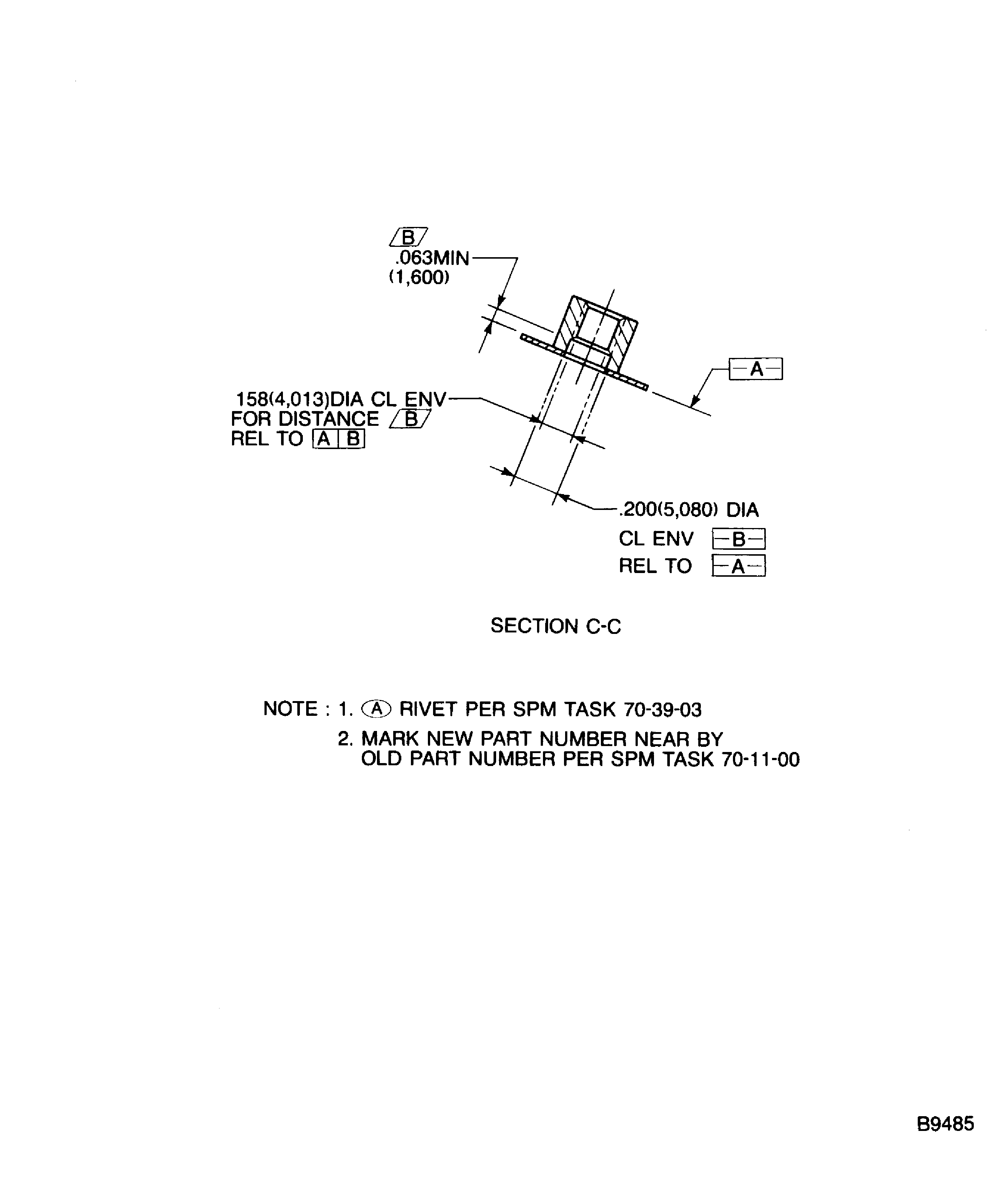

Refer to SPM TASK 70-39-03-390-501.

Examine the rivets.

Refer to Figure.

Examine the dimensions.

