Export Control

EAR Export Classification: Not subject to the EAR per 15 C.F.R. Chapter 1, Part 734.3(b)(3), except for the following Service Bulletins which are currently published as EAR Export Classification 9E991: SBE70-0992, SBE72-0483, SBE72-0580, SBE72-0588, SBE72-0640, SBE73-0209, SBE80-0024 and SBE80-0025.Copyright

© IAE International Aero Engines AG (2001, 2014 - 2021) The information contained in this document is the property of © IAE International Aero Engines AG and may not be copied or used for any purpose other than that for which it is supplied without the express written authority of © IAE International Aero Engines AG. (This does not preclude use by engine and aircraft operators for normal instructional, maintenance or overhaul purposes.).Applicability

All

Common Information

TASK 75-24-48-840-001 HPT ACC Air Manifold - Replace the Support Bracket, Rework-001 - SBE 75-0026

General

The practices and processes referred to in the procedure by the TASK numbers are in the SPM.

NOTE

Preliminary Requirements

Pre-Conditions

NONESupport Equipment

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| Grinder, Hand held pneumatic | LOCAL | Grinder, Hand held pneumatic | ||

| Marking pencil, vibrating | LOCAL | Marking pencil, vibrating | ||

| Tungsten Inert Gas (TIG) system | LOCAL | Tungsten Inert Gas (TIG) system | ||

| Magnifying glass | LOCAL | Magnifying glass | 8X |

Consumables, Materials and Expendables

| Name | Manufacturer | Part Number / Identification | Quantity | Remark |

|---|---|---|---|---|

| CoMat 01-031 ACETONE (CH3)2CO | LOCAL | CoMat 01-031 | ||

| CoMat 02-099 LINT-FREE CLOTH | LOCAL | CoMat 02-099 | ||

| CoMat 03-204 WELDING FILLER WIRE | LOCAL | CoMat 03-204 |

Spares

NONESafety Requirements

NONEProcedure

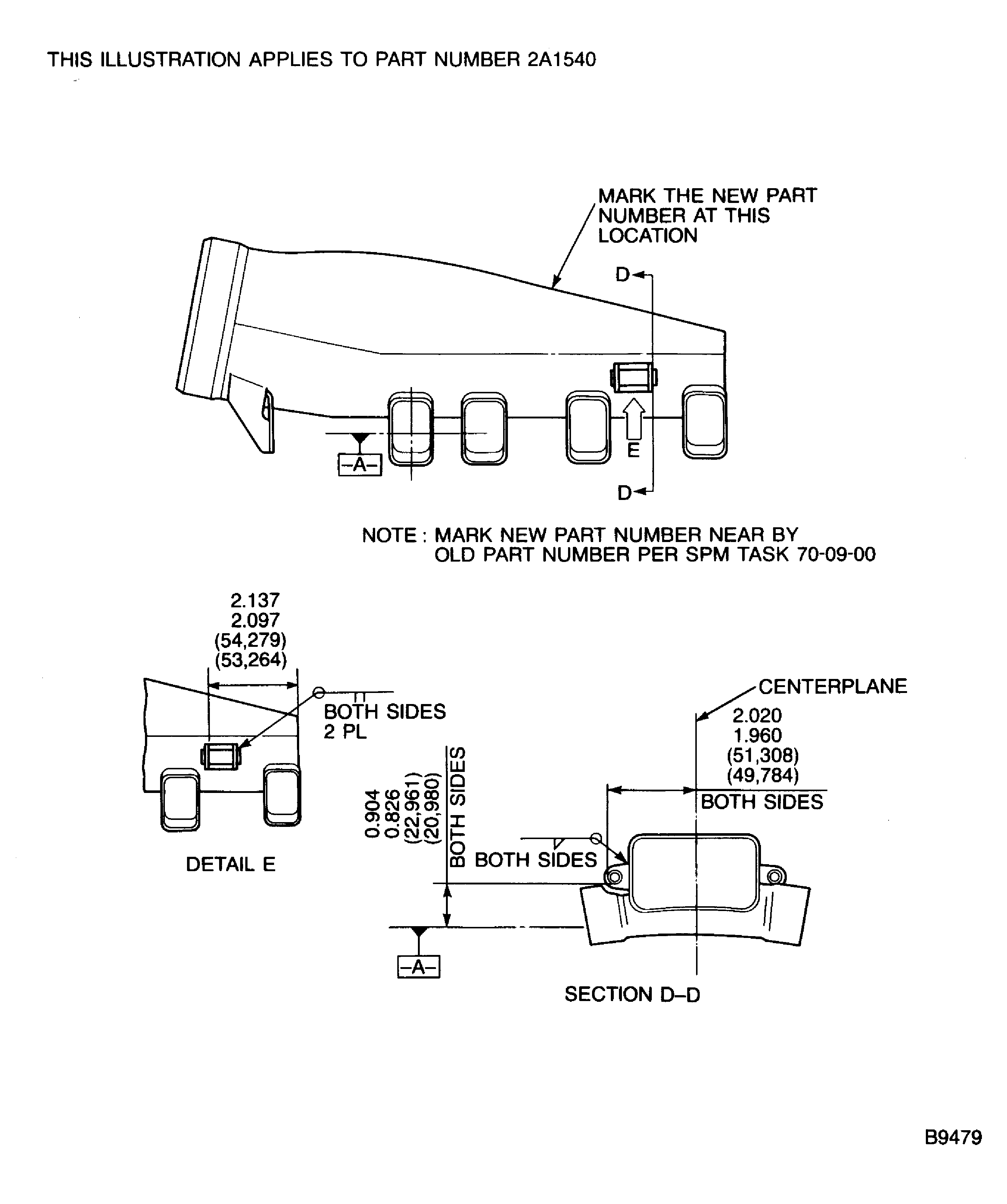

Refer to Figure.

Use a wire cutter.

Cut out the support at two points. Make each point as close as possible to the manifold body.

Refer to Figure.

Remove the remaining support from the manifold body. Keep the original thickness of the manifold body.

SUBTASK 75-24-48-350-084 Cut Out the Pin and the Support from the Turbine Cooling Manifold Assembly

Refer to Cleaning-000 TASK 75-24-48-100-100.

Locally clean the surface to be welded and the adjacent area to remove all the oxides, hydrocarbon, grit and scale.