SUBTASK 75-24-48-350-091 Examine the Installed Plate Nuts

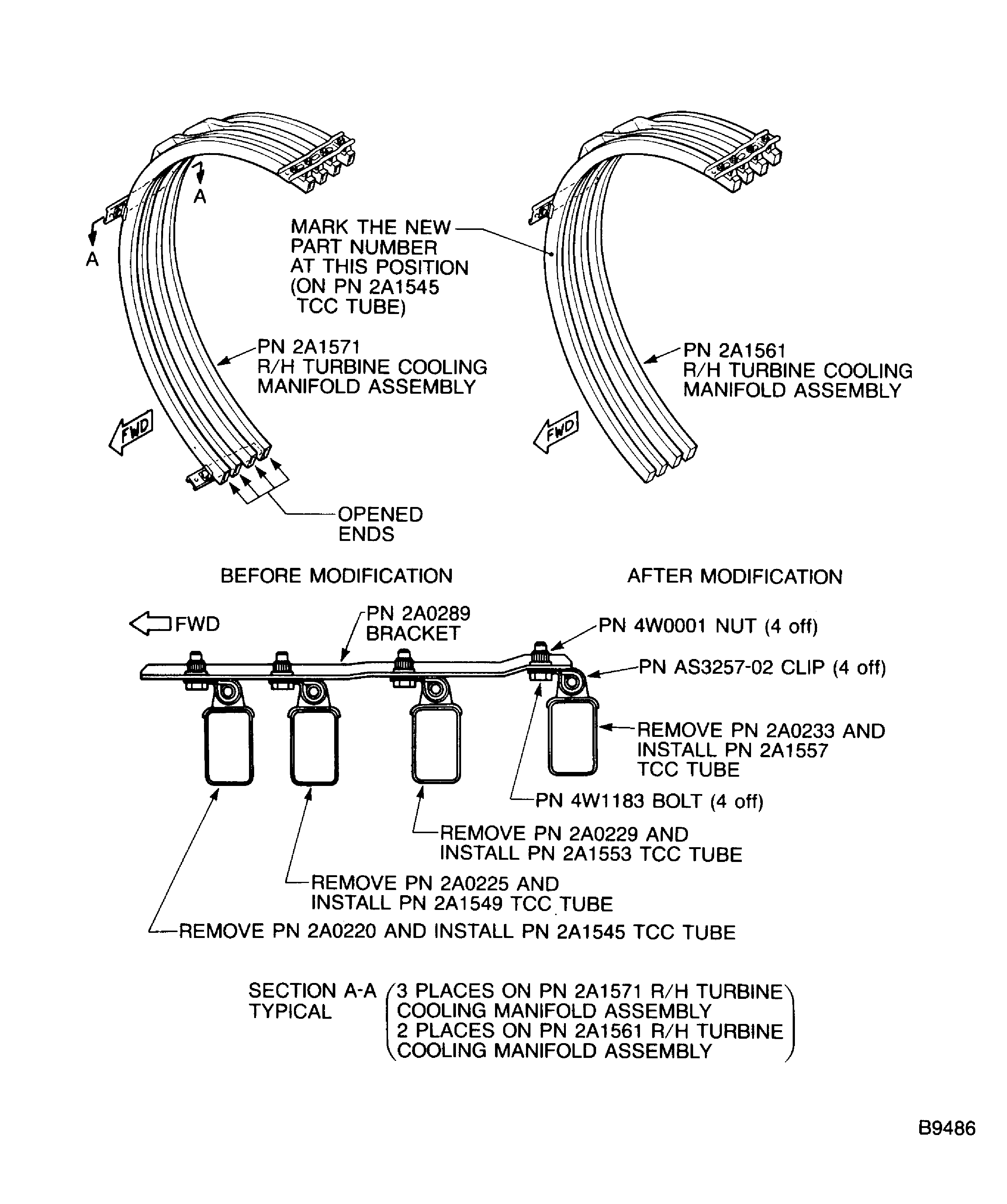

Refer to Figure.

Case 1. NUMBER BEFORE - 2A0220 NEW NUMBER - 2A1545

Case 2. NUMBER BEFORE - 2A0225 NEW NUMBER - 2A1549

Case 3. NUMBER BEFORE - 2A0229 NEW NUMBER - 2A1553

Case 4. NUMBER BEFORE - 2A0233 NEW NUMBER - 2A1557

Case 5. NUMBER BEFORE - 2A0223 NEW NUMBER - 2A1547

Case 6. NUMBER BEFORE - 2A0227 NEW NUMBER - 2A1551

Case 7. NUMBER BEFORE - 2A0231 NEW NUMBER - 2A1555

Case 8. NUMBER BEFORE - 2A0235 NEW NUMBER - 2A1559.

Refer to SPM TASK 70-09-00-400-501.

Identify the TCC tube assemblies with the new part number adjacent to the part number that was there before.

SUBTASK 75-24-48-850-053 Identify the TCC Tube Assemblies with the New Part Number

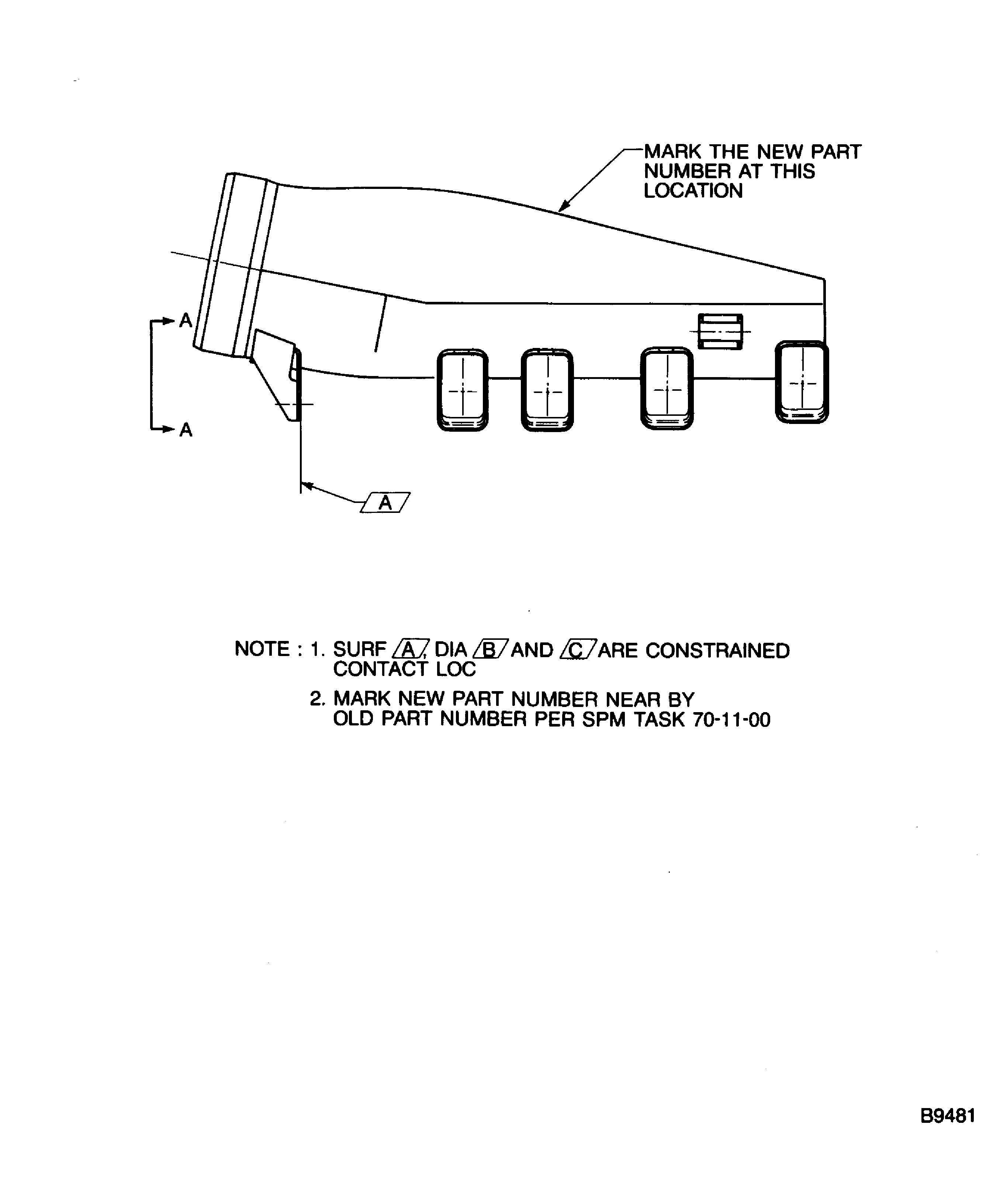

Refer to Figure.

NUMBER BEFORE - 2A1571 NEW NUMBER - 2A1561.

Refer to SPM TASK 70-09-00-400-501.

Identify the R/H turbine cooling manifold assemblies with the new part number adjacent to the part number that was there before.