SUBTASK 75-24-48-350-085 Remove all the Contamination from the Surface

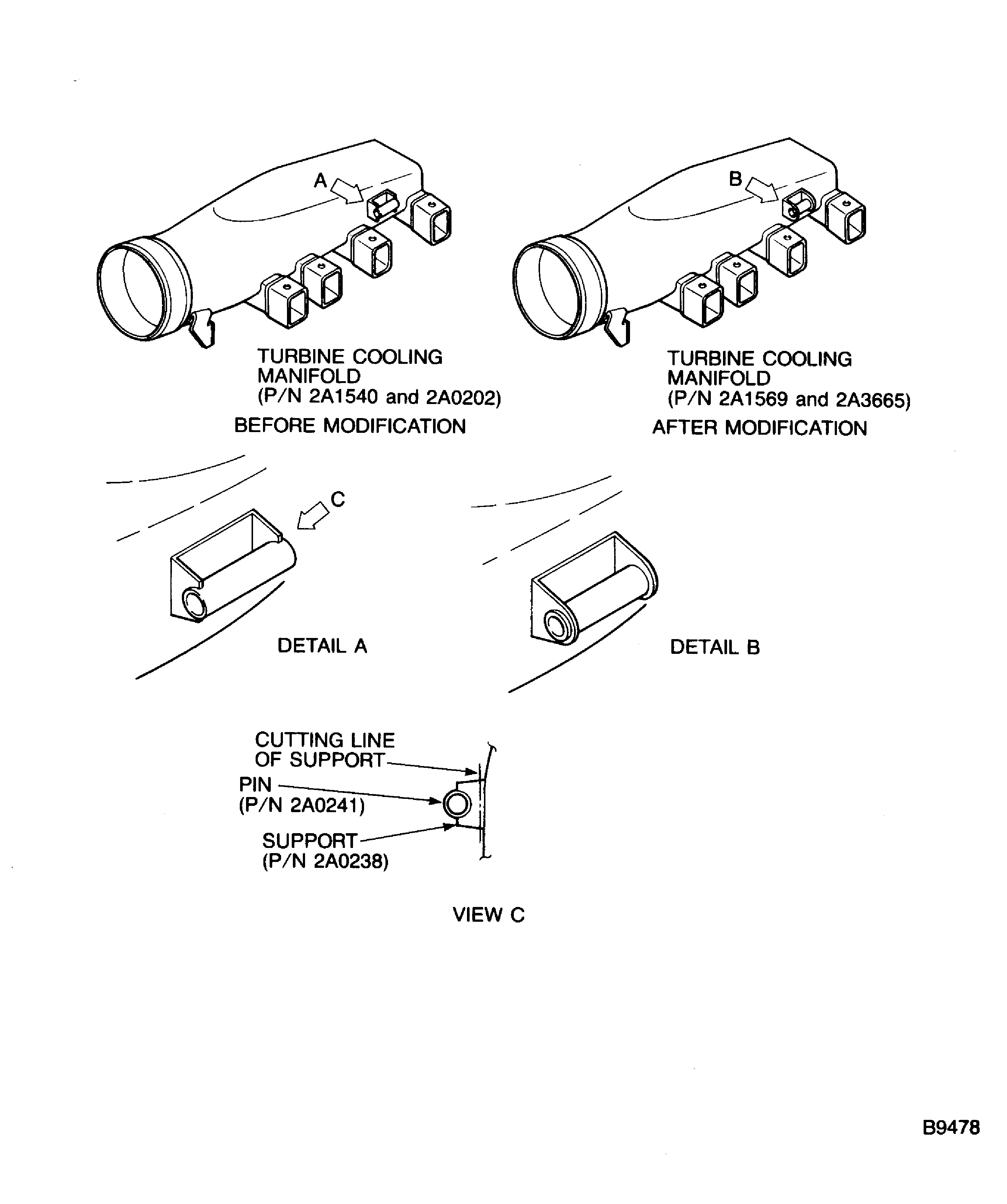

Refer to Figure.

Refer to SPM TASK 70-31-02-310-501-001.

Weld the pin to the support.

Refer to Figure.

Refer to SPM TASK 70-31-02-310-501-001.

Weld the support to the manifold.

Remove unwanted weld from the contact area and dress it flush with the adjacent area.

SUBTASK 75-24-48-350-086 Weld the Pin and the Support

Refer to SPM TASK 70-23-05-230-501.

Examine the repaired area by local application fluorescent penetrant inspection.

Use an 8X Magnifying glass.

Refer to Inspection-000 TASK 75-24-48-200-100.

Visually examine the repaired area.

SUBTASK 75-24-48-220-074 Examine the Welded Area for Cracks

Refer to Figure.

Case 1. NUMBER BEFORE - 2A0202 NEW NUMBER - 2A3665.

Case 2. NUMBER BEFORE - 2A1540 NEW NUMBER - 2A1569.

Refer to SPM TASK 70-09-00-400-501.

Identify the turbine cooling manifold assembly with the new part number adjacent to the part number that was there before.

SUBTASK 75-24-48-850-051 Identify the Turbine Cooling Manifold Assembly with the New Part Number

Figure: Rework of Turbine Cooling Manifold Assembly

Rework of Turbine Cooling Manifold Assembly

Rework of Turbine Cooling Manifold Assembly

Rework of Turbine Cooling Manifold Assembly