SUBTASK 75-24-48-850-054 Identify the R/H Turbine Cooling Manifold Assemblies with the New Part Number

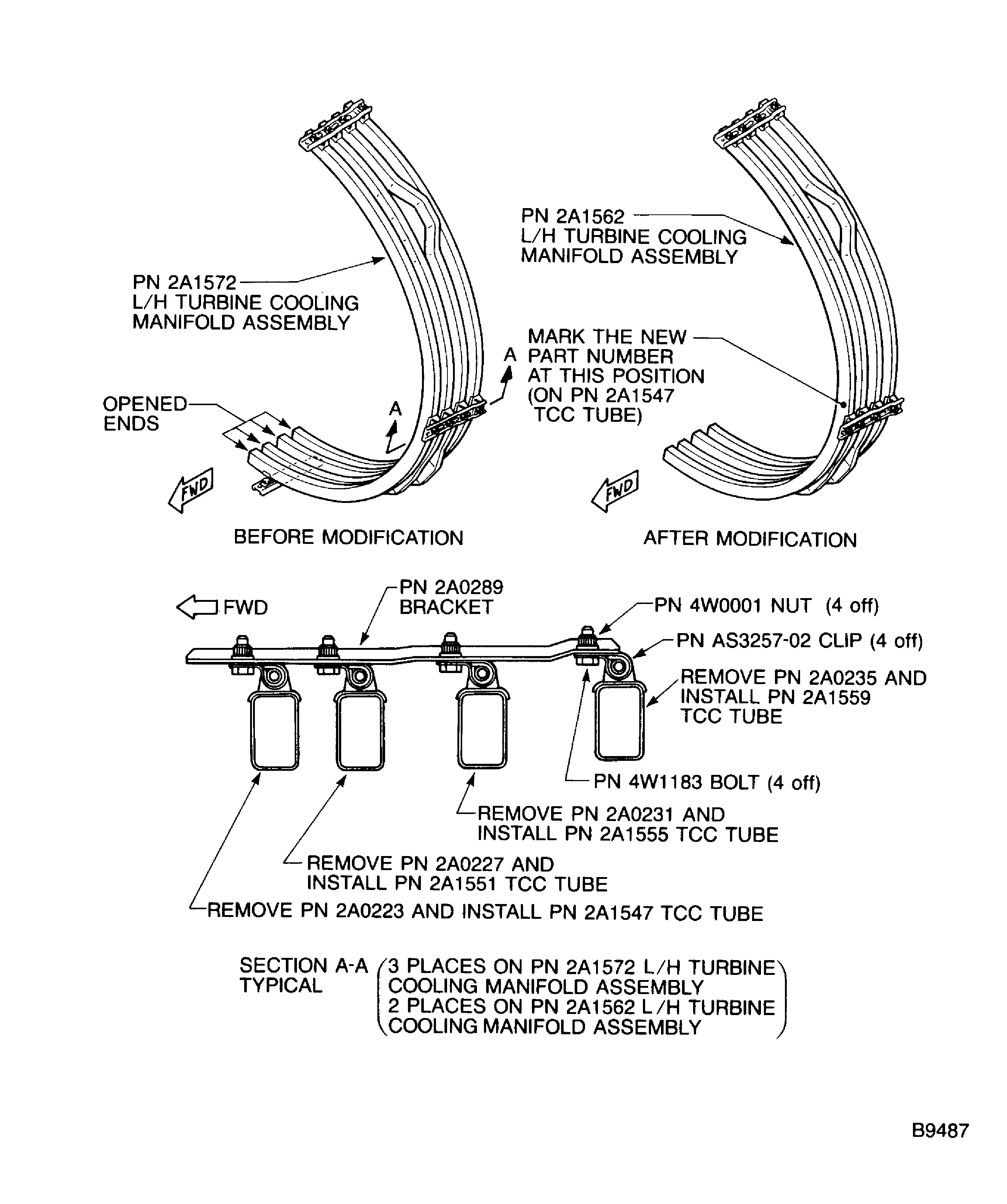

Refer to Figure.

NUMBER BEFORE - 2A1572 NEW NUMBER - 2A1562.

Refer to SPM TASK 70-09-00-400-501.

Identify the L/H turbine cooling manifold assemblies with the new part number adjacent to the part number that was there before.

SUBTASK 75-24-48-850-055 Identify the L/H Turbine Cooling Manifold Assemblies with the New Part Number

Figure: Rework of the turbine cooling manifold assembly

Rework of the turbine cooling manifold assembly

Rework of the turbine cooling manifold assembly

Figure: Rework of the TCC tube assemblies

Rework of the TCC tube assemblies

Rework of the TCC tube assemblies

Rework of the TCC tube assemblies

Figure: Rework of the R/H turbine cooling manifold assembly

Rework of the R/H turbine cooling manifold assembly

Figure: Rework of the L/H turbine cooling manifold assembly

Rework of the L/H turbine cooling manifold assembly